Abstract

This study investigated the difference in sound-absorbing capabilities by thermally modified wood with respect to temperature and anatomical direction. Indonesian Homalium foetidum was used as testing material. After the samples were thermally modified at 170, 200, and 230 °C for 8 h, sound absorbing capability in the transverse and radial planes was investigated. As the treatment temperature was increased, the noise reduction coefficient (NRC) of the radial plane increased by 26.4%, and that of the transverse section increased by 7.3%. However, at 230 °C, the maximum NRC of the radial plane was 0.097 (SD: 0.015), and that of the transverse section was 0.263 (SD: 0.016). As a consequence, the sound absorption effect of the radial plane was negligible. Therefore, thermally modified Indonesian Homalium foetidum could be expected to absorb sound when used as a transverse section.

Download PDF

Full Article

Change in Sound Absorption Capability on Thermally Modified Transverse and Radial Planes of Indonesian Homalium foetidum

Eun-Suk Jang, and Chun-Won Kang *

This study investigated the difference in sound-absorbing capabilities by thermally modified wood with respect to temperature and anatomical direction. Indonesian Homalium foetidum was used as testing material. After the samples were thermally modified at 170, 200, and 230 °C for 8 h, sound absorbing capability in the transverse and radial planes was investigated. As the treatment temperature was increased, the noise reduction coefficient (NRC) of the radial plane increased by 26.4%, and that of the transverse section increased by 7.3%. However, at 230 °C, the maximum NRC of the radial plane was 0.097 (SD: 0.015), and that of the transverse section was 0.263 (SD: 0.016). As a consequence, the sound absorption effect of the radial plane was negligible. Therefore, thermally modified Indonesian Homalium foetidum could be expected to absorb sound when used as a transverse section.

DOI: 10.15376/biores.17.3.5234-5242

Keywords: Thermal modification; Sound absorption coefficient; Homalium foetidum

Contact information: Department of Housing Environmental Design, and Research Institute of Human Ecology, College of Human Ecology, Jeonbuk National University, Jeonju 54896, South Korea;

*Corresponding author: kcwon@jbnu.ac.kr

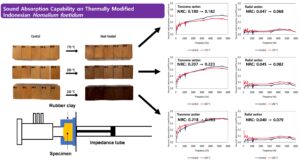

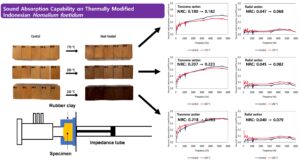

GRAPHICAL ABSTRACT

INTRODUCTION

Wood is a natural material that is sensitive to moisture, has low dimensional stability, and is subject to bio-deterioration (Sandberg et al. 2017). Consequently, wood modification is a technique applied to overcome the weakness of wood as a natural material (Hill 2011; Sandberg et al. 2017). Wood modification can be achieved via chemical, physical, or biological methodologies (Hill 2011).

Among the various wood modification processes, thermal modification is by far the most commercially available method (Ghorbani et al. 2012). Thermally modified wood has increased dimensional stability with improved weather resistance against bacterial decay (Esteves and Pereira 2009; Ghorbani et al. 2012; Kim 2016).

As the thermal modification temperature increases, the amorphous region of cellulose is decomposed first, the crystallinity of the cellulose increases to around 230 °C, and the size of the crystalline region rises (Kim 2016). As the crystallinity of cellulose increases, the number of hydroxyl groups accessible to water molecules in cellulose decreases, and the number of water molecules adsorbed to cellulose also decreases, resulting in a decrease in hygroscopicity (Kim 2016). This phenomenon increases the dimensional stability and weather resistance of wood (Kim 2016).

When thermal modification of wood causes thermal decomposition of the main chemical components, the weight of wood is reduced (Herrera-Díaz et al. 2018). In addition to this, the cell wall of the wood becomes thin, and cracks occur (Boonstra et al. 2006b). For this reason, thermally modified wood shows increased porosity and pore size, which leads to an increase in permeability (Boonstra et al. 2006a; Petrissans et al. 2013; Jang and Kang 2019).

According to previous studies, high-permeability wood has a high sound-absorbing capability. Taghiyari et al. (2014) investigated the gas permeability and sound absorption coefficient of 5 species of woods (poplar, beech, walnut, mulberry, and fir) and reported a positive correlation between gas permeability and sound absorption with 50-mm-length specimens.

Kang et al. (2020) investigated the gas permeability and sound absorption coefficient of sapwood and heartwood of 3 Japanese hardwoods (Sugi, Chanchin-modoki, and Yurinoki). In all three species, sapwood had superior gas permeability and sound absorption performance in comparison to heartwood. It was also reported that sound absorption performance was related to gas permeability.

Jang and Kang (2021a) investigated gas permeability, pore size, and porosity of 6 species of Korean hardwoods (red toon, Korean castanea, East Asian hackberry, Korean aspen, Oriental plane tree, and East Asian alder). Gas permeability had a stronger relationship with sound absorption coefficient at high frequency than at low frequency. In addition, through-pore porosity was a significant factor in the sound absorption performance of the cross-section of hardwoods.

Thermal modification of wood improves permeability, and it is also effective in improving sound absorption. Chung et al. (2017) reported the change in sound-absorbing capability of Larix kaempferi heat-treated at 200, 220, and 240 °C for 9, 12, 15, and 18 h. The high frequency band sound absorption coefficient increased according to treatment temperature and treatment time.

Kang et al. (2018) reported that, after heat treatment of Papua New Guinea Homalium foetidum at 190 °C for 3 h, the gas permeability increased by 8 times, increasing the average sound absorption coefficient by 40%. Kolya and Kang (2021) reported that hygrothermally treated Paulownia at 110 °C increased the average sound absorption coefficient in the 2000 Hz to 6400 Hz frequency band by 47.4% compared to that of untreated Paulownia.

Among the heat-treated wood species of previous studies, Homalium foetidum had the best sound absorption performance (Kang et al. 2018) because of its diffuse porous nature of wood with vessels distributed over a wide area and no tyloses (Kang et al. 2010).

In the authors’ previous study, heat treatment of Homalium foetidum was performed only at a temperature of 190 °C, and only the transverse plane was used to evaluate the sound absorption characteristics (Kang et al. 2018). Also, they are reported that after heat treatment of Homalium foetidum at 210 °C for 6 hours, the through-pore porosity and gas permeability of the transverse section were improved by 22.7 and 4.3%, respectively, and this improved the NRC of Homilium by 6.8% (Jang and Kang. 2021b).

Therefore, in this study, as an extension of previous studies, Indonesian Homalium foetidum was prepared and heat-treated at 170, 200, and 230 °C for 8 h, and sound absorption was measured in the transverse and radial planes.

Recently, interest in eco-friendly sound-absorbing materials is increasing (Mamtaz et al. 2016; Hassan et al. 2020; Yang et al. 2020) as research on the use of wood as a porous sound-absorbing material is also increasing (Wang et al. 2014; Kang et al. 2021a,b). It is expected that the results of this study will be useful for researchers who want to use wood as a porous sound-absorbing material.

EXPERIMENTAL

Specimen Preparation and Thermal Modification

Air-dried Indonesian Homalium foetidum timber 4 × 4 × 100 cm was supplied by Saehan Timber Co., Ltd., Ilsan, Korea. The moisture content (MC) of the sample was 11%. The timber was cut to approximately 4 × 4 × 4 cm cube samples using a table saw. Fifteen uncracked cube samples were selected for each heat trial group, with they were divided into three groups of five cubes each depending on the modification temperature. Heat treatment was performed for 8 h at 170, 200, and 230 °C for each group using a laboratory air-dry oven (OF-02GW, Jeotech Co., Ltd, Daejeon, Korea). Figure 1 shows the cube samples before and after thermal modification depending on process heat temperature.

Fig. 1. Photos of cube samples before and after thermal modification depending on the heating temperature

Sound-absorbing Capabilities of Transverse and Radial Planes

The sound absorption coefficients of cube samples were measured using an impedance tube (Model: Type 4206, Bruel and Kjaer, Nærum, Denmark), to which the transfer function method was applied before and after thermal modification. This method is based on ISO 10534-2 (2001), and it measured the sound absorption coefficient at a frequency range of 50 Hz to 6400 Hz in about 8 s per sample. This method is suitable for investigating the sound absorption capability of small sample on a laboratory scale. According to the difference between the incident plane wave and the reflected plane wave, the sound absorption coefficient (α) was calculated using Eq. 1.

(1)

where R is the ratio of the sound pressure of the reflected wave to that of the incident wave.

If a small impedance tube is used, the measurement can be conducted by mounting a sample with a diameter of 2.9 cm in a sample holder. However, the 4 × 4 × 4 cm cube samples that were prepared for this study were impossible to mount in the sample holder of the impedance tube. Therefore, the cube sample was attached to the impedance tube without using a sample holder, as shown in Fig. 2 (Jang and Kang 2022). The entire connection area between the sample and the impedance tube was wrapped with rubber clay to reduce the loss of white noise from the impedance tube and to block external noise. The thickness of the rubber clay surrounding the sample was approximately 1 cm.

Additionally, the NRC (Noise Reduction Coefficient), which is the average sound absorption coefficient at frequencies of 250, 500, 1000, and 2000 Hz, was calculated. NRC is a widely used index to evaluate the performance of sound-absorbing materials in the acoustics industry.

To determine whether the NRC was statistically significant with respect to change in thermal modification temperature, the paired t-test was performed using Excel 2019 (Microsoft, Redmond, USA). The paired t-test is a statistical technique that evaluates whether the difference between a group’s average before the experiment is significant compared to that after the experiment.

Fig. 2. Installation of an impedance tube for cube sample measurement (Jang and Kang 2022)

RESULTS AND DISCUSSION

Figure 3 provides the average sound absorption coefficient curve for cube samples depending on thermal modification temperature. Overall, the sound-absorbing capability of the transverse plane was higher than that of the radial plane because wood has an anisotropic characteristic, and the vessels are developed in the transverse plane, which is advantageous for sound absorption (Kang et al. 2010). The sound absorption coefficient of the transverse plane showed a typical porous material characteristic of increase in the high frequency direction (Arenas and Crocker 2010).

As the thermal modification temperature increased, the sound absorption coefficient curve of the radial plane was located higher than that of the control samples. However, in the transverse plane, only the absorption coefficient curve up to about 1000 Hz increased up 200 °C, and that in the high frequency region decreased. On the other hand, the overall sound absorption capability was improved at 230 °C.

After thermal modification, the frequency of the maximal absorption coefficient was changed. In the transverse section, the maximum sound absorption coefficient changed from 0.315 at 5408 Hz to 0.260 at 4200 Hz after thermal modification at 170 °C. When thermally modified at 200 °C, the maximum sound absorption coefficient changed from 0.362 at 5208 Hz to 0.331 at 4176 Hz; when thermally modified at 230 °C, it changed from 0.387 at 5408 Hz to 0.390 at 5352 Hz. In the radial section, the maximum sound absorption coefficient changed from 0.083 at 5208 Hz to 0.100 at 488 Hz after thermal modification at 170 °C. When thermally modified at 200 °C, the coefficient changed from 0.079 at 5408 Hz to 0.134 at 72 Hz; when thermally modified at 230 °C, it changed from 0.079 at 4656 Hz to 0.167 at 72 Hz. Overall, the frequency of the maximum sound absorption coefficient shifted in the low-frequency direction after heat treatment.

Fig. 3. The sound absorption coefficient curves of the thermally-modified cube sample

Table 1 reveals the NRC of cube samples depending on temperature. A statistically significant increase in NRC was noted after thermal modification in all cube samples except for the transverse plane that was thermally modified at 170 °C (t=-0.195, p=0.855, paired T-test). The level of increase of NRC of the transverse plane heat-treated at 200 °C was approximately 7.72% (t=-2.331, p=0.08), and that at 230 °C was approximately 26.44% (t=-10.472, p=0.001). On the other hand, in the radial plane, the NRC increases with increasing heat treatment temperature were approximately 44.7% (t=-7.478, p=0.001), 82.22% (t=-3.897, p=0.017), and 97.50% (t=-5.886, p=0.004). The maximum NRC for the transverse plane of thermally-modified Indonesian Homalium foetidum was 0.263 (SD: 0.016) at 230 °C and 0.097 (SD: 0.015) in that of the radial plane.

The increase of the NRC was higher in the radial plane than in the transverse plane with the increase in modification temperature; however, the NRC increase of the radial plane corresponds to a level with almost no sound absorption effect.

When wood is thermally modified, lignin, cellulose, and hemicellulose are chemically rearranged, and the micro or macropore structure of wood is physically changed (Chung et al. 2017; Jang and Kang 2019). For this reason, gas permeability is improved in both the transverse and radial planes, contributing to improvement of sound absorption performance.

As a result, to expect a sound-absorbing effect from thermally-modified Indonesian Homalium foetidum, the transverse plane orientation should be used, not a radial plane. This is a basic study on the sound-absorbing effect from thermally-modified transverse sectional Indonesian Homalium foetidum. Future studies will examine the use of modified transverse sectional Indonesian Homalium foetidum as a sound-absorbing material. Floors using a transverse plane wood have been commercialized (Cochran 2017). Thus, it is possible to produce a thermally-modified transverse sectional Indonesian Homalium foetidum as eco-friendly sound-absorbing material by applying these techniques as shown in Fig. 4.

Table 1. NRC of Cube Samples Depending on Thermal Modification Temperature

Fig. 4. Sound-absorbing board of Homalium foetidum transverse plane (manufactured by authors)

CONCLUSIONS

- Through thermal modification, the physicochemical structure of Homalium foetidum was changed and had a positive effect on improvement of NRC except for transvers section treated at 170 °C.

- Sound absorption of a thermally modified transverse plane of Homalium foetidum was higher than that of the radial plane.

- To use thermally-modified Indonesian Homalium foetidum as a sound-absorbing material, it should be used as a transverse plane.

ACKNOWLEDGEMENTS

This research was supported by a grant from the Basic Science Research Program of the National Research Foundation of Korea (NRF), funded by the Ministry of Education (NRF-2019R1I1A3A02059471). It was also supported by a grant from the international cooperation program framework managed by the NRF (NRF-2020K2A9A2A08000181). Authors are also thankful to the “The Business Startup Incubator Support Program” supported by the Ministry of Education and National Research Foundation of Korea.

Authors’ Contributions

Eun-Suk Jang is first author of this study, he designed the study, conducted all experiments, and was a major contributor in the original-writing, reviewing, and editing of the manuscript. Chun-Won Kang is corresponding author, he was the supervisor of this project and contributed by reviewing and editing. All authors read and approved the final manuscript.

REFERENCES CITED

Arenas, J. P., and Crocker, M. J. (2010). “Recent trends in porous sound-absorbing materials,” Sound and Vibration 44(7), 12-18.

Boonstra, M. J., Rijsdijk, J., Sander, C., Kegel, E., Tjeerdsma, B., Militz, H., Van Acker, J., and Stevens, M. (2006a). “Microstructural and physical aspects of heat treated wood. Part 1. Softwoods,” Maderas. Ciencia y Tecnología 8(3), 193-208. DOI: 10.4067/S0718-221X2006000300006

Boonstra, M. J., Rijsdijk, J., Sander, C., Kegel, E., Tjeerdsma, B., Militz, H., Van Acker, J., and Stevens, M. (2006b). “Microstructural and physical aspects of heat treated wood: Part 2. Hardwoods,” Maderas. Ciencia y Tecnología 8(3), 209-218. DOI: 10.4067/S0718-221X2006000300007

Chung, H., Park, Y., Yang, S.-Y., Kim, H., Han, Y., Chang, Y.-S., and Yeo, H. (2017). “Effect of heat treatment temperature and time on sound absorption coefficient of Larix kaempferi wood,” Journal of Wood Science 63(1), 575-579. DOI: 10.1007/s10086-017-1662-z

Cochran, B. (2017). “What is End Grain Flooring?,” (https://www.cochranslumber.com/end-grain-flooring), Accessed 1 Sep 2021.

Esteves, B., and Pereira, H. (2009). “Wood modification by heat treatment: A review,” BioResources 4(1), 370-404. DOI: 10.15376/biores.4.1.370-404

Ghorbani, M., Akhtari, M., Taghiyari, H. R., and Kalantari, A. (2012). “Effects of silver and zinc-oxide nanoparticles on gas and liquid permeability of heat-treated Paulownia wood,” Austrian Journal of Forest Science 129(2), 67-147.

Hassan, T., Jamshaid, H., Mishra, R., Khan, M. Q., Petru, M., Novak, J., Choteborsky, R., and Hromasova, M. (2020). “Acoustic, mechanical and thermal properties of green composites reinforced with natural fibers waste,” Polymers (Basel), 12(3) 654. DOI: 10.3390/polym12030654

Herrera-Díaz, R., Sepúlveda-Villarroel, V., Pérez-Peña, N., Salvo-Sepúlveda, L., Salinas-Lira, C., Llano-Ponte, R., and Ananías, R. A. (2018). “Effect of wood drying and heat modification on some physical and mechanical properties of radiata pine,” Drying Technology 36(5), 537-544. DOI: 10.1080/07373937.2017.1342094

Hill, C. A. (2011). “Wood modification: An update.” BioResources 6(2), 918-919. DOI: 10.15376/biores.6.2.918-919

ISO 10534-2 (2001). “Acoustics – Determination of sound absorption coefficient and impedance in impedance tubes – Part 2. Transfer-function method,” International Organization for Standardization, Geneva, Switzerland.

Jang, E.-S., and Kang, C.-W. (2019). “Changes in gas permeability and pore structure of wood under heat treating temperature conditions,” Journal of Wood Science 65(37), 1-9. DOI: 10.1186/s10086-019-1815-3

Jang, E.-S., and Kang, C.-W. (2021a). “Effect of porous traits of hardwoods cross section on sound absorption performance – focusing on six species of korean hardwoods,” Wood and Fiber Science 53(4), 260-272. DOI: 10.22382/wfs-2021-26

Jang, E.-S., and Kang, C.-W. (2021b). “Investigation of sound absorption properties of heat-treated Indonesian momala (Homalium foetidum (Roxb.) Benth.) and Korean Red Toon (Toona sinensis (A. Juss.) M. Roem.) cross sections,” Forests 12(1447), 1-15. DOI: 10.3390/f12111447

Jang, E.-S., and Kang, C.-W. (2022). “An experimental study on changes in sound

absorption capability of spruce (Picea sitchensis), Douglas fir (Pseudotsuga menziesii), and larch (Larix kaempferi) after microwave treatment,” Journal of Wood Science 68(2), 1-6. DOI: 10.1186/s10086-021-02010-5

Kang, C.-W., Kang, W., and Kim, G.-C. (2010). “Sound absorption capability and anatomical features of highly sound absorptive wood,” Journal of the Korean Wood Science and Technology 38(4), 292-297.

Kang, C.-W., Li, C., Jang, E.-S., Jang, S.-S., and Kang, H.-Y. (2018). “Changes in sound absorption capability and air permeability of Malas (Homalium foetidum) specimens after high temperature heat treatment,” Journal of the Korean Wood Science and Technology 46(2), 149-154. DOI: 10.5658/WOOD.2018.46.2.149

Kang, C.-W., Jang, E.-S., Hasegawa, M., and Matsumura, J. (2020). “Studies of the relationship between sound absorption coefficient and air permeability of wood.” J. Faculty of Agriculture, Kyushu University 65(2), 351-355. DOI: 10.5109/4103900

Kang, C.-W., Jang, E.-S., Lee, N.-H., Jang, S.-S., and Lee, M. (2021a). “Air permeability and sound absorption coefficient changes from ultrasonic treatment in a cross section of Malas (Homalium foetidum),” Journal of Wood Science 67(10), 1-5. DOI: 10.1186/s10086-020-01940-w

Kang, C.-W., Kolya, H., Jang, E.-S., Zhu, S., and Choi, B.-S. (2021b). “Steam exploded wood cell walls reveals improved gas permeability and sound absorption capability,” Applied Acoustics 179(1), 108049. DOI: 10.1016/j.apacoust.2021.108049

Kim, Y.-S. (2016). “Research trend of the heat-treatment of wood for improvement of dimensional stability and resistance to biological degradation,” Journal of the Korean Wood Science and Technology 44(3), 457-476. DOI: 10.5658/WOOD.2016.44.3.457

Kolya, H., and Kang, C.-W. (2021). “Hygrothermal treated paulownia hardwood reveals enhanced sound absorption coefficient: An effective and facile approach,” Applied Acoustics 174(1), 107758. DOI: 10.1016/j.apacoust.2020.107758

Mamtaz, H., Fouladi, M. H., Al-Atabi, M., and Narayana Namasivayam, S. (2016). “Acoustic absorption of natural fiber composites,” Journal of Engineering (2016),1-11. DOI: 10.1155/2016/5836107

Petrissans, M., Petrissans, A., and Gerardin, P. (2013). “Pore size diameter, shrinkage and specific gravity evolution during the heat treatment of wood,” Innovation in Woodworking Industry and Engineering Design 2013/1(3), 18-24.

Sandberg, D., Kutnar, A., and Mantanis, G. (2017). “Wood modification technologies-a review,” Iforest-Biogeosci.Forestry 10(6), 895-908. DOI: 10.3832/ifor2380-010

Taghiyari, H., Zolfaghari, H., Sadeghi, M., Esmailpour, A., and Jaffari, A. (2014). “Correlation between specific gas permeability and sound absorption coefficient in solid wood,” Journal of Tropical Forest Science 26(1), 92-100.

Wang, D., Peng, L., Zhu, G., Fu, F., Zhou, Y., and Song, B. (2014). “Improving the sound absorption capacity of wood by microwave treatment,” BioResources 9(4), 7504-7518. DOI: 10.15376/biores.9.4.7504-7518

Yang, T., Hu, L., Xiong, X., Petrů, M., Noman, M. T., Mishra, R., and Militký, J. (2020). “Sound absorption properties of natural fibers: A review,” Sustainability 1220(12), 8477. DOI: 10.3390/su12208477

Article submitted: September 13, 2021; Peer review completed: October 30, 2021; Revised version received and accepted: July 20, 2022; Published: July 26, 2022.

DOI: 10.15376/biores.17.3.5234-5242