Research Articles

Latest articles

- Researchpp 917-924Nguyen, B. N., Bui, D. N., Ha, T. M., Nguyen, T. T., and Nguyen, T. H. (2024). “Effect of drying schedules on the drying time and quality of Dendrocalamus barbatus bamboo using solar energy integrated with steam heated source,” BioResources 19(1), 917-924.AbstractArticlePDF

Bamboo is recognized as a promising material. It is widely distributed in Vietnam. Bamboo products are quite diverse. However, bamboo materials have been primarily air-dried in open locations. Thus, the bamboo does not achieve the required moisture contents for use in certain products. This can lead to easily being infected by fungi, especially molds that affect the quality of the bamboo’s products. To date, bamboo drying using solar energy integrated with a steam-heated source has not been studied. This study investigated the effect of drying schedules on the drying time and quality of Dendrocalamus barbatus bamboos in “culm” and “strip” forms using solar energy integrated with steam-heated source. Higher temperatures yielded faster drying times, but they also created more drying defects in the bamboo because of the drying gradient being higher. However, depending on the manufacturer’s requirements, the drying schedule No. 1 (40 °C to 60 °C) or No. 2 (50 °C to 70 °C) can be used for drying the bamboo culms. In relation to the bamboo strips, drying schedule No. 3 (60 to 80 °C) is recommended because it was the shortest drying time and had a low defect rate (9%).

- Researchpp 925-943Purusatama, B. D., Kim, S. W., and Kim, N. H. (2024). “A comparative study on quantitative anatomical characteristics of compression, lateral, and opposite woods in Agathis loranthifolia and Pinus merkusii,” BioResources 19(1), 925-943.AbstractArticlePDF

Quantitative anatomical characteristics and their radial variation in compression (COW), lateral (LAW), and opposite (OPW) woods of Agathis loranthifolia and Pinus merkusii stem woods growing in Indonesia were observed and compared to understand wood quality. The length, diameter, wall thickness, and lumen diameter of tracheids and ray height and numbers were observed using optical microscopy. In both species, COW had the shortest tracheid length, smallest tracheid and lumen diameter, thickest cell wall, and highest ray numbers among the parts, while LAW and OPW showed comparable or variable values in quantitative characteristics. In A. loranthifolia, COW had the highest ray height, whereas, in P. merkusii, it had the lowest uniseriate and fusiform ray heights. No significant difference was observed in ray numbers and heights between LAW and OPW. In both species, the tracheid length and lumen-to-diameter ratio in COW, LAW, and OPW tended to increase from near the pith to near the bark while the wall-to-diameter ratio decreased. The ray heights of all parts increased with increasing distance from the pith, whereas the ray number decreased.

- Researchpp 944-954Cui, Z., Jiao, Z., and Tong, W. (2024). “Design value of tensile strength of raw bamboo,” BioResources 19(1), 944-954.AbstractArticlePDF

Bamboo has the advantages of a short growth cycle, good mechanical properties, energy savings, and environmental protection. It is regarded as a new building material with great development potential and application prospects. However, current research on the design values of raw bamboo materials is lacking. In this study, the design value of tensile strength of raw bamboo material was determined by a tensile test of the raw bamboo material, and the statistical values of the tensile strength and elastic modulus of the raw bamboo material were obtained. The standard value and resistance uncertainty statistical parameters of the tensile strength of the raw bamboo material were determined. Considering different load combinations and load effect ratios, the relationship between the reliability index and the resistance component coefficient and the optimal resistance partial coefficient under different load combinations were obtained, and the design value of the tensile strength of the raw bamboo material was obtained.

- Researchpp 955-972Qin, S., Liu, Y., Shi, X., Shen, X., Chu, D., and Liu, S. (2024). “Phytic acid-based NP fire retardant and its effect on combustion property of poplar wood,” BioResources 19(1), 955-972.AbstractArticlePDF

To enhance the synergistic effect of phosphorus (P) and nitrogen (N) on flame retardant property, four different phytic acid-based NP flame retardants (FR-PAN) were manufactured using phytic acid and urea with various molar ratios, ranging from 1:3 to 1:12. The FR-PAN water solution was used to impregnate poplar wood under vacuum condition, and the thermal degradation performance of the FR-PAN treated wood were investigated. Compared to untreated wood, the PAN-6 (molar ratio is 1:6) group showed a reduction of 57.1% in total heat release and 80.0% in total smoke release. In the combustion, due to the introduction of P and N, FR-PAN generates O=P/C-O/C-P/C-N bonds, forming highly graphitized char residues, which effectively isolate the entry of oxygen and heat and play a good protective role in the condensed phase. Morphological and chemical analysis of the residual char layer revealed that the introduction of P and N elements formed a more stable hybrid structure, significantly improving the thermal stability of the char layer. Among them, the PAN-6 group exhibited the highest char layer stability, indicating optimal synergistic effects of nitrogen and phosphorus under these conditions.

- Researchpp 973-984Mun, J. S., and Mun, S. P. (2024). “Potential of hardwood kraft lignin as a bio-based dye for cotton fabrics,” BioResources 19(1), 973-984.AbstractArticlePDF

The dyeing characteristics of hardwood kraft lignin (KL) were investigated on cotton fabrics, assessing its potential as a sustainable and environmentally friendly dye. Dyeability was evaluated by varying the KL concentrations, temperature, and time. An aqueous solution of Na2CO3 (1.0%) as the dye bath and a fabric-to-liquor ratio of 1:50 were used. Cationizing effects were studied using (3-chloro-2-hydroxypropyl) trimethylammonium chloride (CHPTAC), and the mordanting effects of various mordants were also evaluated. Post-mordanting was performed with FeSO4, FeCl2, Fe-lactate (Fe-lac), MgSO4, CuCl2, CuSO4, and Al2(SO4)3. A mordant concentration of 1 mM o.w.f. (0.5 mM for Al2(SO4)3), with a liquor ratio of 1:30, at 60 °C for 30 min were employed. Suitable dyeing conditions were 2.0% o.w.b., 90 °C, and 90 min, resulting in a brownish color of the cotton fabric. The fabrics exhibited a range of light brown to light grayish brown colors and showed lighter colors than the untreated fabrics when mordanted with MgSO4 and Al2(SO4)3. The color difference (ΔE) between cationized and uncationized cotton fabrics was 3.48. From the colorfastness assessment, KL-dyed cotton fabric showed good rubbing and washing fastness for staining, but poor light and washing fastness for fading.

- Researchpp 985-997Ovalı, G., and Özdamar Ünlü, H. O. (2024). “Effects of chitosan application on the yield and quality of lettuce,” BioResources 19(1), 985-997.AbstractArticlePDF

Modern agricultural production has adopted the principle of maximizing yields in an environmental-friendly, inexpensive, and non-hazardous way. With these characteristics, chitosan has become an increasingly preferred biostimulant in sustainable agriculture. The aim of this study was to determine the effects of chitosan application on yield and quality in lettuce cultivation. For this purpose, Yedikule 5107 lettuce variety was used, and foliar chitosan applications were applied 3 times at 4 different doses of 0, 75, 150, and 300 ppm levels. The total yield, leaf number, leaf width, chlorophyll, total phenolic, and antiradical activity values ranged from 2970 to 3290 kg da-1, from 35.8 to 37.7, from 11.27 to 12.33 cm, from 38.05 to 41.82, from 21.50 to 38.71 mg/100 g, and 46.0% to 54.9%, respectively, and the highest values were obtained in the 300 ppm chitosan application. The highest root collar and plant diameter values were determined at 75 ppm and 150 ppm chitosan doses, respectively. All chitosan applications increased leaf length. Furthermore, chitosan applications were effective in preventing nitrate accumulation. In conclusion, it was determined that the effect of pre-harvest chitosan application was positive, and especially 300 ppm chitosan dose was more effective than other doses.

- Researchpp 998-1009Mun, J. S., and Mun, S. P. (2024). “Alkaline hydrogen peroxide delignification of three lignocellulosic biomass under atmospheric pressure,” BioResources 19(1), 998-1009.AbstractArticlePDF

The study’s goal was to investigate the delignification characteristics using alkaline hydrogen peroxide (AHP) under atmospheric pressure, intending it as a pre-treatment method for transforming low-value lignocellulosic biomass into high-performance structural materials. The lignocellulosic biomass used in this study were Japanese cedar (Cryptomeria japonica), Hyun aspen (Populus alba x glandulosa), and bamboo (Phyllostachys pubescens), which are underutilized and low-value lignocellulosic biomass in Korea. The delignification conditions used were pH 11, liquor ratio 12.5, H2O2 (3 to 10%), temperature (25 to 100 °C), and time (1 to 24 h). Japanese cedar exhibited <30% delignification even under the most severe conditions. In contrast, Hyun aspen achieved more than double that level of delignification. However, reaching over 60% delignification was challenging. Bamboo was easily delignified, reaching approximately 80% delignification using similar conditions performed in Japanese cedar and Hyun aspen. These differences observed in AHP delignification among three species were likely to be primarily due to the structural differences and proportion of condensed units in lignin. Consequently, for Hyun aspen and bamboo, the AHP delignification process under atmospheric pressure was considered to be feasible as a pre-treatment method for high-performance structural materials.

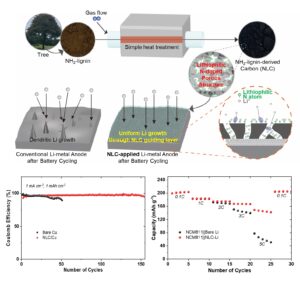

- Researchpp 1010-1029Kim, N. H., Lee, M., Kwon, H. M., Sim, W. H., Kim, D., Son, S., Bae, K. Y., Kim, J. Y., Youn, D. H., Kim, Y. S., and Jeong, H. M. (2024). “Lignin-derived lithiophilic nitrogen-doped three-dimensional porous carbon as lithium growth guiding layers for lithium-metal batteries,” BioResources 19(1), 1010-1029.AbstractArticlePDF

The growing demand for high-performance next-generation lithium (Li)-based batteries has brought Li-metal anodes into the spotlight, due to their high theoretical capacity (3,860 mAh g-1) and low electrochemical potential (-3.04 V vs. SHE). However, the practical application of Li-metal anodes faces formidable challenges, primarily associated with dendritic Li growth resulting from non-uniform ion flux. Although previous studies utilizing carbonaceous materials having pores and lithiophilic atoms have demonstrated powerful performances, the complex process involving pore creation and doping with heteroatoms still has limitations in terms of cost-effectiveness. This study introduces a lithiophilic nitrogen (N)-doped three-dimensional (3D) porous carbon (NLC) by simply reusing and carbonizing NH2-functionalized lignin (NL), an eco-friendly biopolymer derived from waste wood generated during the pulping process. The NLC offers macro-porous spaces with a rich array of N-doped sites, capable of accommodating and guiding Li deposition to facilitate uniform Li growth. The results demonstrate the effectiveness of the NLC as the Li growth guiding layer in Li-metal batteries. A full cell incorporating the NLC as a Li growth guiding layer, with NCM811 as cathodes, exhibits a remarkable capacity of 145. 57 mAh g-1 even at a high C-rate of 5C and capacity retention of 90.3% (167 mAh g-1) after 150 cycles at 1C. These findings represent significant advancements compared to conventional Li-metal batteries.

- Researchpp 1030-1057Karlström, A., Hill, J., and Johansson, L. (2024). “Data-driven soft sensors in pulp refining processes using artificial neural networks,” BioResources 19(1), 1030-1057.AbstractArticlePDF

Pulp refining processes are most often complicated to describe using linear methodologies, and sometimes an artificial neural network (ANN) is a preferable alternative when assimilating non-linear operating data. In this study, an ANN is used to predict pulp properties, such as shives (wide), fiber length, and freeness. Both traditional process variables (external variables) and refining zone variables (internal variables) are necessary to include as model inputs. The estimation of shives (wide) results achieved an R2 (coefficient of determination) of 0.9 (0.7) for the training and (validation) sets. Corresponding measures for fiber length and freeness can be questioned using this methodology. It is shown that the maximum temperature in the flat zone can be modeled using the external variables motor load and production instead of the specific energy. This resulted in an R2 of approximately 0.9 for the training sets, while the R2 for the validation set did not reach an acceptable level – most likely due to inherent non-linearities in the process. Additional results showed that the consistency profile is difficult to estimate properly using an ANN. Instead, a model-driven sensor is preferred to be used. The main results from this study indicate that shives (wide) should be the prime candidate when introducing advanced pulp property control concepts.

- Researchpp 1058-1078Kaçamer, S., Katırcıoğlu, F., and Budakçı, M. (2024). “Determining abrasion resistance of decorative coated wood-based panels using retinex model,” BioResources 19(1), 1058-1078.AbstractArticlePDF

An Image Processing Based Scrub Tester (IPBST) was used to imitate the effect of household chemicals on furniture and decoration elements. For this purpose, 8 mm-thick, bright white, acrylic coated medium density fiberboard (MDF), polyvinyl chloride coated MDF, MDF lam ready-to-use sheets, and cellulosic, polyurethane, acrylic, and water-based paint applied MDF sheets were used. Carbon fiber patterned decorative coating was applied to the prepared sample surfaces using the water transfer printing and ultraviolet printing methods. The surfaces of the samples were scrubbed with various household chemicals in accordance with the Turkish Standard TS EN ISO 11998. In the image processing phase, the images before and after scrubbing were first converted to hue, saturation, and value color space. The relationship between the abrasion measurement method of the proposed IPBST and the abrasion data obtained from the stereo microscope device was examined using the Pearson Correlation analysis. The relationship between both abrasion test methods was positive, very strong, and significant (0.81). Thus, the IPBST can be used as an alternative to industrial test devices as it obtains similar data.