Volume 17 Issue 4

Latest articles

- Researchpp 5803-5819Hunniger, J., Engisch, L., Hamblyn, S., Kappeler, U., and Hofmann, A. (2022). "Influence of ultrasound on embossing results for cardboard," BioResources 17(4), 5803-5819.AbstractArticlePDF

The requirements for embossing of cardboard for print and packaging applications are constantly increasing. High degrees of forming, richness of detail, and high shape accuracy are desired. However, current embossing technology can only fulfill these requirements to a limited extent. A loss of detail and moderate degrees of forming are typical defects in the embossing process. In previous research work, a positive effect on the forming behavior of cardboard could be observed by the application of ultrasound. Therefore, the influence of ultrasound was also investigated for embossing. In order to quantify the effects of ultrasound, conventional and ultrasonic-assisted embossing results were compared. New approaches for analysis and evaluation of embossing results and new characteristic values for describing the forming were applied for the comparison. Two exemplary embossing geometries and a range of ultrasonic parameters were used to characterize the impact of ultrasound and showed positive effects to the forming results.

- Researchpp 5820-5830Ma, L., Wang, J., Zhi, R., Lucia, L., Li, G., and Deng, Y. (2022). "Utilization of corncob hydrolysate enables 2,3-butanediol production in Enterobacter cholerae," BioResources 17(4), 5820-5830.AbstractArticlePDF

2,3-Butanediol (2,3-BDO) is an important industrial diol that could function in various fields. Currently, there are many substrates used for 2,3-BDO biosynthesis, but studies using green carbon sources such as corncob hydrolysate as a substrate are lacking. As a widely distributed waste lignocellulose-derived substrate, corncob hydrolysate is nutrient-rich and cost-effective. The present study evaluated 2,3-BDO production via an Enterobacter cholerae strain using corncob hydrolysate as carbon source. Chemical component analysis showed that concentrated corncob hydrolysate contained 233 g/L total sugar and showed no inhibitory effect, but it was beneficial for 2,3-BDO synthesis. Optimization experiments for fermentation resulted in a titer of 47.23 g/L 2,3-BDO with a yield of 0.30 g/g and a productivity rate of 0.66 g/L•h. This study is expected to provide insights for large-scale bioproduction of bulk chemicals utilizing corncob hydrolysates.

- Researchpp 5831-5847Čavlović, A. O., Bešlić, I., Pervan, S., Barlović, N., Mikšik, M., Klarić, M., and Prekrat, S. (2022). "Occupational exposure to inhalable and respirable wood dust of pedunculate oak (Quercus robur L.) in a furniture factory," BioResources, 17(4), 5831-5847.AbstractArticlePDF

Given the well-known carcinogenicity of hardwood dust, occupational exposure to oak wood dust has been determined in a furniture factory on different wood processing machines during sanding, planing, and milling. Determination of the mass concentrations of respirable and inhalable oak wood dust from ambient air was performed using personal sampling pumps and two types of filter holders: the Higgins-Dewell respirable dust cyclone, manufactured by Casella (Bedford, UK), and the inhalable dust IOM sampler manufactured by SKC (Dorset, UK). Out of a total of 30 values of inhalable mass concentration, 7 (23%) exceeded the occupational exposure level (OEL). The highest exposure levels for inhalable and respirable wood dust from the belt sander were 1.569 to 3.710 mg/m3 and 0.243 to 1.342 mg/m3, respectively. Worker exposure may be below the level of increased risk of 2 mg/m3 if a machine such as a planer or router is connected to a suction system. The share of respirable particles in the inhalable fraction ranged between 12% and 31%, and for samples with an inhalable mass concentration exceeding 2 mg/m3, the share was lower than 16%, with a slightly decreasing tendency. Thus, the risk of lower respiratory tract diseases increases with higher exposure to inhalable particles, and the OEL is an indirect measure of protection against exposure to respirable particles.

- Researchpp 5848-5860Župčić, I., Povrženić, K., Balaško, K., and Radmanović, K. (2022). "Temperatures in rotary welding of dowels in the beech wood," BioResources 17(4), 5848-5860.AbstractArticlePDF

Welding temperature is an important factor of rotary welding and affects the strength of the joint or the embedded force. This research focused on the parameters that affect the welding temperature and the effect of welding temperature on the embedded force of the dowel. Welding temperature was measured using measuring probes that were moved away from the dowel being welded. The results indicate that the speed of the dowel feed (duration of the welding process) influenced the welding temperature; the embedded force was then determined. With increased rotation frequency with the same duration of the welding process, there was a slight increase in the welding temperature. The influence of the rotational frequency on the extraction force was not unambiguously determined, because the rotational frequency is related to the duration of the welding process. As the welding temperature increased, the embedded force decreased. To avoid difficulties in contact measurement of welding temperature, it is necessary to develop a mathematical model of heat transfer to more accurately determine the welding temperature.

- Researchpp 5861-5877Lee, E., Kim, J., Bandi, R., Dadigala, R., Han, S., Kwon, G., Gwon, J., Youe, W., Park, J., Park, C., Kim, N., and Lee, S. (2022). "Ionic liquid-assisted isolation of lignin from lignocellulose and its esterification with fatty acids," BioResources 17(4), 5861-5877.AbstractArticlePDF

Ionic liquids (ILs) have been widely used for lignocellulose fractionation and lignin isolation. However, the effect of IL treatment on lignin structure has been less explored. This study aimed to explore the chemical structure of lignin isolated by widely used imidazolium based ILs and compare it with the well-known milled wood lignin structure (MWL). Four types of ILs were used, and the effects of the treatment conditions on the isolated lignin (ILL) characteristics were evaluated. As the treatment temperature was increased from 60 to 140 °C, the ILL yield increased, whereas the molecular weight and hydroxyl group content decreased. Among the ILs, [EMIM]Ac produced the highest lignin yield (5.28%), and the ILL obtained had the lowest hydroxyl content (1.27 mM/g) and a molecular weight (Mw) of 29,500 g/mol. Esterification of the ILL isolated with [EMIM]Ac was performed using three fatty acid chlorides, octanoyl chloride (C8), lauroyl chloride (C12), and palmitoyl chloride (C16), to extend its applicability. The effects of esterification on the characteristics of ILL were evaluated, and successful esterification was confirmed using Fourier transform infrared and nuclear magnetic resonance spectroscopies.

- Researchpp 5878-5889Zhou, K., Chen, Y., Sun, C., and Na, B. (2022). "Prediction of veneer moisture content based on near infrared spectroscopy," BioResources 17(4), 5878-5889.AbstractArticlePDF

The physical properties of wood, particularly the dimensional stability, are affected by the water content. Most wood properties can be detected by near infrared spectroscopy (NIRS), which is used as a nondestructive testing method. At different wavelengths, different absorption peaks are presented with the moisture absorbed by wood. According to this feature, the absorption peaks can be collected, and the data can be processed by partial least squares method combined with NIRS. In this study, softwood oak and hardwood ash tree specimens were studied. In the infrared spectrum range, the wood moisture absorption curve was noticeable and the curve trend was similar, although the tree species were different. After centralization, standardization, and derivative processing of the spectral data, the correlation coefficients of oak and ash tree validations were high, reaching 0.9021 and 0.9661, respectively. The wood moisture content was predicted using NIRS and an algorithm. The experiments showed that this method is feasible.

- Researchpp 5890-5904Xie, J., Yang, Z., Feng, Y., Chen, H., Hu, L., Jia, J., and Wu, D. (2022). "Optimization of extraction process of pine needle essential oil by response surface methodology and its chemical composition analysis," BioResources 17(4), 5890-5904.AbstractArticlePDF

The extraction of essential oil from pine needles was optimized by response surface methodology, and the following optimal conditions were obtained: a fresh pine needle of 100 g, an extraction time of 2 h, a water dosage of 850 mL, and a NaCl concentration of 2.50%. The extraction yield of essential oil was 0.611% under optimal conditions, which was extremely close to the predicted value. The extraction yields of essential oil from needles of 12 common pines in Guangxi were compared. The contents of essential oil in needles of Pinus massoniana, Pinus crassicorticea, and Pinus taeda were relatively higher than other pines. A total of 44 chemical components were identified by GC-MS, including 12 monoterpenes, 14 sesquiterpenes, and 12 alcohols. The chemical components of essential oil from different pines have their own features, and it is speculated that they have good and diversified application potential in the fields of medicine, food, spices, and so on. The chemical compositions of essential oil with high extraction yield have similar characteristics. This phenomenon can be used as the basis and means for the selection of pines with high content of essential oil in needles.

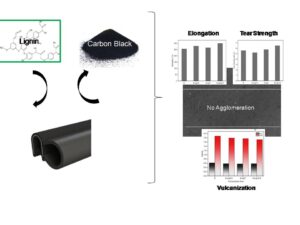

- Researchpp 5905-5918Poyraz, B., Güner, Y., Tozluoglu, A., Yamanoğlu, R., Candan, Z., and Şen, M. (2022). "Lignin in place of carbon black for ethylene-propylene-diene-monomer based automotive sealing profiles," BioResources 17(4), 5905-5918.AbstractArticlePDF

This study examined the effects of lignin used in EPDM elastomer composites in place of carbon black. For that purpose, lignin was added in amounts of 3.5, 7, and 10.5 phr to investigate the chemical, thermal, rheological, mechanical, and morphological properties of the EPDM elastomers. At the end of the study, tear strength and elongation were enhanced, whereas thermal stability was lowered due to the lignin. The lignin facilitated the vulcanization process and improved the torque values. In the morphology, the lignin was dispersed homogeneously in the matrix, and no voids or cracks were observed except with 10.5 phr. In conclusion, when incorporated at a specified ratio, lignin is economical and provides ecological benefits. Its use as a natural filler can be recommended to automotive industries to provide enhanced properties and ecological properties as a substitute for carbon black.

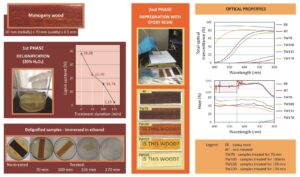

- Researchpp 5919-5935Popović, J., Svrzić, S., Gajić, M., Maletić, S., Dodevski, V., Djiporović-Momčilović, M., Krstić, S., and Popović, M. (2022). "Light transmittance of mahogany wood treated with 20% hydrogen peroxide solution," BioResources 17(4), 5919-5935.AbstractArticlePDF

There is an increased research interest in methods for transparent wood production and its use. Wood transparency could be achieved by its delignification followed by an impregnation process with polymers having proper optical properties. However, delignification processes are mainly time consuming and not environmentally friendly. The possibility of treating mahogany wood (Swietenia macrophylla King) with 20% hydrogen peroxide for 70, 100, 135, and 170 min at 103 °C is presented in this research. According to the treatment duration, lignin content decreased 40 to 94% relative to its initial content in the control samples, whilst the cell structure remained intact. Due to the light scatter effect, caused mainly by wood tissue structure, the direct optical transmittance of treated samples in the visible light spectrum (400 to 800 nm) was less than 40%. Simultaneously, the total optical transmittance of samples treated for 100 and 135 min reached values between 70 to 80% with high values of the haze at approximately 30 and 60%. Optical transmittance in the visible spectrum area of the samples treated for 170 min was from 45 to 80% and the haze from 25 to 45%.

- Researchpp 5936-5957Li, X., Che, W., Piao, J., Li, X., Jin, F., Yao, T., Li, P., Wang, W., Tan, T., and Shao, X. (2022). "Peanut shell biochar’s effect on soil physicochemical properties and salt concentration in highly saline-sodic paddy fields in northeast China," BioResources 17(4), 5936-5957.AbstractArticlePDF

Soil salinization is a major ecological threat to crop growth and production. Biochar addition can alleviate the negative impacts of saline-sodic stress in crops. Here, a two-year field experiment was conducted in a highly saline-sodic paddy field to evaluate the response of soil physico-chemical properties, ionic concentration, and rice yield to biochar applications. The soil was amended with peanut shell biochar as follows: zero biochar (B0), 33.75 t ha−1 (B1), 67.5 t ha−1 (B2), and 101.25 t ha−1 (B3). Biochar significantly reduced soil bulk density (BD), while it markedly increased total porosity (TP) and saturated hydraulic conductivity (Ks). Furthermore, biochar markedly decreased the Na+ concentration, Na+/K+ ratio, Na+/Ca2+ ratio, HCO3-, and CO32- while it increased the concentrations of K+, Ca2+, and Mg2+. Biochar significantly decreased the electrical conductivity of soil saturation extract (ECe). The exchangeable sodium percentage (ESP) of B1, B2, and B3 were 53.6%, 62.3%, and 71.0% lower, respectively, than that of B0, and the corresponding decrease in sodium adsorption ratio (SARe) was 51.2%, 58.1%, and 60.5%. Biochar had no effect on the soil pH but significantly increased the soil cation exchange capacity (CEC). The rice biomass yield, grain yield, and harvest index significantly increased after biochar application.