Abstract

This study was aimed at determining the effects of the force loading direction on bending strength (MOR) and modulus of elasticity (MOE) in laminated wooden materials obtained in different compositions from cut veneers of Oriental beech and Lombardy poplar with thicknesses of 4 mm and 5 mm. A total of 180 experimental specimens were prepared for determining the MOR and MOE values in parallel and perpendicular directions to the glue line. The study involved a total of 6 air-dried density layer organizations of solid Oriental beech and Lombardy popular in 4 different laminate compositions and in the same dimensions, aimed at control. Polyvinyl Acetate (PVAc) and Polyurethane (PU) were used as the adhesive type in laminations with PVAc5-PU5-PVAc4-PU4. The specimens were subjected to bending strength and modulus of elasticity experiments in parallel and perpendicular directions to the glue line in accordance with the TS EN 310 standards. As a result of the statistical analysis of the data obtained at the end of the experiments, it was determined that in the laminated materials, the force loading direction in parallel or perpendicular to the glue line affected the MOR and MOE results. The best result in the laminated materials was found to be approximately 10% higher for MOR and MOE in a parallel direction to the PU4 glue line compared to the perpendicular direction.

Download PDF

Full Article

THE EFFECTS OF THE FORCE LOADING DIRECTION ON BENDING STRENGTH AND MODULUS OF ELASTICITY IN LAMINATED VENEER LUMBER (LVL)

Murat Kılıç

This study was aimed at determining the effects of the force loading direction on bending strength (MOR) and modulus of elasticity (MOE) in laminated wooden materials obtained in different compositions from cut veneers of Oriental beech and Lombardy poplar with thicknesses of 4 mm and 5 mm. A total of 180 experimental specimens were prepared for determining the MOR and MOE values in parallel and perpendicular directions to the glue line. The study involved a total of 6 air-dried density layer organizations of solid Oriental beech and Lombardy popular in 4 different laminate compositions and in the same dimensions, aimed at control. Polyvinyl Acetate (PVAc) and Polyurethane (PU) were used as the adhesive type in laminations with PVAc5-PU5-PVAc4-PU4. The specimens were subjected to bending strength and modulus of elasticity experiments in parallel and perpendicular directions to the glue line in accordance with the TS EN 310 standards. As a result of the statistical analysis of the data obtained at the end of the experiments, it was determined that in the laminated materials, the force loading direction in parallel or perpendicular to the glue line affected the MOR and MOE results. The best result in the laminated materials was found to be approximately 10% higher for MOR and MOE in a parallel direction to the PU4 glue line compared to the perpendicular direction.

Keywords: Laminated veneer lumber (LVL); Oriental beech; Lombardy poplar; Bending strength; Modulus of elasticity; Adhesives for wood

Contact information: Republic of Turkey, Ministry of Environment and Forestry, Central Anatolia Forestry Research Institute, Bahçelievler, Ankara, 06501, TURKEY; kilicm@hacettepe.edu.tr

INTRODUCTION

Despite the fact that it is a renewable natural resource, the amount of wood in the world is gradually decreasing. Thus, it is important when using wood used as a building material to employ techniques and technologies that will provide the highest levels of performance. By eliminating negative attributes of natural wood, stemming from either external factors or from genetic structure, high performance new products can be obtained that can be used as building materials. One such technology is “lamination.” This process eliminates faults, provides for the ease of shaping and processing, and makes it possible to obtain layered building materials. Just as is the case with all building materials, it is necessary to define the technical performance of the materials produced with laminates clearly in order to be able to use them in building. Otherwise, the material cannot hold up under the conditions to which it is subjected (Kılıç 2004).

Laminated wooden material is defined as “building elements obtained with the parallel gluing of lamellas, especially fibers” (TS EN 310, 1997). In accordance with this definition, laminated wooden material is obtained by gluing thin wooden plaques that come from the same or different wood species in the same or different thicknesses. One plaque is placed on top of another, parallel to each other in the direction of the fibers, and they are glued with different adhesive types suitable for the purpose. In this manner, a material is obtained that displays different structural attributes compared to the solid of the same wood species at the same thickness. A method appears that is suitable for cold or hot bending processes. The economy of the process can be increased by using lower quality or less expensive materials from the same or different wood species in the intermediate layers. Furthermore, composite materials that have different behavior can be made by combining other industrial materials together with wood (Burdurlu et al. 2007).

Laminated wooden elements are named differently according to the layer thicknesses. Solid wooden materials with a thickness between 25.4 and 50.8 mm are used in the production of large-sized laminated wood (beam, column, arch, etc.), and such products are used in the construction sector. Laminated wooden materials that have these attributes are called “Glued Laminated Timber (GLULAM)”. Wood veneers are used with a maximum layer thickness of 3.2 mm according to the form implemented in the production of small-sized wooden laminated elements. This product is applied in the furniture industry, and these types of wooden laminated elements are called “Laminated Veneer Lumber (LVL)” or “MICROLAM” (Stevens and Turner 1970).

It is stated that the bending strength of solid beams supported with a laminated layer is 10% more than those not supported with a laminated layer. The bending strength of beams supported with first class 3 mm veneer is 6% more than those supported with second and third class 2.2 mm veneers (Braun and Moody 1977).

A study has been conducted on the usability of veneer as a support system element in wood buildings made by laminating tall fir trees with small diameter, which have low economic value. According to the results of the study, it has been determined that using the lamination method can produce higher quality attributes from wooden materials with lower quality. Also, layer thicknesses can be implemented in a variable manner (Tichy and Bodig1978).

It was determined that tensions form in glued support elements due to heat and humidity. Those tensions influence the modulus of elasticity of the wood: an increase in heat or a decrease in the ratio of relative humidity decreases the tension in a perpen-dicular direction to the fibers (Kurtoğlu 1979).

The effects on bending strength of the width of laminated layers in beams were studied. The beams were prepared as 4 laminated layers from Fir and Southern pine with minimum quality attributes. At the end of the study conducted with layer widths of 15 mm and 20 mm, it was determined that the width of laminated layers did not affect bending strength (Marx and Moody 1982).

The effects of layer width, layer thickness, length joining method, and quality of wooden materials on mechanical attributes were studied in laminated Fir beams. According to the results of the study, it was determined that in specimens with different layer thicknesses and different veneer quality classes, the layer thickness was not a factor relative to bending strength and modulus of elasticity. The bending strength decreased as the thickness of laminated layers increased; whereas the modulus of elasticity was not affected by the layer thickness (Youngquist et al. 1984).

Elements (beams) under the influence of bending strength are differentiated into two groups: “horizontal laminated elements” and “perpendicular laminated elements” according to the direction of force applied. If the element is loaded perpendicular to the glue line, then it is called horizontal and if the element is loaded parallel to the glue line, then it is called perpendicular (Baird and Ozelton 1990). Examples of horizontal and vertical laminated elements are given in Fig. 1.

Fig. 1. Horizontal and perpendicular elements (Baird and Ozelton 1990)

It has been emphasized that laminated wooden materials are preferred over solid wooden materials in the production of furniture because laminated wooden materials are superior in aesthetics, economy, and technology (Eckelman 1993). The technological attributes of laminated Oriental beech were studied. The perpendicular and parallel bending strengths to the glue line laminated by using polyvinyl acetate (PVAc) and polyurethane (PU) adhesives with 2 mm and 4 mm layer thicknesses were evaluated. According to the results of the experiment, the highest bending strength in the specimens was when the force direction was parallel (1134.3 kgf/cm²) to the glue line and perpendicular (1136 kgf/cm²) to the glue line. It was determined that in specimens with 4 mm veneers and in which force was applied in a different direction; the direction of force applied affected the bending strength. The bending strengths of specimens in which force was applied parallel (1006.6 kgf/cm²) to the glue line were higher than the bending strengths of specimens in which force was applied perpendicular (952.8 kgf/cm²) to the glue line. It is found that the effect of the adhesive type and veneer thickness on bending strength was not completely definite in specimens joined with Polyurethane (PU) adhesive. There were no significant differences among the bending strength values of specimens prepared with polyvinyl acetate (PVAc); that is, there was no effect on bending strength of the force direction applied and the thickness of veneer. However, these values were less than in the polyurethane (PU) adhesive specimens. According to the results, the direction of force applied is not effective on bending strength. The specimens with polyurethane (PU) adhesive display a higher bending strength compared to the polyvinyl acetate (PVAc) specimens and a higher bending strength can be obtained in thin laminated layers with the use of an adhesive with higher mechanical and technological attributes (Şenay 1996).

A mixed lamination was applied to the fir to develop hardness and resistance attributes by using graphite-epoxy and polyester-glass. Adhesion, three- point bending, and console bending tests were applied to the composite laminated materials obtained. According to the results of the study, the hardness value of the graphite-epoxy lamination was higher compared to the polyester-glass lamination. Nevertheless, in the three-point bending test, the polyester-glass lamination was more successful than the graphite-epoxy lamination (Pidaparti and Johnson1996).

In response to cracks that could appear in laminated beams due to tension, the resistance point of beams was studied in different forms that were strengthened with fiberglass. It was determined that the cracks in the experimental specimens strengthened with fiberglass advanced slowly compared to unstrengthened beams and that the strengthening assumed the role of stopping cracks by lowering tensions (Hallstrom and Grenestedt 1997).

The effects on bending strength of the adhesive types, tree species, and number of layers were studied. Specimens from Scotch pine, Oriental beech, and oak woods were subjected to bending strength experiments by gluing 3-, 5-, and 7-layered laminated materials with the PVAc, Desmodur-VTKA, and Klebit 303 adhesives. The highest bending strength was obtained at the end of the experiments in 5-layered beech glued with PVAc adhesive (Döngel 1999).

Laminated wooden materials were produced in different compositions from Oriental beech (Fagus orientalis Lipsky) and Lombardy poplar (Populus nigra) cut veneers with a thickness of 3 mm by using polyvinyl acetate (PVAc-Kleiberit 303). As a result of the statistical analysis of the data obtained from the tests, the bending strength and modulus of elasticity values of solid woods both perpendicular and parallel to the glue line were observed to be smaller than the values of laminated woods made of the same species of wood. It was also observed that as the contribution rate of beech in lamination increases, the bending strength and modulus of elasticity values increase (Burdurlu et al. 2007).

The suitability of three hybrid poplar clones was studied for laminated veneer lumber (LVL). According to the results of the study, the physical and mechanical attributes of laminated popular clones were better than the same clones of the solid poplar (Kurt 2010).

This study was aimed at determining the effects of layer organization and force loading direction on bending strength and modulus of elasticity of the lamellas obtained from Lombardy poplar (Populus nigra). This species has a widespread distribution in Turkey, grows rapidly, and is a species with a low economic value. Oriental Beech (Fagus orientalis Lipsky) has better structural attributes but is a more expensive species economically compared to Lombardy poplar.

Laminates were prepared in two different combinations from the aspect of wood species by gluing them with PVAc (Kleiberit 303) and with PU (Bizon Timber PU-Max Express).

EXPERIMENTS

Materials

Wood

The Oriental beech (Fagus orientalis Lipsky) woods used in this study were obtained from the Mengen district at the Bolu Yaylacık Research Forest. The Lombardy poplar (Populus nigra) woods were obtained from the Beytepe district in Ankara, Turkey. In felling, care was taken that the trunk and crown formation of the trees was normal and strong, the colors were normal, there were no cross grains on the trunks, and that they had not been attacked by insects or fungi. Some properties of beech and poplar trees used in the study are given in Table 1. They were cut into specimens in accordance with the TS 4176 standards (TS 4176 1982).

Table 1. Some Characteristics of the Beech and Poplar Woods used in the Study

Adhesives

Two different types of adhesives were used in the preparation of test specimens. These were Polyvinyl Acetate (PVAc) (Kleiberit 303) adhesive (Kleiberit 2004), which was suitable for applications in interiors and dry spaces, and Polyurethane (PU) (Bizon Timber PU Max Express) (Bizon 2004), which was suitable for applications in open (exposed to outdoor conditions) and humid spaces. PVAc (Kleiberit 303) is a glue type that has D3 grade for adhesion according to the BS EN 204 standards, whereas Polyurethane-PU (Bizon Timber PU Max Express) has the grade of D4 for adhesion according to the BS EN 204 standards (BS EN 204 1991).

Preparation of the specimens

The felled trees were cut into lumber. Subsequently, the lumber was dried in a drying oven until it reached an air-dried humidity of 12%. The lumber with dimensions of 70×600 mm was cut with a circular saw machine to a thickness of 6 mm. Both surfaces of the cut wooden materials were brought to a thickness of 4 mm and 5 mm through calibrated sanding with a No. 50 sanding machine.

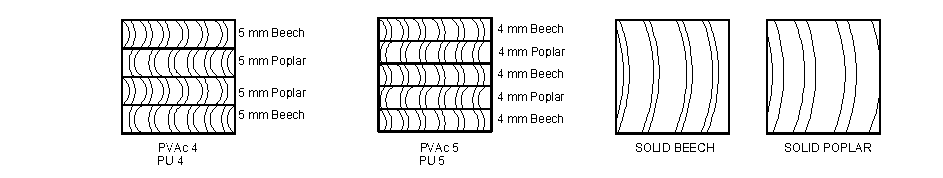

First of all, the plates of the lamellas with a thickness of 4 mm and 5 mm that had defects such as knots, cracks, etc. were sorted and not used. The Kleiberit 303 (PVAc) adhesive was spread on one surface of the layer according to the calculation of 160 g/m². They were pressed under 0.7 N/mm² at a temperature of 20ºC for a period of 15 minutes. The Bizon (Timber PU-Max Express) (PU) adhesive was spread on one surface of the layer according to the calculation of 200 g/m². They were pressed under 0.7 N/mm² at a temperature of 20ºC for a period of 2 hours. A headless nail with a length of 18 mm was driven into place at the ends of the laminated materials so that the glued layers would not slip in the press. The experimental specimens were prepared according to the plan in Fig. 2.

Fig.2. Preparation plan for the test specimens

A total of 120 (with measurements of 20x20x360 mm) experimental specimens were prepared. These specimens included 80 [2 (layer thickness) x 2 (adhesive types) x 2 (loading direction) x 10 tests] repeated and with 40 [2 wood species) x 2 (loading direction) x 10 tests] repeated control specimens. Furthermore, 60 (with measurements of 20x20x30 mm) air-dried density specimens were prepared. The general principles of the TS 2472 standards (TS 2472 1976) were used in the determination of the air-dried densities of the specimens. The general principles of the TS EN 310 standards (TS EN 310 1997) in the determination of the bending strength and modulus of elasticity were also used. The specimens were kept in a humidity chamber at a relative humidity of 65±5% and a temperature of 20±2°C until they reached an unchanging weight with about 12% moisture content) (TS 2471 1976).

Methods

Air-dried density

The determination of the air-dried density was made according to the TS 2472 standards. The 60 experimental specimens prepared in the dimensions of 20x20x30 mm were used in this determination. The air-dried moisture level of these specimens was provided by keeping them in a humidity chamber at a temperature of 20±2°C and a relative humidity of 65±5%. The experimental specimens were weighed on an electronic scale with a sensitivity of 0.01 g, and their dimensions were measured with a digital caliper guage with a sensitivity of 1/100 mm. Formula 1 was used in the calculation of the air-dried density,

(1)

where D12 is the air-dried density (g/cm³), M12 is the air-dried weight of the experimental specimen (g), and V12 is the air-dried volume of the experimental specimen (cm³)

Bending strength

The experiments for bending strength were made with computer-controlled 1000 kg capacity universal test equipment according to the TS EN 310 standards. The humidity-conditioned measurements of the climatized experimental specimens were made by measuring the width cut dimensions with a guage that could make a measurement with a sensitivity of 1/100 mm. The experiments were made by placing them in the test equipment in a manner in which the force loading direction would come either perpendicular or parallel to the glue line (Fig. 3). For the solid beech and poplar control samples the force loading direction was either perpendicular (tangential to annual rings) or parallel (radial to annual rings) (Figs. 1 and 2).

Fig. 3. Experimental mechanism of the bending strength and modulus of elasticity

The distance between the resistance points was determined to be 300 mm, and the force was applied in a manner so that the specimen would be broken in 1.5±0.5 minutes with a fixed speed either perpendicular or parallel to the glue line from exactly the center of the load resistance points. The maximum load at which the experimental specimen was broken was read within 1% accuracy from the dial of the test equipment, and the bending strength was determined by making use of formula 2,

(2)

where E is the bending strength (N/mm²), Pmax is the breaking load (N), l is the aperture between the resistance points (mm), b is the width of the specimens (mm), and h is the height of the specimens (mm).

Modulus of Elasticity

The specimens made for bending strength were used in the determination of the modulus of elasticity. Experiments were conducted according to the TS EN 310 standards. The experiments were made as shown in Fig. 4, and the results were recorded.

Equation 3 was used in the determination of the modulus of elasticity with the help of the bending amounts difference (ΔF) in the example for the resistance difference ( ) applied in the elastic deformation region,

(3)

where E is the m Modulus of elasticity at bending (N/mm2), l is the distance between supports (mm), and b and h are the width and depth cut dimensions of the experimental piece (mm).

Fig. 4. The bending strength and modulus of elasticity module experiments

The F test was used to determine the effect of the force loading direction on the bending strength and modulus of elasticity with the two different layer thicknesses (4 mm and 5 mm) and with the two different glues used (PVAc and PU). If the difference among the groups was significant, they were compared with the Duncan test at a signifigance level of α=0.05. The SPSS 11.5 package program was used for the statistical analyses.

RESULTS AND DISCUSSION

Specimens were prepared in order to determine the effect on the bending strength and modulus of elasticity of the air-dried density of two different layer thicknesses (4 mm and 5 mm) and two different adhesives (PVAc and PU). The specimens were subjected to tests included in the related standards; the results are given in Table 2.

The F test was applied to determine whether or not there was a significant difference among the air-dried densities, bending strengths, and modulus of elasticity values. Thus, there was a significant difference at the level of α=0.05 and a 95% confidence among the density, bending strength, and modulus of elasticity values, which emerged according to the material combinations. It was determined that this difference was significant (p<0.05). It was determined that the application of the force direction perpendicular or parallel to the glue line was effective relative to the bending strength and the modulus of elasticity (Table 2).

Table 2. Air-dry Density, Bending Strength, and Modulus of Elasticity Values Corresponding to Different Woods, Loading Direction and Ply Organization Types

The Duncan test was applied to determine among which groups there was a significant difference and which groups were homogeneous at the end of the test. These results are given in Table 3.

As it can be observed in Table 3, the highest air-dried density was found in solid beech at 0.695 g/cm³, and this was followed by the air-dried density of PU at 0.602 g/cm³. The lowest air-dried density was in poplar at 0.400 g/cm³, and the second smallest density was in the laminated materials with PVAc5 (PVAc adhesive) at 0.538 g/cm³. The density of the laminated materials rose naturally with the use of beech, which has a higher density. Just as expected, due to the fact that glue enters the structure, the beech-poplar mixture with the same layer thickness containing the PU adhesives (PVAc5, PU5 and PVAc4, PU4) in the laminated materials produced higher air-dried density values compared to the PVAc adhesives.

In these examples, the highest bending strength at 130.09 N/mm² was also obtained in the solid beech in the loadings made perpendicular to the glue line (tangential to the annual rings in solid beech and poplar). This was followed by the PU4, PVAc4, PU5, PVAc5, and poplar materials, respectively. In addition, according to the results of the Duncan test, there was no statistical difference between the PU4 and the PVAc4 and between the PU5 and the PVAc5 adhesives (Table 3).

In the specimens where loading perpendicular to the glue line was made, the highest modulus of elasticity was found in the solid beech material at 12010.00 N/mm², followed by the PU4 at 11031.01 N/mm². On the other hand, the lowest modulus of elasticity value was in the solid poplar material at 6780.00 N/mm²; the modulus of elasticity of the PVAc5 at 10130.00 N/mm² was found to be the second lowest value. According to the Duncan test results, there was no statistically significant difference between PU5 and PVAc5. These two laminated materials can be used interchangeably for obtaining the same modulus of elasticity. Due to the fact that the modulus of elasticity of beech is higher compared to that of poplar, in general, the increase in the mixture ratio (number of layers) of the beech in laminations brings with it an increase in the modulus of elasticity.

Table 3. Duncan’s Multiple Range Test for Woods and Ply Organization Types, Air Dry Densities, Bending Strengths, and Modulus of Elasticity Perpendicular to the Glue Line

In the case where the loading was made parallel to the glue line, the bending strength and modulus of elasticity values according to the layer organizations are given in Table 4. Solid beech showed the largest bending strength (136.28 N/mm2) in the loadings made parallel to the glue line. This was followed by the bending strengths of PU4 at 108.29 N/mm2 and by the laminated materials having PVAc4 layer combinations. On the other hand, the smallest bending strength parallel to the glue line was also obtained in solid poplar at 73.58 N/mm2. The differences between the PU4 and PVAc4 and between the PU5 and PVAc5 in the bending strengths were insignificant (Table 4). Consequently, in practice, any layer combination within the group can be preferred.

The highest modulus of elasticity value (12740.00 N/mm2) parallel to the glue line was also obtained in solid beech. The lowest modulus of elasticity value (7650.00 N/mm2) in parallel to the glue line was found in solid poplar. According to the Duncan test results, the difference among the modulus of elasticity parallel to the glue line of the laminated materials having the PU5, PVAc5, and PVAc4 combinations was insignificant (Table 4).

Table 4. Duncan’s Multiple Range Tests for Woods and Ply Organization Types, Bending Strengths and Modulus of Elasticity Parallel to the Glue Line

CONCLUSIONS

- Wooden materials, in situations where they have any sort of openness, for example when they are used as beams, are subjected to bending. From this aspect, bending strength is very important for buildings. In this study, the effect of loading perpendicular or parallel to the glue line in laminated materials was found to be significant. In loadings made parallel to the glue line, both the bending strength and the modulus of elasticity were found to be higher. Among the laminated materials, the highest bending strength was obtained when the loading was made parallel to the glue line in PU4, yielding a value of 108.29 N/mm². This result was 9% higher than the value (99.08 N/mm²) of the bending strength of PU4 made with loadings perpendicular to the glue line.

- The moment the forces applied from outside to a solid material are lifted, the event of regaining of the deformation formed is called elastic recovery. As the modulus of elasticity increases, materials show a higher resistance against the forces producing deformation and as they decrease, they change shape more easily. The highest (11550.00 N/mm²) modulus of elasticity in laminated combinations was found in the loadings made parallel to the glue line in PU4. This value is 10% higher than the value (11031.00 N/mm²) of the modulus of elasticity made in perpendicular loadings to the glue line.

- It was determined that the increase in density (with the increase in the mixture ratio of beech and with the use of PU adhesives) increases the bending strength and the modulus of elasticity. When the breaking forms were examined in the experimental specimens, it was observed that the deformation occurred slowly in proportion to the force applied in the PVAc adhesive specimens (due to the elasticity of PVAc), whereas, in the polyurethane adhesive specimens, when the maximum load was reached, there was a sudden deformation (due to the hard layer of PU). According to these results, it would be possible to use an adhesive (PU) with more superior technological attributes and to be able to carry a greater load in a manner that would bring the load parallel to the glue line (especially in critical cross-sections, which remain under the influence of excessive loads). Furthermore, it would be beneficial to carry out new research studies related to the same topic, but with different layer thicknesses and different wood species, contributing to the literature on this subject.

REFERENCES CITED

Baird, J. A., and Ozelton, E. C. (1990). Timber Designer Manual, Blackwell Science Inc., Great Britain, 20-30.

Bizon. (2004). Bizon timber PU Max catalogue.

Braun, M. O., and Moody, R.C. (1977). “Bending strength of small beams with a laminated veneer tension lamination,” Forest Product Journal 27(11), 46-50.

BS EN 204. (1991). “Non structural adhesives for jointing of wood and derived timber products,” British standards, England.

Burdurlu, E., Kilic, M., Ilce, A. C., and Uzunkavak, O. (2007). “The effects of ply organization and loading direction on bending strength and modulus of elasticity in laminated veneer lumber (LVL) obtained from beech (Fagus orientalis L) and lombardy poplar (Populus nigra L),” Constr. Build Mater. 21, 1720-1725.

Döngel, N. (1999). “Effect of wood types, number of plies, and glue types on bending strength of laminated lumber,” Gazi University, Institute of Sciences, Master’s Degree Thesis, Ankara.

Eckelman, C.A. (1993). “Potential uses of laminated veneer lumber in furniture, department of forestry and natural resources,” Forest Product Journal 43(4), 19-24.

Hallstrom, S., and Grenestedt, J. L. (1997). “Failure analysis of laminated timber beams reinforced with glass fiber composites,” Wood Science and Technology 31(1), 17-34.

Kılıç, M. (2004). “Determination of performance characteristics of composite laminated construction material produced from beech and poplar,” Gazi University Institute of Sciences Ph.D. Dissertation, Ankara.

Kleiberit. (2004). Kleiberit 303 catalogue.

Kurt, R. (2010). “Suitability of three hybrid poplar clones for laminated veneer lumber manufacturing using melamine urea formaldehyde adhesive,” BioResources (http://www.bioresourcesjournal.com), 5(3), 1868-1878.

Kurtoğlu, A. (1979). “Yapıştırılmış tabakalı ağaç malzemede rutubet değişimi nedeniyle gerilmelerin oluşumu,” İ.Ü Orman Fakültesi Dergisi. ISSN 1309-6257, Seri A, Cilt 29 (In Turkish).

Marx, C. M., and Moody R. C. (1982). “Effects of lumber width and tension laminated quality on the bending strength of four ply laminated beams,” Forest Product Journal 32(1), 45-52.

Pidaparti, R. M. V., and Johnson, K. (1996). “Composite lamination to wood,” Polymers & Polymer Composites 4(2), 125-128.

Stevens, W. C., and Turner, N. (1970). Wood Bending Handbook, Woodcraft Supply Corp., London, 30-40.

Şenay, A. (1996). “Technological properties of laminated wood material,” Istanbul University Institute of Sciences, Ph.D. Dissertation, Istanbul.

Tichy, R. J., and Bodig, G. J. (1978). “Flexural properties of glued laminated lodgepole pine dimension lumber,” Forest Product Journal 28(3), 27-32.

TS EN 310. (1997). “Wood- based panels – Determination of modulus of elasticity in bending and of bending strength,” Turkish Standards Institution, Ankara.

TS 2471. (1976). “Wood determination of moisture content for physical and mechanical tests,” Turkish Standards Institution, Ankara.

TS 2472. (1976). “Wood determination of density for physical and mechanical tests,” Turkish Standards Institution, Ankara.

TS 4176. (1982). “Wood- sampling sample tree and logs for determination of physical and mechanical properties of wood in homogenous stands,” Turkish Standards Institution, Ankara.

Youngquist, J. A., Laufenberg, T. L., and Bryant, B. S. (1984). “End jointing of laminated veneer lumber for structural use,” Forest Product Journal 34(11-12), 25-32.

Article submitted: April 19, 2011; Peer review completed: May 26, 2011; Revised version received and accepted: June 3, 2011; Published: June 7, 2011.