Abstract

The tension test parallel-to-fiber in anisotropic materials, such as bamboo, is one of the most important tests because it makes it possible to evaluate mechanical properties used in calculations for different types of stresses. For this type of test there are standards that apply to wood in general, others to bamboo, and other more specific ones that apply to bamboo Guadua angustifolia Kunth. These rules suggest the use of dog bone test specimens. When performing such tests parallel to the fiber direction, failures are observed in undesired zones. This document characterizes and analyzes the possible types of failures. It also evidences the difficulties presented and quantifies them finding that, for 59 failed test pieces, only 18.6% had failures within the desired zones, while the other 81.4% had failures within undesired zones in the tension test parallel to the fiber. Finally, it can be concluded that there are gaps in the rules that influence the variation of the results obtained by different authors. The dog bone test specimens are not recommended for tension tests parallel to the Guadua fiber. Rather, utilization of straight specimens is recommended with a calculated clamping height and the standard equation and protected clamping area.

Download PDF

Full Article

Determination of the Suitable Shape for Tensile Tests Parallel to the Fibers in Guadua angustifolia Kunth Specimens

Ricardo Acosta,a,* Jorge A. Montoya,b and Johannes Welling c

The tension test parallel-to-fiber in anisotropic materials, such as bamboo, is one of the most important tests because it makes it possible to evaluate mechanical properties used in calculations for different types of stresses. For this type of test there are standards that apply to wood in general, others to bamboo, and other more specific ones that apply to bamboo Guadua angustifolia Kunth. These rules suggest the use of dog bone test specimens. When performing such tests parallel to the fiber direction, failures are observed in undesired zones. This document characterizes and analyzes the possible types of failures. It also evidences the difficulties presented and quantifies them finding that, for 59 failed test pieces, only 18.6% had failures within the desired zones, while the other 81.4% had failures within undesired zones in the tension test parallel to the fiber. Finally, it can be concluded that there are gaps in the rules that influence the variation of the results obtained by different authors. The dog bone test specimens are not recommended for tension tests parallel to the Guadua fiber. Rather, utilization of straight specimens is recommended with a calculated clamping height and the standard equation and protected clamping area.

Keywords: Tension test; Bamboo; Dog bone samples; Failure; Parallel fiber

Contact information: a: School of Technology, Technological University of Pereira, Pereira, Colombia; b: School of Environmental Sciences, Technological University of Pereira, Pereira, Colombia; c: Institute of Wood Research, Thuenen Institute, Hamburg, Germany; *Corresponding author: ricosta@utp.edu.co

GRAPHICAL ABSTRACT

INTRODUCTION

The consolidation of technical standards to establish the mechanical properties of bamboo was carried out in 2004, in collaboration between the International Organization for Standardization (ISO) and the International Network of Bamboo and Rattan (INBAR). These standards were referenced as ISO 22156 (2004), ISO 22157-1 (2004), and ISO 22157-2 (2004) (Titilayo Akinlabi et al. 2017). Standards from other organizations exist, such as the American Society for Testing Materials ASTM D143-14 (2014), which are for wood in general and the Colombian Technical Standard NTC 5525 (2007), in which the stress test parallel to the fibers is based on the ISO reference and is specifically for bamboo Guadua angustifolia Kunth. These standards have in common that they suggest the use dog bone samples (name given to the specimens that adopt the geometry of a bone given to a dog) to the tension test parallel to the fibers. Straight specimens are currently suggested in the latest update of ISO 22157 (2019).

Several authors report failures due to shear stresses for the test of tension parallel to the fibers with dog bone-type specimens in bamboo (González et al. 2006; Kariuki et al. 2014; Takeuchi 2014). Other authors note that an important factor in the failure mode is the section from which the samples are extracted, noting that specimens manufactured from the external cross-section (higher density of fiber) suffer from shear failure

Fig. 1. a) Failures in test samples of type dog bone manufactured in bamboo section of the external section; b) Failures in test samples of type dog bone made of bamboo of the internal section (Chen et al. 2015)

Arce (1993) theoretically demonstrated that the dog bone test specimens are not the most appropriate to perform stress tests in bamboo, because the shear stresses can reach values close to the tensile stresses for these proposed geometries.

Richard and Harries (2015) warn of the influence of fiber density on the thickness of the bamboo wall and the conditions of the test piece in the results obtained for the tension test parallel to the fibers. They also propose a matrix of six failure modes characterized from A to F (Table 1). The G and H failures are not contemplated by the original author; however, they were considered as failures that should be characterized in dog bone specimens.

Failure modes C and F are considered correct failures for this type of test, where there is no influence on the results due to the clamping of the specimen and the clamps. Faults C and E are considered correct if you are working with uniformly reinforced materials with unidirectional fibers (Richard and Harries 2015). Fault G is related to the internal shear in the material and failure H is the combination between failure B and failure G in which it cannot be shown which occurs first, but if one can be said to lead to the other.

EXPERIMENTAL

Three-year-old bamboo culm (Guadua angustifolia Kunth) was harvested from a natural plantation located in the botanical garden of the Technological University of Pereira (Pereira, Colombia). The site was located at a latitude of 4.791959, a longitude of -75.68896, a height above sea level of 1450 m, an average temperature of 20 °C, and an annual rainfall of 2600 mm. Test samples were extracted internode basal section and external walls of cross-section removing the cuticle. Test samples were dried in an oven at 100 ± 3 °C for 24 h, sanded, and sized with a bench router, standard sample, and a milling cutter. The final dimensions were width (a) = 10 mm, thickness (b) = 5 mm, clamping width (c) = 20 mm, equivalent grip height (h) = 30 mm, and total length of the specimen (l) = 140 mm and 50 mm radius of curvature (Fig. 2).

Fig. 2. Dimensions test sample dog bone

Test samples were then subjected to a conditioning stage at a temperature of 20 °C at 65% relative humidity (RH) for 12 days to guarantee hygroscopic equilibrium moisture. Subsequently, each of the specimens was glued, adhering wooden elements to protect the clamping area and avoid possible damage due to excessive compression of the clamps (type A failure). To perform this operation, manual presses, assembly frames, and adhesive of the advanced polymer type of Titebond® Ultimate trademark (Franklin International Inc., Columbus, OH, USA) were used, with a final effort equal to 27.58 MPa (Fig. 3a).

Fig. 3. a) Gluing test samples type dog bone; b) Curing of glued specimens

Finally, the adhesion of the elements could cure for 96 h (Fig. 3b). The tests were carried out under controlled conditions (20 °C and 65% RH), and each of the specimens was subjected to a gradual axial load at a speed of 2 mm/min. The clamping was done by fixed universal wedge type jaws (it does not allow rotation) universal testing machine (ZwickRoell Z050, Zwick GmbH & Co. KG, Ulm, Germany).

RESULTS AND DISCUSSION

To guarantee the tension failures of the dog bone test specimens, the analytical verification of two previously characterized faults was carried out.

Type B fault: Total or Partial Failure Due to Slippage on the Tail Line

This failure is due to the lack of resistance of the adhesive or to an insufficient adhesion area, for which it was verified that the samples fulfilled this request. The total area was not considered because the dog bone test specimens when subjected to axial load presented a longitudinal fracture coinciding with the throat width of the specimen (Fig. 4a).

Fig. 4. a) Longitudinal fractures of the test sample subjected to axial load; b) Test dog bone with the effective areas of calculation

The reported effort for stress tests in bamboo, especially in Guadua angustifolia Kunth, is around 200 MPa (Ciro Velásquez et al. 2005; Kariuki et al. 2014). The clearing force P is obtained according to the stress definition (Eq. 1),

where σu is the ultimate stress (MPa), A1 is the cross-sectional area (mm2), and P is the tension force.

This force (P), which is at tension, behaves as a shear (V) in the analysis of the adhesive (Fig. 4b) because it acts parallel to the areas where the force is exerted.

In the case of the shear analysis, it was considered that the external elements adhere to four faces of the specimen Eq. 2:

This result was checked against the technical specifications of the adhesive as per ASTM D905-08 (2013), and it was verified that it fulfills the requests (27.58 MPa > 7.5 MPa).

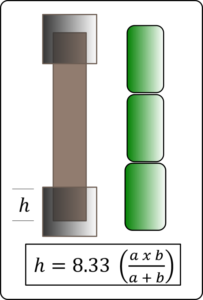

Failure Type G: Failure Due to Internal Shear in the Clamping Area

This failure is characterized by a shear stress to the interior of the material, which allows displacement in the clamping area and is evidenced by a removal of the material at the end of the specimen.

Tension stress is given by the relationship between the applied axial force and the area of the cross-section in the throat of the specimen. The area of the cross-section in the throat of the specimen is given by the product of the width (a) by the thickness (b), Eq. 3:

For the shear stress in the clamping of the specimens, it is considered that each specimen is held at both ends where four areas act for each end, Eq. 4:

It is considered that the force (P) acting on the tensile stress becomes a shearing force (V) when the shear stress is analyzed in the clamping section of the specimen. The area A2 will be given by the product of the width (a) by the equivalent clamping height (h) of subjection. And the area A3 will be given by the product of the thickness (b) by the equivalent clamping height (h) of clamping, as shown in Eq. 5:

The tensile stress and shear stress for Guadua angustifolia Kunth is around 200 MPa and 6 MPa, respectively (Ciro Velásquez et al. 2005; Takeuchi 2014). The relationship between the tensile stress (σ) and the shear stress (τ) is given by Eq. 6:

If Eq. 6 is taken into account and equalized using Eq. 3, which yields Eq. 5, then Eq. 7 relates the necessary equivalent clamping height (h) of subjection in terms of the width (a) and the thickness (b) of the specimen for the Guadua angustifolia Kunth:

The frequencies of failure modes for the specimens are listed in Table 2.

The type B faults found were possibly due to deficiencies in the gluing process (Fig. 5a), such as irregularities in the surfaces in contact with the adhesive and insufficient mechanical pressure between the frame and the manual presses.

In type G failures, there was a considerable reduction in the thickness of the end of the specimen (Fig. 5b), due to the fact that in the interior of the fastener there remains tissue adhered to the additional elements of wood. This type of failure was possibly due to a low grip height because a safety factor was not applied to guarantee that another failure mode is obtained. Considering the coefficients of variation of the results found by the authors in the mechanical tests, it is recommended to apply a high safety factor that guarantees the failure in the throat section of the specimen.

Type H failures are difficult to characterize in some cases, but failure of the glue line can be observed on one side and on the other side loss of material that manifests itself in a decrease in the thickness of the specimen due to internal shear in the clamping area (Type G fault).

Fig. 5. a) Total or partial fault due to slippage on the glue line (Type A fault); b) partial failure

There are type C failures reported with dog bone specimens, which include nodes in the throat section (Kariuki et al. 2014). The tensile stress of the nodes is 30% of the stress effort of the internodes, which means that tension stress is reduced 70% (Arce 1993). In addition, this discontinuity of the fibers in the node causes the stresses to be concentrated in this line and premature failure is obtained.

The clamping of the specimen is an important aspect. Results of tests to tension parallel to the fiber that were obtained with fixed jaws were lower than those obtained with rotating jaws; this was due to the tendency to turn, causing tension in bamboo due to the difference in properties between the different layers, and attributed to the variation in fiber density (Richard and Harries 2015).

Guadua is a natural composite material, which is made up of unidirectional short fibers in a lignin matrix that gives it an additional feature called laminated material. Defining and predicting the failure in this type of material is complex because the failure depends on several factors (properties and interface fiber matrix) and the combination of different failure modes (Arias and Vanegas 2004). Generalizing results for lignocellulosic materials, the expected mechanical behavior should be similar in dog bone type specimens, since for all shear stresses they are much lower than tensile stresses.

Several authors report differences of up to 82% in stress strain results parallel to the fibers for Guadua angustifolia Kunth. It is possible that this is due to the anisotropy of the material, the operation parameters of the test and the environmental conditions, among others (Ciro Velásquez et al. 2005). The new straight specimens proposed (Fig. 6a), with height of subjection calculated with Eq. 7, and clamping area protected with softwood glued showed a type F failure (Fig. 6b), which is desired.

Fig. 6. a) Straight specimens with clamping area protected; b) Faults by combination of previous failure modes (Type F fault)

CONCLUSIONS

- The dog bone test specimens used in the test of tension parallel to the fiber in this type of material does not guarantee that the efforts are concentrated in the throat of the specimen to obtain a failure, because in general the shear stress is much lower than the tension stress.

- The technical characteristics of the adhesive surface of the fastening area are important factors to consider in the mechanical tests of tension parallel to the fiber in Guadua when protective elements are used at the ends of the specimens.

- Only 18.6% of the test piece had failures by desired zones (Failure type D), while the other 81.4% had failures by undesired zones (Failures type B, G, and H) in the tension test parallel to the fiber.

- Failure due to internal slippage in the material (type G failure) must be considered to calculate the height (h) of the test piece, considering the relationship between tension stress and shear stress of each material. Additionally, it is recommended to apply a high safety factor due to the coefficients of variation of the results.

- The clamps to attach the dog bone specimens in this type of material must allow the rotation to avoid additional efforts in the material that alter the results when the test is being carried out.

- The standards of mechanical tests in this type of materials have gaps that influence the variation of the results of the mechanical properties obtained by different authors for the Guadua angustifolia Kunth.

- The dog bone test specimens are not recommended for tension tests parallel to the Guadua fiber. Instead, straight specimens with a calculated clamping height using Eq. 7 and a protected clamping area are recommended.

ACKNOWLEDGMENTS

The authors are grateful for the support of the Technological University of Pereira, Colombia (Research 9-17-7) and labs of Thünen Institute in Hamburg, Germany.

REFERENCES CITED

Arce, O. A. (1993). Fundamentals of the Design of Bamboo Structures, Ph.D. Thesis, Technische Universiteit Eindhoven, Eindhoven, Netherlands. DOI: 10.6100/IR402687

Arias Maya, L. S., and Vanegas Useche, L. (2004). “Falla de los materiales compuestos laminados [Laminate composite material failure],” Scientia et Technica 2(25), 113-118.

ASTM D905-08 (2013). “Standard test method for strength properties of adhesive bonds in shear by compression loading,” ASTM International, West Conshohocken, PA, USA. DOI: 10.1520/D0905-08R13

ASTM D143-14 (2014). “Standard test methods for small clear specimens of timber,” ASTM International, West Conshohocken, PA, USA. DOI: 10.1520/D0143-14

Chen, H., Cheng, H., Wang, G., Yu, Z., and Qiang Shi, S. (2015). “Tensile properties of bamboo in different sizes,” Journal of Wood Science 61, 552-561. DOI: 10.1007/s10086-015-1511-x

Ciro Velásquez, H. J., Osorio Saraz, J., and Vélez Restrepo, J. M. (2005). “Determinación de la resistencia mecánica a tensión y cizalladura de la Guadua angustifolia Kunth [Determination of the mechanical resistance to tension and shear of Guadua angustifolia Kunth],” Revista Facultad Nacional de Agronomía Medellín 58(1), 2709-2715.

González, H., Montoya, J. A., and Bedoya, J. (2006). “Esfuerzo de tensión y la influencia de la humedad relativa del ambiente y la altura a lo largo del tramo en la especie de bambú Guadua angustifolia Kunth [Tensile stress and the influence of the relative humidity of the environment and the height along the span in the bamboo species Guadua angustifolia Kunth],” Scientia et Technica 12(32), 45-60.

ISO 9087 (1998). “Wood determination of nail and screw holding power under axial load application,” International Organization for Standardization, Geneva, Switzerland.

ISO 22156 (2004). “Bamboo structural design,” International Organization for Standardization, Geneva, Switzerland.

ISO 22157-1 (2004). “Bamboo determination of physical and mechanical properties-Part I: Requirements,” International Organization for Standardization, Geneva, Switzerland.

ISO 22157-2 (2004). “Bamboo determination of physical and mechanical properties-Part II: laboratory manual,” International Organization for Standardization, Geneva, Switzerland.

ISO 22157 (2019). “Bamboo structures — Determination of physical and mechanical properties of bamboo culms — Test methods,” International Organization for Standardization, Geneva, Switzerland.

Kariuki, J., Nyomboi, T., and Mumenya, S. (2014). “Effect of orientation and arrangement of bamboo strips on structural strength of laminated bamboo beam,” International Journal of Engineering Sciences & Emerging Technologies 7(2), 555-567.

NTC 5525 (2007). “Test methods to determine physical and mechanical properties of Guadua angustifolia Kunth,” Instituto Colombiano de Normas Técnicas (ICONTEC) [Colombian Institute of Technical Standards], Bogotá, Colombia.

Richard, M. J., and Harries, K. A. (2015). “On inherent bending in tension test of bamboo,” Wood Science and Technology 49, 99-119. DOI: 10.1007/s00226-014-0681-9

Takeuchi, C. P. (2014). Caracterización Mecánica del Bambú Guadua Laminado para Uso Estructural [Mechanical Characterization of Laminated Guadua Bamboo for Structural Use], Ph.D. Dissertation, Universidad Nacional de Colombia, Bogotá, Colombia.

Titilayo Akinlabi, E., Anne Fenin, K., and Richard Akwada, D. (2017). Bamboo, The Multipurpose Plant, Springer, Johannesburg, South Africa. DOI: 10.1007/978-3-319-56808-9

Article submitted: September 16, 2020; Peer review completed: November 15, 2020; Revised version received and accepted: March 3, 2021; Published: March 11, 2021.

DOI: 10.15376/biores.16.2.3214-3223