Abstract

Use of alkali-pretreated rice straw and untreated rice straw as substrates for enzyme production under solid-state cultivation was investigated. Cellulase produced from untreated rice straw showed higher activity of FPase, CMCase, β-glucosidase, and xylanase at 6.25 U/g substrate, 111.31 U/g substrate, 173.71 U/g substrate, and 433.75 U/g substrate respectively, as compared to 1.72 U/g substrate, 23.01 U/g substrate, 2.18 U/g substrate, and 45.46 U/g substrate for FPase, CMCase, β-glucosidase, and xylanase, respectively, when alkali-pretreated substrate was used. The results of the X-ray diffractogram analysis showed an increase in relative crystallinity of cellulose in alkali-pretreated rice straw (62.41%) compared to 50.81% in untreated rice straw. However, the crystalline structure of cellulose was partially disrupted after alkali pretreatment, resulting in a decrease in absolute crystallinity of cellulose. The higher the crystallinity of cellulose, the more cellulase production was induced. The structural changes of rice straw before and after alkali pretreatment were compared by using Scanning Electron Microscopy. Fungal mycelial growth was also observed for both untreated and alkali-pretreated substrates. The results of this study indicated that untreated rice straw is a better substrate for cellulase and xylanase production under solid-state fermentation with low environmental impact.

Download PDF

Full Article

Effect of Alkali Pretreatment of Rice Straw on Cellulase and Xylanase Production by Local Trichoderma harzianum SNRS3 under Solid State Fermentation

Nooshin Rahnama,a Suhaila Mamat,a Umi Kalsom Md Shah,a,b,* Foo Hooi Ling,a,c Nor Aini Abdul Rahman,a and Arbakariya B. Ariff a

Use of alkali-pretreated rice straw and untreated rice straw as substrates for enzyme production under solid-state cultivation was investigated. Cellulase produced from untreated rice straw showed higher activity of FPase, CMCase, β-glucosidase, and xylanase at 6.25 U/g substrate, 111.31 U/g substrate, 173.71 U/g substrate, and 433.75 U/g substrate respectively, as compared to 1.72 U/g substrate, 23.01 U/g substrate, 2.18 U/g substrate, and 45.46 U/g substrate for FPase, CMCase, β-glucosidase, and xylanase, respectively, when alkali-pretreated substrate was used. The results of the X-ray diffractogram analysis showed an increase in relative crystallinity of cellulose in alkali-pretreated rice straw (62.41%) compared to 50.81% in untreated rice straw. However, the crystalline structure of cellulose was partially disrupted after alkali pretreatment, resulting in a decrease in absolute crystallinity of cellulose. The higher the crystallinity of cellulose, the more cellulase production was induced. The structural changes of rice straw before and after alkali pretreatment were compared by using Scanning Electron Microscopy. Fungal mycelial growth was also observed for both untreated and alkali-pretreated substrates. The results of this study indicated that untreated rice straw is a better substrate for cellulase and xylanase production under solid-state fermentation with low environmental impact.

Keywords: Alkali pretreatment; Rice straw; Cellulase; Xylanase; Trichoderma; Solid state fermentation

Contact information: a: Department of Bioprocess Technology, Faculty of Biotechnology and Biomolecular Sciences, Universiti Putra Malaysia; b: Institute of Tropical Forestry and Forest Products; c: Institute of Bioscience, Universiti Putra Malaysia, 43400 Serdang, Selangor, Malaysia;

* Corresponding author’s e-mail: umi@biotech.upm.edu.my

INTRODUCTION

Lignocellulose is one of the cheapest complex organic carbons that exist in nature in abundance in the form of plant biomass. Cellulose, hemicellulose, and lignin are the three major constituents of lignocellulosic substrates (Badhan et al. 2007). Rice straw is a main agricultural by-product in many countries in which rice is a major crop (Sun et al. 2008). Being considered a renewable resource, rice straw can be converted to biofuels through the application of biotechnology. An environmentally friendly method of rice straw disposal can save energy by conversion of this agricultural waste into value-added products (Chang et al. 2011). Cellulases are currently regarded as the third largest volume of industrial enzyme (Singhania et al. 2010). Cellulolytic enzymes have a wide range of applications in industry including biomass hydrolysis for the production of biofuels. For cellulase production, the use of lignocellulosic biomass along with the application of cost-effective fermentation strategies such as solid-state fermentation (SSF), have been suggested (Sukumaran et al. 2009). SSF is cost-effective due to the production of higher titers of cellulases. This could be attributed to the similarity of fermentation conditions to those in a natural environment (Singhania et al. 2010). Solid-state cultivation is considered advantageous in comparison to submerged fermentation (Kang et al. 2004; Singhania et al. 2009; Vu et al. 2009). Tengerdy (1996) reported a 10-fold decrease in the production cost of cellulases. Cost-effective production of cellulase, high productivity of enzymes being produced, and generation of less effluent are all positive aspects of SSF that contribute to its superiority over submerged fermentation (Singhania et al. 2010).

The pretreatment process aims at making cellulose more accessible to enzymes for hydrolysis in order to be converted to biofuels, and this may be achieved by lignin removal (Hu et al. 2008; Kumar et al. 2009). Over the past few years, a variety of pretreatment techniques have been developed including alkali pretreatment. However, pretreatment can be the most costly process in the production of biofuels (Kumar et al. 2009).

This study investigated the effect of alkali pretreatment of rice straw as the substrate for SSF on cellulase and xylanase production. Therefore, we made a comparison between the alkali-pretreated and untreated rice straw for cellulase and xylanase production.

EXPERIMENTAL

Substrate Preparation and Pretreatment

Rice straw that was obtained from a rice field in Sekinchan, Selangor, Malaysia was ground to 2 mm in size and kept in a cold room at 4 °C prior to use; this was defined as untreated rice straw throughout this study. The alkali pretreatment of rice straw was conducted with 1:10 ratio by using 0.5 % (w/v) NaOH [1 g rice straw in 10 mL of 0.5% (w/v) NaOH solution]. Rice straw was then autoclaved at 121 °C for 20 min. Alkali-pretreated rice straw was then washed with tap water and neutralized to around pH 7 using HCl. After being rinsed with distilled water and oven dried overnight at 60 °C, it was stored at 4 °C prior to use.

Strain Maintenance and Inoculum Preparation

A local isolate of Trichoderma harzianum SNRS3 was used. The fungus was isolated from rice straw collected from a rice field in Sekinchan, Selangor, Malaysia. The fungal spores were kept in 30% (v/v) glycerol at minus 20 °C. Reactivation of the spores was performed by growing on Potato Dextrose Agar (PDA) for 7 to 9 days. Spore suspension was freshly prepared prior to fermentation experiment by washing the agar surface with sterilized distilled water. The spores were then quantified and adjusted to 1×106 spores mL-1 by using a haemocytometer.

Fermentation

SSF was the method applied for cellulase enzyme production. A series of 250 mL Erlenmeyer flasks with cotton stoppers were autoclaved and used for the production and collection of the enzymes. Three grams of untreated and alkali-pretreated rice straw were placed separately in different flasks. Mandels medium (Mandels et al. 1974) was added to each flask containing the rice straw, and the moisture content was kept at 65% (w/v). Mandels medium (1 L) contained 1.4 g (NH4)2SO4, 2 g KH2PO4, 0.63 g urea, 0.3 g CaCl2, 0.3 g MgSO4.7H2O, 1 mL of Trace elements, 0.75 g peptone, and 2 mL Tween 80. The pH of the medium was adjusted to 5. The flasks were then incubated at 30 °C prior to the extraction of crude enzyme. The extraction of crude enzyme mixture was carried out by adding 30 mL of 50 mM citrate buffer (pH 4.8) into each flask, followed by agitation for 30 min at 150 rpm and 30 °C. The mixture was then centrifuged at 4 ºC and 1000 × g for 10 min. The supernatant was filtered and kept at 4 °C prior to use.

Analytical Procedure

Cellulose, hemicellulose, and lignin were determined using the method described by Goering and Van Soest (1970). The activity of the crude enzyme was assayed using the method described by Wood and Bhat (1988). Carboxymethylcellulase (CMCase) activity was determined by estimating the reducing sugars produced from 1% (w/v) carboxymethylcellulose, whereas Filter Paperase (FPase) activity was determined by measuring the reducing sugars released from Whatman filter paper No.1. The liberated reducing sugars were measured using the DNS method (Miller 1959). The reactions were carried out in 1.8 mL of 0.05 M sodium citrate buffer pH 4.8 and incubated at 40 ºC for 30 min for CMCase and for 1 h for FPase assay. One unit of CMCase and FPase activity was defined as the amount of enzyme that liberated 1 µmol reducing sugars/min under assay conditions and expressed as a unit of enzyme activity per gram fermented substrate (U/g). For β-glucosidase assay, the ρ-nitrophenol liberated from ρ-nitrophenyl-ß-D-glucopyranoside (PNPG) was determined spectrophotometrically (Wood and Bhat 1988). The reaction mixture was incubated at 40 °C for 30 min. One unit of β-glucosidase was defined as the amount of enzyme that liberated 1 µmol ρ-nitrophenol/min under assay condition and expressed as a unit of enzyme activity per gram fermented substrate (U/g). Xylanase activity was assayed by estimating the reducing sugars released from 1% (w/v) Birchwood xylan (Dong et al. 1992; Ling 1994). One unit of xylanase activity was defined as the amount of enzyme that liberated 1 µmol reducing sugars/min under assay condition and expressed as a unit of enzyme activity per gram fermented substrate (U/g). The reaction was carried out in 1.8 mL of 0.05 M sodium citrate buffer pH 4.8 and incubated at 40 ºC for 30 min.

Protein content was determined by a modified method described by Lowry et al. (1951) using bovine serum albumin as a standard reference. The crystallinity percentage of untreated rice straw and alkali-pretreated rice straw was determined using an x-ray diffractometer (XRD 6000 Shimadzu). The x-ray unit was operated at 40 kV and 30 mA. The θ-2θ method was applied to collect the diffraction spectra (Fan et al. 1980; Kim et al. 2003; Segal et al. 1959), and samples were scanned over the angular range of 2 to 40° 2θ. The crystallinity index was calculated with Equation (1), using the intensities of crystalline and amorphous regions, where I is the intensity of crystalline and amorphous regions at 2θ=22.28 and 18.64, respectively.

Crystallinity index (CrI) = (I crystalline ¯ I amorphous) / I crystalline × 100 (1)

Fourier Transform Infrared Spectroscopy (FTIR) spectra of untreated and pretreated rice straw were obtained by direct transmittance using the KBr pellet technique. Spectra were recorded using Perkin-Elmer spectrometer 100 (USA). The spectra of 500 to 4000 cm-1 were measured at a spectral resolution of 4 cm-1 and 64 scans per sample.

Scanning Electron Microscopy (SEM) was used to study the morphological changes of the fiber structure and mycelial growth on untreated and alkali-pretreated rice straw. Dried samples were coated with gold–palladium according to the method of Pathan et al. (2008) and then observed by a scanning electron microscope (LEO 1455 VP SEM attached with EDX) at a voltage of 20 kV.

RESULTS AND DISCUSSION

Rice Straw Pretreatment

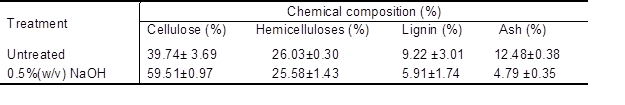

Table 1 shows the content of cellulose, hemicellulose, lignin, and ash of rice straw before and after pretreatment. Delignification of rice straw by alkali pretreatment resulted in a decrease in lignin content from 9.22% in untreated rice straw to 5.91% in pretreated rice straw, while hemicelluloses were decreased from 26.03% to 25.58%. However, cellulose content was increased from 39.74% to 59.51% in alkali-pretreated rice straw.

Table 1. Chemical Composition of Rice Straw Before and After Alkali Pretreatment

These results were in agreement with Zhu et al. (2005), who had reported that alkali pretreatment [1% (w/v) NaOH] increased the cellulose content to 65.4%, whereas lignin and hemicelluloses content were reduced to 6.0% and 14.3%, respectively. Zhu et al. (2006) also studied the effect of three combinations of microwave/chemical pretreatment techniques on rice straw composition. Among microwave/alkali, microwave/acid/alkali, and microwave/acid/alkali/H2O2, microwave/acid/alkali/H2O2 resulted in the highest total weight loss, the highest rise in the amount of cellulose, and the lowest moisture, ash, lignin, and hemicellulose content. As a result of this pretreatment, cellulose content increased to 80.6% while there was a reduction in lignin and hemicelluloses content to 3.8% and 3.2%, respectively. The reduction in lignin and hemicelluloses content indicated the efficient removal of lignin and hemicelluloses in rice straw. The highest cellulose content was obtained as a result of efficient removal of the other components and its low loss using this pretreatment method. The lowest moisture probably was obtained due to the pretreatment, where pore size of cellulose fiber was enlarged, leading to a decrease of water bound to rice straw. Furthermore, Hideno et al. (2009) studied the effect of wet disk milling pretreatment, hot-compressed water pretreatment, and ball milling pretreatment on rice straw composition. Among the pretreatment techniques, wet disk milling pretreatment was shown to be the most efficient method for pretreatment of rice straw for enzymatic hydrolysis and yield of reducing sugars. In another study, Niu et al. (2009) investigated the effect of using 1.5% (w/v) NaOH assisted by 2 g/L nano-TiO2 on delignification of rice straw. The pretreatment resulted in a reduction in lignin and hemicellulose content from 18.5% and 38.5% in untreated rice straw to 13.3% and 25% in the alkali-pretreated sample and to 9% and 13% in alkali assisted by photocatalysis pretreated rice straw, respectively. However, there was a rise in cellulose content from 37.5% in untreated sample to 55.7% and 71.5% in alkali-pretreated sample and when photocatalysis technology was used to assist alkali pretreatment of rice straw, respectively.

Natural substrates are normally not suitable as fermentation substrates for the growth of fungi, and the growth of the fungus is usually very slow. Therefore, the choice of an appropriate pretreatment is required to overcome this limitation. However, pretreatment methods induce structural changes in the substrate, which in turn could alter physiochemical properties of the substrate. Changes in physiochemical attributes of the substrate such as crystallinity, bed porosity, and volumetric specific surface could affect cellulolytic enzyme production (Brijwani and Vadlani 2011). Brijwani and Vadlani (2011) mentioned that consumption of some of the alkali by the biomass itself could be considered as an outstanding feature of alkali pretreatment. Consequently, changes occurring due to the effect of alkali pretreatment cause lignin, and hemicellulose to solubilize, distribute, and condense and may result in modification of the cellulosic structure as well. On the other hand, such effects are likely to counter the positive sides of an alkali pretreatment. SSF is a method for enzyme production in which fungal mycelium is in direct contact with substrate particles. This characteristic of solid state cultivation makes the physiochemical nature of the substrate perhaps as important as its composition. To elucidate the significance of physiochemical characteristics of the substrate for enzyme production under SSF, Brijwani and Vadlani (2011) demonstrated that higher activity of cellulases was produced when steam-pretreated soybean hulls were used as the fermentation substrate compared to when the enzyme was produced from the native substrate. According to Brijwani and Vadlani (2011), the higher production of the enzyme could be due to a difference in physiochemical properties of the native and steam-pretreated substrate, since they had compositional similarity.

Enzyme Activity and Protein Profile

Figure 1 shows a higher activity of FPase (6.25 U/g substrate) was obtained when untreated rice straw was used as substrate as compared to 1.72 U/g substrate of FPase when the fermentation substrate was alkali pretreated.

Figure 2 depicts the time course profile of CMCase and β-glucosidase production by the local T. harzianum SNRS3 under SSF from untreated and alkali-pretreated rice straw. The activity of CMCase and β-glucosidase were 111.31U/g substrate and 173.71U/g substrate, respectively, when untreated rice straw was employed as the fermentation substrate. However, when pretreated substrate was used for SSF, much lower production of CMCase and β-glucosidase were obtained, with 23.01 U/g substrate and 2.18 U/g substrate, respectively.

Figure 3 shows that alkali-pretreated substrate resulted in the production of 433.75 U/g substrate xylanase when untreated rice straw was used as substrate. However, xylanase was produced with the activity of 45.46 U/g substrate when alkali-pretreated substrate was applied. The highest FPase and CMCase were produced on day 6 of fermentation, whereas the highest activity of β-glucosidase and xylanase were obtained on day 7 of fermentation for both untreated and alkali-pretreated substrates.

Using an alkali pretreatment, the crystalline structure of cellulose in rice straw could be partially disrupted. CellobiohydrolaseII (CBHII) is responsible for the hydrolysis of cellulose from the non-reducing end. The bigger the crystalline structure part is, the greater the amount of CBHII that will be secreted for hydrolysis. In a study carried out by Sun et al. (2008) using Trichoderma reesei, less production of CBHІІ was reported when NaOH-pretreated rice straw was used compared to non-pretreated ground rice straw used as cellulase inducer.

Fig. 1. FPase produced from untreated and pretreated rice straw. Values are means of 3 replicates with ± SD. Open symbols represent: pretreated rice straw; Closed symbols represent: untreated rice straw

Fig. 2. CMCase and β-glucosidase from untreated and pretreated rice straw. Values are means of 3 replicates with ± SD. Symbols represent: (▲) CMCase activity; (♦) β-glucosidase activity. Open symbols represent: pretreated rice straw; Closed symbols represent: untreated rice straw

Fig. 3. Xylanase from untreated and pretreated rice straw. Values are means of 3 replicates with ± SD. Open symbols represent: pretreated rice straw; Closed symbols represent: untreated rice straw

Figure 4 depicts the protein profile of untreated rice straw compared to alkali-pretreated rice straw. A higher protein concentration was obtained when untreated rice straw was used as substrate as compared to the pretreated substrate.

Fig. 4. Protein profile of untreated and pretreated rice straw. Values are means of 3 replicates with ± SD. Open symbols represent: pretreated rice straw; Closed symbols represent: untreated rice straw

To make a comparison between the results obtained in this research and other findings, the yields of each enzyme are presented in Table 2.

Table 2. Enzyme Yields under Solid State Fermentation by Different Fungal Isolates Grown on Lignocellulosic Substrates

Note: ⃰ Untreated carbon sources were used in respective experiment.

Table 2 shows a comparison between the results obtained in this study and other findings. According to the results obtained in this research, when rice straw was used as fermentation substrate, the enzyme activities were increased 2.56-, 3.38-, and 23.22-fold in FPase, CMCase, and β-glucosidase, respectively, in comparison with those obtained from Myceliophthora sp.IMI 387099. However, lower FPase, CMCase, and β-glucosidase were obtained when wheat straw, bagasse, corn cob, and wheat bran were used as the substrate, as reported by Badhan et al. 2007 (Table 2). Substrate nature affects the production of cellulase and hemicellulase. Therefore, an appropriate inducing substrate becomes an important factor in fermentation. The aforementioned results in Table 2 indicate that rice straw is a potential substrate for SSF, besides corn stover. The results also showed that FPase, CMCase, and β-glucosidase activities increased 1.07-, 8.84-, and 10.98-fold, respectively, compared to those obtained when Aspergillus ustus was grown on rice straw as reported by Shamala and Sreekantiah (1986) (Table 2). The results of this study also demonstrated a 2.70-fold increase in FPase activity compared to that obtained in the cultivation of Trichoderma reesei MCG77 using rice bran as reported by Latifian et al. (2007). The comparisons of cellulase activities obtained in this study with those reported for other cellulase producing fungi showed that this local fungus can even perform better than the mutants regarding β-glucosidase production. The activity of β-glucosidase for the local T. harzianum SNRS3 under SSF was increased 10.98-fold as compared to 3.76-, 1.73-, 1.35 -, and 23.22-fold that obtained from other fungi grown on lignocellulosic biomass as reported by Shamala and Sreekantiah (1986); Kalogeris et al. (1999); Kang et al. (2004); Gao et al. (2008); and Badhan et al. (2007), respectively. Accumulation of cellobiose due to insufficient amount of β-glucosidase in the cellulase system will result in inhibition of cellobiohydrolase and endoglucanase. Therefore, to avoid inhibition of cellobiohydrolase and endoglucanase, it is crucial for β-glucosidase to be present in significant quantity (Hamzah et al. 2011).

XRD Analysis

Figure 5 presents X-ray diffractograms for both untreated rice straw and alkali-pretreated substrates. Two peaks appeared at 2θ of 18.64º and 22.28º, representing amorphous and crystalline regions of the samples.

Percentage crystallinity [CrI (%)] of untreated rice straw and alkali-pretreated rice straw were 50.81% and 62.41%, respectively. Cellulose is a complex polymer that consists of crystalline and amorphous regions. Crystallinity is defined as the ratio of the amount of crystalline area in a cellulosic material to the total amount of cellulose sample, which includes both crystalline and amorphous areas. Based on the results of XRD analysis, there was a rise in the crystallinity of cellulose from 50.81% in untreated rice straw to 62.41% in NaOH-pretreated rice straw. This could be attributed to the hydrolysation and peeling of amorphous regions during pretreatment, resulting in the rise in relative crystallinity of cellulose after pretreatment. However, absolute crystallinity of cellulose decreased after pretreatment, indicating that NaOH could partially disrupt the crystalline area. The results obtained in this study are in agreement with He et al. (2008), who reported an increase in the crystallinity of rice straw from 60.26% in untreated substrate to 64.33% in NaOH-pretreated rice straw. In a study conducted by Bak et al. (2009), rice straw was pretreated using electron beam irradiation, and this pretreatment resulted in an increase in crystalline portion of rice straw which is mainly cellulose from 54.5% in untreated rice straw to 58.0% in electron beam irradiated pretreated rice straw.

The increase in crystalline portion of pretreated rice straw could be due to the loss of amorphous regions. Hemicellulose and lignin, which mainly constitute amorphous regions of rice straw, are hydrolysed during the pretreatment process, and this leads to more cellulose being exposed after pretreatment in rice straw. Based on the results of XRD analysis of untreated rice straw and electron beam irradiated pretreated rice straw, the intensity of the crystalline region showed an increase in the pretreated rice straw compared to those of amorphous and crystalline regions in untreated rice straw. Hsu et al. (2010) pretreated rice straw using dilute sulfuric acid and reported a crystallinity index of 57% for untreated rice straw. The crystallinity for the acid-pretreated rice straw was different, ranging from 58% to 65%, and it kept increasing as the pretreatment temperature was increased from 160 ºC to 180 ºC. The increase in pretreatment temper-ature resulted in the breakdown of the hydrogen bonds within the crystalline region of cellulose and consequently increased the amount of amorphous cellulose in the sample.

Manning and Wood (1983) reported a lag in the production of extracellular enzyme when Agaricus bisporus was grown on carboxymethylcellulose. This could be attributed to the simple, easily degradable structure of the substrate. Therefore, only small amounts of cellulase are required for degradation of the substrate and monomeric sugar production. However, as the substrate becomes more complex in the structure, more cellulase is produced so that the growth could be well maintained. Ciolacu et al. (2008) and Hall et al. (2010) have shown the significance of the crystallinity of a cellulosic substrate in cellulose degradation rate.

Sun et al. (2008) reported that the more crystallinity of cellulose, the more cellulase production would be induced. Brijwani and Vadlani (2011) reported that crystallinity of a cellulosic substrate not only influenced the quality of the enzymes produced, but also the quantity of the enzymes. Yoon and Kim (2005) reported the production of cellulases as a result of the growth of Fomitopsis palustris on 2% (w/v) Avicel as carbon source, whereas in the presence of 2% glucose, cellulases were not detected. As a result of Avicel degradation by the fungal cellulases, a decrease in cellulose crystallinity from 83% to 78.5% was reported.

As a result of the alkali pretreatment, the structure of rice straw was disrupted, leading to a decrease in absolute crystallinity of cellulose. This reduction in the crystal-line portion of rice straw could impact cellulase production greatly. However, it is concluded that it was the whole complexity of the untreated rice straw structure that eventually resulted in higher cellulase production. Growing on a substrate with a complex structure makes it more challenging for the fungus to survive, and cellulose might act as a strong inducer for cellulase production in such a condition compared to when simple, easily degradable substrate is available for the fungus to consume. Therefore, more amounts of cellulase are required to degrade cellulose in order to produce monomeric sugars.

Fig. 5. X–ray diffraction diagram of untreated rice straw compared to alkali-pretreated rice straw

Scanning Electron Microscopy (SEM)

Figure 6 shows the SEM images for both untreated rice straw(A), (C) and alkali-pretreated substrate (B), (D) before and after being inoculated. The SEM observations revealed ultrastructural changes in rice straw following alkali pretreatment (B). A comparison between the structure of rice straw before and after pretreatment showed a smooth, rigid, and highly ordered structure for untreated rice straw, whereas pretreatment induced changes in the structure. The pretreatment disrupted the structure, leaving the substrate with an uneven, unsmooth, rough, and rugged surface, in which some parts of the outer surface were missing. These findings indicate the removal of some external fibers due to the pretreatment. The same changes have been reported after rice straw was pretreated by electron beam irradiation (Bak et al. 2009) and aqueous ammonia (Ko et al. 2009).

Numerous studies have demonstrated that the production of extracellular proteins by filamentous fungi is growth-rate associated (Carlsen et al., 1996; Spohr et al. 1998; Pedersen et al. 2000; Schrickx et al. 1993; Withers et al. 1998). Both growth and protein synthesis were found to be closely dependent on cellulose hydrolysis, and in many cellulolytic organisms, cellulase production and growth occur simultaneously (Manning and Wood 1983). According to the SEM images, it could be concluded that the fungus had better growth when it was grown on untreated rice straw (C). Using alkali-pretreated substrate, dehydrated, lysed, and shriveled mycelia were observed (D), indicating poor growth of the fungus, which could have been related to less cellulase production.

Fig. 6. Scanning electron micrographs of rice straw. (A) Untreated rice straw (x1000), (B) Alkali-pretreated rice straw (x1000), (C) Untreated fermented rice straw (x1000), (D) Alkali-pretreated fermented rice straw presenting lysed, shriveled, and dehydrated mycelium (x1000)

FTIR Analysis

FTIR spectroscopy was used to demonstrate the physical structure and changes in the functional groups of rice straw before and after pretreatment. FTIR spectroscopy of untreated rice straw and pretreated with 0.5% (w/v) NaOH is shown in Fig. 7. FTIR spectroscopy analysis showed obvious changes in the functional groups of lignin during pretreatment. The peaks located at 3400 cm־1 and 2900 cm־1 correspond to –OH stretching and –CH2 stretching, respectively. Both peaks indicate the distinguished features of cellulose (Sun et al. 2007). The most important functional groups of cellulose units include hydrogen bonds, methyls, methylenes, and C-O-C. In a study reported by He et al. (2008), the structural changes in cellulose during rice straw pretreatment using NaOH was investigated. According to the results of FTIR spectroscopy, spectra of rice straw for both untreated and NaOH-pretreated rice straw showed the same profile. However, the intensities of the absorption bands were different. The absorption peak at 3338 cm־1 is assigned to the stretching of –OH groups, which was diminished after NaOH pretreatment, suggesting that the partial hydrogen bond of cellulose was destroyed, enhancing the accessibility of cellulose to reagents (He et al. 2008). The peak located at 2918 cm־1 corresponds to the C-H stretching, the decrease of which content specifies some rupture in methyl and methylene of cellulose (He et al. 2008). The absorption band at 1639 cm־1 was diminished in the spectrum of pretreated rice straw. This absorption is assigned to the functional group that is present in the lignin (Viera et al. 2007). The band observed at 1427 cm־1 is due to C-H deformation within the methoxyl group of lignin. Since the absorption of the band was diminished after pretreatment, it is suggested that the release of lignin had occurred. The absorption peak located at 1368 cm־1 is associated with aromatic hydroxyl groups. The cleavage of ether bonds within the lignin may have caused the peak to appear (Hsu et al. 2010). A broad shoulder located at 1238 cm־1corresponds to C-O stretching of ether linkage. It was diminished in the spectrum of pretreated rice straw (Rosa et al. 2012). According to Viera et al. (2007), the decrease of this band indicates that lignin was diminished after the substrate was pretreated. The prominent band observed at 1033 cm־1 is typically related to the structural characteristics of cellulose and hemicelluloses (Hsu et al. 2010).

Fig. 7. FTIR spectroscopy of untreated (a) and alkali-pretreated (b) rice straw

CONCLUSIONS

1. Untreated rice straw was advantageous over alkali-pretreated rice straw as the substrate for SSF for cellulase and xylanase production. It was able to induce the production of cellulase and xylanase production better, and no chemical addition was needed. Therefore, it is more environmentally friendly.

2. The SEM images showed that the pretreatment process disrupted the hemicellulose and lignin, which might have caused the changes in the structure of cellulose. Alkali pretreatment of the substrate caused the crystallinity of cellulose to decrease. Absolute crystallinity could most impact cellulase production. However, the overall complexity of the untreated substrate might have actually induced greater enzyme production.

ACKNOWLEDGEMENT

The authors would like to extend their gratitude for the financial support generously provided by Ministry of Science, Technology and Innovation (MOSTI), Malaysia, grant NO. 02-01-04-SF1036.

REFERENCES CITED

Badhan, A. K., Chadha, B. S., Kaur, J., Saini, H. S., and Bhat, M. K. (2007). “Production of multiple xylanolytic and cellulolytic enzymes by thermophilic fungus Myceliophthora sp. IMI 387099,” Bioresource Technology 98, 504-510.

Bak, J. S., Ko, J. K., Han, Y. H., Lee, B. C., Choi, I. G., and Kim, K. H. (2009). “Improved enzymatic hydrolysis yield of rice straw using electron beam irradiation pretreatment,” Bioresource Technology 100, 1285-1290.

Brijwani, K., and Vadlani, P. V. (2011). “Cellulolytic enzymes production via solid-state fermentation: Effect of pretreatment methods on physiochemical characteristics of substrate,” Enzyme Research 2011, 1-10.

Carlsen, M., Nielsen, J., and Villadsen, J. (1996). “Growth and α-amylase production by Aspergillus oryzae during continuous cultivations,” Journal of Biotechnology 45, 81-93.

Chang, K. L., Thitikorn-amorn, J., Hsieh, J. F., Ou, B. M., Chen, S. H., Ratanakhanokchai, K., Huang, P. J., and Chen, S. T. (2011). “Enhanced enzymatic conversion with freeze pretreatment of rice straw,” Biomass and Bioenergy 35, 90-95.

Ciolacu, D., Ciolacu, F., and Popa, V.I. (2008). “Supramolecular structure – A key parameter for cellulose biodegradation,” Macromolecular Symposia 272, 136-142.

Fan, L. T., Lee, Y. H., and Beardmore, D. H. (1980). “Mechanism of the enzymatic hydrolysis of cellulose: Effects of major structural features of cellulose on enzymatic hydrolysis,” Biotechnology and Bioengineering 22, 177-199.

Gao, J., Weng, H., Zhu, D., Yuan, M., Guan, F., and Xi, Y. (2008). “Production and characterization of cellulolytic enzymes from the thermoacidophilic fungal Aspergillus Terreus M11 under solid state cultivation of corn stover,” Bioresource Technology 99, 7623-7629.

Goering, H. K., and Van Soest, P. J. (1970). “Forage fiber analysis (apparatus, reagents, procedures and some applications),” Agricultural Handbook No.379. Agricultural Research Service- United States Department of Agriculture, Washington, DC.

Hall, M., Bansal, P., Lee, J. H., Realff, M. J., and Bommarius, A. S. (2010). “Cellulose crystallinity – A key predictor of the enzymatic hydrolysis rate,” FBES Journal 277, 1571-1582.

Hamzah, F., Idris, A., and Shuan, T.K. (2011). “Preliminary study on enzymatic hydrolysis of treated oil palm (Elaeis) empty fruit bunches fibre (EFB) by using combination of cellulase and β 1-4 glucosidase,” Biomass and Bioenergy 35, 1055-1059.

He, Y., Pang, Y., Liu, Y., Li, X., and Wang, K. (2008). “Physiochemical characterization of rice straw pretreated with sodium hydroxide in the solid state for enhancing biogas production,” Energy and Fuels Vol. 22, 2775-2781.

Hideno, A., Inoue, H., Tsukahara, K., Fujimoto, S., Minowa, T., Inoue, S., Endo, T., and Sawayama, S. (2009). “Wet disk milling pretreatment without sulfuric acid for enzymatic hydrolysis of rice straw,” Bioresource Technology 100, 2706-2711.

Hsu, T. C., Guo, G. L., Chen, W. H., and Hwang, W. S. (2010). “Effect of acid pretreatment of rice straw on structural properties and enzymatic hydrolysis,” Bioresource Technology 101, 4907-4913.

Hu, G., Heitmann, J. A., and Rojas, O. J. (2008). “Feedstock pretreatment strategies for producing ethanol from wood, bark and forest residues,” BioResources 3(1), 270-291.

Kalogeris, E., Fountoukides, G., Kekos, D., and Macris, B. J. (1999). “Design of a solid-state bioreactor for thermophilic microorganisms,” Bioresource Technology 67, 313-315.

Kang, S. W., Park, Y. S., Lee, J. S., Hong, S. I., and Kim, S. W. (2004). “Production of cellulases and hemicelluloses by Aspergillus niger KK2 from lignocellulosic biomass,” Bioresource Technology 91,151- 156.

Kim, T. H., Kim, J. S., Sunwoo, C., and Lee, Y. Y. (2003). “Pretreatment of corn stover by low liquid ammonia recycle percolation process,” Applied Biochemistry and Biotechnology 133, 41-57.

Ko, J. K., Bak, J. S., Jung, M. W., Lee, H. J., Choi, I.-G., Kim, T. H., and Kim, K.H. (2009). “Ethanol production from rice straw using optimized aqueous-ammonia soaking pretreatment and simultaneous saccharification and fermentation processes,” Bioresource Technology 100, 4374-4380.

Kumar, P., Barrett, D. M., Delwiche, M. J., and Stroeve, P. (2009). “Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuels production,” Industrial Engineering and Chemical Research 46, 3713-3729.

Latifian, M., Hamidi-Esfahani, Z., and Barzegar, M. (2007). “Evaluation of culture conditions for cellulase production by two Trichoderma reesei mutants under solid-state fermentation conditions,” Bioresource Technology 9, 3634-3637.

Lowry, O. H., Rosebrough, N. J., Farr, A. L., and Randall, R. J. (1951). “Protein measurement with the folin phenol reagent,” The Journal of Biological Chemistry 193, 265-275.

Mandels, M., Hontz, I., and Nystrom, J. (1974). “Enzymatic hydrolysis of waste cellulose,” Biotechnology and Bioengineering 16, 1471-1493.

Manning, K., and Wood, D. A. (1983). “Production and regulation of extracellular endocellulase by Agaricus bisporus,” Journal of General Microbiology 129, 1839-184.

Miller, G. L. (1959). “Use of dinitrosalicylic acid for determination of reducing sugar,” Analytical Chemistry 31(3), 426-428.

Niu, K., Chen, P., Zhang, X., and Tan, W. S. (2009). “Enhanced enzymatic hydrolysis of rice straw pretreated by alkali assisted with photocatalysis technology,” Journal of Chemical Technology and Biotechnology 84, 1240-1245.

Pathan, A.K., Bond, J., and Gaskin, R.E. (2008). “Sample preparation for scanning electron microscopy of plant surfaces – Horses for courses” Micron 39: 1049-1061.

Pedersen, H., Beyer, M., and Nielsen, J. (2000). “Glucoamylase production in batch, chemostat, and fed-batch cultivations by an industrial strain of Aspergillus niger,” Applied Microbiology and Biotechnology 53, 272-277.

Rosa, S. M. L., Rehman, N., De Miranda, M. I. G., Nachtigall, S. M., and Bica, C. I. D. (2012). “Chlorine-free extraction of cellulose from rice husk and whisker isolation,” Carbohydrate Polymers 87, 1131-1138.

Schrickx, J. M., Krave, A. S., Verdoes, J. C., van den Hondel, C. A., Stouthamer, A. H., and van Verseveld, H. W. (1993). “Growth and product formation in chemostat and recycling cultures by Aspergillus niger N402 and a glucoamylase overproducing transformant, provided with multiple copies of the glaA gene,” Journal of General Microbiology 139, 2801-2810.

Segal, L., Creely, J. J., Martin, A. E. Jr, and Conrad, C. M. (1959). “An empirical method for estimating the degree of crystallinity of native cellulose using the x-ray diffractometer,” Textile Research Journal 29, 786-794.

Shamala, T. R., and Sreekantiah, K. R. (1986). “Production of cellulases and D-xylanase by some selected fungal isolates,” Enzyme and Microbial Technology 8, 178-182.

Singhania, R. R., Patel, A. K., Soccol, C. R., and Pandey, A. (2009). “Recent advances in solid state fermentation,” Biochemical Engineering Journal 44 (1),13-18.

Singhania, R. R., Sukumaran, R. K., Patel, A. K., Larroche, C., and Pandey, A. (2010). “Advancement and comparative profiles in the production technologies using solid-state and submerged fermentation for microbial cellulases,” Enzyme and Microbial Technology 46, 541-549.

Spohr, A., Carlsen, M., Nielsen, J., and Villadsen, J. (1998). “α-amylase production in recombinant Aspergillus oryzae during fed-batch and continuous cultivations,” Journal of Fermentation and Bioengineering 86, 49-56.

Sukumaran, R. K., Singhania, R. R., Mathew, G. M., and Pandey, A. (2009). “Cellulase production using biomass feedstock and its application in lignocellulose saccharification for bio-ethanol production,” Renewable Energy 34, 421-424.

Sun, W. C., Cheng, C. H., and Lee, W. C. (2008). “Protein expression and enzymatic activity of cellulases produced by Trichoderma reesei Rut C-30 on rice straw,” Process Biochemistry43(10), 1083-1087.

Sun, Y., Lin, L., Pang, C., Deng, H., Peng, H., and Li, J. (2007). “Hydrolysis of cotton fiber cellulose in formic acid,” Energy and Fuels 21, 2386-2389.

Tengerdy, R. P. (1996). “Cellulase production by solid substrate fermentation,” Journal of Scientific and Industrial Research 55, 313-316.

Viera, R. G. P., Filho, G. R., Assuncao, R. M. N., Da, S., Meireles, C., Vieira, J. G., and De Oliveira, G. S. (2007). “Synthesis and characterization of methylcellulose from sugar cane bagasse cellulose,” Carbohydrate Polymers 67, 182-189.

Vu, V. H., Pham, T. A., and Kim, K. (2009). “Fungal strain improvement for cellulase production using repeated and sequential mutagenesis,” Mycobiology 37(4), 267-271.

Withers, J. M., Swift, R. J., Wiebe, M. G., Robson, G. D., Punt, P. J., van den Hondel, C. A. M. J. J., and Trinci, A. P. J. (1998). “Optimisation and stability of glucoamylase production by recombinant strains of Aspergillus niger in chemostat culture,” Biotechnology and Bioengineering 59, 407-418.

Wood, T. M., and Bhat, K. M. (1988). “Measuring cellulase activities,” Methods in Enzymology 160, 87-112.

Yoon, J.-J., and Kim, Y-K. (2005). “Degradation of crystalline cellulose by the brown-rot basidiomycete Fomitopsis palustris,” The Journal of Microbiology 43(6), 487-492.

Zhu, S., Wu, Y., Yu, Z., Liao, J., and Zhang, Y. (2005). “Pretreatment by microwave/ alkali of rice straw and its enzymatic hydrolysis,” Process Biochemistry 40, 3082-3086.

Zhu, S., Wu, Y., Yu, Z., Wang, C., Yu, F., Jin, S., Ding, Y., Chi, R., Liao, J., and Zhang, Y. (2006). “Comparison of three microwave/chemical pretreatment processes for enzymatic hydrolysis of rice straw,” Biosystems Engineering 93(3), 279-283.

Article submitted: January 23, 2013; Peer review completed: March 3, 2013; Revised version received and accepted: April 13, 2013; Published: April 26, 2013.