Abstract

Deacidification refers to chemical treatments meant to slow down the acid hydrolysis and embrittlement of books and paper documents that had been printed on acidic paper. From the early 1800s up to about 1990, papermakers used aluminum sulfate, an acidic compound, in most printing papers. Certain deacidification methods use non-aqueous media to distribute alkaline mineral particles such as MgO within the pages of the treated books. Evidence is considered here as to whether or not the proximity of alkaline particles within such documents is sufficient to neutralize the acidic species present. Because much evidence suggests incomplete neutralization, a second focus concerns what to do next in cases where books already have been treated with a non-aqueous dispersion system. Based on the literature, the neutralization of acidic species within such paper can be completed by partial moistening, by high humidity and pressure, by water condensation, as well as by optional treatments to enhance paper strength and a final drying step.

Download PDF

Full Article

Deacidification of Acidic Books and Paper by Means of Non-aqueous Dispersions of Alkaline Particles:A Review Focusing on Completeness of the Reaction

Martin A. Hubbe,a,* Richard D. Smith,b Xuejun Zou,c Svetozar Katuscak,d Antje Potthast,e and Kyujin Ahn f

Deacidification refers to chemical treatments meant to slow down the acid hydrolysis and embrittlement of books and paper documents that had been printed on acidic paper. From the early 1800s up to about 1990, papermakers used aluminum sulfate, an acidic compound, in most printing papers. Certain deacidification methods use non-aqueous media to distribute alkaline mineral particles such as MgO within the pages of the treated books. Evidence is considered here as to whether or not the proximity of alkaline particles within such documents is sufficient to neutralize the acidic species present. Because much evidence suggests incomplete neutralization, a second focus concerns what to do next in cases where books already have been treated with a non-aqueous dispersion system. Based on the literature, the neutralization of acidic species within such paper can be completed by partial moistening, by high humidity and pressure, by water condensation, as well as by optional treatments to enhance paper strength and a final drying step.

DOI: 10.15376/biores.12.2.Hubbe

Keywords: Acids; Embrittlement; Deacidification of paper and books; Accelerated aging protocols; Capillary condensation; Diffusion; pH of paper; Paper degradation

Contact information: a: Department of Forest Biomaterials, North Carolina State University, Campus Box 8005, Raleigh, NC 27695-8005 USA; b: Wei T’o Associates, Inc., 21750 Main Street, Unit 27, Matteson, IL 60443 USA; c: FPInnovations, 570 Saint-Jean Blvd., Pointe-Claire, QC, Canada H9R 3J9; d: Department of Wood, Cellulose and Paper, Institute of Natural and Synthetic Polymers, STU, Bratislava, SK 81237, EU; e: Univ. Nat. Resources & Life Sci., Dept. Chem., Division of Chem of Renewable Resources, Konrad Lorenz Str 24, A-3430 Tulln, Austria; f: Archival Preservation and Restoration Center, National Archives of Korea, 30 Dawangpangyo-ro 851beon-gil, Sujeong-gu, Seongnam-si, Gyeonggi-do, Korea (13449); *Corresponding author: hubbe@ncsu.edu

Contents

INTRODUCTION

A large proportion of books and other paper documents stored in libraries, museums, and private collections have become so brittle over the course of time that they no longer can be checked out to readers (Smith 1969, 1987; Cunha 1987, 1989). Though there are a number of contributing factors, it is well known that one of the dominant mechanisms tending to shorten the useful life of paper documents is acid-catalyzed hydrolysis, a process that attacks the cellulose chains in the fibers that make up paper (Williams 1971; Wilson and Parks 1979; Arney and Chapdelaine 1981; Baty et al. 2010). Millions of tons of acidic paper had been produced worldwide for printing applications during the previous two centuries, and it is still being produced in Asia and other continents (Drewes and France 2012). Starting in about 1980, the paper industry went through a major shift in its manufacturing practices, such that most books nowadays are printed on paper that was made under near-neutral to weakly alkaline conditions (Hubbe 2005). As a consequence, the books are much less likely to suffer from embrittlement during ordinary storage. Meanwhile, it has been estimated that 20 to 40% of Indian publications and 2 to 3% of papers from the United States require deacidification, since some publishers source papers from outside the United States (Drewes and France 2012).

The focus of this review article is on the completeness of certain technologies intended to overcome problems arising from the acidic nature of paper within many existing books. The term “non-aqueous dispersions” will be used in this article to denote such treatments, which typically employ a low-energy liquid (often fluorinated or silicone-based compounds) to distribute MgO or other alkaline particles within the pages of the treated books. The carrier liquid is subsequently drained and evaporated, leaving behind the particles distributed among the fibers of the paper. This review will consider evidence from the literature regarding whether or not such treatment actually neutralizes the acidic species present on and within the fibers of a paper-based document. In the context of this article, the words “completeness” or “completion” will refer to the degree to which acidic groups present within a treated book or other paper article have undergone a reaction such as RCOOH ® RCOO– ½Ca2+, where R may refer to H, CH3, or other structures that make up other organic acids often present in paper materials. Alternatively, the neutralization may involve inorganic species such as sulfuric acid, for which the reaction could be written as H2SO4 ® CaSO4, or related reactions.

This article has a primary focus on MgO as a deacidification agent. The reason for this focus is that processes based on MgO particles (BookkeeperÒ and ZfB:2) are presently the most widely employed in the world for deacidification of books. Since its adoption in 1994 by the US Library of Congress (Buchanan et al. 1994), the use of MgO particles suspended in non-aqueous fluid has spread worldwide in the form of compressor devices, thousands of hand sprayers, and many chamber deacidification machines. Since then, non-aqueous dispersion type deacidification facilities have been deployed in many nations, especially for the BookkeeperÒ process (Preservation Technologies 2017). More recent implementation of such deacidification technology, in the form of the ZfB:2 process, is based in Germany (Zentrum für Bucherhaltung 2017). Thus it is important to address concerns about the treatment’s efficacy, possible incompleteness, and whether there is likely to be an acid paper core or acid parts in the book microstructure.

Before one can have reactions between alkaline particles and acidic moieties within paper, the particles first need to be well distributed in the paper. Questions concerning the nonuniform distribution of alkaline MgO particles in deacidified books already were being asked as early as 1993 when carrying out tests to meet the Library of Congress (LoC) requirements (Buchanan et al. 1994). It was suggested that non-aqueous dispersion deacidification treatment can yield nonuniform results. The LoC Requirement of 1994 (updated 2004) concerning the uniformity is as follows: “The Alkaline Reserve Uniformity for a given paper type shall vary from specified optimal concentrations by no more than 20% between books and by no more than 20% within individual pages” (Buchanan et al. 1994). The process is specified to result in an alkaline reserve of not less than 1.5% with stable and uniform distribution. Uniformity of distribution of alkaline particles in paper also has been considered by Whitmore (1994); Wagner et al. (2008), and Ahn et al. (2012b). Nonuniformity of distribution of alkaline particles on the paper surface and in the cellulose micro- and nanostructure of books, as well as any incompleteness in the neutralization of acidic materials in the paper, may affect many issues of concern to conservators. The uniformity of deacidification treatment can be expected to affect a book’s lifetime, since failure would be expected to occur at the weakest part of a paper structure. Other issues include the appearance of the paper surface or tactile properties of the surface such as a gritty texture. Nonuniformity of treatment implies uncertainty about concentrations of acids within paper, as well as the possibility of continuing acid hydrolysis in the acidic parts of the incompletely deacidified paper and books. Concerns about the efficacy and longevity of paper and books that contain acidic parts or microstructures have been widely considered (Bansa 1990; Buchanan et al. 1994; Pauk 1996; Banik 2005; Bielikova 2005; Blüher et al. 2006; Hanus et al. 2006, 2008; Bielikova and Katuscak 2009; Katuscak et al. 2009b; Baty et al. 2010; Burd 2012; Jablonsky et al. 2012b,c, 2013; Johnson et al. 2012; Hubbe 2015; Ahn et al. 2013; Vizarova et al. 2016a,b).

Much less attention has been paid in the literature to the question of whether and to what extent the insertion of alkaline particles into an acidic paper document, by means of non-aqueous dispersion treatment, achieves neutralization of acidic species present in the paper. The first to call attention to this issue appears to have been Whitmore (1994), as part of a report prepared for the US Library of Congress. It has been widely assumed that, over long periods of storage on library shelves, some kind of molecular migration and neutralization reactions between acidic and alkaline entities in the material would take place (Baty et al. 2010; Burd 2012). However, as will be discussed in the present review article, there has been a lack of research findings that strongly support such an assumption.

Various researchers have attempted to estimate how much money is represented by the ongoing process of acid hydrolysis within tens of millions of bound and unbound paper documents in various collections throughout the world. For instance, Cunha (1987) estimated that 4.7% of the value of books in a typical library is lost each year due to aging and embrittlement. Smith (1987) estimated that the Library of Congress was losing $179,000 each day due to acid hydrolysis of books during storage. In cases where only the information is regarded important, rather than the book itself, options can include digital scanning (McCrady 1990), or even the reprinting of a book onto archival-quality alkaline paper. Though details of cost are generally beyond the scope of this article, it will be assumed that the unit cost of deacidification is likely to be lower than most other available options (Smith 1987).

Another way to prolong the life of books, which does not involve deacidification, involves storing them under conditions of dry refrigeration. Such conditions have been predicted to greatly slow down the degradation process of the acidic paper (Zou et al. 1996a; Smith 2004; Balažic et al. 2007). But even when such practices are implemented, the books are not protected when being checked out and used by a library client.

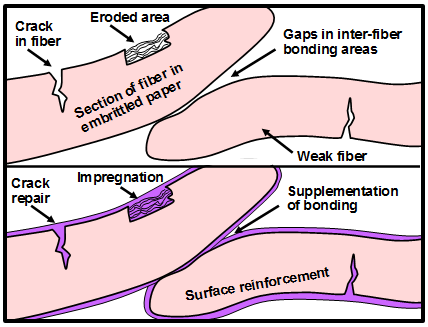

Based on the reviewed publications there is reason to expect that deacidification reactions can be brought to completion by a suitable post-treatment. Such a process might involve homogenization of alkaline reserve to all parts of books endangered by acid hydrolysis, including neutralization of acidic species present in the paper’s microstructure. Such treatments, depending how they are done, may provide an opportunity to implement other preservation functions required by conservators, such as strengthening and multi-thread protection of paper, inks, and book bindings against oxidation, photo-oxidation, biodegradation, and other optional treatments. If performed in a well-designed conservation process, this could also minimize wasteful repeated manipulation of future monofunctional operations, reduce costs in libraries, and increase the longevity and usability of books (Blüher et al. 2006; Katuscak et al. 2009a,b; Katuscak 2011; Ahn et al. 2012a; Drewes and France 2012; Katuscak and Konvit 2013; Vizarova et al. 2016b).

Deacidification Practices

As a means to address the problems just described, deacidification practices already have been implemented for many years to overcome or at least slow down the effects of acid hydrolysis during storage of books and other printed matter. Such technology has been explained and compared in earlier review articles (Porck 1996; Kaminska and Burgess 1994; Liénardy 1994; Kaminska 1995; Blüher and Vogelsanger 2001; Cedzova et al. 2006; Ramin et al. 2009; Baty et al. 2010). Starting in the 1930s, the storage-stability of paper has been quantified by means of accelerated aging tests (Rasch 1931; Rasch and Scribner 1933; Porck 2000; Zervos and Moropoulou 2006; Zervos 2010). Barrow (1953, 1965) was among the first to quantify the effects of paper’s acidity on its rate of strength loss. He also developed procedures to treat paper with aqueous solutions of alkaline reserve agents, such as soluble carbonates and bicarbonates (Barrow 1965; Moll 1965). Aqueous deacidification systems continue to be highly regarded for the treatment of acidic paper-based documents, especially for the treatment of unbound printed or written documents (Wächter et al. 1998; Sundholm and Tahvanainen 2003a,b; Baty et al. 2010).

Available methods and technology for individual sheets of paper (archive documents) using water-based processes (Blüher et al. 2006; Smith 2011; Katuscak et al. 2012) can assure high efficacy, longevity, and usability through both completeness of neutralization and multifunctional preservation completeness. The aqueous processes can assure (1) homogeneous distribution of alkali in the cellulose micro- and nano-structure, as well as (2) completeness in terms of the preservation functions that are necessary for a particular type of acid documents, such as information, color, ink or print letters, characters or images fixation, strengthening brittle paper, biocidic protection, etc. The preservation (“deacidification”) water bath also can contain fixation, strengthening, and other conservation compounds. Interactions between water and paper are considered in depth in the book by Banik and Brückle 2011).

The deacidification of bound books presents additional challenges. The soaking of a book in an aqueous solution swells the paper sheets. This can cause some bindings to break (Smith 1992; Kellerman 1999) or the pages to become wavy (Brückle and Banik 2011b). In addition, the drying of a bound volume, while preserving its flatness, is more difficult and time-consuming (Kelly and Fowler 1978; Liénardy 1994; Jablonsky et al. 2009a,b; Hubacek et al. 2011). Accordingly, some libraries and deacidification services have instituted rebinding of books as a routine practice associated with deacidification (Kellerman 1999). Such practices increase the complexity and cost of deacidification of books. Thus, the most widely used deacidification methods that have been applied to whole books have been based on non-aqueous treatments, of which there are several competing systems (Liénardy 1994; Blüher and Vogelsanger 2001; Cedzova et al. 2006; Baty et al. 2010). These have become known as mass-deacidification programs. The two general classes of such treatments are summarized in Table 1.

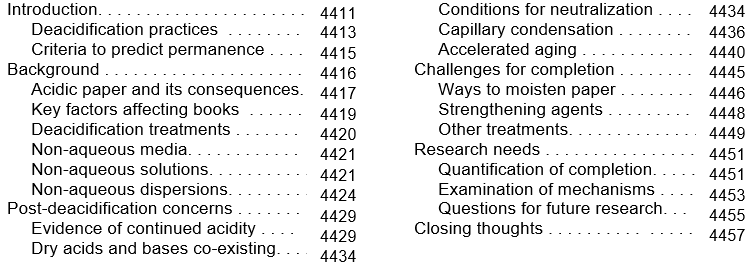

Table 1. Main Classes of Non-aqueous Mass Deacidification Systems that have been Used for Bound Books

Notes: An example of a highly fluorinated liquid is 3M Performance Fluid PF-5060; the product literature says it has zero adverse effect on the ozone layer; hexa-methyldisiloxane (HMDS) is used in organic synthesis, analytical chemistry, and in paper deacidification. For non-aqueous dispersion systems, a highly fluorinated liquid is used in the Bookkeeper® process, and heptane is used in the ZfB:2 process.

Of the principal classes of the deacidification system listed in Table 1, the first of them has a long track record of beneficial usage (Smith 1977; Scott 1987; Morrow 1988; Wittekind 1994; Baty et al. 2010), though there also have been issues related to the uniformity and completeness of treatment in some cases (Kruth 1988). The second option listed in Table 1, which will be the main focus of the present article, is unique in that it does not involve either solubilization of the treatment agent or its direct reaction with acidic entities in the paper during the treatment. Rather, by means of non-interactive solvent, the dry particles are distributed throughout the book (Kundrot 1985; Leiner and Kifer 1995; Leiner and Burd 1998). The concept is that, over time, the presence of the alkaline particles will bring about neutralization of any acidity within the paper. Commercially available non-aqueous dispersion programs include BookkeeperÒ (Preservation Technologies), ZfB:2 (Zentrum für Bucherhaltung), the previously available LibertecÒ, as well as products that have been sold for small-scale treatments under the trade name KrylonÒ.

When evaluating stored paper-based documents, the most important attribute from the perspective of archival institutions is longevity (Drewes and France 2012). Longevity-related data are typically determined by accelerated aging tests, followed by evaluation of selected properties reflecting paper stability, such as folding endurance or molar mass of cellulose. The values after accelerated aging are compared between treated and untreated species, and the relative increase in performance can be given as an efficacy factor, indicating how much longer the paper will last compared to the untreated reference. The advantage of the efficacy factor is that it is largely independent of the details of the analytical method used to assess paper stability.

Efficacy factors have been used to compare deacidified paper specimens with untreated specimens exposed to the same conditions of accelerated aging (Buchanan et al. 1994; Liénardy 1994; Whitmore 1994; Banik 2004, 2005; Banik et al. 2006; Hanus et al. 2008; Ramin et al. 2009; Katuscak 2006, 2009a, 2012; Ahn et al. 2013; Potthast and Ahn 2017). As will be detailed later in this article, relative to the other tested methods of whole-book deacidification, the non-aqueous dispersion treatment often have been found to be among the least effective. Earlier evaluations, also based on accelerated aging tests, have yielded a range of results for non-aqueous dispersion treatment (Pauk 1996; Vrska et al. 2004; Balažic et al. 2007).

During the period 2010 to 2012, a large evaluation of all important deacidification processes was carried out in the US and in Europe, including synthesis of all available objective data and meta-analysis (Ahn et al. 2012a). The results included a ranking of the six best mass deacidification processes (Katuscak et al. 2010, 2012). The sequence of the processes was judged to range from the best available technology (BAT) for deacidification of books – PapersaveÒ (non-aqueous solution), CSC BooksaverÒ (non-aqueous solution), and SoBu, down to the least effective BookkeeperÒ (non-aqueous dispersion) process. Paradoxically, though the non-aqueous dispersion method with MgO particles has become the most widely used method in the world, except for Europe, the study results showed that it can, at least sometimes, provide incomplete deacidification. It achieved low long-term efficacy of the mechanical permanence factors, as measured by the testing laboratories, implying that the treatment was less effective or even ineffective.

Doubts about Criteria Used to Predict Permanence

Concerns about composition-based criteria

Some investigators have raised questions about the criteria often used in predicting the storage-stability of paper (ISO 1994; Shahani 1995; Havermans 2002; Library of Congress 2004; Area and Cheradame 2011). One such criterion involves the pH of the paper (ANSI 1984; Daniels 1996; Ramin et al. 2009), a quantity that can be determined either by placing a drop of water on the paper surface (TAPPI Method T529), or by extracting the paper with aqueous solution (TAPPI Methods T435, T509; ISO 6588 2012), or possibly by redispersing some of the paper in water and then measuring the pH. Since all such measures involve liquid water, ordinary pH tests cannot answer the question as to whether a given deacidification treatment had already brought about neutralization of acidic sites within the paper prior to the test itself or whether such neutralization became completed only at the time of pH testing.

Another criterion often used is that archival-quality paper should contain a well-distributed alkaline reserve of a suitable compound, such as CaCO3 or MgCO3 throughout the material (Bukovský 2005; Ramin et al. 2009; Smith 2011; Ahn et al. 2012b, 2013; ISO 10716 1994b). An alkaline reserve level of 2% is specified in the ISO and ANSI standards for permanence of paper (ANSI 1984; ISO 1994a; Shahani 1995). The level of alkaline reserve can be determined by treating the paper sample with a standard amount of hydrochloric acid, then back-titrating with base (Liers 1999). It has been pointed out that, in order for the alkaline reserve species to be useful, they must somehow interact with acidic species that either were in the paper to begin with or were subsequently brought there by either hydrolysis reactions within the paper or by air pollution (Smith 1987; ASTM 2002b). Notably, deacidification involving non-aqueous dispersion treatment is totally reliant upon such dry-state interactions within the paper as a primary mechanism of deacidification (Whitmore 1994). Other widely used deacidification technologies, both non-aqueous and aqueous, employ soluble alkaline species that can be expected to migrate freely into small pores within the material, offering a chance to react directly with exposed acidic compounds present in the paper sheet.

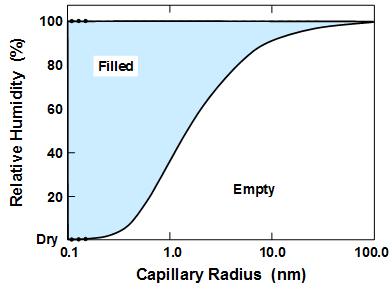

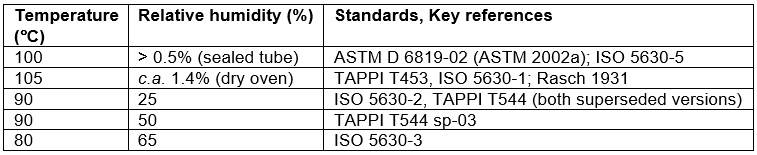

Doubts also have been raised about the conditions used for accelerated aging tests. The conditions of accelerated aging, usually involving temperatures of 80 °C or higher, are quite likely to result in different chemical reactions and different degradation products in comparison to natural aging (Luner 1969; Kruth 1988). Some of the most widely used accelerated aging tests involve the presence of water vapor (e.g. TAPPI Method T544; ISO 5630-3). At a specified relative humidity value, the proportion of water molecules increases with the temperature of the air. On the one hand, the presence of water may be required in order to best simulate the process of normal aging, while speeding it up for the sake of making an early prediction (Zou et al. 1996a,b). A complication arises, however, if the paper to be evaluated contains both acidic and alkaline species within its microstructure. In such cases, there is reason to wonder whether or not accelerated aging with high temperature and with relative humidity value in the range 25 to 65%, which represents the range that has been used for accelerated aging tests, might inadvertently bring about completion of reaction between adjacent acidic and alkaline entities within the paper microstructure (Hubbe 2015). This topic will be considered in more detail later in this article.

Thermodynamics does not determine the rate of decomposition

Though books are thermodynamically unstable, many of them have the potential to last for at least a thousand years (Balažic et al. 2007; Ramin et al. 2009; Sundholm and Tahvanainen 2004; Vrska et al. 2004; Jeong et al. 2014). Light a match, and the same book may be consumed in minutes. Analogously, the “slow fires” of acid hydrolysis and oxidation can gradually break down the chemical structure of books, especially if acidity is present (Aspler 1989). Baking powder offers a common example of a product that comprises a meta-stable mixture of acidic and alkaline compounds (Ciullo 1994). Add water, and reaction takes place immediately (Derr et al. 2000). By contrast, when it is put on a shelf, the reaction may be so slow that it can be ignored in a busy kitchen (Ishii 1950; Wolke 2002). Such phenomena will be considered in more detail later in the article. How slowly do non-aqueous dispersion deacidification reactions take place, and what to do about it, are questions that will be addressed in this article. These questions are pertinent with respect to books that have been deacidified by non-aqueous dispersion treatments that distribute alkaline particles within the microstructure of the material.

BACKGROUND

To provide context for addressing questions about completion of deacidification, this section will summarize some key points about paper’s acidic nature, as well as the most important methods that have been used to deal with the consequences of such acidity.

Acidic Paper and the More Rapid Degradation of Books

Observations of paper aging and acidity

People have been concerned about the premature degradation of stored books and the poor quality of the paper for a long time (Murray 1824; Johnson 1891; MacAlister 1898). Gradually it became known that acidity is a key factor in shortening the useful life of books (Kohler and Hall 1925; Barrow 1965, 1974; Moll 1965; Koura and Krause 1978; Sclawy and Williams 1981). Barrow compared books manufactured during the years between 1500 and 1950 and observed a disturbing decline in folding endurance, especially during the period of manufacture between about 1670 and 1900. During the same period, the typical pH values of manufactured books became lower than 6 and continued to decrease to a range between 4.5 and about 5. Wilson and Parks (1980) reported related findings. A correlation between pH and the rate of strength loss was found for both accelerated and natural aging tests of the same books. Katuscak et al. (2010, 2012), who studied more recent specimens, observed a coincidence of low pH and low folding endurance of printing papers produced during the decades between 1900 and 1990. By contrast, some books from previous centuries have been found to remain in relatively good condition, and such findings were generally correlated to higher pH values (Stephens et al. 2008a). Especially low values of pH happened to be measured for samples manufactured in the 1960s and 1970s (Katuscak et al. 2012). But the situation was very different for the samples that had been manufactured in the 1980s and 1990s, for which the average pH of the paper was near neutral and the number of double-folds before breakage was dramatically higher. Not only were those relatively recent samples newer, but they also were not degrading as fast. What happened, in order to bring about that change, was almost certainly the emergence of alkaline papermaking practices, which in just a few years has come to be dominant for the production of printing papers (Hubbe 2005).

In addition to acidity present in paper at the time of its manufacture, acids are formed continually both in acidic and alkaline cellulose material due to hydrolysis or oxidation reactions, which will be described later. Also, some acidity accumulates through absorption of pollutants from the air, particularly in urban areas (Smith 1987). However, the detailed effects are different, depending on whether the paper’s microstructure is acidic or alkaline: The acids arising in the alkaline part of the microstructure, which contains alkaline reserve, presumably can be continually neutralized. The degradation in the alkaline paper continues very slowly, and most probably the effects of the likely predominant peeling reaction can be neglected (Green et al. 1977; Ahn et al. 2012c, 2013; Testova et al. 2014). Peeling reactions cause only splitting off of a single monomer unit per reaction, thus decreasing the degree of polymerization (DP) by 1, for example from DP = 1000 to DP = 999 per 1 split, or to the DP = 998 per 2 splits, etc. Such a process would result in a negligible difference of the DP, longevity, brittleness, folding endurance, usability, and other mechanical and chemical quantities of paper or books. Another alkaline degradation mechanism, the beta-elimination reaction, could be detected in the deacidified book papers (Ahn et al. 2012c, 2013). However, it had little influence on the molar mass of cellulose in the paper compared to the beneficial effects obtained by deacidification treatment.

In any acidic paper, even if it contains alkaline particles on its surface or within some of the larger pore spaces, there may be an interior acidic region (i.e. an acid core) or acid remaining in microstructures of the paper after nonuniform or incomplete deacidification (Buchanan et al. 1994; Katuscak et al. 2012; Hubbe 2015). Within such zones the pH would tend to be further decreased by continually arising acids. Acid hydrolysis can cause rapid random cellulose degradation, in which a handful of breaks in a chain can reduce the cellulose DP in paper from an initial high value to the range 300 to 700, at which point the paper is subject to crumbling (Zou et al. 1996a; Smith 2004). Zou et al. (1996a) observed a dramatic drop in tensile strength and folding endurance after the DP of cellulose chains within paper fell below about 700. Likewise, Smith (2004) suggested that the range of 400 to 500 is a critical range of DP, beyond which paper falls apart when folded. According to Jeong et al. (2014) the critical value for DP was found to be about 1000 in the case of Hanji papers. Thus, the level of DP needed to maintain the strength of paper may depend on the type of paper. Zervos and Moropoulou (2005) found a high correlation between the DP of cotton cellulose and strength properties of paper made from the fibers. When considering such data, however, it should be kept in mind that the correlation between cellulose DP and paper strength can be different for different test procedures. Such results must be considered cautiously, since paper’s strength also can be highly affected by localized damage that within the fibers during pulping operations (Gurnagul et al. 1992).

Moisture content

The mechanism of acid hydrolysis, leading to the breakdown of cellulose, requires the presence of water molecules (Williams 1971; Baty et al. 2010). The fact that acid hydrolysis can take place at typical humidities and temperatures found in libraries provides evidence that bulk liquid water is not required. Rather, the amount of adsorbed or hydrated water associated with the cellulosic material (Joubert et al. 1959) appears to be sufficient. On the other hand, many studies have reported increasing rates of hydrolytic decomposition with increasing relative humidity (Zou et al. 1996a; Baty et al. 2010; Zervos 2010). Also, the activation energy for the hydrolysis reaction appears to become lower when the humidity is higher (Gray 1969, 1977). Some investigators have maintained that water molecules need to be present during accelerated aging in order to achieve a degradation process having a predictive value for natural aging (Graminski et al. 1979; Wilson and Parks 1983; Shahani et al. 2001). Luner (1969) urged caution in interpreting results from accelerated aging tests in general based on a concern that the mode of failure is likely to be different at elevated temperatures.

Catastrophic failure and auto-catalysis

A frightening aspect of the aging of books is a tendency for catastrophic failure to occur after the aging process has reached a certain stage of decomposition. Rather than taking place at a steady rate, with easily predicted results, many researchers have found evidence that acid-catalyzed breakdown of books often takes place with increasing speed (Calvini et al. 2007, 2008; Zervos 2007). This situation has been attributed to the production of acetic and formic acids during acid hydrolysis of some of the hemicellulose macromolecules or other components of the paper (Polovka et al. 2006; Zervos 2007; Jablonsky et al. 2012a). The term “autocatalysis” can be applied to this situation, since the acetic and formic acids produced by the paper’s decomposition further raise the level of acidity. The fact that books often degrade faster than separate sheets of similar paper (Shahani et al. 1989; Shahani 1995) has been attributed to entrapment of acidic decomposition products within stored books.

It is also important to keep in mind that acids are formed continually in paper by oxidation with oxygen, ozone, nitrogen, sulfur oxides, and other oxidants, in both acidic and alkaline cellulosic material, including paper and books during the whole paper lifetime (Katuscak et al. 2006, 2009b, 2016; Vizarova et al. 2016a,b). Acids arising from oxidation presumably can be continually neutralized by alkaline reserve, assuming that contact is achieved locally between the alkaline and acidic substances. However, the neutralization of acids does not stop their formation. Continuing generation of acidic species in paper might help to explain observations of a gradual drift to lower surface pH values over time (Ahn et al. 2011).

Key Factors Affecting Books and Papers

Alum and wood-derived acidity

Aluminum sulfate (or “papermaker’s alum) is often the major source of acidity in typical paper products (Kohler and Hall 1925; Arnson and Stratton 1983; Wittekind 1994). Alum was used in manufacturing most printing paper from the early 1800s up to about 1990 (Hubbe 2005; Cedzova et al. 2006). Its purpose included the “setting” of rosin products in the paper, rendering the paper suitably resistant to the penetration of aqueous fluids. In addition, in the case of paper containing groundwood fibers or other mechanical pulp fibers, acidity was contributed by fatty acids and resin acids from the wood (Back and Allen 2000). The latter effect may explain why some researchers have been especially concerned about the acid-catalyzed hydrolytic degradation during storage of books containing mechanically pulped fibers (Barrow 1953; Bukovský 1999; Kacik et al. 2009). Though alum and natural acidic compounds present in wood appear to play a major role in reaching an initial damaging level of breakdown of cellulose, it appears that much of their effect is indirect. As already noted, acid-catalyzed hydrolysis of the ester groups from the hemicellulose components of the fibers in paper gives rise to acetic acid, which can further lower the pH and accelerate the decomposition process.

Acidic pollutants in the air

Though acid rain has become a well-known phenomenon in modern times, air pollution of various types has been known for a long time to hurt the storage stability of books ( Smith 1987; Dupont et al. 2002). A test method has been established to evaluate such effects (ASTM D 6833-02, 2002b). Acid gases such as SO2 and NO2 (Smith 1969; Dupont et al. 2002) have been implicated in the damage to books, especially in certain urban libraries.

An especially damaging form of air pollution involves oxidation of the paper (Arney et al. 1979; Selli et al. 1998). Ozone coming from electrical equipment is a likely source of such oxidation in libraries (Andretta et al. 2016). Daniels (1996) showed that such effects can be accelerated by the presence of iron and copper in paper. Whitmore and Bogaard (1995) and Stephens et al. (2009) showed that oxidation tends to make the paper more susceptible to mechanical breakdown during subsequent acid hydrolysis.

Deacidification Treatments

To provide context for later discussion concerning non-aqueous dispersion-type deacidification, some points about deacidification processes in general will be summarized here. Such processes will be roughly divided as aqueous systems, non-aqueous systems involving dissolved alkali species, and non-aqueous systems involving suspensions of particles, i.e. non-aqueous dispersion systems.

Many of the acids likely to be present in paper, which may be inorganic acids such as sulfuric acid, or organic acids such as fatty acids, acetic acid, of formic acid, all can be classified as Brønsted acids (Pearson 1969; Hrivnak 2007; Cox 2013). Such acids can interact with water to form the H3O+ hydrated ion, which becomes the active species for many subsequent reactions. In addition, various aluminum compounds, which are often classified as Lewis acids, can contribute to acidity in the paper by consuming OH– ions. It follows logically that aqueous solutions can be used to neutralize acidic species present in paper (Barrow 1965; Kolar and Novak 1996; Wächter et al. 1998; Sundholm and Tahvanainen 2003a,b; Smith 2011). Bredereck et al. (1990) compared a number of different alkaline compounds to use for aqueous deacidification; it was concluded that solutions of either Mg(HCO3)2 or a mixture of Mg and Ca bicarbonates is the best choice for treatment of acidic paper. According to Middleton et al. (1996), for deacidification to be complete, the protonated forms of carboxylic acids all need to be converted to their respective conjugate bases, e.g. the Ca or Na salts of carboxylic acids. A fuller discussion of these issues is provided by Smith (2011).

In addition to direct neutralization of acidic species present in the paper, aqueous treatments (as in the case of non-aqueous treatments) can be used to leave behind an alkaline reserve. In other words, the paper is provided with a capacity to consume newly-formed acidity or acidic compounds that may reach the paper through the air or due to reactions within the material. As an example, a compound such as sodium bicarbonate may precipitate out of solution and remain in the paper when it is dried after the treatment. Another potential advantage of aqueous treatments is that they can be used to wash the paper free of dirt, as well to remove products of hydrolytic decomposition, which may include acidic compounds (Tang 1981; Bogaard and Whitmore 2001; Zervos 2007; Zervos and Alexopoulou 2015).

Certain potentially unfavorable aspects of aqueous-based deacidification appear to have provided the main motivation for widespread adoption of non-aqueous deacidification systems. For instance, if a book is dropped into a sink of water, the paper can become wavy (Brückle and Banik 2011b) and a lengthy drying period may be needed (Smith 1992). Each individual page tends to expand when it is wetted by water, increasing its thickness (Scallan and Tigerström 1992; Enomae and Lepoutre 1998). Such swelling may exceed the binder’s capacity, causing the book to break (Kellerman 1999). When deacidifying individual sheets of paper documents, such development of waviness can be avoided by drying the sheets individually against a smooth surface (Hubbe and Bowden 2009) or by other means of restraint during drying (Brückle and Banik 2011b). In the case of books, freeze-drying has been used successfully to avoid deformation of pages (Liénardy 1994; Jablonsky et al. 2009a; Hubacek et al. 2011). To overcome these issues concerning the aqueous treatment of bound books, it is common practice to remove and replace the original binder for the book, allowing the pages to be treated and dried individually. Advantages of this approach include optional washing of the pages, the ability to directly neutralize acidic groups present in the material, the ability to apply pH-buffering agents and/or alkaline particles, the ability to treat the paper with reducing agents such as borohydride, and the opportunity to apply dissolved starch or other hydrophilic polymers able to increase the strength of the paper. The down-side of such an approach is that it requires a considerable expense and time to disassemble and reassemble each treated book.

Other concerns about aqueous treatment include possible bleeding or dissolution of water-susceptible print colorants (Banik and Brückle 2011), a tendency of paper to become more bulky (thicker pages) after a cycle of wetting and drying (Bristow 1971; Banik and Brückle 2011), and the sticking together of pages after redrying of bound volumes, especially if the paper had been coated during its manufacture (Piltonen et al. 2013). For all of these reasons, when bound volumes need to be acidified, non-aqueous deacidification programs or treatments involving freeze drying processes generally have been selected.

Non-aqueous Media for Deacidification Systems

To avoid the issues described above (such as possible bleeding of colorants, waviness of paper, or sticking together of pages), researchers have been motivated to consider non-aqueous fluids as a possible means of transporting alkaline agents into paper documents. One of the key attributes of such a medium is that it ought not to solubilize common types of ink (Wittekind et al. 1994). Some of the earliest non-aqueous treatments were done with methanol, which did not completely avoid ink solubilization and also is quite flammable (Baynes-Cope 1969). Sequeira et al. (2006) describe more recent work employing isopropanol. Another desirable attribute of a liquid medium for deacidification is that the fluid ought to completely wet the paper with a near-zero contact angle (Hubbe et al. 2015) such that it can readily penetrate small pores in the material. Both objectives – noninteraction with inks and excellent wetting – have been demonstrated in systems employing low-surface tension perfluorinated liquids (Smith 1977; Leiner and Kifer 1995; Dupont et al. 2002; Polovka 2006). Clark et al. (1998) studied the use of hexamethyldisiloxane (HMDS) as a low-energy suspending medium with proven utility for deacidification. European mass deacidification processes are mainly being carried out with hexamethyldisiloxane (for non-aqueous solution treatments) or heptane (for non-aqueous dispersions of MgO) (Zentrum für Bucherhaltung 2017). A perfluorinated liquid is employed as the carrier in the case of the widely-used BookkeeperÒ process (Preservation Technologies 2017).

Even after committing oneself to carrying out non-aqueous deacidification, there are several general approaches that can be used. For instance, certain alkaline agents may be soluble within the selected non-aqueous fluid; in principle such soluble agents could be used to directly neutralize acidic species within the paper document. Alternatively, the medium might consist of a gas or plasma. And finally, the alkaline agent could be dispersed as small particles in the medium.

Non-aqueous Treatments with Soluble Alkaline Agents

Certain organometallic compounds can be dissolved in low-energy liquids, allowing them to be distributed in monomeric form into paper documents. Such compounds also typically have low volatility. Methylmagnesium carbonate is an example of such a compound that can be deposited within the paper upon evaporation of the carrier liquid, bringing about deacidification of the paper (Kelly et al. 1977; Green and Leese 1991; Bukovský 1999; Andres et al. 2008). Because the alkaline agent is dissolved, and because the low-energy liquid can be expected to completely wet the document, it is reasonable to hypothesize that acid groups located throughout the structure will be neutralized. At least there is potential for the alkaline agent to diffuse efficiently to all parts of the paper and fiber that can be wetted by the liquid. A likely exception is that acidic groups within the cell walls of the cellulosic fibers may be inaccessible due to pore closure during drying (Scallan 1990). In addition, Kelley and Fowler (1978) noted a likely problem in such systems when the alkaline compound is not sufficiently soluble in the carrier fluid; in such cases the alkaline agent may lag behind the liquid front as the paper is being permeated, thus possibly failing to deacidify the most interior parts of the documents.

Certain metal alkoxides meet the criteria of being soluble in low-energy liquids, and they also have the potential advantage of having a relatively high reactivity with water. The agent can react with residual water in the paper, thereby neutralizing acid groups and becoming firmly insolubilized (Smith 1970). Baynes-Cope (1969) reported early research carried out in 1961 related to such a system. That work revealed that magnesium methoxide can be highly effective as a deacidification agent. However, the material was judged to be not stable enough for practical usage.

During the period between 1992 and 1995 (see weito.com) the National Library of Canada employed a system based on a mixture of magnesium methylcarbonate and magnesium methoxide in a fluorocarbon solvent (Smith 1970, 1977, 1988; Scott 1987; Morrow 1988). A related system, using alkoxides in a hexamethyldisiloxane carrier liquid, was developed by Battelle Laboratories (Wittekind 1994); this system has been mainly implemented in Germany and Switzerland (PapersaveÒ and Papersave SwissÒ). Reaction of the alkoxide (magnesium and titanium ethoxide, METE) with residual water in the paper (maybe 0.5% after a pre-drying step) converts the organomagnesium and titanium to, e.g., Mg(OH)2; the Mg(OH)2 formed initially or during a subsequent conditioning period is able to react with CO2 from the air, forming MgCO3 (Polovka et al. 2006). For the Booksaver process, for which no drying step is usually needed, the active species is n-propoxycarbonate (Henniges et al. 2004, 2012).

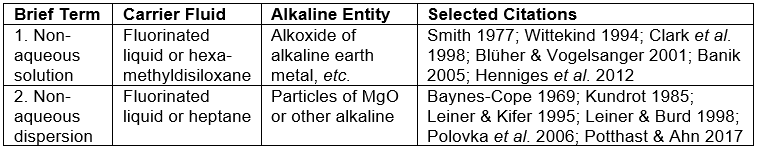

Figure 1 indicates the main steps in the type of treatments just described for PapersaveÒ. It should be noted that the purpose of the initial drying step is not to remove every molecule of water. Rather, the goal is to have an optimized moisture content so that the reactive compound or compounds are able to diffuse essentially all the way to the cellulose fiber surfaces and then be converted to the hydroxide form when they encounter water molecules associated with those surfaces. Such a sequence can be expected to favor efficient uptake of the oxide and its byproducts both at the fiber surfaces and within pores.

In principle, the systems just described share a number of desirable attributes: Because they rely on non-aqueous carriers (e.g. fluorocarbons or hexamethyldisilazane) having no hydrogen bonding ability, no distortion of the paper is expected. Because the compound is converted into Mg(OH)2 or MgCO3, an alkaline reserve material becomes deposited within the paper. The first versions of these systems sometimes exhibited visible powder deposits or sometimes not enough alkaline reserve; however, continuing developments have made the systems suitable for most kinds of books, and they have become the most widely used systems in Germany and Switzerland (Booksaver®, Papersave®, Papersave Swiss®). Coated papers can represent a particular challenge due to the very fine porosity of the surface layers, which can slow down the permeation of liquids (MacInnes and Barron 1992).

Fig. 1. Schematic procedure for deacidification of bound volumes by treatment with an alkoxide-type reagent dissolved in a low-energy liquid

Gas-phase treatments

Certain organic amine compounds have potential to be applied to paper in gaseous form, such that they have potential to react directly with acidic species present in the paper. For instance, Walker (1977) found that paper may be effectively deacidified by morpholine treatment. Koura and Krause (1980), described a similar approach using ammonia gas. Both agents have a relative strong surface tension, which raises concerns about possible solubilization of inks. An inherent drawback of any treatment that relies completely upon treatment with a volatile organic alkali such as ammonia or morpholine is that essentially no alkaline reserve is left behind in the paper (Cheradame et al. 2003).

A gaseous di-ethyl zinc deacidification system was implemented during the period from 1982 to 1993 for deacidification of books and papers held by the Library of Congress (Sparks 1987; Dufour and Havermans 2001; Cheradame et al. 2003). As in the metal alkoxide systems just described, the DEZ system entails interaction of the reagent with moisture in the paper to become transformed to Zn(OH)2 or the corresponding oxide form (MacInnes and Barron 1992). According to the cited work, distribution of ZnO particles within the documents was quite uniform. Due to operational difficulties, possibly related to the high reactivity of DEZ, the system is no longer being used.

Recently Li et al. (2014) described a newly developed system in which a plasma was formed from a mixture of argon gas and saturated Ca(OH)2 solution. This is an example of a cold-plasma system, meaning that a minor fraction of free-radical ionized species is present in a mixture together with ordinary gas molecules. The plasma was directed toward sheets of acidic paper. The authors reported an increase in the pH of the paper, whereas other properties of the paper were unaffected. A concern about plasma-based systems is that they have been found to be one-sided, mainly affecting the side of an object to which the beam is directed (Mukhopadhyay and Fangueiro 2009). In any case, more research is needed to explore the mechanisms and potential utility of plasma treatments to bring about deacidification.

Non-reactive, Non-aqueous Dispersion Treatments

Since about 1994 the US Library of Congress has been relying mainly on a system in which suspensions of MgO particles in a non-aqueous fluid are used to meet their requirements for deacidification (Leiner and Kifer 1995; Leiner and Burd 1998). The books are treated under ambient temperature and pressure while being held so that their pages are fanned open. The suspension is sprayed inward in such a way as to favor adequate treatment of the spine area (Leiner and Burd 1998), which otherwise might be the least accessible part of a bound book. Polovka et al. (2006) demonstrated that the deposited MgO particles were able to be converted to Mg(OH)2 when present in the paper, and that the hydroxide was further able to interact with CO2 from the air, yielding MgCO3. The earliest related system may have been that described by Baynes-Cope (1969), who employed a mixture of barium hydroxide and methanol to treat acidic books. The cited work describes the employed mixture as a solution, though subsequent work has shown only weak solubility of barium hydroxide in methanol (Gryglewicz 1999).

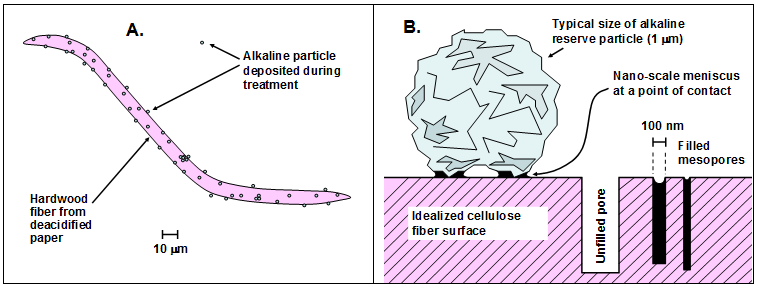

Particle distribution

Because the particles employed in the non-aqueous dispersion system are typically about a micrometer in size, one can expect that the particles will be effectively excluded from the interior of fiber cell walls. In fact, studies have shown that the particles mainly become situated on the external surfaces of sheets of paper, rather than in the interior of the sheets (Ramin et al. 2009). When non-aqueous dispersion treatment was applied to one side of paper sheets by spray application, none of the applied magnesium could be detected on the opposite sides of those specimens (Stauderman et al. 1996). The last-cited authors also found that the distribution of particles on the treated surface could be nonuniform, though their findings might have been associated with the hand-spray procedures that they employed in that work. For mechanized, mass-deacidification treatment, Wagner et al. (2008) observed a suitably uniform distribution of particles, from the perspective of the surface of the paper, based on imaging with laser ablation inductivity coupled plasma mass spectroscopy. Wojciak (2015) found that a more uniform distribution can be achieved by using nano-sized particles.

Zumbühl and Wuelfert (2001) evaluated the role of perfluorinated dispersants employed in a major non-aqueous dispersion deacidification program. The surfactant was reported to play an important role in uniform distribution of the particles.

Assumed chemical reactions in non-aqueous dispersion treatment

Once the MgO particles have been distributed onto or into the pages of a book, a series of reactions has been assumed to occur over an unspecified time period. These reactions are represented here by Eqs. 1 through 3:

MgO + H2O ® Mg(OH)2 (1)

Mg(OH)2 + CO2 (from the air) ® MgCO3 + H2O (2)

MgCO3 + (Acidic species in the paper) ® Neutralization (3)

Presumably the reaction of MgO with H2O could already take place during the deacidification treatment, since there is no oven-drying step to remove equilibrated water before non-aqueous deacidification according to descriptions of the procedures used (Buchanan et al. 1994; Burd 2012). In addition, once the treated books are returned to usual conditions of storage, where humidities of at least 50% are common, the conditions for completion of the reaction in Eq. 1 would be improved due to higher water content (typically within the range 5 to 10% in a book under typical conditions). A study by Newberg et al. (2011) using X-ray photoelectron spectroscopy (XPS) showed that such a reaction was favored by increasing humidity, and that Mg(OH)2 tended to form initially at the surface of MgO. Notably, the formation of hydroxide already was important at a relative humidity of 10%, which is well below the range experienced during typical storage of books. Work by Sutcu et al. (2009) showed that the (1 1 1) crystal face of MgO particles was most susceptible to hydration by exposure to water vapor and a relative humidity of 88% in the cited work. Research by Baumann et al. (2015) has shown that the rate of dissolution of MgO particle increases with their decreasing size, and that dissolution takes place more slowly if a stable layer of Mg(OH)2 has formed on the particle surfaces.

The further reaction of the material to form MgCO3 (Eq. 2) also is supported by the literature. Vandeperre and Al-Tabbaa (2007) found that MgO could be converted to MgCO3 at either 65% or 98% relative humidity in the presence of CO2 in the air. Both reactions, including the hydration and then then the carbonation, were supported by infrared absorption analysis by Polovka et al. (2006). Those researchers utilized 81% and 98% relative humidity conditions and ambient levels of CO2 at a temperature of 80 °C and 5 days of exposure. Only minor changes were noted at lower temperatures, including 35 °C, so it is unclear whether or not the reaction with CO2 (Eq. 2) would be brought to completion under ordinary conditions of deacidification, conditioning, and storage.

Equation 3, as shown above, is in fact the central question of the present discussion. Presumably, if MgCO3 particles present in dry paper were effective in neutralizing acidic species also in the sheet, then the same could be assumed for any remaining MgO or Mg(OH)2 species. In an effort to be more specific, suppose that acetic acid is the acidic species in the sheet that interacts with MgCO3 particles. A balanced equation then can be written in the form,

MgCO3 + 2HOAc ® Mg(OAc)2 + H2O + CO2 ↑ (4)

where the upward arrow suggests that the CO2 may be released to the atmosphere. Similarly, balanced equations can be written that result in hypothetical bicarbonate species:

MgCO3 + HOAc ® MgHCO3(OAc) (5)

or 2MgCO3 + 2HOAc ® Mg(HCO3)2 + Mg(OAc)2 (6)

Though Eqs. 4 through 6 appear to be plausible, there is as yet no firm evidence whether or not such reactions occur after the non-aqueous dispersion deacidification treatment of paper. At 80 °C Polovska et al. (2006) found evidence of conversion of carboxylic acid groups to the carboxylate form, which is consistent with the completion of a deacidification reaction under the high relative humidity conditions employed. However, to achieve clear effects corresponding to completing of the neutralization reaction, the cited authors had to employ not only high temperature but also high humidity (81% or more) during a 5-day time of exposure. Since those conditions are quite unlike what has been used for deacidification, they do not settle the question of whether Eqs. 3, 4, 5, of 6 take place during non-aqueous dispersion treatment, subsequent conditioning, or subsequent storage of books.

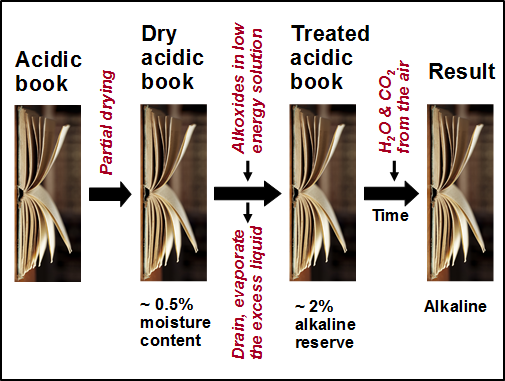

Based on the mechanisms just described, Fig. 2 presents the main steps involved in a non-aqueous dispersion deacidification treatment. As depicted, the book to be treated is assumed to contain about 4 to 10% moisture as a consequence of equilibration with ambient air in typical ranges of relative humidity. The deacidification treatment involves MgO particles dispersed in a low-energy liquid, which is then drained from the paper material, followed by evaporation. As depicted, the alkaline particles left behind in the paper after such treatment can be roughly 2%, depending on the targeted level. After reaction of the MgO with water (perhaps adsorbed water already present in the paper), and with CO2 from the air, it is expected that much or all of the MgO will have become converted to Mg(OH)2 or MgCO3 by the time the post-conditioning period is done and the books are ready to be returned to library stacks.

Fig. 2. Main steps in the non-aqueous dispersion deacidification of bound volumes

Proximity suggesting eventual interaction

Various evidence in the published literature supports an assumption that acidic and alkaline substances within dry material such as paper will be able to react with each other, over time, to bring about neutralization. In particular, certain acidic substances appear to be capable of migrating from one point to another. Barrow (1953) reported that organic acid materials were able to migrate from one sheet to another in bound documents having different composition in their covers vs. their interiors. For example, the cover of an 1857 booklet, which contained mechanical pulp fibers, was found to have influenced the properties of adjacent sheets of inherently higher-quality paper. The first three sheets below the cover had folding endurance values of 16, 116, and 328, sequentially. In the case of a 1760 record book having a groundwood cover the first three pages in the interior had folding endurances of zero, 9, and 10. Likewise, it has also been shown that fatty acids are able to migrate from the interior to the outsides of paper sheets (Swanson and Cordingly 1959).

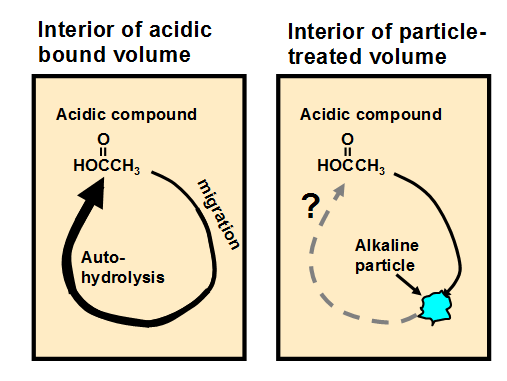

Based on the migration mechanism just suggested, Fig. 3 presents a hypothesis regarding the function of alkaline particles in a bound volume that has been subjected to non-aqueous dispersion deacidification treatment. The left frame of the figure represents the auto-catalytic role of acidic species such as acetic acid (without assuming that acetic acid is the major species in a given case) when they are held within a bound volume during storage. The expanding arrow represents the migration of the acidic compound, resulting in hydrolysis of polysaccharides (cellulose and hemicellulose) or hydrolytic deacetylation of hemicellulose and the release of increasing amounts of acetic acid. The right-hand frame depicts the idea of one such acidic molecule colliding with an active site on an alkaline particle, thus potentially breaking the catalytic cycle. The process depicted in Fig. 3, if valid, suggests that smaller or better distributed alkaline particles (with a fixed total mass) might be more effective at neutralizing mobile acidic species that migrate from other sites within the paper material.

Fig. 3. Potential role of alkaline particles in breaking the cycle of auto-catalytic hydrolysis when acidic compounds such as acetic acid are able to hydrolyze hemicellulose in the fibers, thus releasing more acetic acid

The hypothetical mechanism just described depends on an assumption that acidic species such as the protonated forms of acetic acid and formic acid are able to move from one point to another at a sufficient rate to make a difference. Such migration and effectiveness is supported by various publications (Barrow 1953; Nerin et al. 1998; Wenzl and Lankmayr 2000; Banik 2005; Area and Cheradame 2011). But the present review of the literature did not reveal evidence of corresponding migration of alkaline species. The vapor pressure of inorganic compounds such as MgO and CaCO3 can be expected to be extremely low at typical conditions of storage of books (Lide and Kehiaian 1994). In addition, conjugate bases that might be present in paper (e.g. sodium acetate or calcium acetate), due to their polar nature, can be expected to have much lower vapor pressures than their protonated counterparts (e.g. acetic acid) (Barsanti et al. 2009). Another example of the very low vapor pressures inherent in ionic compounds is provided by ionic liquids (Earle and Seddon 2000). Based on these considerations, there is only limited evidence that the presence of alkaline particles within paper would result in sufficient migration of alkaline species toward acidic sites to bring about neutralization (see later discussion concerning litmus paper tests).

Evidence of efficacy based on paper strength

As already noted, the value of a stored book depends on its usability over an extended time (Drewes and France 2012; Johnson et al. 2012). While estimating the absolute longevity in years is of questionable reliability (Shahani 1995), a meaningful evaluation can be made by testing the relative increase of stability of the paper in comparison with acidic non-deacidified paper from the same source. This has been called efficacy and used for the quantitative evaluation of deacidification process (Buchanan et al. 1994; Katuscak et al. 2010, 2012; Drewes and France 2012).

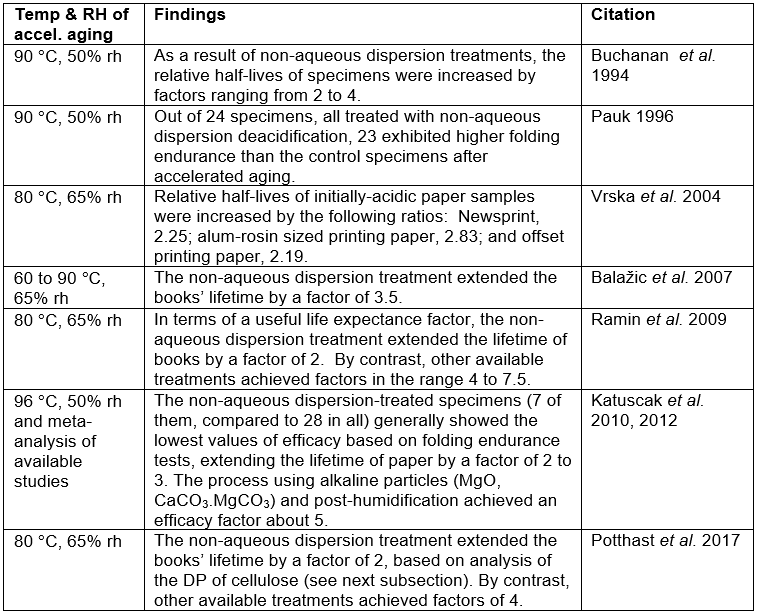

Table 2. Results of Accelerated Aging and Strength or DP Evaluation Testing of Paper Deacidified by the Non-aqueous Dispersion Treatment System *

* Efficacy factors included in the table generally compare the time of accelerated aging needed to reduce paper strength or DP of deacidified paper to a critical level; the base case consists of specimens from the same source but without the deacidification. Strength criteria (or DP), as well as other details, differ from study to study.

The efficacy of the conservation process can be quantified as a coefficient expressing by how many times the process prolongs longevity, in terms of an evaluated property such as folding endurance, tensile strength, or degree or polymerization. Published evaluations of the effectiveness of non-aqueous dispersion deacidification have shown mixed results, especially with respect to the evaluation of paper strength after accelerated aging. Results of different studies dealing with the efficacy of the non-aqueous dispersion deacidification program are summarized in Table 2.

Evidence of efficacy based on cellulose degree of polymerization

A recently established standard (ISO/TS 183444:2016) can be expected to be adopted in various future studies related to those listed in Table 2. The ISO/TS provides test methods, minimum requirements, and levels of replication for accelerated aging tests. In addition, one of the key elements of the new standard is its reliance on evaluation of changes in the degree of polymerization of paper specimens exposed to accelerated aging. Potthast and Ahn (2017) used such an approach when conducting parallel evaluations of two kinds of deacidification treatments – non-aqueous dispersion and solution-based treatments. The tests were carried out with typical acidic paper from selected books. Accelerated aging was performed under conditions of 80 °C, 65% relative humidity, and 40 days of exposure. At the end of that period, the paper that had been deacidified by the non-aqueous dispersion process showed an effectiveness factor of about 1.8, based on a lower rate of the degree of chain scissions of the cellulose molecule when comparing the control specimens to those that had been deacidified. The corresponding factor was about 4.0 when comparing a control specimen to paper that had been deacidified by a non-aqueous solution-based process. In other words, the solution-based treatment was much more effective. In the described experiments, the effectiveness factor can be defined by the following equation,

Fe = [(DPo-DP)/DP]control / [(DPo-DP)/DP]deacidified

where DPo is the degree of polymerization of the cellulose in the paper prior to accelerated aging, DP is the degree of polymerization of the cellulose at the end of the exposure.

POST-DEACIDIFICATION CONCERNS

Evidence of Continued Acidity in some Deacidified Books and Papers

Various evidence can be found within the published literature relative to whether or not non-aqueous dispersion deacidification treatment has been successful, in various cases, in neutralizing acidic groups within the treated documents. Such evidence, to be discussed in this section, involves such factors as mechanical strength after accelerated aging, the continued evolution of gaseous products from the paper, the color of pH-sensitive dyes in the paper, and spectroscopic information that sheds light on the degree of neutralization of carboxylic acid groups within the paper.

Acidic species within a dry sheet of paper or book may be present in various forms, and they may be either at the surface or within the nanostructure of fiber cell walls. They can include weak acids, such as acetic acid and the resin acids of wood, and they may include strong acids, such as sulfuric acid (Katz et al. 1984). Protonated carboxyl groups, in particular, are known to be very common in cellulose-based materials (Scallan et al. 1989; Middleton et al. 1996).

Efficacy factors

If one refers back to Table 2, although the non-aqueous dispersion system was successful in some of the evaluations in extending the projected useful life of treated acidic paper (Buchanan et al. 1994; Hanus et al. 2008; Ramin et al. 2009; Banik 2005; Banik et al. 2006; Katuscak et al. 2010, 2012; Ahn 2013), not all such tests met the Library of Congress requirement of achieving an efficacy factor of at least 3 (Buchanan et al. 1994; Vrska et al. 2004; Ramin et al. 2009; Potthast and Ahn 2017). Based on some recent tests, the non-aqueous dispersion systems were judged to be less effective than several different deacidification programs that were considered (Katuscak et al. 2010, 2012). It should be noted that an addendum to the publication by Buchanan et al. (1994) indicated higher lifetimes for items treated with a non-aqueous dispersion system. The originally presented results were obtained with a 1 kg mass during the folding endurance tests, and the follow-up evaluations were with a 0.5 kg mass. However, in general the non-aqueous dispersion deacidification processes (e.g. BookkeeperÒ, ZfB:2, and formerly LibertecÒ) have been judged to be significantly less effective in achieving the desired neutralization (Blüher et al. 2006).

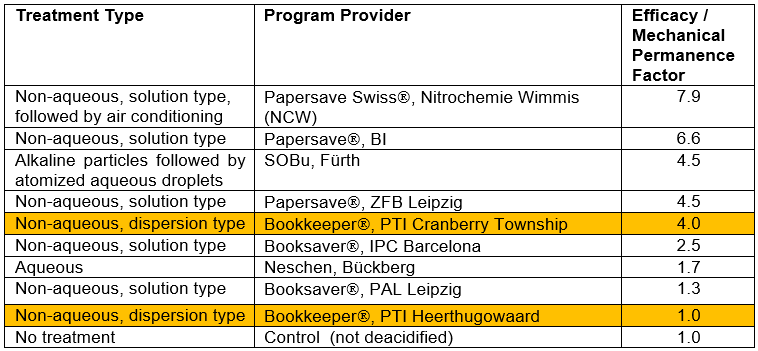

Table 3 shows results based on collected data from a consortium project (Katuscak et al. 2012, see Fig. 6 of that work).

Table 3. Mechanical Permanence Factors Reported for Documents Deacidified by Different Programs *

* Katuscak et al. 2012, see Fig. 6; the efficacy / mechanical performance factor was determined by comparing the time of accelerated aging (96 °C, 50% relative humidity) for the logarithm of folding endurance to reach zero in the case of modified vs. control samples, Stw = tlog w = 0,m / tlog w = 0,n .

As shown, two specimens that had been deacidified by the non-aqueous dispersion program exhibited efficacy factors that were, respectively, 1 (not significantly different from the untreated acidic paper control) and 4, whereas the most successful deacidification method increased the life expectancy factor to 7.9. Results corresponding to deacidification by means of non-aqueous dispersion treatment are shown in Table 3 with highlighting. It should be noted that data collected in the table had been combined from different sources; future studies are needed in which such comparisons are done under controlled conditions in an independent laboratory.

A larger study, reported in the same article (Katuscak et al. 2012), gave a multi-factor assessment rating of deacidified documents, included nine non-aqueous dispersion deacidified specimens among a total of 31 cases considered. The nine specimens deacidified by the non-aqueous dispersion program were among the 15 lowest-rated cases reported in the meta-analysis, the synthetic comparative analysis of all available objective measurements and studies. Such findings cannot be completely attributed to differences in deacidification, since some of the other systems involved application of strengthening agents.

Gas evolution

Banik (2005) reported that specimens of books treated by a non-aqueous dispersion program still contained a high concentration of acids. The acid levels were comparable with those of the untreated control acid paper. This was demonstrated by evaluating the volatile organic compounds (VOCs) in the headspace. The acid VOC concentration was approximately the same as for untreated books, under matched conditions of testing. Papers deacidified by non-aqueous dispersion processes, with two commercial programs (Bookkeeper® and Libertec®) judged to be relatively ineffective in bringing about the desired neutralization of acids in the paper. In contrast to the non-aqueous dispersion processes, the concentration of the volatile organic acids above the paper surface deacidified by aqueous-based treatments were decreased substantially in comparison with the acidic paper.

pH-sensitive dyes and litmus paper

It is well known that certain dyes can be employed in order to sense the pH in wetted paper (Walpole 1913). In principle, if a deacidification agent is able to neutralize acidic groups in the paper, then one would expect there to be a corresponding change in color of the dye. To demonstrate this, Middleton et al. (1996) placed blue litmus paper strips adjacent to acidic and alkaline paper sheets, all previously equilibrated to laboratory conditions (50% relative humidity). They found that the litmus paper strips adjacent to the acidic paper would turn red over the course of a day or so. Then, if the litmus paper strips were placed adjacent to an alkaline paper sheet, the original blue color would return after another day or two. However, Whitmore and Bogaard (1994) observed paper sheets in which the litmus dye color indicated the persistence of acidic conditions even after non-aqueous dispersion deacidification. The cited researchers concluded that the tested papers had not been successfully deacidified in those specimens, possibly due to a higher initial level of acidity compared to some other specimens that they tested. As noted earlier (Hubbe 2015), subsequent conversion of the litmus paper to a blue color, suggesting successful deacidification, could be achieved by exposure of the deacidified samples to high humidity.

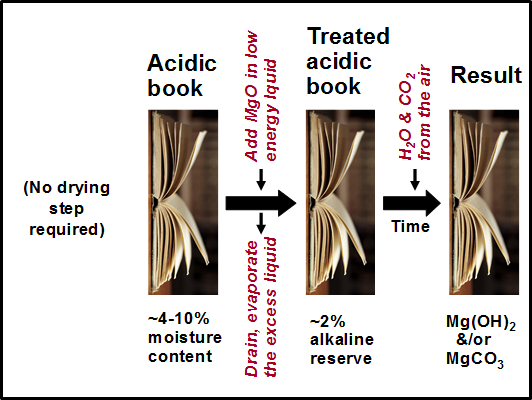

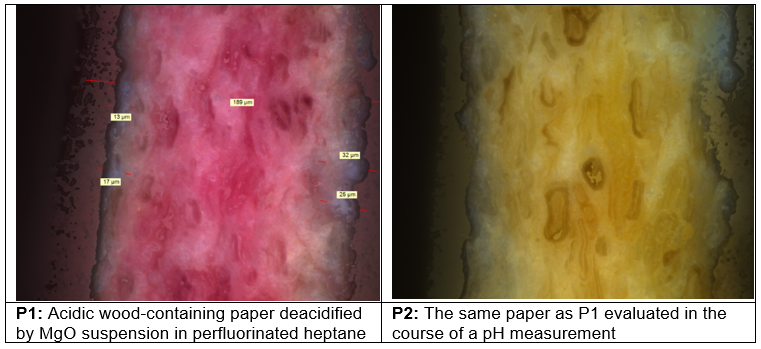

Water, when it is used for pH measurement by a water extraction method, or even when a small drop of water is used for the traditional or standardized pH measurements, can cause redistribution of acidic or alkali ions or compounds determining the pH from one place to another. For example, such water can redistribute soluble acidic or alkaline species from the measured paper surface into the inner structure, pores, cell lumens, or inner surface of cellulosic fibers, as well as into cellulose macromolecules (Katuscak et al. 2016). A pH-sensitive dye was used in the cited work. As can be seen from part P1 of Fig. 4, based on the color change of the surface layers, there was an alkaline boundary that penetrated only a short distance from the outside of the paper thickness. Part P2 of the figure shows the same specimen during the measurement of pH, immediately after the drop of water needed for the measurement had been applied to the paper surface. Despite the fact that most of the paper thickness of the sample in Fig. 4 microstructure had been acidic, the paper after the pH measurement appears to be neutralized, deacidified, and alkaline, with a pH value of about 8 to 9. This result is misleading, caused by an improper method of pH measurement, which is blind to the presence of acidic species or locations inside the paper or books.

Fig. 4. Acid wood paper impregnated with pH indicator and deacidified (P1) and after superposing the prescribed drop of water during the surface pH measurement (P2).

P1 – The sample was acid wood (CTMP) paper (NOVO, KLUG Conservation), surface pH 4.5, impregnated by pH indicator methyl red, then deacidified by the immersion in suspension of MgO in perfluoroheptane, 10 seconds.

P2 – Image obtained at a later stage of the same experiment during the pH measurement sequence. The image was made immediately after the pH drop of water needed for the measurement had been applied to the measured surface.

Paper characteristics: weight 90 g/m2; pulp 55% CTMP with lignin content 17%, 45% bleached cellulose; filler 12-15% kaolin; sizing Cobb60 < 20 (rosin and alum); headbox pH 4-5, adjusted with alum.

The underlying cause of the findings just described can be referred to as secondary migration or secondary diffusion, in which the test procedure itself causes the movements of acidic or basic species from one position to another in the specimen. As a result of the secondary diffusion by the drop of water used for analysis, an artifact arises: the whole paper appears to be alkaline. This is the case even if the acids had been present inside the cell microstructure. Such acidic places can be dangerous because they cause rapid degradation at random locations along cellulose chains, increasing brittleness, and rapidly decreasing longevity of the material. On the other hand, this experiment clearly shows the potential of bringing about a beneficial effect by post-deacidification moisturizing or humidification. The pH test results demonstrated that the pH can be rendered homogeneously alkaline by a small amount of water. This transformation takes place despite the insolubility of the MgO. Similarly, it can be effective with other insoluble particles such as CaCO3 or MgCO3.

Spectroscopic evidence

Infrared absorbance maxima can be used not only as evidence of the presence of functional groups, but also in some cases to detect the chemical form in which they are present (Strlič et al. 2008; Lichtblau et al. 2009). In particular, the protonated and carboxylate forms of carboxylic acid groups can be distinguished (Pappas et al. 1999; Ayora-Cañada and Lendl 2000; Dioumaev 2001; Tannenbaum et al. 2004).

It is worth reconsidering here the work of Polovka et al. (2006), who used FTIR measurements to detect changes in acidic paper when treated by a non-aqueous dispersion deacidification method. Accelerated aging of the control and deacidified specimens was carried out at selected temperatures (35 and 80 °C) and relative humidities (81 and 98%), generally for a period of 5 days. Significant changes were found only at the higher temperature. From an analytical chemistry standpoint, the FTIR measurements had the advantage of providing information about changes in both the inorganic and organic species involved in the intended deacidification reactions (see Eqs. 1 through 3). A pronounced peak at 3700 cm-1, in the deacidified samples, was attributed to OH groups associated with metal ions (presumably Mg2+). Changes also were detected in the 3000 and 1600 cm-1 regions, which were attributed to water and hydrogen-bonded structures. Some changes also were detected in the 1720 to 1740 and 1630 to 1650 cm-1 wavenumber regions corresponding to changes in carbonyl/carboxylate groups. A known limitation of analyses based on infrared absorption is the fact that the intensities at different wavelengths often cannot be used precisely to compare the amounts of two different functional groups (Sakamoto and Tasumi 2014). Thus, only in the case of a complete disappearance of absorbance intensity related to the carboxylic acid group and a new appearance of a band corresponding to the carboxylate form can one make a highly precise statement about the extent of neutralization of carboxylic acids present in the paper. Nevertheless, given the high relevance of the information, it is hoped that future studies employ FTIR observations to evaluate the effects of various “equilibration” or “conditioning” conditions at specified temperature and relative humidity following non-aqueous deacidification treatments.

The visual color of paper also has been considered as evidence of whether a deacidification treatment has been successful. Stauderman et al. (1996) evaluated the color change when individual sheets were optionally deacidified for non-aqueous dispersion treatment, using a manual spraying operation. After the exposure to accelerated aging with 90 °C, 50% relative humidity treatment, all of the sheets had decreased in L* (lightness) value from an initial value in the range 83.l3 to 84.3 to a final value in the range 72.2 to 77.4. The loss in lightness was slightly larger in the case of the non-aqueous dispersion deacidified sheets, compared to the control specimens, whereas sheets that had been washed exhibited less decrease in L* value.

Evidence that Acid and Bases Can Exist Micro-meters Apart

There are several situations, described in published literature, which provide evidence that acidic species and alkaline species can exist in close proximity within dry materials at ordinary levels of humidity. Some examples to be considered are baking powders, archival papers that contain both acidic inks and alkaline particles, and archival papers that contain both acidic degraded linseed oil and alkaline particles.

Baking powder studies

Commonly available baking powders consist of sodium bicarbonate together with a dry acidic material such as tartaric acid, monocalcium phosphate, or sodium aluminum phosphate (Ciullo 1994). Cream of tartar also can be used as a source of acidity, but it tends to give immediate gassing, so it is less suitable for preparation of a dry powder that will need to be stored. Baking powders often contain about 30% starch, one of the roles of which is to absorb moisture and keep other components of the mixture dry. According to Wolke (2002), baking powder can lose its potency during several months of storage, especially if the conditions become humid.

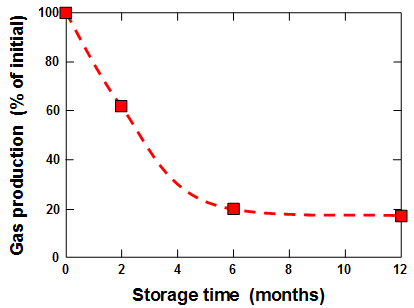

Ishii (1950) evaluated the storage stability of baking powder. After two months of storage the amount of CO2 generated by the powder had declined to 62% of its initial value. After six months the CO2 production had declined to 20%, and after a year it had declined to 17%. By contrast, very little change could be detected if the sodium bicarbonate and the acidulent were stored separately under similar conditions.

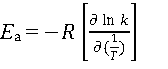

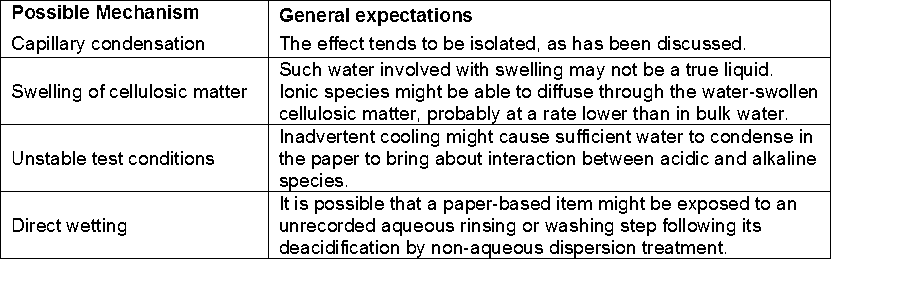

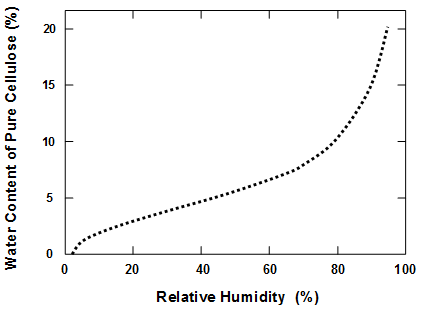

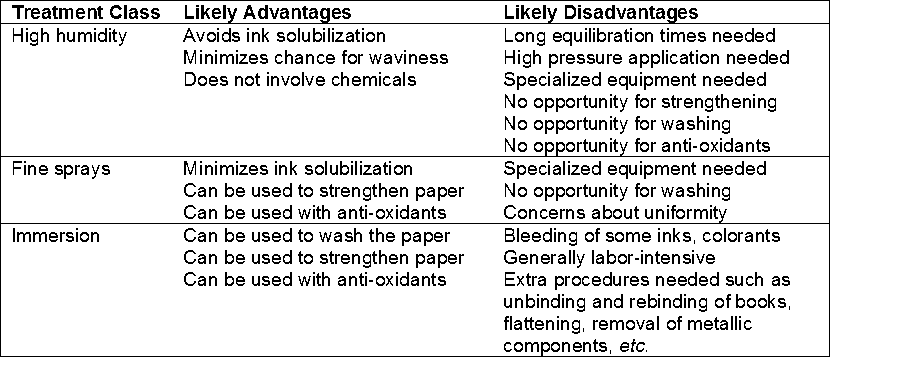

Paper archival research with acidic ink and alkaline particles