Volume 18 Issue 2

Latest articles

- Editorialpp 2520-2521Kim, J. D. (2023). “Time to collaborate for the age of paper,” BioResources 18(2), 2520-2521.AbstractArticlePDF

An awareness of the problems associated with the use of plastics can provide new opportunities for the paper industry. We have to try to enhance the public awareness of the environmental value of papers by using diverse advertising approaches. We have to collaborate to make paper more viable to replace plastics in many uses. The collaboration not only between industry and academia but also between countries and associations is essential to advance the age of paper.

- Editorialpp 2522- 2525Suota, M. J., Corazza, M. L., and Ramos, L. P. (2023). “Green solvents in biomass delignification for fuels and chemicals,” BioResources 18(2), 2522- 2525.AbstractArticlePDF

Lignin is considered by many as the ultimate barrier that impedes biomass conversion to fuels and chemicals. Several delignification strategies have been developed so far, but alkaline extraction remains the most widely used. However, this technology has a high chemical demand, consumes large amounts of water, and generates effluents that are hard to handle. Organosolv pulping is a good option for such application, but the impact of solvent losses and harmful emissions may be unsustainable. To this end, the use of greener alternatives such as water, biobased solvents, ionic liquids, and deep eutectic solvents, under sub- or supercritical conditions, may pave the road for the development of sustainable biorefineries.

- Editorialpp 2526-2527Zhang, S., Zhang, Q., Sa, M., and Zhu, S. (2023). “Lignocellulosic biomass for sustainable energy: Some neglected issues and misconceptions,” BioResources 18(2), 2526-2527.AbstractArticlePDF

Lignocellulosic biomass (LB) is widely used in the field of renewable energy production because of its low price and easy availability. Many kinds of fuels from LB have been developed and are being used in our daily lives. The LB energy has become an indispensable part in the energy mix on account of its steady and sustainable supply. However, there are some neglected issues and misconceptions regarding its development and utilization, although it has numerous advantages over other energy sources. Firstly, its development and utilization can change the living environment of organisms and decrease biodiversity to some extent, relative to using other sources of energy. Secondly, it is not a completely carbon-neutralized fuel as has been claimed in some literature. Finally, its excessive exploitation can seriously damage the environment and biosystems. This editorial will give a brief discussion on some neglected issues and misconceptions during its development and utilization for its suitable exploitation.

- Editorialpp 2528-2530Song, S., Wang, Q., and Zhang, M. (2023). “Bamboo fiber-based insulating paper: A potential choice towards greener power and paper industries,” BioResources 18(2), 2528-2530.AbstractArticlePDF

Insulating paper is the key material utilized in ultra-high voltage (UHV) projects, and it affects the safe and stable operation of the whole power system. Cellulose fiber-based insulating paper, having the advantages of low price and environmental friendliness, has been widely used as the preferred insulating material for certain transformers. Bamboo, as a fast-growing raw material, has a favorable fiber length and its carbon sequestration is better than that of wood. Bamboo can be potentially used as a new raw material for insulating paper, thus promoting the green development of the power and paper industry. This article mainly discusses the challenges and potentials of bamboo fiber-based insulating paper and the opportunities of bamboo fiber-based paper materials.

- Editorialpp 2531-2534Hubbe, M. A. (2023). "How to make cellulose hate water – Change it, cover it, confuse it, or accept it as it is,” BioResources 18(2), 2531-2534.AbstractArticlePDF

In many of its current and potential applications, technologists treat the surface of cellulose to render it more hydrophobic. By use of a variety of hydrophobic sizing treatment strategies, the bulk cellulose phase becomes covered up with a layer having lower polarity and less inclination to interact with water. Often, the goal is to use a relatively low amount of additive to cover up or change just the surface of the cellulosic material, while still benefiting from the strength, recyclability, relatively low cost, and other favorable features of the bio-based material. But what often gets forgotten is that the hydrophilic nature of pure cellulose is not very high, and there are ways to manipulate such characteristics without reacting the material or covering it up. Sometimes reacting the cellulose with hydrophobic substituent groups appears to make it more water-loving. So, when thinking broadly of processing options for new applications, there are several contrasting approaches to consider.

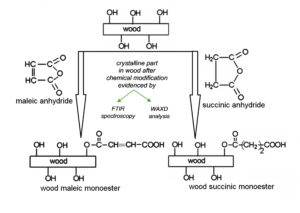

- Researchpp 2535-2550Teacă, C.-A. (2023). “Crystalline structure of cellulose in wood after chemical modification using cyclic acid anhydrides (maleic and succinic),” BioResources 18(2), 2535-2550.AbstractArticlePDF

The chemical modification of wood can be directed to improve various properties, e.g., the dimensional stability, hardness properties, and/or durability properties, against weathering. In this study, a Romanian softwood species Abies alba L. was treated and chemically modified using two cyclic acid anhydrides, i.e., maleic and succinic, to improve its interfacial properties relative to unmodified wood. Structural changes, with focus on the evolution of crystalline part in wood after chemical modification, the water absorption, and the water repellent efficiency, were determined. Maleic anhydride exhibited a lower reactivity towards wood substrate than succinic anhydride, presumably because of their different chemical structure (maleic anhydride is very sensitive to the presence of water). It was found that the percentage of water absorption was diminished, primarily after the succinic anhydride treatment. The chemically modified wood was characterized via Fourier transform-infrared spectroscopy and wide-angle X-ray diffraction methods. The crystalline part from wood structure was evidenced in relation to the employed anhydride in chemical modification approach.

- Researchpp 2551-2572Yer Çelik, E. N., Ayan, S., Özel, H. B., Turfan, N., Mehmet Yer, B., and Abdaloğlu, G. (2023). “Effects of melatonin applications on Anatolian black pine (Pinus nigra J. F. Arnold. subsp. pallasiana (Lamb.) Holmboe) afforestation performance in semi-arid areas,” BioResources 18(2), 2551-2572.AbstractArticlePDF

Melatonin, a substantial hormone, is a natural antioxidant agent that functions as a protector against the harmful effects of free radicals. Studies have found that “exogenous melatonin” applications have a positive effect on the growth and development of plants. This study investigated the adaptation of the seedlings that were transported from the nursery to the afforestation site for the process of planting. In 2019 the 2+0 aged bare-rooted Kastamonu/Taşköprü Anatolian Black pine seedlings, which are suitable for planting in semi-arid areas, were selected as research materials. Four different doses of “exogenous melatonin” (250, 500, 1000, and 1500 μM) were administered through two different methods (root-dipping and needle-spraying). Morphological seedling characteristics and bioactive chemical variables were measured for the control group and the seedlings treated with different doses of melatonin. Antioxidant enzyme activities were identified. When both the needle-spraying and root-dipping methods for melatonin application were evaluated in terms of morphological and biochemical variables, the best results were determined in low doses (250 to 500 μM). The results suggest that melatonin provides support to the metabolic process for the resistance of seedlings to low temperatures and semi-arid climatic conditions.

- Researchpp 2574-2588Liu, M., Zhu, X., Chen, Y., and Kong, Q. (2023). “Evaluation and design of dining room chair based on analytic hierarchy process (AHP) and fuzzy AHP,” BioResources 18(2), 2574-2588.AbstractArticlePDF

From the perspective of user needs, a design evaluation system for dining room chairs that can meet user needs was established. Based on the analytic hierarchy process (AHP), the user needs of a dining room chair were quantitatively analyzed by combining qualitative and quantitative methods. Moreover, the comprehensive weight ranking of 14 factors in the object hierarchy was obtained, which provided the design focus and quantitative indexes for designers in the early stage of dining room chair design. Then, in the later stage of dining room chair design, the fuzzy analytic hierarchy process (FAHP) method was used to quantitatively evaluate the three design schemes and obtain the optimal design scheme. The experimental results showed that the user needs evaluation results were positively correlated with the “excellent” grade in the FAHP method. This indicated that the evaluation system realized a symmetry, reliability, and effectiveness between the user needs evaluation and FAHP. Therefore, it can be concluded that this evaluation system based on AHP and FAHP proposed in this study has reliability and validity, and it can be used for design evaluation to judge the popularity of products, enhance the competitiveness of products, and reduce product design costs.

- Researchpp 2589-2610Hassan, B., Fitzgerald, C., and Minett, R. (2023). “Toxicity, repellency, and horizontal transfer of foam insecticides for remedial control of an invasive drywood termite, Cryptotermes brevis (Blattodea: Kalotermitidae),” BioResources 18(2), 2589-2610.AbstractArticlePDF

Laboratory tests were conducted to compare imidacloprid and fipronil foams against various criteria to determine the effect of the deposit conditions, exposure method, and exposure time on the toxicity, repellency, and horizontal transfer of selected foam insecticides. Results of toxicity assays showed that imidacloprid and fipronil foams caused significantly higher mortality than control treatments; however, fipronil foam in fresh or old deposits killed Cryptotermes brevis pseudergates more quickly in the short and continuous exposure tests than foam containing imidacloprid. In brief exposure tests, imidacloprid failed to kill all termites when exposed to fresh deposits and delayed total mortality when exposed to dry residues. The mortality of C. brevis pseudergates was also significantly quicker when the fipronil foam was applied topically compared with the imidacloprid foam. In the repellency test, termites were not repelled from the surface treated with fipronil foam, but more than 90% repellency was observed after 24 h of exposure to imidacloprid-treated surfaces. Moreover, the non-repellent mortality of C. brevis with fipronil was significantly higher than imidacloprid in avoidance tests. Results showed that fipronil was effectively transferred to untreated termites from live or dead donors exposed via residual and topical spray.

- Researchpp 2611-2625Liu, W., Chen, M., Liu, H., Yi, B., Hu, H., Zhang, Y., Liu, D., and Li, C. (2023). “Isothermal drying characteristics and kinetic mechanism for tobacco with different water content,” BioResources 18(2), 2611-2625.AbstractArticlePDF

The effect of drying temperature on the drying characteristics of tobacco was investigated with different water content. The isothermal drying characteristics and kinetics of three kinds of tobacco on the production line of a tobacco factory in Hubei were studied by halogen water analyzer. The drying characteristics of tobacco with different water content under isothermal conditions were evaluated by water loss characteristics, water diffusion coefficient, and activation energy. The results showed that the drying time of cut tobacco was reduced by increasing the drying temperature within a certain range. The water diffusion coefficient of cut tobacco decreased with the increase of temperature from 70 to 100 °C, and increased with the increase of initial water content. The activation energy of cut tobacco was related to the production process. The activation energy in the experiment was as follows: CT-2 > CT-3 > CT-1. Five drying models were used for non-linear fitting of the drying behavior of tobacco. The fitting degree of the Midilli model was the highest, reaching 0.9944. This data will be useful in the design of tobacco drying equipment.