Volume 19 Issue 1

Latest articles

- Researchpp 1348-1364Gezer, E. D., and Kuştaş, S. (2024). “Acoustic and thermal properties of mycelium-based insulation materials produced from desilicated wheat straw - Part B,” BioResources 19(1), 1348-1364.AbstractArticlePDF

The acoustic and thermal properties were determined for biodegradable insulation materials produced from desilicated wheat straws with two different fungi and three different incubation periods. Ganoderma lucidum (GL) and Pleurotus ostreatus (PO) fungi and wheat straw were exposed to fungal incubation for 10, 20, and 30 days to produce mycelium-based insulation materials. The sound absorption coefficients of mycelium-based insulation boards produced using PO fungus were higher than those produced with GL fungus. It was found that the acoustic absorption coefficients of insulation boards produced using PO fungus at 1,000 Hz were 87 to 99% according to the incubation periods. The sound transmission losses of mycelium-based insulation boards produced ranged from 46.4 to 59.7 dBa at 1000 Hz. The group of boards labeled as YP2 exhibited the lowest level of sound transmission loss, whereas GL2 revealed the highest degree of sound transmission loss at 1000 Hz. The lowest thermal conductivity coefficient was obtained in insulation boards produced with PO fungus and an incubation period of 20 days. The limiting oxygen index (LOI) value of mycelium-based insulation materials was considerably higher than the insulation boards commonly used today. Thermogravimetric analysis and derivative thermogravimetry curves of mycelium-based insulation materials were also determined.

- Researchpp 1365-1376Rajalekshmi, P., and Arul Jose, J. P. (2024). “Impact of coconut husk microcrystalline cellulose on the properties of geopolymer lightweight concrete,” BioResources 19(1), 1365-1376.AbstractArticlePDF

Geopolymer composite is an alternative to ordinary Portland cement. It has potential to avoid CO2 emissions to the atmosphere and to save raw materials during its manufacture. Flyash-based geopolymer concrete is altered by adding ground granulated bast-furnace slag (GGBS) to improve its fresh and hardened properties. Thermal ash aggregate is used as coarse aggregate to reduce geopolymer concrete density, improve strength, and conserve natural aggregate. Along with this matrix, coconut husk microcrystalline cellulose (MCC) is added to enhance its performance. In a M40 grade flyash and GGBS-based geopolymer concrete, MCC was used to replace fly ash at 1% to 5% levels. The geopolymer composites were tested for slump, compression, split tensile, water absorption, and acid resistance to determine the way coconut husk MCC interacts with lightweight concrete. An inclusion of 3% MCC with geopolymer composites improved 2% slump, 6% of compressive and split tensile strength. About 1.6% of water absorption was reduced in GPC matrix with 3% of MCC. Meanwhile 3% of MCC in geopolymer concrete improved, 4% of weight and 7% of strength under acid exposure. The research strongly supported utilizing MCC in geopolymer concrete to render it more sustainable and eco-friendlier.

- Researchpp 1377-1393Zhang, K., Li, Z., Duan, R., Li, M., Wang, J., Sheng, J., Ren, H., Wang, S., Wang, X., and Hao, Y. (2024). “Rheological effects of montmorillonite and ethyl cellulose for Xanthoceras sorbifolium Bunge oil-based lubricants,” BioResources 19(1), 1377-1393.AbstractArticlePDF

Xanthoceras sorbifolium Bunge oil exhibits favorable characteristics such as excellent low temperature fluidity, high flash point, and degradability. However, it also suffers from drawbacks including low kinematic viscosity at low temperatures and significant loss of kinematic viscosity at high temperatures. In view of these characteristics of X. sorbifolium oil, it was modified in this work with a combination of ethyl cellulose (EC), montmorillonite (MMT), and cetyltrimethylammonium chloride (CTAB). The effects of temperature, time, and additive content on the rheological properties of lubricating oil were studied. The kinematic viscosity of the prepared lubricating oil reached up to 433 mm2/s at 40 °C and 51.1 mm2/s at 100 °C. The coagulation point could be reduced to -25 °C, the friction coefficient was 0.026, and the average wear spot diameter was 0.81 mm, The anti-friction performance was enhanced, and the anti-wear performance decreased somewhat. The prepared lubricating oil had the characteristics of high kinematic viscosity at high temperature and excellent rheological properties at low temperature. It also met the energy and environmental application requirements of a green, environmentally friendly, and biodegradable sustainable development strategy. This study greatly broadens the application range of lubricating oil.

- Researchpp 1394-1409Yoo, S., Lee, S., Kang, S.-W., and Ahn, K.-H. (2024). “Upcycling waste tempura flake-derived starch powder as an environment-friendly polymer matrix filler for thermoplastic starch compounds,” BioResources 19(1), 1394-1409.AbstractArticlePDF

Waste tempura flakes collected from local restaurants were upcycled to be utilized as a polymer filler material. The oil fraction in collected waste tempura flakes were extracted two times via centrifugal solid-liquid separation and organic solvent extraction. Then, oil-extracted residual starch was freeze-milled to produce fine powders. Waste tempura flake-derived starch powder was substituted with 1%, 3%, and 5% (wt%) of virgin starch powder to produce thermoplastic starch. Composition, X-ray diffraction, and Fourier transform infrared analyses showed that the mixture was successfully thermally plasticized. Substitution of waste tempura flake-derived starch decreased tensile strength while increasing elongation at break of some samples. Produced thermoplastic starch samples again were compounded with polylactic acid (PLA) and poly-butylene adipate-co-terephthalate (PBAT) following a mixing ratio of 3:5:2. The analyses indicated that thermoplastic starch, PLA, and PBAT were successfully compounded. The compound containing 1 wt% substituted thermoplastic starch showed the minimal mechanical strength decrease. This study revealed the possibility of upcycling waste fried food into a valuable bioplastic material. Waste tempura flakes can be utilized as both bio-jet fuel and bioplastic filler material.

- Researchpp 1410-1432Quin, Jr., F., Franca, T., Street, J., Lim, H., and Shmulsky, R. (2024), “Structural performance of connectors in a hardwood stairway handrail guard system,” BioResources 19(1), 1410-1432.AbstractArticlePDF

Wood is a preferred material for constructing staircases due to its appealing aesthetic features. The use of wood, especially hardwoods such as red oak (Quercus rubra), white oak (Quercus alba), yellow poplar (Liriodendron tulipifera), and hard maple (Acer saccharum), has been the main construction material for staircases over the years. Staircase designs have evolved because of the flexibility of wood and working with specialized manufacturing machinery. A stair guard system connection must be designed to resist rotational and translational movements whenever a force is applied to the handrail. The demand for structural design values in wooden stair guards has been steadily increasing, driven by the needs of engineers, designers, builders, and end-users alike. This paper presents experimental data for four stair guard connections (post-to-rail, infill-to-footing, infill-to-rail, and rail-to-rail) encountered in a hardwood stairway handrail guard system. The data generated from this research could be useful for modeling the structural behavior of the connections.

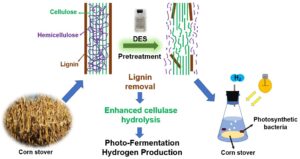

- Researchpp 1433-1445Li, C., Lu, Y., Liu, Y., Yue, J., Zhou, X., and Jing, Y. (2024). “Comparative analysis of photo-fermentation hydrogen production from pretreated corn stover by deep eutectic solvents,” BioResources 19(1), 1433-1445.AbstractArticlePDF

To compare the pretreatment effect of deep eutectic solvents (DESs) on corn stover, three types of DESs (acid, neutral, and alkaline) were used to pretreat corn stover, and their effects on lignin removal were investigated. Then the performance of photo-fermentation hydrogen production (PFHP) using DESs pretreated corn stover was compared and analyzed. The results showed that acid DESs had the best lignin removal efficiency, and the lignin removal percentages of choline chloride/formic acid (ChCl/Fac) and choline chloride/oxalate (ChCl/Oac) were 64.7% and 65.6%, respectively. The alkaline DESs had the second highest removal of lignin, while the neutral DESs had a poor effect on lignin removal. The comparison of hydrogen production indicated that the corn stover pretreated with ChCl/Oac had the best hydrogen production effect. In conclusion, the DESs pretreatment can obviously remove the lignin in corn stover, and then improve the hydrogen production capacity and efficiency of photo-fermentation, which provides a potential pretreatment method for the efficient utilization of straw biomass.

- Researchpp 1446-1464Tozluoğlu, A. (2024). “Potential use of nanofibrillated cellulose-loaded cationic starch solutions as coating formulation for recycled fluting papers,” BioResources 19(1), 1446-1464.AbstractArticlePDF

Effects of cellulose nanofibers (CNF) and cationic starch (CS) were evaluated as coating components relative to the physical and mechanical properties of fluting papersheets fabricated from recycled corrugated cardboard fibers. Fabricated fluting papers were subjected to size press applications by three different coating blends. Coating suspensions were prepared at various concentrations of CNF (0.5%, 1%, 2%, 3%, and 4%) and 4 wt% CS, and the same amounts of CS/CNF. The paper sheets were fabricated using size press machine as three-time repetitive applications, followed by one-time drying section, and compared to uncoated, CS-coated, and CNF-coated papers. The application of CNF suspensions increased tensile indices up to 11.7%. Moreover, CS/CNF suspensions resulted in a 67.2% increase in tensile index values. The coating of CS/CNF suspensions increased the burst index values by 163% at the CS+1%CNF concentration when compared to the control pulp. Surface application of prepared suspensions reduced the porosity of the samples under all conditions. The highest reduction in the air permeability was observed in the CS+4%CNF-coated samples as 91.5%. It can be concluded that the superficial applications of CNF on the physical and mechanical properties of recycled fluting paper was more effective in the presence of CS.

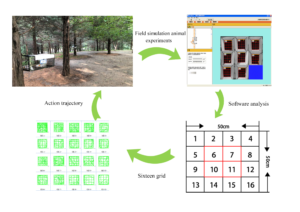

- Researchpp 1465-1478Wang, D., Wang, Q., Du, W., Wang, Y., Shu, J., Ma, L., Cao, X., Han, L., and Wang, Y. (2024). “Broad-leaved forest’s impact on spontaneous activities of mice and their mental state,” BioResources 19(1), 1465-1478.AbstractArticlePDF

Empirical studies on the effects of urban forests on the health of humans and other animals are needed to rationalize the construction of urban forests for healthcare. The effects of urban forests (coniferous, broad-leaved, and mixed coniferous and broad-leaved) were studied relative to the physical and mental health of mice and the major environmental factors influencing them. Compared with the control group, the total movement distance of the mice that stayed in the coniferous forest, mixed coniferous and broad-leaved forest, and broad-leaved forest increased 9.7% to 18.1%, the central grid movement distance increased 7.2% to 23.9%, central grid dwell time increased 10.7% to 16.3%, and the number of entries increased 5.2% to 18.6%, indicating that the mental state and the exploration and cognitive abilities of mice were significantly improved in the three urban forests. The broad-leaved forest had greater positive effects than the other two forest types. This can be attributed to a decrease in temperature and the increases in humidity and concentrations of oxygen and negative ions in the air in the broad-leaved forest. The research results provide a theoretical basis for building urban forests that are beneficial to the health of urban residents.

- Researchpp 1479-1493Zou, Y., Zhao, W., Zhang, W., Zhang, J., Zhao, Y., Yuan, S., and Chen, H. (2024). “Dimensions, microstructure, chemical, and hygroscopic analysis of steam-exploded bamboo fibers at different ages,” BioResources 19(1), 1479-1493.AbstractArticlePDF

Bamboo fibers (BFs) at different ages (1, 3, and 5 years old) were prepared by pretreatment and steam explosion. The results demonstrated that the separation degrees of BFs increased with the age of the bamboo. The combined effects of pretreatment and steam explosion partially removed the hemicellulose and lignin from BFs, while the crystalline structure of cellulose remained unaltered. The water vapor adsorption isotherms of BFs at different ages all showed a typical S-shape and could be classified as type II, and the hysteresis of BFs increased with the age of the bamboo. After pretreatment and steam explosion, the tissues in the vascular bundle were effectively crushed, and the parenchyma tissues were dislodged and separated from the fiber sheath. During the steam explosion process, hot steam penetrated the bamboo’s pores, including the pores induced by pretreatment. This caused fractures and delamination in the interface between the vascular bundle and the parenchyma tissues. These cracks progressed layer by layer along the vascular bundle interface, leading to the fracture of the bamboo.

- Researchpp 1494-1516Kılıç, I., Avcı, B., Atar, I., Korkmaz, N, Yılmaz, G., and Mengeloğlu, F. (2024). “Utilization of flours from hemp stalks as reinforcement in polypropylene matrix,” BioResources 19(1), 1494-1516.AbstractArticlePDF

Utilization of hemp stalks (HS) was investigated as filler and maleic anhydride-grafted polypropylene (MAPP) as a coupling agent relative to some mechanical, physical, morphological, and thermal properties of polypropylene (PP) composites. The test sample manufacturing used 10, 15, 20, 25, 30, and 35 wt% of HS and 0 wt% or 3 wt% of MAPP. Test specimens were manufactured by combining extrusion and injection molding processes. Results showed that incorporating filler and MAPP increased the mechanical properties significantly. The utilization of HS filler or MAPP provided an improvement of 11.7% (samples containing 35 wt% HS and 3 wt% MAPP) improvement in tensile strength, 44.2% (samples containing 35 wt% HS and 3 wt% MAPP) in flexural strength, and 60.2% (samples containing 30 wt% HS and 0 wt% MAPP) in impact strength compared to neat PP. The scanning electron microscopy analysis provided visual evidence that MAPP improved adhesion between the filler and the polymer matrix. This study showed that using hemp stalks in composite manufacturing provided good overall properties.