Research Articles

Latest articles

- Researchpp 7846-7854Baraúna, E. E. P., Stallbaun, P. H., Monteiro, T. C., Silva, T. C., Baldin, T., Colen, F., and Arantes, M. D. C. (2021). "The effect of carbonization on the wood anatomy of Sclerolobium paniculatum Vogel," BioResources 16(4), 7846-7854.AbstractArticlePDF

Considering the extraordinary diversity of the Brazilian Cerrado and the difficulties related to the inspection of environmental crimes, knowing the wood and charcoal anatomy of widely exploited species is important. Thus, this study aimed to verify the anatomical characteristics of the wood and charcoal of Sclerolobium paniculatum. Therefore, anatomical characterizations of the wood and the charcoal produced were performed in order to compare the characteristics of both materials and observe any possible changes in the anatomical properties after carbonization. The results exposed that the qualitative anatomical characteristics of S. paniculatum wood can be maintained after the carbonization process. However, quantitatively, the carbonization increased the vessel frequency value and height and width of rays, despite reducing the frequency of rays. The diameter of the vessels was not altered by carbonization. This characterization of the species can then serve as a database for future identification of charcoal produced with this wood. In addition, it can encourage increasing the quality of inspection and consequently reducing the illegal exploitation of the species in natural environments.

- Researchpp 7855-7869Mardani, B., Jahan Latibari, A., and Tajdini, A. (2021). "Presenting a risk management model for residential wooden structures in earthquake-prone areas of Iran," BioResources 16(4), 7855-7869.AbstractArticlePDF

A risk management model was applied to residential wooden structures in earthquake-prone areas of Iran. The statistical population of the study consisted of academic and organizational experts. Thirty individuals were interviewed using a purposive non-random sampling technique and the data adequacy and saturation principle. A semi-structured interview was used to collect the required data. The validity was assessed using content and construct validity. Cronbach’s alpha coefficient was used to measure reliability, and it was greater than 0.7 for all components. In the qualitative section, data analysis was performed via a theoretical coding method that used the Grounded Theory approach, and the model was presented using interpretive structural modeling. The results revealed that the dimensions of the seismic related risks in the implementation of wooden residential structures in earthquake-prone areas of Iran, which included the internal risks (employer risk, implementation risk, scheduling risk, manpower risk, and design risk) and the external risk (risk due to political, economic, legal, and natural factors), were the most important risks.

- Researchpp 7870-7883Witorożec-Piechnik, A., Matyka, M., Wolszczak, P., and Oleszek, M. (2021). "Yield and selected physiological parameters of maize, sorghum, and triticale depending on fertilization system," BioResources 16(4), 7870-7883.AbstractArticlePDF

Effects of fertilization with digestate from agricultural biogas plant and its influence on growth and selected physiological parameters of maize, triticale, and sorghum plants cultivated for biogas production were studied in this work. The digestate was used as an organic fertilizer, being a substitute or supplement to mineral fertilization. The fertilization with the digestate had a positive effect on the fresh matter yield (FMY) of sorghum (85.4 Mg ha-1), the dry matter content (DM) of maize (41.9%) and sorghum (23.6%), as well as on the dry matter yield (DMY) of triticale (12.2 Mg ha-1) and sorghum (19.8 Mg ha-1). Among the studied species, the maize fertilized with digestate (variants N2 and N3) showed better growth responses compared to the maize that was fertilized with mineral fertilizers (plant nutrition status – SPAD of 54.8). No significant influence of fertilization variant was observed on the photosynthetic active radiation (PAR) and the leaf area index (LAI) of the tested plant species. The digestate proved to be a good fertilizer, supporting high yields without adverse effects on the physiological parameters of the plants.

- Researchpp 7884-7900Rajko, Ľ., Koleda, P., Barcík, Š., & Koleda, P. (2021). "Technical and technological factors’ effects on quality of the machined surface and energetic efficiency when planar milling heat-treated meranti wood," BioResources 16(4), 7884-7900.AbstractArticlePDF

As heat-treated wood has an ever-increasing application, the research of its machining is the subject of many studies. This article investigated the technical, technological, material, and tool-related factors that influence the quality of the machined surface (average roughness Ra) and energy consumption during the process of planar milling of heat-treated meranti wood. The experimental measurements were performed on samples that were treated by four methods at temperatures of 160 °C, 180 °C, 200 °C, and 220 °C. One sample was in its natural state. The cutting conditions were as follows: feed rates 6 m × min-1, 10 m × min-1, and 15 m × min-1, cutting speeds of 20 m × s-1, 40 m × s-1, and 60 m × s-1, and tool rake angles of 20°, 25°, and 30°. Experimental measurement of the surface roughness was performed using an LPM – 4 profilometer. Individual measurements of cutting power were performed via a frequency converter. The experiments determined the effects of the individual parameters on surface roughness in the following order: rake angle, heat treatment of the material, feed rate, and cutting speed. The effects of observed parameters on energetic efficiency were in the order: cutting speed, feed rate, rake angle, and heat treatment.

- Researchpp 7901-7915Büyüksarı, Ü., and Özyürek, Ö. (2021). "Dimensional stability and mechanical properties of bio-based composites produced from hydro-thermal treated wheat straw," BioResources 16(4), 7901-7915.AbstractArticlePDF

Bio-composites were produced from untreated (UT) and hydro-thermally treated (HTT) wheat straw (WS) particles and wood, and their dimensional stability and mechanical properties were investigated. The HTT treatment consisted of subjecting the WS particles to a steam explosion process for 8 min at 180 °C. The HTT and UT WS particles were mixed with the wood particles at 10, 20, 30, and 40% ratios. The physical properties, including density, water absorption (WA), and thickness swelling (TS), were determined for the bio-based composites. The mechanical properties evaluated included the modulus of rupture, modulus of elasticity, and internal bond strength. Statistical analyses showed that the hydro-thermal treatment and the WS ratio had significant effects on the dimensional stability and mechanical properties of the bio-composites. The WA of the composites after 2-h and 24-h rose significantly when the HTT WS particle ratio was increased from 10 to 40%. The 2-h and 24-h WA values of HTT-10 were 6.3% and 5.3% lower than those of UT-10, respectively. Improvements in the 2-h TS value were achieved by the HTT WS particles at the 10% ratio, and in the 24-h TS value at the 10 and 40% ratios. The mechanical properties of the composites were higher in the HTT group, but decreased in both the UT and HTT groups as the WS ratio increased.

- Researchpp 7916-7934Aluvihare Gedara, A. K., Chianella, I., Bhattacharyya, D., Endrino, J. L., and Zhang, Q. (2021). "Alkali-treated wheat gluten cross-linked with sodium alginate as a bio-based wood adhesive for interior grade particleboard," BioResources 16(4), 7916-7934.AbstractArticlePDF

A bio-based wood adhesive formulation free of formaldehyde and made from alkali-treated wheat gluten (WG) and sodium alginate (SA) was developed. Its formulation was optimised, and it was characterised by Fourier Transform Infrared (FT-IR) spectroscopy. The bio-adhesive was utilized to make particleboards both with virgin wood particles and recycled wood particles. A dry bio-adhesive content of 35% (w/w) was used to make samples with both type of particles. Single-layer samples of 10 mm thickness were obtained using wood particles of 1 mm (both virgin and recycled). These samples then were subjected to 3-point bending tests. Whereas the bending strength of samples made with recycled wood particles was 18.09 N/m2 and therefore satisfied Type 18 of the Japanese industrial standards (JIS A 5908:2015), the bending strength of the samples made with virgin wood particles was 8.08 N/m2 and satisfied ‘Type 8 Base particleboard Decorative particleboard’ of the Japanese standards. The density of particleboard samples made from recycled wood particles was 916 kg/m3, while that of samples made from virgin wood particles was 732 kg/m3. The alkali-treated WG and SA bio-adhesive has the potential to be used to re-manufacture particleboards, which can then be recycled and not disposed in landfills.

- Researchpp 7935-7952Tsalagkas, D., Börcsök, Z., Pásztory, Z., Gryc, V., Csóka, L., and Giagli, K. (2021). "A comparative fiber morphological analysis of major agricultural residues (used or investigated) as feedstock in the pulp and paper industry," BioResources 16(4), 7935-7952.AbstractArticlePDF

The suitabilities of major agricultural residues were assessed as papermaking feedstocks. All the examined agricultural residues were assumed as potential candidates for substituting hardwood fibers in mixed pulp blends from a fiber morphological perspective. Wheat, barley, rice, rapeseed, maize, sunflower, sugarcane bagasse, coconut husk, and two genotypes of miscanthus grass underwent identical maceration. The fiber length, fiber width, cell wall thickness, and lumen diameter were measured to calculate the slenderness ratio, flexibility coefficient, and Runkel ratio. The average fiber length ranged from 0.50 mm ± 0.32 mm (MG-S-02-V) to 1.15 mm mm ± 0.58 mm (sugarcane bagasse). The fiber width ranged from 10.77 μm ± 3.28 μm (rice straw) to 22.99 mm ± 5.20 mm (sunflower stalk). The lumen diameter ranged from 4.52 μm ± 2.52 μm (rice straw) to 13.23 μm ± 4.87 μm (sunflower stalk). The cell wall thickness ranged from 3.02 μm ± 0.95 μm (rice straw) to 4.80 μm ± 1.48 μm (sunflower stalk). The slenderness ratio, flexibility coefficient, and Runkel ratio values ranged between 28.08 to 58.11, 37.97 to 60.8, and 0.62 to 1.68, respectively. Wheat, maize, rapeseed, sugarcane bagasse, and coconut husk were found to be appropriate residue sources for papermaking feedstocks.

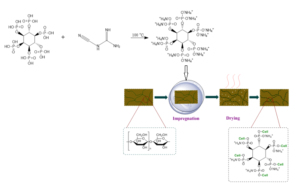

- Researchpp 7953-7965Chen, Q., Rong, Z., Liu, Z., You, N., and Xie, G. (2021). "Application of modified phytic acid as flame retardant in cellulosic paper," BioResources 16(4), 7953-7965.AbstractArticlePDF

A flame retardant containing phosphorus and nitrogen was synthesized using phytic acid and dicyandiamide, and it was subsequently used to prepare flame-retardant cellulosic paper via an impregnation method. Vertical flame and limiting oxygen index (LOI) were used to evaluate the flame retardancy of the paper. The paper containing modified phytic acid was characterized with Fourier transform infrared spectroscopy (FTIR), thermogravimetry (TG), X-ray diffraction (XRD), and scanning electron microscopy (SEM). When the concentration of modified phytic acid was 20%, the char length of the treated paper decreased from 12.5 cm to 4.1 cm, the LOI value increased from 19.6% to 41.5%, and the tensile index was only 3.66% lower than that of the control paper. The modified phytic acid was judged to have good flame-retardant effects on the paper.

- Researchpp 7966-7990Cachet, N., and Benjelloun-Mlayah, B. (2021). "Comparison of organic acid-based organosolv lignins extracted from the residues of five annual crops," BioResources 16(4), 7966-7990.AbstractArticlePDF

Organosolv lignins were extracted from corn stover, wheat, rice straw, reed straw, and sugarcane bagasse using a mixture of acetic and formic acids, at relatively low temperature and atmospheric pressure. Lignin content, residual carbohydrates, ash levels, proteins, and molecular weights were determined in each extracted lignin. The lignin content of all samples was relatively high, confirming the performance of the pretreatment process. The low molecular weights were in a narrow range, in accordance with the organosolv lignin molar masses. However, some differences between studied lignins were highlighted, in particular in rice straw lignin, which contained the highest silica, calcium, and nitrogen contents. Nuclear magnetic resonance spectroscopies (31P and semi-quantitative Heteronuclear Single Quantum Correlation) underlined the structural similarities and differences between these organosolv lignins. Corn stover and sugarcane bagasse lignins were rich in non-methoxylated (H-Unit) or mono-methoxylated (G-Unit) phenolic units, making them the best promising candidates for production of phenolic resins. Wheat straw lignin was richer in aliphatic OH than in phenolic OH. This is an advantage for use as polyol substitute in polyurethane synthesis. Reed straw lignin was less specific, with a balanced content of OH groups. However, it contained a high concentration of β-O-4 linkages, which is favorable for depolymerization.

- Researchpp 7991-8005Kopra, R., Vanhatalo, K., Päärnilä, S., Pappinen, A., and Dahl, O. (2021). "Bleaching microcrystalline cellulose using hydrogen peroxide, peracetic acid, and ozone," BioResources 16(4), 7991-8005.AbstractArticlePDF

AaltoCell™ based microcrystalline cellulose was bleached using hydrogen peroxide, peracetic acid, and ozone. The target brightness was set at 85% ISO brightness of the sheet (93% Y-brightness), which is white enough for the traditional use of microcrystalline cellulose. Both the paper pulp and dissolving pulp can be hydrolyzed using the AaltoCell™ process. Using paper pulp as a raw material, the brightness of the final microcrystalline cellulose decreased. The higher the temperature and retention time during the hydrolysis process, the greater the brightness loss. This effect can be explained by the so-called caramelization reaction. Due to this phenomenon, the microcrystalline cellulose should be bleached before using the product in food and pharmaceutical applications. The results showed that the target brightness was reached with ozone at doses of approximately 5 kg/ton with a reaction time of a few minutes; peroxide and peracetic acid required approximately twice the dose and a reaction time of at least 30 min. The concentrations of the chemical oxygen demand and total organic carbon in the pulp filtrate fraction varied with the bleaching chemicals used, with both values being low with ozone and the highest with peracetic acid.