Research Articles

Latest articles

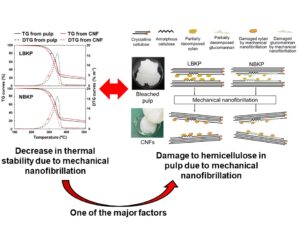

- Researchpp 8573-8584Hideno, A. (2023). “Thermal-degradation characteristics of mechanically nanofibrillated bleached pulps from hardwood and softwood,” BioResources 18(4), 8573-8584.AbstractArticlePDF

Nanofibrillated cellulose (NFC) consists of ultrafine cellulose structures in which the fibrils can have widths in the range from about 5 to 100 nm. NFC has been studied and developed in the paper industry, using bleached pulp from wood as the raw material. One of the issues in the application of NFC is their heat resistance to thermal degradation. The production process of NFC results in a decrease in their pyrolysis temperature during the nanofibrillation of bleached pulp; however, the details behind the reason and mechanisms are still unclear. In this study, NFC was prepared from bleached hardwood and softwood pulp by mechanical nanofibrillation using a grinder, and the pyrolysis behavior was investigated. For both bleached pulps, a decrease in the pyrolysis temperature was observed after nanofibrillation. The results suggest that the decrease in the pyrolysis temperature from nanofibrillation is not due to damage of the crystalline cellulose by nano fibrillation, but the damage of the hemicellulose components in the surface of the cellulose microfibrils or the interface between the crystalline cellulose and hemicellulose. If the hemicellulose on the surface of crystalline cellulose could be removed from the NFC, then the decrease in the pyrolysis temperature could be suppressed.

- Researchpp 8585-8600Bashyal, B. M., Gupta, A. K., Singh, D., Singh, D., Raman, R., Yadav, G. K., Gopalakrishnan, S., and Aggarwal, R. (2023). “Integrated management practices against an emerging Bakanae disease of rice under the hot-humid climate of Indo-Gangetic plains of India,” BioResources 18(4), 8585-8600.AbstractArticlePDF

Bakanae disease caused by Fusarium fujikuroi is emerging in India. In this work, fungicides and biocontrol agents were evaluated as seed, seedling treatment, and foliar spray(s) against bakanae disease in rice under field conditions. Carbendazim (50% WP) was found to be the most effective fungicide for seed and seedling root dip treatments. Soil drenching with 0.25% carbendazim (50% WP) 5 days before transplanting of seedlings was effective for large scale treatments. Foliar spray of 0.1% tebuconazole 50%+ trifloxystrobin 25% w/w (75 WG) significantly reduced the percentage of infected seeds (7.17%) compared with the control (32.50%). The minimum disease incidence (31%) was observed when seeds were treated with Talaromyces flavus. Individual treatments were integrated in the form of six management modules and evaluated under the field conditions of New Delhi (India) and Pusa Bihar (India) with the susceptible cultivars ‘Pusa Basmati 1121’ and ‘Pusa 1176’. Bakanae disease incidence was lower in the modules tested compared with the inoculated control or the individual treatment. The most favorable results at two locations achieved the lowest disease incidence of 7% and 2.41%.

- Researchpp 8601-8613Chen, C., Qiu, Y., Yang, Y., and Xu, W. (2023). “Formaldehyde emission pattern of melamine impregnated paper decorated medium density fiberboard and its furniture products,” BioResources 18(4), 8601-8613.AbstractArticlePDF

Melamine-impregnated paper decorated medium-density fiberboard (MIP-MDF) is the main board used for wooden furniture materials in China, and the formaldehyde released from the board and furniture products is harmful to human beings and is a wide concern. This paper aimed to pay attention to the formaldehyde emission of MIP-MDF and its furniture products. This study utilized a 1 m³climatic chamber to measure the formaldehyde emission of MIP-MDF and nightstand made of MIP-MDF in relation to the time and load factors. According to the results, in the 2 to 24 h stage, the emission of formaldehyde in the nightstand made of MIP-MDF materials changed significantly, and the overall trend showed a changing trend of first increasing and then declining. The formaldehyde emission of MIP-MDF stabilized after 40 h, while the formaldehyde emission of the nightstand stabilized after 60 h. As time passed, the formaldehyde emission changes of MIP-MDF and nightstand were almost the same. The formaldehyde emission of MIP-MDF and nightstand has a specific positive correlation with the carrying load. With increased carrying loads, the formaldehyde emission tends to increase, but the degree of influence gradually decreases with the addition of the carrying loads.

- Researchpp 8614-8630Ibanez, C. M., Kartal, S. N., Soytürk, E. E., Kurul, F., Şeker, S., Önses, M. S., Çelik, N., and Temiz, A. B. (2023). “Changes in the physical and mechanical properties of Pinus taeda and Eucalyptus bosistoana wood modified by contact charring,” BioResources 18(4), 8614-8630.AbstractArticlePDF

Physical and mechanical properties were evaluated for all-sided charred Pinus taeda and Eucalyptus bosistoana wood by hot plate contact heating system followed by treatment with linseed oil. The water absorption, volumetric swelling, wettability, hardness, modulus of rupture, and modulus of elasticity in bending strength and compression strength parallel to grain were determined. The water absorption and volumetric swell were determined after immersion in water, as measured at various intervals of water immersion up to 120 h. The results suggested that the contact charring process with the addition of a linseed oil application improved water absorption and volumetric swell properties of charred specimens compared to un-charred controls. Hardness of the charred wood decreased by 38% and 43% in P. taeda and E. bosistoana specimens, respectively, compared with their respective controls. The highest reductions were seen in modulus of elasticity and compression strength values in charred P. taeda specimens, while modulus of rupture (MOR) values decreased more in charred E. bosistoana specimens than in charred P. taeda specimens. These results suggested that charring of P. taeda and E. bosistoana wood does improve the moisture-related characteristics; however, their mechanical behavior and hardness decreased.

- Researchpp 8631-8652Aigner, D. J., Hinterholzer, L., Almhofer, L., Bischof, R. H., and Wrodnigg, T. (2023). “Conversion of xylose into D-xylitol using catalytic transfer hydrogenation with formic acid as H-donor,” BioResources 18(4), 8631-8652.AbstractArticlePDF

d-Xylitol, a biomass-derived sweetener, is increasingly used in cosmetics and pharmaceutical products. The raw material for d-xylitol production, d-xylose, is easily accessible from dissolving pulp production. d-xylitol production involves the heterogeneously catalyzed hydrogenation of d-xylose; this process is energy intensive, as the use of H2 requires high pressure and temperature. This work examined catalytic transfer hydrogenation for xylose conversion into xylitol. Formic acid (FA) was used to replace H2 as the H-donor, as it is easily available, inexpensive, may be obtained from renewable sources, and it avoids the risks associated with the use of high-pressure inflammable gas. A variety of commercially available catalysts were screened to reveal the one enabling the highest yield. The experiments were performed at 40, 80, and 140 °C, with pure xylose as a model compound. Triethylamine (Et3N) was added to ensure sufficient conversion rates. Based on the preliminary studies an experimental design was created (Design Expert®), including the two best performing catalysts Ru/Al2O3 and Ru/C, to investigate the influence of temperature and H-donor and base concentration on xylitol yield. Ru/C resulted in maximum d-xylitol yield of 73.2 % at 100 °C, FA to d-xylose ratio 5:1 and Et3N to FA ratio 0.4.

- Researchpp 23-40Adhikari, S., Bond, B., and Quesada, H. (2024). “Producing structural grade hardwood lumber as a raw material for cross-laminated timber: Yield and economic analysis,” BioResources 19(1), 23-40.AbstractArticlePDF

The economic feasibility of producing structural-grade hardwood lumber (SGHL) that qualifies as a raw material for structurally rated cross-laminated timber (CLT) was examined. 126 yellow poplar logs from diameters 12 to 15 inches were selected and divided into test and control samples. A log yield study was then conducted of the yield and revenue generated when producing lumber graded with National Hardwood Lumber Association (NHLA) rules, SGHL rules, and a mix of both rules (NHLA and SGHL-graded lumber). Producing mix-grade lumber added approximately 27% more revenue than producing NHLA-grade lumber on average if sawmills adopt a cant sawing method. Mix-grade lumber production resulted in 32% of the total volume produced as SGHL and the remaining 68% as NHLA lumber. As a result, 2 Common and lower-grade lumber board footage was reduced to only 29% in test samples and remained converted into SGHL compared to more than 85% of 2 Common and lower-grade lumber boards for control samples. 95% of the SGHL produced as mixed-graded lumber with NHLA-grade lumber met the specifications required to produce structural CLT, and the remaining 5% can be utilized to produce non-structural grade CLTs if they meet the minimum requirement of the materials for CLT production.

- Researchpp 41-52Takeuchi, T., Luengrojanaku, P., Ito, H., Rimdusit, S., and Shibata, S. (2024). “Effect of processing temperature and polymer types on mechanical properties of bamboo fiber composites,” BioResources 19(1), 41-52.AbstractArticlePDF

Bamboo fiber was extracted after alkaline treatment, and the mechanical properties of fibers and polymer composites were measured. The results showed that the strength of bamboo fiber was higher when the diameter was smaller. Smaller diameter bamboo fibers were dense, while larger diameter ones were composed of vascular bundles, which contained inside voids and outside parts having insufficient lignification. Tensile tests were conducted on bamboo fibers after heating at constant temperatures, and a significant decrease in mechanical properties was observed at heating temperatures above 250 °C. Bamboo fibers were compounded with PE, PA12, ABS, PA6, and biobased PC (Durabio), and injection-molded to prepare the composite specimens for flexural testing. The composite of polyethylene with 30 wt% bamboo exhibited considerably high flexural modulus compared to pure PE. Nevertheless, a large plastic deformation, which was equivalent to that of pure PE was observed. In other polymer composites, those flexural moduli increased, and degree of plastic deformation decreased dramatically, leading to brittleness. For PA6, which was molded above 250 °C, the increment in flexural modulus by fibers was less than the other composites due to the thermal decomposition of the fibers.

- Researchpp 53-65Ma, Z., Wang, H., Wang, C., and Yu, Z. (2024). “Creep characteristics of corn straw particles simulated based on Burgers model,” BioResources 19(1), 53-65.AbstractArticlePDF

To simulate the creep characteristics of corn straw particles under uniaxial compression, a 6-level 2D model was created using PFC 2D software according to the actual uniaxial creep test, the grain size, and shape of corn straw particles. Five groups of controlled tests were designed by the control variable method to study the influence of Maxwell body parameters Em, ηm; Kelvin body parameters Ek, ηk; and friction coefficient f on the creep curve of Burgers model. Results revealed that the creep characteristics of corn straw are affected by these 5 parameters. After multiple debugging by trial-and-error method, simulation parameters suitable for describing the creep characteristics of corn straw particles were obtained. The creep curves obtained by simulation under these parameters are consistent with those obtained by physical tests. It was shown that PFC software can not only study the creep characteristics of geotechnical materials, but also study the creep characteristics of agricultural fiber materials, which provides a reference for the subsequent rheological characteristics of biomass materials.

- Researchpp 66-83Öztürk, S., and Baltacı, C. (2024). “Effect of different stabilizers and rebaudioside A (reb A) sweetener on quality characteristics of low-calorie orange marmalade,” BioResources 19(1), 66-83.AbstractArticlePDF

Low-calorie orange marmalade was produced using sugar and reb A (0.08%) or reb A-sugar free recipes with pectin (1%) and agar agar (AA) (1%) stabilizers. The physical, chemical, and sensory properties of the marmalades were evaluated. AA stabilizers increased the viscosity of the marmalades compared to pectin, but they did not affect samples with reb A. Low-calorie samples had higher L* and b* values and lower a* values than sugar-containing samples. Total sugar content in reb A samples was 8.30 to 9.28 g/100 g, and it was lower in agar samples produced in parallel with pectin. The hydroxymethyl furfural (HMF) value was lower in sugar-free recipes (3.03 to 3.62) than in sugar-containing samples. Pectin-reb A samples had favorable taste, while AA-reb A samples favored consistency among reb A-containing samples.

- Researchpp 84-102Milani, H. S., Rahmaninia, M., and Li, B. (2024). “Improved drainage of LNFC-reinforced recycled pulp and mechanical properties of end papers by the zeolite-chitosan microparticle drainage aid system,” BioResources 19(1), 84-102.AbstractArticlePDF

Good drainage of the pulp suspension is vitally important for stable papermaking. Although the addition of lignocellulosic nanofibers (LNFC) in pulp could highly reinforce the end paper sheets, the application of LNFC could diminished the pulp drainage. To solve this problem, the impact of the zeolite-chitosan and bentonite-chitosan microparticle drainage aid systems on the LNFC-reinforced recycled pulp was systematically investigated. Results indicated that the mentioned microparticle systems improved the drainage and retention especially in applying 1% chitosan with 0.3% zeolite. In mechanical properties, applying the microparticle systems, not only did not deteriorate these properties, but also improved most of them, especially in treatment containing zeolite-chitosan. It seems that the improved pulp drainage and the mechanical properties of the end papers was due to successful mission of microparticle system and synergistic interactions of pulp fibres, LNFC, chitosan, and zeolite, which could also lead to denser and more uniform structure of handsheets.