Abstract

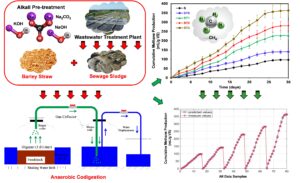

Straw pretreatment enhances the cellulose accessibility and increases the methane yield from anaerobic digestion. This study investigated the effects of alkali pretreatments with different chemical agents (NaOH, KOH, and Na2CO3) on the physicochemical and thermal characteristics of barley straw, as well as methane production from codigestion with sewage sludge. Artificial neural network modeling with a feedforward neural network (FFNN) and slime mold optimization (SMO) techniques were used to predict methane production. NaOH pretreatment was shown to be the best pretreatment for removing hemicellulose and lignin and for increasing the cellulose accessibility. Moreover, there was a 2.57-fold higher level of methane production compared to that from codigestion with untreated straw. The removal ratios for the total solids, volatile solids, and chemical oxygen demand reached 59.3, 67.2, and 73.4%, respectively. The modeling results showed that the FFNN-SMO method can be an effective tool for simulating the methane generation process, since training, validating, and testing produced very high correlation coefficients. The FFNN-SMO accurately predicted the amount of methane produced, with an R2 of 0.998 and a 3.1×10-5 root mean square error (RMSE).

Download PDF

Full Article

Effect of Alkaline Pretreatment on the Characteristics of Barley Straw and Modeling of Methane Production via Codigestion of Pretreated Straw with Sewage Sludge

Raid Alrowais,a Mahmoud M. Abdel daiem,b,c Ahmed M. Helmi,d,e Basheer M. Nasef,e Ananda Rao Hari,f Pascal Saikaly,f,g and Noha Said b,*

Straw pretreatment enhances the cellulose accessibility and increases the methane yield from anaerobic digestion. This study investigated the effects of alkali pretreatments with different chemical agents (NaOH, KOH, and Na2CO3) on the physicochemical and thermal characteristics of barley straw, as well as methane production from codigestion with sewage sludge. Artificial neural network modeling with a feedforward neural network (FFNN) and slime mold optimization (SMO) techniques were used to predict methane production. NaOH pretreatment was shown to be the best pretreatment for removing hemicellulose and lignin and for increasing the cellulose accessibility. Moreover, there was a 2.57-fold higher level of methane production compared to that from codigestion with untreated straw. The removal ratios for the total solids, volatile solids, and chemical oxygen demand reached 59.3, 67.2, and 73.4%, respectively. The modeling results showed that the FFNN-SMO method can be an effective tool for simulating the methane generation process, since training, validating, and testing produced very high correlation coefficients. The FFNN-SMO accurately predicted the amount of methane produced, with an R2 of 0.998 and a 3.1×10-5 root mean square error (RMSE).

DOI: 10.15376/biores.19.2.2179-2200

Keywords: Alkali pretreatment; Barley straw; Anaerobic digestion; Artificial neural networks (ANNs); Slime mold optimizer (SMO)

Contact information: a: Department of Civil Engineering, College of Engineering, Jouf University, Sakakah 72388, Saudi Arabia; b: Environmental Engineering Department, Faculty of Engineering, Zagazig University, Zagazig, 44519, Egypt; c: Civil Engineering Department, College of Engineering, Shaqra University, 11911, Dawadmi, Ar Riyadh, Saudi Arabia; d: Computer Engineering Department, Engineering and Information Technology College, Buraydah Private Colleges, Buraydah, 51418, Saudi Arabia; e: Computer and Systems Engineering Department, Faculty of Engineering, Zagazig University, Zagazig 44519, Egypt; f: Water Desalination and Reuse Center (WDRC), Biological and Environmental Science and Engineering (BESE) Division, King Abdullah University of Science and Technology (KAUST), Thuwal 23955-6900, Kingdom of Saudi Arabia; g: Environmental Science and Engineering Program, Biological and Environmental Science and Engineering (BESE) Division, King Abdullah University of Science and Technology (KAUST), Thuwal 23955-6900, Kingdom of Saudi Arabia;

* Corresponding author: nsmohammed@zu.edu.eg

GRAPHICAL ABSTRACT

INTRODUCTION

Biochemical conversion to biogas through anaerobic digestion is more economically viable and environmentally friendly than other physicochemical and thermochemical methods, as it requires moderate conditions and is less energy intensive (Sabeeh et al. 2020). Biogas is an attractive source of renewable vehicular fuel and energy for electricity and heat production (Said et al. 2020; Mirmohamadsadeghi et al. 2021). Sewage sludge is widely used for biogas production, since it is rich in nutrients, and optimum conversion of the organic components into biogas can be achieved (Abdel daiem and Said 2023). The production of biogas via anaerobic digestion is enhanced by codigestion with agricultural biomass waste (Abdel daiem et al. 2021b, 2022; Alrowais et al. 2023b). Agricultural wastes comprising lignocellulosic materials have attracted high interest as anaerobic digestion substrates due to their abundance and renewability (Aghbashlo et al. 2018). Straw biomass is one of the most abundant lignocellulosic materials found in nature. A small fraction of the straw is collected from fodder, bedding material, or incineration at heating plants, and after harvesting, a large amount is left in the field for open burning, which causes air pollution (Abdel Daiem and Said 2022).

Anaerobic digestion of lignocellulosic materials is limited due to their complex structures in which cellulose and hemicelluloses are tightly bound to the lignin and prevent microbial degradation (Rani et al. 2022). Cellulose and hemicellulose are biodegradable, while lignin is not easy to degrade via anaerobic digestion, and it is difficult for enzymes to contact the cellulose and hemicellulose, which leads to slow degradation (Du et al. 2019). Straw pretreatment is necessary to improve the accessibility of cellulose, lignin, and hemicelluloses and increase the biodegradation rate and biogas yield of anaerobic digestion (Ouahabi et al. 2021). Various pretreatment methods have been used in different studies and have had significant effects on enzymatic digestibility, lignin reduction and cellulosic crystallinity. Chemical pretreatment is highly effective at solubilizing hemicellulose and lignin (Sabeeh et al. 2020). Alkali pretreatment is an efficient and cost-effective approach. It removes the hemicellulose and lignin and increases the porosity and surface area of the straw (Tan et al. 2021). This process involves the addition of bases to the biomass, which leads to lignin breakdown, decreased crystallinity, and increases in the internal biomass surface area.

Recent studies have shown the significant effects of sodium hydroxide (NaOH), potassium hydroxide (KOH), and sodium carbonate (Na2CO3) pretreatments for improving methane production (Mirmohamadsadeghi et al. 2021; Ouahabi et al. 2021; Peyrelasse et al. 2021; Rani et al. 2022). Moreover, the incorporation of thermal pretreatment into chemical pretreatment has the benefits of decreasing chemical consumption and increasing biogas production (Dumlu et al. 2021). According to the literature and previous published studies (Patowary and Baruah 2018; Du et al. 2019; Mirmohamadsadeghi et al. 2021), thermoalkali pretreatment had a positive impact on substrate degradation and methane production for different contact times (1-9 h) based on the substrate type.

Recently, various artificial neural networks (ANNs) have been proposed for modeling experimental data related to bioenergy production. Because of their advantages compared to traditional methods, such as the capacity to learn intricate input/output relationships, parallel computing, and generalization, ANNs have emerged as the most popular choice for modeling and predicting a wide range of environmental issues (Barik and Murugan 2015; Abdel daiem et al. 2021a; Oloko-Oba et al. 2018; Alrowais et al. 2023a,b,c). The most important ANNs are feedforward neural networks (FFNNs), recurrent neural networks (RNNs), and nonlinear autoregressive exogenous (NARX) networks. A detailed review of studies on biogas production via ANNs has been presented in the literature (Alrowais et al. 2023b). Among ANNs, the FFNN is the most popular type of ANN and has shown high accuracy in modeling and predicting biogas and methane production. Ghatak and Ghatak (2018) used FFNNs to predict and model the biogas yield from anaerobic digestion of mixed compositions comprising cattle dung, bamboo dust, sugar-cane bagasse, and saw dust. Almomani (2020) used an FFNN for modeling methane production from the codigestion of cow manure and agricultural solid wastes. Şenol (2021) used an FFNN to model the methane yield from sewage sludge digestion. Beltramo et al. (2019) conducted FFNN modeling of the biogas production rate from digestion of maize and grass silages together with pig and cattle manure. Biogas production from anaerobic codigestion of waste activated sludge and wheat straw was modeled and predicted with FFNN modeling (Abdel daiem et al. 2021b).

Based on the oscillation modes of slime molds found in nature, a novel stochastic optimizer known as the slime mold algorithm (SMA) is proposed. It features a novel mathematical model with adaptive weighting to mimic the generation of positive and negative feedback from slime mold propagation waves based on a bio-oscillator to form the ideal path for connecting food; the SMA has exceptional exploratory ability and exploitation propensity, and the proposed SMA has several new features. To confirm its effectiveness, the proposed SMA was evaluated with the most recent metaheuristics via a large collection of benchmarks. In addition, the performance of the algorithm in optimizing constrained issues was estimated with four traditional engineering problems. The findings showed that the suggested SMA achieved competitive, frequently exceptional, performance across several search environments (Li et al. 2020). Most optimization approaches need their properties changed to fit the needs of the necessary applications. To avoid being trapped in local optima and to reduce the calculation time, slime mold optimization (SMO) features are also recommended.

Several studies have investigated the effects of pretreating different straw types to enhance methane production; however, studies related to barley straw (the highest crop residue in Saudi Arabia, 781,000 tons/year) are very limited (Abdel Daiem and Said 2022). Thus, the main objective of this work was to analyze the effects of different alkali pretreatments with the most effective chemical agents (NaOH, KOH, and Na2CO3) on the physical, thermal, and chemical characteristics of barley straw and to investigate the effect of pretreatment on enhancing methane production from digestion of the pretreated straw with sewage sludge. This study was also intended to model methane production with FFNN-SMO techniques and use the MATLAB program (2020a) to investigate the accuracies of these techniques in predicting and optimizing methane production.

EXPERIMENTAL

Materials and Methods

Sample collection

Barley straw samples were collected from a field in the Al Jouf region, Saudi Arabia. The samples were ground to particle size < 1 mm and stored at room temperature in plastic bags until subsequent use. Waste activated sludge samples were collected from the Sakaka wastewater treatment plant in the Al Jouf region and stored at 4 °C.

Lab analyses

Total solids (TS), volatile solids (VS), total carbon (C), and total nitrogen (N) were measured according to standard methods (Rice and Bridgewater 2012). Elemental analyses (Si: silicon, H: hydrogen, P: phosphorus, K: potassium, Ca: calcium, Cl: chlorine, Cu: copper, Ni: nickel, Fe: iron, Zn: zinc, Mn: manganese, Co: cobalt, Mo: molybdenum, and S: sulfur) were performed with an Oxford X-MET7500 Scrap Metal Analyzer according to the manufacturer’s instructions. The chemical oxygen demand (COD) was measured with a spectrophotometer (DRB200 Reactor 1 Block 9X16 MM/2X20 MM) according to standard methods (Rice and Bridgewater 2012). The pHs were measured with a pH meter (UL-TRAMETER 6PII FCE W/OUT PKUU KIT pocket-sized). A JEOL JEM-850 scanning electron microscope (SEM) operating at 35 kV was used to image the straw samples. The lignocellulosic compositions were determined according to Sluiter et al. (2008) and Said (2016). The methane contents were determined by withdrawing biogas samples from the reactors with an airtight syringe (10 µL) and injecting them into a gas chromatograph equipped with a thermal conductivity detector (Agilent Technologies 7890A). For all of the parameters, three analytical replicates per sample were conducted, and the mean values and standard deviations were computed.

Thermal analyses

Thermogravimetric analyses (TGA) and derivative thermogravimetric (DTG) analyses of the samples were performed with a SHIMADZU TGA-50H thermoanalyzer in an oxidizing atmosphere. The samples were heated from 30 to 1000 ℃ at a heating rate of 10 ℃/min in air with a flow rate of 100 mL/min (Deng et al. 2013; Saddawi et al. 2012). The analysis for each sample was repeated to ensure that the results were consistent for the same conditions.

Laboratory model

Anaerobic batch reactors (1.00 L) were connected to gas collectors connected to open jars to collect the water volume displaced from the gas collectors by the biogas pressure. The reactors were placed in a water bath shaker for continuous mixing, and the temperature was maintained at 35 °C. Five reactors with different substrates were studied (Table 1). The first reactor (S) contained 500 mL of solo sludge, and the second reactor (ST0) contained 500 mL of sludge mixed with 5 g of untreated barley straw (T0) to determine the effect of sludge with straw codigestion on methane production. The third (ST1), fourth (ST2), and fifth (ST3) reactors contained 500 mL of sludge mixed with 5 g of alkali-pretreated barley straw with Na2CO3 (T1), KOH (T2), and NaOH (T3), respectively, to investigate the effect of codigestion with pretreated straw on methane production and compare it to that for untreated straw in the second reactor. The experiments were repeated three times, and the average values were taken.

Table 1. Anaerobic Reactors Used in the Study

Statistical analyses

MS Excel and Statistical Package for Social Sciences (SPSS 22.0) were used to conduct the statistical analyses. The mean values and standard deviations (SD) of the parameters were computed. The relationships among different parameters were studied with Pearson’s correlation analysis.

Straw pretreatment

Alkaline pretreatment of the barley straw was conducted with three chemical agents: NaOH, KOH, and Na2CO3. In respective, 0.5 M solutions were prepared with chemical percentages of 2.0%, 2.8%, and 5.3% for each chemical agent. The solutions were mixed with ground straw samples (with 1 g of straw to 25 ml of solution) and then put in an air oven at 100 ℃ for 5 h. The pretreated samples were washed with distilled water until a neutral pH was reached. The washed samples were then filtered, dried, and stored in plastic bags until subsequent use.

Artificial Neural Networks

Feedforward neural networks

The neuron, which resembles the human brain, is the primary component of the ANN layers. The sizes of the inputs and outputs for the underlying problem determine the numbers of neurons in each of the input and output layers, respectively. The procedure used to implement an ANN involves choosing the (input, output) pairs of data. The input data for this study included the percentage of wheat straw and waste-activated sludge mixed, as well as the time of day. The total amounts of methane produced over a 30-day period were the output data. The number of neurons (M) in the hidden layer depended on the data complexity. The linear activation function was chosen as the transfer function for the input and the output layers. For the hidden layers, a sigmoid function was employed, as in Eq. 1, and the output of the hidden layers was computed as in Eq. 2.

(1)

(2)

where the weight factor from the xth input and the yth neuron in the hidden layer are represented by the symbol wyx, where ix is the x-th input to the FFNN, and k is the size of the inputs. The yth neuron in the hidden layer has by and hy as its base and output, respectively. Frequently, the neuronal output is expressed as in Eq. 3. Network training is the process of determining the appropriate values of the weights and biases for network connections between the input/hidden and hidden/output layers.

(3)

The mean square error (MSE), defined in Eq. 4, was used in this work as the main indicator for the efficiency of the training algorithm applied to the FFNN model,

(4)

where Tj is the target output and N is the total number of training sets. The training cost function (CF) was computed with Eq. 5:

(5)

The FFNN weights and biases of the network connections from the output layer back to the input layer were adjusted with the MSE function. The FFNN can be trained with optimization approaches to determine the appropriate number of neurons for the hidden layer, as well as the weight factors and biases. The optimal structure of the suggested FFNN was obtained in this study with the SMO.

Modeling of methane production by FFNN-SMO

Because they affect the performance of the proposed FFNN, the number of neurons in the hidden layers must be carefully selected. The error between the actual outputs (target) and the projected values are minimized by training the suggested FFNN. To determine the ideal weight factors, the suggested FFNN was trained with the SMO approach. The oscillation modes of slime molds found in nature provided the basis for the SMO algorithm. With an effective mathematical model that employs adaptive weights to mimic the process of generating positive/negative feedback from the slime mold propagation wave, the SMA offers several new features. It also provides the ideal path for connecting food with superior exploitation ability and exploitation tendencies (Li et al. 2020; Sarhan et al. 2022). The mold is one of the key components of the SMO algorithm. The potential solutions that move in the search space are represented by molds.

Every d-dimensional optimization phase started with an initially randomized SMO population of size n. Every member of the population was initialized as a d-entry vector with Eq. 6,

(6)

where Zmin and Zmax are the solutions that showed the minimal and maximum boundaries of the control variables, respectively. There are two steps in the conventional SMO: approach and food wrapping (Sarhan et al. 2022). The following formula was used to determine the activity of a slime mold during the first stage, when it may seek nourishment based only on the scent in the air:

(7)

In this case, Zi is the position of the slime mold, Zb is the position with the highest concentration of odor, and Zr1 and Zr2 are two randomly selected solutions from the population. Two components, u1 and u2, mirror the behavior of slime mold selection, with linearly decreasing from 1 to 0. W is the weight of the search agent, while r is a random number in the interval [0, 1]. Pr was defined as follows,

(8)

where CF is the overall best fitness value over all iterations and S(j) is the fitness score of the current person. The formula for is as follows,

(9)

where maxit is the maximum number of search iterations. The definition of the weight W is presented in Eq. 10,

(10)

where R is a randomized value inside [0, 1], and the condition denotes the first half of the population. BF and WF indicated the best and worst values, respectively, obtained after this iteration, while Indsmell showed the sorted sequence of fitness ratings:

(11)

In the second stage, the arrangement of venous tissue in the slime mold was modeled computationally throughout the search process. The type of food consumed by the slime mold can affect the search. This is the precise model that the slime mold uses to change its location,

(12)

where the random values r and rand are within the range [0, 1]. The ability of a balancing process to explore and use data was determined with a parameter called Y, which might have different values depending on the circumstances.

The FFNN-SMO algorithm was applied to model methane production and predict the output amount with minimal error. The following steps were used to apply the suggested FFNN-SMO algorithm:

- Input: the assigned FFNN inputs (time, reactor type, mixture) and the output target (cumulative methane production) were chosen;

- The search parameters of the designed SMO (number of slime mold agents, maximum number of search iterations, and upper and lower bounds of search vectors) were set.

- Within the limits of the lower and upper bounds, initial random populations of slime molds were collected, and the slime molds were considered predictable solutions.

- The fitness function was evaluated in terms of the MSE of the FFNN model for the slime mold with Eq. 6.

- The search populations were sorted according to their fitness values, after which the best slime mold was identified.

- The positions of the slime molds were updated based on the new positions of the flames, as shown in Eq. 9 and Eq. 10.

- If the problem constraint conditions were satisfied or the maximum number of search iterations was exhausted, then the optimal solution corresponded to the first slime mold.

- The best slime mold position that represented the optimal attained values of the model weights was output.

Figure 1 provides an illustrative flowchart showing the process of identifying weights and biases while utilizing the suggested SMO algorithm to reduce the MSE.

Fig. 1. Diagram of the FFNN-SMO algorithm

The suggested FFNN-SMO model was trained and tested on a set of eighty patterns. To determine the ideal FFNN structure, these gathered data were input into the suggested FFNN-SMO model. MATLAB (2020a) implemented the training technique (SMO). The suggested FFNN was created and trained with the m.file program, and it was simulated with the ANN toolbox. As previously mentioned in describing the algorithm and as shown in the flowchart in Fig. 1, the SMO approach was used to identify the appropriate weight/bias factors. The quantity of neurons in the hidden layers affected the ANN performance. A relatively small number of neurons may restrict the ability of ANNs to learn the relationships between the inputs and outputs of the model. In contrast, employing numerous neurons in the hidden layer(s) might lead to overfitting. The ideal structure of the suggested FFNN-SMO comprised a hidden layer with 13 neurons. This led to the best performance of the FFNN-SMO model in simulating the methane generation process, which had the fewest errors. With a sufficient level of accuracy, the FFNN-SMO modeled the biomethane synthetic process. The first hidden layers employed the sigmoid function, whereas the output layer used the linear activation function. The type of reactor, day number, and chemical agent mixture were the input data, and the total amount of methane produced (cumulative methane) over time was the output data.

RESULTS AND DISCUSSION

Physicochemical Characteristics

Table 2 shows the characteristics of the untreated and treated straw samples (based on the dry weight, % DW). The results indicated that the major constituents of barley straw were cellulose (37.54±0.25%) and hemicellulose (27.36±0.37%). Alkali pretreatment enhanced the destruction of the hemilignin structure, resulting in lignin removal and hemicellulose solubilization, as well as increased susceptibility of the microbes to anaerobic digestion (Hassan et al. 2017; Tan et al. 2021). As shown in Table 2, compared with no pretreatment, the alkali pretreatment decreased the hemicellulose and lignin contents in the straw (Hassan et al. 2017; Jaffar et al. 2016; Liu et al. 2015; Memon and Memon 2020; Ouahabi et al. 2021). Moreover, increased cellulose content was detected because of degradation and decreased lignin and hemicellulose contents (Liu et al. 2015; Hassan et al. 2017; Tan et al. 2020; Sabeeh et al. 2020; Samar et al. 2021). A previous study also showed a reduction in the hemicellulose and lignin contents and an increase in the cellulose content after NaOH pretreatment of the barley straw, which indicated improved biogas potential (Fjørtoft et al. 2019). On the other hand, the degradation of VS indicated dissolution of the organic matter due to substrate pretreatment (Du et al. 2019). In the present study, alkali pretreatment resulted in a decrease in the VS content, as seen previously (Liu et al. 2015; Jaffar et al. 2016; Rani et al. 2022). This was attributed to the effect of the alkali treatment in degrading some of the lignin and hemicellulose, which caused a decrease in the VS content of the straw (Fjørtoft et al. 2019; Tan et al. 2021). Decreases in some elements, including C, Si, N, P, K, Cl, and H, was attributed to the alkali pretreatment and washing of the pretreated straw with water; this decreased the contents of some elements, such as Cl and the alkali metals, and K also dissolved well in water (Said et al. 2013; Rani et al. 2022). Siddiqi et al. (2022) also detected a reduction in C, H, and N contents, as well as extraction of some minerals, due to wheat straw pretreatment with NaOH. As a result of the loss of these elements, the contents of other elements, such as Ca, Cu, Ni, Fe, Zn, Mn, Co, Mo, and S, increased, as reported previously (Jaffar et al. 2016; Hassan et al. 2017; Al-Da’asen et al. 2022; Rani et al. 2022). Moreover, a statistical analysis showed a significant difference between the T3 and T0 values for most parameters, and straw pretreatment with NaOH (T3) was associated with the greatest reductions in the reducing elements, followed by those of KOH (T2) and Na2CO3 (T1). This indicated that NaOH pretreatment had the greatest effect on solid degradation, followed by the KOH and Na2CO3 pretreatments, in accordance with the literature (Rezania et al. 2020; Mirmohamadsadeghi et al. 2021; Ouahabi et al. 2021). Sabeeh et al. (2020) studied different alkaline pretreatments of rice and proved that, compared with other chemical pretreatments, the NaOH pretreatment was most effective in solubilizing lignin and increasing the surface area available for microbial attack; a small portion of the hemicellulose removed and swelling of the crystalline structure of cellulose was observed.

Table 2. Characteristics of Untreated and Pretreated Straws with Different Treatments (mean value±SD)

Note: Values in the same row with the same letter showed insignificant difference at p ≤ 0.05.

Structural Analyses

The untreated and pretreated straw samples were inspected to determine the structural changes in the barley straw samples caused by the alkali pretreatment process. The morphological features of the untreated straw showed a flat, smooth, and compact surface structure (Fig. 2 a). Because the NaOH pretreatment had the greatest effect on the lignocellulosic composition, an SEM image of the straw pretreated with NaOH was taken as an example of the pretreated straw samples (Fig. 2 b). The alkali pretreatment destroyed the straw surface, which was composed of hemicellulose and lignin. As observed, the hemicellulose and lignin of the pretreated samples were partially broken and removed, causing internal surface exposure, as found by the authors (Siddiqi et al. 2022). Therefore, the alkali pretreatment destroyed the complex lignocellulosic structures and removed some external fibers. This process increased the cellulose accessibility and improved biodegradation, which was consistent with the results of previous studies (Jaffar et al. 2016; Memon and Memon 2020; Mirmohamadsadeghi et al. 2021; Ouahabi et al. 2021; Tan et al. 2021).

Fig. 2. SEM images of a) untreated straw and b) pretreated straw

Thermal Analyses

Thermograms from the TGA and DTG studies of the untreated and pretreated straw samples were obtained to determine their thermal properties and are shown in Fig. 3. These thermograms revealed insignificant differences between them. The TGA thermograms indicated mass losses from the different straw samples. The initial mass loss was due to the removal of moisture and light VS compounds, while sharp reductions in the masses were due to degradation of the samples; subsequently, little additional mass loss was detected.

The DTG thermograms showed three peaks, indicating three stages of mass loss. In the first stage (0 to 120 °C), the first peak occurred below 100 °C, which was attributed to moisture removal (Said et al. 2013). A slight increase in the mass loss was observed after moisture removal due to the removal of light volatile components, which decomposed earlier than the lignocellulosic matrix (Marin-Batista et al. 2021). In the second stage (250 to 320 °C), the mass loss corresponded to straw devolatilization. In addition, the volatile compounds of hemicellulose and cellulose were decomposed (Sidi-Yacoub et al. 2019). The maximum peaks in the DTG profiles for the different samples occurred in this stage and were detected in the temperature range 300 to 320 °C due to exothermic reactions of the cellulose. Moreover, the peaks for the pretreated samples were greater than those for the untreated samples, which was explained by the increased cellulose proportion after pretreatment, similar to the findings of Marin-Batista et al. (2021).

In the third stage (320 to 480 °C), the mass losses corresponded to lignin decomposition (Mahmood et al. 2016). The decomposition rates were very low and became negligible after this stage. Similar results were found by the authors (Marin-Batista et al. 2021; Siddiqi et al. 2022). The TGA curves indicated that there was less degradation residue (char) from the pretreated straw than from the untreated straw. Moreover, T3 had the least char residue from the TGA and the highest peak in the DTG profile among the different samples since T3 gave the greatest cellulose decomposition and lowest lignin content compared to the other samples. These results confirmed the lignocellulosic compositions of the untreated and pretreated straws, as indicated in Table 1.

Fig. 3. TGA and DTG curves for the untreated and pretreated straw

Anaerobic Digestion

Table 3 shows the characteristics of the raw barley straw and sewage sludge used in the anaerobic digestion process. The straw had a high content of solids (93.40±0.54%), while the sludge had a low solids content (1.45±0.01%). Moreover, the straw had a high volatiles content (80.51±0.20%) and a high carbon content (31.25±0.32% TS), indicating its potential for biogas production via anaerobic codigestion with sewage sludge.

Table 3. Characteristics of Raw Barley Straw and Sewage Sludge (mean value±SD)

Note: * COD value of the straw in g/kg and the sludge in g/L.

The anaerobic digestion process was sensitive to the C/N ratios of the feedstocks. Anaerobic codigestion of a feedstock resulted in a higher C/N ratio than straw (75.94±8.75), and a feedstock with a lower C/N ratio than sludge (7.01±0.32) increased the efficiency of biogas production due to the synergistic effect of the feedstocks. Moreover, mixing straw with sludge maintained the nutrient balance for healthy growth of the microorganisms essential for anaerobic digestion (Al‑Da’asen et al. 2022). The C/N ratio of the sludge (7.01±0.32) was increased to 12.27±0.23 by the addition of barley straw to the sludge. Figure 4 illustrates the cumulative methane production from the different reactors. The cumulative methane production increased with increasing digestion time, and after Day 26, negligible methane production was detected. Reactor S (solo sludge) recorded a total methane production of 97.01±5.31 mL/g VS. Codigestion with the barley straw in (ST0) increased the methane production by a factor of 1.45 compared to that for digestion of sludge alone.

Fig. 4. Cumulative methane production from different reactors

Rani et al. (2022) investigated anaerobic codigestion with raw and KOH-pretreated wheat straw and showed that codigestion helped in balancing the nutrients; hence, optimizing the conditions for methanogenesis by microbes and pretreatment exposed the complex materials to methanogens by enhancing depolymerization of the celluloses, hemicelluloses, and lignin. In the present study, compared with that from ST0, the methane production levels from ST1, ST2, and ST3 were 1.62, 1.99, and 2.57-fold higher, respectively. This was attributed to the fact that the cellulose in the untreated straw was highly protected by lignin and hemicellulose, resulting in low accessibility to the active sites for the cellulose reaction; thus, less methane production resulted. Otherwise, pretreatment of the straw broke the physical barrier and hydrogen bonds between the lignin and hemicellulose and increased the cellulose accessibility to enzymatic hydrolysis (Hassan et al. 2016; Tan et al. 2021). Thus, the digestibility and anaerobic digestion rate, biodegradation rate, and overall methane yield were improved, as found in previous studies (Hassan et al. 2016; Nargotra et al. 2018; Memon and Memon 2020; Ouahabi et al. 2021; Tan et al. 2021, 2020).

In the present study, ST3 exhibited the greatest improvement in methane production, followed by ST2 and ST1. This occurred because the alkaline NaOH showed excellent delignification performance and was more effective than the other alkaline substances in enhancing the digestibility and methane production, as found in previous studies (Fjørtoft et al. 2019; Rezania et al. 2020; Mirmohamadsadeghi et al. 2021; Ouahabi et al. 2021; Samar et al. 2021; Dumlu et al. 2021). Moreover, compared with carbonate radicals, hydroxyl radicals caused greater degradation of straw, increased the accessibility of the substrate to microorganisms, and increased methane production. Rani et al. (2022) showed that alkaline pretreatment of wheat straw with KOH resulted in significant changes in the physical and chemical properties of the substrates, increased their biodegradabilities, and yielded greater biogas production than pretreatment with a complex composition. Peyrelasse et al. (2021) also reported that codigestion with NaOH-pretreated wheat straw provided a 31% greater methane yield than that of untreated wheat straw. Mirmohamadsadeghi et al. (2021) studied a thermoalkaline pretreatment of straw with NaOH and Na2CO3, and NaOH was more effective than Na2CO3 and resulted in a higher methane yield. Thus, NaOH and KOH were the most effective alkali pretreatments for improving biomass digestibility (Ouahabi et al. 2021; Meenakshisundaram et al. 2023).

The characteristics of the substrates from the different reactors are presented in Table 4. The addition of straw to the sludge had a significant effect on the characteristics of the substrate. The TS content of the sludge in the first reactor (S) was 1.45±0.01%, while it increased to 2.36±0.02% with the addition of (raw/pretreated) straw to the different reactors. The VS content for S was 1.04±0.00%, while it increased in ST0 to 1.90±0.03% after straw addition and was slightly lower for reactors ST1, ST2, and ST3 for pretreated straw (1.77±0.03 and 1.81±0.02%). This occurred because of the effect of the alkali pretreatment on the degradation of hemicellulose, which caused a decrease in the solid content of the straw (Tan et al. 2021). The COD value for S was 23.20±0.04 g/L, and this was increased by the addition of raw straw to 40.20±0.37 g/L for ST0, while lower values were detected after the addition of pretreatment and were in the range 34.21±0.24 to 36.60±0.27 g/L for the remaining reactors. This difference was attributed to precipitation of complex compounds due to alkaline pretreatment of the straw, as found in previous studies (Liu et al. 2015; Rani et al. 2022).

The pH for S was 7.10±0.04 and decreased to 6.86±0.01 in ST0 after the addition of raw straw to the sludge. Moreover, the addition of pretreated straw to the sludge resulted in higher pH values than those from the addition of untreated straw, ranging between 6.89±0.01 and 6.95±0.02. This was due to the straw alkali pretreatment, as found in previous studies (Jaffar et al. 2016; Memon and Memon 2020). In these studies, alkaline pretreatment of the straw with KOH increased the pH above that of untreated straw. It was also observed that, among the different pretreatment methods, ST3 showed the lowest values for the different parameters, indicating that this was the most efficient pretreatment method.

The TS, VS, and COD values for the different reactors decreased after digestion due to biodegradation of the organic matter into biogas (Table 4). The percentages of TS and VS removed from S were 43.4% and 54.0%, respectively. Meanwhile, ST0 showed higher percentages of TS and VS removed, 47.03% and 56.32%, respectively. Moreover, the reactors with pretreated straw showed higher removal ratios than those with untreated straw, with ranges of 53.0 to 59.3% and 60.7 to 67.2% for TS and VS, respectively. This occurred because pretreated straw was more biodegradable than untreated straw (Jaffar et al. 2016). Thus, compared with no pretreatment, the alkali pretreatment produced desirable changes in the barley straw characteristics, and it improved the degradation efficiency via TS and VS losses, resulting in greater solid reduction (Jaffar et al. 2016; Rani et al. 2022). Furthermore, the highest removal percentage was found in the case of ST3, while ST1 had the lowest removal percentage among the reactors with pretreated straw. Therefore, pretreatment of the straw with NaOH led to the highest reductions in solids contents, followed treatments with KOH and Na2CO3. VSs are composed primarily of organic matter and normally represent the amount of organic matter in the feedstock. Greater VS consumption during anaerobic digestion indicates a greater maximum volume for biogas production. Pretreatment of the straw appeared to increase the biodegradation rates of organic compounds and maximize the consumption of VSs during the anaerobic digestion process, hence improving the process performance and increasing biogas production (Al‑Da’asen et al. 2022). The TS and VS results confirmed methane production from the different reactors, and the solid reduction percentages were proportional to the methane yields of the reactors (Alrowais et al. 2023b).

After digestion, the COD values had decreased by 61.6% and 64.4% for S and ST0, respectively. The COD values of the pretreated straw reactors showed higher removal ratios, from 68.6 to 73.4%, than those of the untreated straw. This was because pretreated straw was easily decomposed by microorganisms due to structural loosening (Dumlu et al. 2021; Rani et al. 2022). Moreover, it was noted that, compared with the untreated straw, the alkali-pretreated straw showed greater biodegradability, which led to greater methane production. The NaOH pretreatment gave the greatest reduction in COD among all pretreatments. Therefore, the alkali pretreatment of straw had a positive effect on the anaerobic digestion process because the high COD removal rate was related to the substantial amount of methane produced (Hamzah et al. 2019; Turek et al. 2019). Moreover, the pHs of the different reactors increased after digestion, ranging from 6.85±0.01 to 7.20±0.18. The pHs before and after digestion were within the standard range (6.5 to 7.5) for maximum methane yields, improved performance, and high stability during the anaerobic digestion process (Kitessa et al. 2022). This was attributed to variations in the pH caused by biological conversion during the anaerobic digestion process, when high volumes of organic acids were produced by the acidogenic bacteria. Acid accumulation occurred and disrupted this process, while under normal conditions, the pH is controlled by the bicarbonate produced by methanogens and the ammonia formed in the reaction medium (Dobre et al. 2014; Abdel daiem et al. 2021b).

Table 4. Characteristics of the Substrates Before and After Digestion (mean value±SD)

Note: B shows values before digestion and A shows values after digestion; values in the same row with the same letter showed insignificant differences at p ≤ 0.05.

ANN Application

Overall, division ratios of 70%, 15%, and 15% for the training, validation, and testing portions, respectively, were applied to the input data patterns (80 patterns).

Fig. 5. Outputs of the FFNN-SMO model (predictions) and comparisons with a) trained data samples, b) test data samples, and c) all data samples

Fig. 6. Linear regression models for each training, validation, testing, and overall dataset with the FFNN-SMO algorithm

The SMO succeeded in training the proposed FFNN in 52 iterations, and the MSE reached 3.1×10-5 with the FFNN structure (3-13-1). The three inputs to the authors’ model were the type of reactor, the day number, and the chemical mixture. Figure 5 a) shows both the output of the designed FFNN-SMO and the measured value for methane production. The two curves were very close; thus, the designed FFNN-SMO modeled the methane production process well. The training process proceeded until the predetermined performance was met, after which the weights/biases of the hidden layer were frozen. Figure 5 b) shows the results from applying the proposed FFNN-SMO algorithm only to the test patterns (15% of the input data patterns); these results were examined. The recorded MSE for the test patterns reached 2.76 with the FFNN-SMO model. This acceptable MSE for the testing set reflected the high accuracy of the proposed model in predicting the amount of methane produced. Figure 5 c) compares the output from the proposed FFNN-SMO (i.e., predictions) with the experimental values for methane production. Using the data generated by the model (FFNN-SMO) and the measured samples for the same input values, Fig. 6 introduces the regression results for the training, validating, and testing processes with the FFNN-SMO, as well as the R2 values recorded by the FFNN-SMO algorithm. This approach provided one common verification step for the performance of the neural network model. The R2 values for the optimal attained FFNN-SMO model were 0.99995, 0.9994, and 0.9998 for training, validation, and testing, respectively. Moreover, the presented results determined the stabilities of the FFNN-SMO outputs under various conditions and rapid convergence of the model. These results ensured the adequacy and effectiveness of the designed FFNN-SMO in predicting experimental biogas production.

Therefore, the methane production modelled with machine learning techniques such as ANNs reinforced the experimental findings. This approach provided an opportunity to elucidate the underlying mechanisms for such processes. Moreover, this approach facilitated generalization of the model and provided a procedure for addressing other datasets from similar experimental work. Moreover, employing a metaheuristic technique such as SMO proved useful in enhancing the performance of the ANN. However, this promising model may need to be retrained with new experimental data or when one of the crucial conditions is changed.

CONCLUSIONS

- The codigestion of waste activated sludge with barley straw (T0) increased the methane production 1.45-fold compared to that from digestion of sludge alone (97 mL/g VS).

- Codigestion with pretreated straw (T1, T2, and T3) increased the methane production levels to 228, 281, and 363 mL/g, respectively.

- Pretreatment T3 was the most significant pretreatment. There was a 2.57-fold increase in methane production compared to that from codigestion with untreated straw; moreover, the greatest reductions in TS (59.3%), VS (67.2%), and COD (73.4%) were recorded among the different pretreatments.

- Training an FFNN with the SMO algorithm notably improved all of the experimental methane production data. The recorded MSE values for training and testing of the designed FFNN-SMO model were 3.1×10-5 and 2.75, respectively.

The alkaline pretreatments used in the present study produced desirable changes in the barley straw characteristics and increased methane production. Therefore, this study suggests that barley straw would be an ideal feedstock for biogas production if it was properly pretreated. Furthermore, the applied model showed high accuracy in predicting methane production. However, future studies will be carried out to explore additional conditions for alkaline pretreatments with different chemical concentrations combined with thermal effects and different contact times.

ACKNOWLEDGMENTS

The authors extend their appreciation to the Deputyship for Research & Innovation, Ministry of Education in Saudi Arabia, for funding this research through project number 223202 (IF-JU-2-070).

REFERENCES CITED

Abdel daiem, M. M., Hatata, A., El-Gohary, E. H., Abd-Elhamid, H. F., and Said, N. (2021a). “Application of an artificial neural network for the improvement of agri-cultural drainage water quality using a submerged biofilter,” Environmental Science and Pollution Research 28(5), 5854-5866. DOI: 10.1007/s11356-020-10964-0

Abdel daiem, M. M., Hatata, A., Galal, O. H., Said, N., and Ahmed, D. (2021b). “Prediction of biogas production from anaerobic Co-digestion of waste activated sludge and wheat straw using two-dimensional mathematical models and an artificial neural network,” Renewable Energy 178, 226-240. DOI: 10.1016/j.renene.2021.06.050

Abdel daiem, M. M., Hatata, A., and Said, N. (2022). “Modeling and optimization of semi-continuous anaerobic co-digestion of activated sludge and wheat straw using Nonlinear Autoregressive Exogenous neural network and seagull algorithm,” Energy 241, article 122939. DOI: 10.1016/j.energy.2021.122939

Abdel daiem, M. M., and Said, N. (2023). “Assessment and contribution of biomass residues to renewable energy resources in Egypt,” in: The Handbook of Environmental Chemistry, Springer Berlin Heidelberg, Berlin, Heidelberg, pp. 1-28. DOI: 10.1007/698_2022_938

Abdel Daiem, M. M., and Said, N. (2022). “Energetic, economic, and environmental perspectives of power generation from residual biomass in Saudi Arabia,” Alexandria Engineering Journal 61(5), 3351-3364. DOI: 10.1016/j.aej.2021.08.049

Aghbashlo, M., Mandegari, M., Tabatabaei, M., Farzad, S., Soufiyan, M. M., and Görgens, J. F. (2018). “Exergy analysis of a lignocellulosic-based biorefinery annexed to a sugarcane mill for simultaneous lactic acid and electricity production,” Energy 149, 623-638.

Al-Da’asen, A., Al-Harahsheh, A., Al-Hwaiti, M., and Irshaid Irshaid, F. (2022). “Biogas production via anaerobic codigestion of chemically treated wheat straw with sewage sludge or cow manure,” Biomass Conversion and Biorefinery 14(8), 1-12.

Almomani, F. (2020). “Prediction of biogas production from chemically treated co-digested agricultural waste using artificial neural network,” Fuel 280, article 118573.

Alrowais, R., Abdel daiem, M. M., Li, R., Maklad, M. A., Helmi, A. M., Nasef, B. M., and Said, N. (2023a). “Groundwater quality assessment for drinking and irrigation purposes at Al-Jouf area in KSA using artificial neural network, GIS, and multivariate statistical techniques,” Water 15(16), article 2982.

Alrowais, R., Said, N., Alotaibi, A., Hatata, A., Essa, M. A., and Abdel daiem, M. M. (2023b). “Comparing the effect of mesophilic and thermophilic anaerobic co-digestion for sustainable biogas production: An experimental and recurrent neural network model study,” Journal of Cleaner Production 392, article 136248.

Alrowais, R., Yousef, R. S., Ahmed, O. konsowa, Mahmoud-Aly, M., Abdel daiem, M. M., and Said, N. (2023c). “Enhanced detoxification methods for the safe reuse of treated olive mill wastewater in irrigation,” Environmental Sciences Europe 35(1), 95.

Barik, D., and Murugan, S. (2015). “An artificial neural network and genetic algorithm optimized model for biogas production from co-digestion of seed cake of karanja and cattle dung,” Waste and Biomass Valorization 6(6), 1015-1027.

Beltramo, T., Klocke, M., and Hitzmann, B. (2019). “Prediction of the biogas production using GA and ACO input features selection method for ANN model,” Information Processing in Agriculture 6(3), 349-356.

Deng, L., Zhang, T., and Che, D. (2013). “Effect of water washing on fuel properties, pyrolysis and combustion characteristics, and ash fusibility of biomass,” Fuel Processing Technology 106, 712-720.

Dobre, P., Nicolae, F., and Matei, F. (2014). “Main factors affecting biogas production-an overview,” Romanian Biotechnological Letters, ARS Docendi Publishing House, 19(3), 9283-9296.

Du, J., Qian, Y., Xi, Y., and Lü, X. (2019). “Hydrothermal and alkaline thermal pretreatment at mild temperature in solid state for physicochemical properties and biogas production from anaerobic digestion of rice straw,” Renewable Energy 139, 261-267.

Dumlu, L., Ciggin, A. S., Ručman, S., and Perendeci, N. A. (2021). “Pretreatment, anaerobic codigestion, or both? Which is more suitable for the enhancement of methane production from agricultural waste?,” Molecules 26(14), article 4175.

Fjørtoft, K., Morken, J., Hanssen, J. F., and Briseid, T. (2019). “Pre-treatment methods for straw for farm-scale biogas plants,” Biomass and Bioenergy 124, 88-94.

Ghatak, M. Das, and Ghatak, A. (2018). “Artificial neural network model to predict behavior of biogas production curve from mixed lignocellulosic co-substrates,” Fuel 232, 178-189.

Hamzah, N., Tokimatsu, K., and Yoshikawa, K. (2019). “Solid fuel from oil palm biomass residues and municipal solid waste by hydrothermal treatment for electrical power generation in Malaysia: A review,” Sustainability 11(4), article 1060.

Hassan, M., Ding, W., Bi, J., Mehryar, E., Talha, Z. A. A., and Huang, H. (2016). “Methane enhancement through oxidative cleavage and alkali solubilization pre-treatments for corn stover with anaerobic activated sludge,” Bioresource Technology 200, 405-412.

Hassan, M., Ding, W., Umar, M., and Rasool, G. (2017). “Batch and semi-continuous anaerobic co-digestion of goose manure with alkali solubilized wheat straw: A case of carbon to nitrogen ratio and organic loading rate regression optimization,” Bioresource Technology 230, 24-32.

Jaffar, M., Pang, Y., Yuan, H., Zou, D., Liu, Y., Zhu, B., Korai, R. M., and Li, X. (2016). “Wheat straw pretreatment with KOH for enhancing biomethane production and fertilizer value in anaerobic digestion,” Chinese Journal of Chemical Engineering 24(3), 404-409.

Kitessa, W. M., Fufa, F., and Abera, D. (2022). “Biogas production and biofertilizer estimation from anaerobic co-digestion of blends of wastewater and microalgae,” International Journal of Chemical Engineering 2022, article 3560068.

Li, S., Chen, H., Wang, M., Heidari, A. A., and Mirjalili, S. (2020). “Slime mould algorithm: A new method for stochastic optimization,” Future Generation Computer Systems 111, 300-323.

Liu, X., Zicari, S. M., Liu, G., Li, Y., and Zhang, R. (2015). “Pretreatment of wheat straw with potassium hydroxide for increasing enzymatic and microbial degradability,” Bioresource Technology 185, 150-157.

Mahmood, H., Moniruzzaman, M., Yusup, S., and Akil, H. M. (2016). “Pretreatment of oil palm biomass with ionic liquids: a new approach for fabrication of green composite board,” Journal of Cleaner Production 126, 677-685.

Marin-Batista, J. D., Mohedano, A. F., and de la Rubia, A. (2021). “Pretreatment of lignocellulosic biomass with 1-ethyl-3-methylimidazolium acetate for its eventual valorization by anaerobic digestion,” Resources 10(12), article 118.

Meenakshisundaram, S., Calcagno, V., Ceballos, C., Fayeulle, A., Léonard, E., Herledan, V., Krafft, J.-M., Millot, Y., Liu, X., and Jolivalt, C. (2023). “Chemically and physically pretreated straw in moderate conditions: Poor correlation between biogas production and commonly used biomass characterization,” Energies 16(3), article 1146.

Memon, M. J., and Memon, A. R. (2020). “Wheat straw optimization via its efficient pretreatment for improved biogas production,” Civil Engineering Journal 6(6), 1056-1063.

Mirmohamadsadeghi, S., Karimi, K., Azarbaijani, R., Yeganeh, L. P., Angelidaki, I., Nizami, A.-S., Bhat, R., Dashora, K., Vijay, V. K., and Aghbashlo, M. (2021). “Pretreatment of lignocelluloses for enhanced biogas production: A review on influencing mechanisms and the importance of microbial diversity,” Renewable and Sustainable Energy Reviews 135, article 110173.

Nargotra, P., Sharma, V., Gupta, M., Kour, S., and Bajaj, B. K. (2018). “Application of ionic liquid and alkali pretreatment for enhancing saccharification of sunflower stalk biomass for potential biofuel-ethanol production,” Bioresource Technology 267, 560-568.

Oloko-Oba, M. I., Taiwo, A. E., Ajala, S. O., Solomon, B. O., and Betiku, E. (2018). “Performance evaluation of three different-shaped bio-digesters for biogas production and optimization by artificial neural network integrated with genetic algorithm,” Sustainable Energy Technologies and Assessments 26, 116-124.

Ouahabi, Y. R., Bensadok, K., and Ouahabi, A. (2021). “Optimization of the biomethane production process by anaerobic digestion of wheat straw using chemical pretreatments coupled with ultrasonic disintegration,” Sustainability 13(13), article 7202.

Patowary, D., and Baruah, D. C. (2018). “Effect of combined chemical and thermal pretreatments on biogas production from lignocellulosic biomasses,” Industrial Crops and Products 124, 735-746.

Peyrelasse, C., Barakat, A., Lagnet, C., Kaparaju, P., and Monlau, F. (2021). “Anaerobic digestion of wastewater sludge and alkaline-pretreated wheat straw at semi-continuous pilot scale: Performances and energy assessment,” Energies 14(17), article 5391.

Rani, P., Bansal, M., and Pathak, V. V. (2022). “Experimental and kinetic studies for improvement of biogas production from KOH pretreated wheat straw,” Current Research in Green and Sustainable Chemistry 5, article 100283.

Rezania, S., Oryani, B., Cho, J., Talaiekhozani, A., Sabbagh, F., Hashemi, B., Rupani, P. F., and Mohammadi, A. A. (2020). “Different pretreatment technologies of lignocellulosic biomass for bioethanol production: An overview,” Energy 199, article 117457.

Rice, E. W., and Bridgewater, L. (2012). Standard Methods for the Examination of Water and Wastewater, American Public Health Association, Washington, DC.

Sabeeh, M., Liaquat, R., and Maryam, A. (2020). “Effect of alkaline and alkaline-photocatalytic pretreatment on characteristics and biogas production of rice straw,” Bioresource Technology 309, article 123449.

Saddawi, A., Jones, J. M., Williams, A., and Le Coeur, C. (2012). “Commodity fuels from biomass through pretreatment and torrefaction: Effects of mineral content on torrefied fuel characteristics and quality,” Energy & Fuels 26(11), 6466-6474.

Said, N. (2016). “Aprovechamiento energético de la biomasa residual procedente de la paja de arroz en Egipto,” Universidad de Granada.

Said, N., Alblawi, A., Hendy, I. A., and Abdel Daiem, M. M. (2020). “Analysis of energy and greenhouse gas emissions of rice straw to energy chain in Egypt,” BioResources 15(1), 1510-1520.

Said, N., Bishara, T., García-Maraver, A., and Zamorano, M. (2013). “Effect of water washing on the thermal behavior of rice straw,” Waste Management 33(11), 2250-2256.

Samar, W., Arora, A., Sharma, A., Sharma, S., and Nandal, P. (2021). “Material flow of cellulose in rice straw to ethanol and lignin recovery by NaOH pretreatment coupled with acid washing,” Biomass Conversion and Biorefinery 13, 2233–2242.

Sarhan, S., Shaheen, A. M., El-Sehiemy, R. A., and Gafar, M. (2022). “An enhanced slime mould optimizer that uses chaotic behavior and an elitist group for solving engineering problems,” Mathematics 10(12), 1991.

Şenol, H. (2021). “Methane yield prediction of ultrasonic pretreated sewage sludge by means of an artificial neural network,” Energy 215, article 119173.

Siddiqi, M. H., Liu, X., Hussain, M. A., Qureshi, T., Tabish, A. N., Lateef, H. U., Zeb, H., Farooq, M., Nawaz, S., and Nawaz, S. (2022). “Evaluation of physiochemical, thermal and kinetic properties of wheat straw by demineralising with leaching reagents for energy applications,” Energy 238, article 122013.

Sidi-Yacoub, B., Oudghiri, F., Belkadi, M., and Rodríguez-Barroso, R. (2019). “Characterization of lignocellulosic components in exhausted sugar beet pulp waste by TG/FTIR analysis,” Journal of Thermal Analysis and Calorimetry 138, 1801-1809.

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D., and Crocker, D. (2008). “Determination of structural carbohydrates and lignin in biomass,” Laboratory Analytical Procedure 1617(1), 1-16.

Tan, J., Li, Y., Tan, X., Wu, H., Li, H., and Yang, S. (2021). “Advances in pretreatment of straw biomass for sugar production,” Frontiers in Chemistry 9, article 696030.

Tan, L., Zhong, J., Jin, Y.-L., Sun, Z.-Y., Tang, Y.-Q., and Kida, K. (2020). “Production of bioethanol from unwashed-pretreated rapeseed straw at high solid loading,” Bioresource Technology 303, article 122949.

Turek, A., Wieczorek, K., and Wolf, W. M. (2019). “Digestion procedure and determination of heavy metals in sewage sludge—An analytical problem,” Sustainability 11(6), article 1753.

Article submitted: December 15, 2023; Peer review completed: January 21, 2024; Revised version received and accepted: February 9, 2024; Published: February 16, 2024.

DOI: 10.15376/biores.19.2.2179-2200