Abstract

Intumescent, flame-retarding wood-flour/polypropylene composites (WPCs) having different ammonium polyphosphate/pentaerythritol (APP/PER) ratios (4/1, 3/1, and 2/1) were prepared in this study. The thermal degradation behavior, flame retardancy, and mechanical properties of the composites were tested. Moreover, the residues of the WPCs were observed by scanning electron microscopy, and the flame retardancy mechanism was investigated. The results showed that WPC/APP/PER exhibited higher thermal stability in the high temperature region and left much more char residue than WPC/APP, according to thermogravimetric analysis. Limiting oxygen index and cone calorimetry tests showed that the addition of PER improved the flame retardancy of the WPCs, especially when APP/PER ratio was 3/1. However, because of the poor compatibility with the composite matrix and uneven dispersion in the WPCs, the incorporation of PER decreased the mechanical performance of WPCs obviously.

Download PDF

Full Article

Effect of Pentaerythritol on the Properties of Wood-Flour/Polypropylene/Ammonium Polyphosphate Composite System

Wen Wang, Yao Peng, Wei Zhang,* and Jianzhang Li*

Intumescent, flame-retarding wood-flour/polypropylene composites (WPCs) having different ammonium polyphosphate/pentaerythritol (APP/PER) ratios (4/1, 3/1, and 2/1) were prepared in this study. The thermal degradation behavior, flame retardancy, and mechanical properties of the composites were tested. Moreover, the residues of the WPCs were observed by scanning electron microscopy, and the flame retardancy mechanism was investigated. The results showed that WPC/APP/PER exhibited higher thermal stability in the high temperature region and left much more char residue than WPC/APP, according to thermogravimetric analysis. Limiting oxygen index and cone calorimetry tests showed that the addition of PER improved the flame retardancy of the WPCs, especially when APP/PER ratio was 3/1. However, because of the poor compatibility with the composite matrix and uneven dispersion in the WPCs, the incorporation of PER decreased the mechanical performance of WPCs obviously.

Keywords: Pentaerythritol; Wood-plastic composite; Intumescent flame retardant; Thermal degradation behavior; Flame retardant mechanism

Contact information: MOE Key Laboratory of Wooden Material Science and Application, Beijing Key Laboratory of Wood Science and Engineering, Beijing Forestry University, 35 Qinghua East Road, Haidian District, Beijing 100083, P. R. China;

* Corresponding authors: zhangweishe@126.com;lijianzhang126@126.com

INTRODUCTION

Due to environmental concerns and dwindling petroleum resources, wood-plastic composites (WPCs) have drawn more and more attention in the past two decades (García et al. 2009). Because of their excellent performance, low cost, high dimensional stability throughout their lifetime, and high relative strength and stiffness (Stark et al. 2010; Li et al. 2014), WPCs have been widely used in decking products, automotive parts, and construction products (Ashori 2008; Ndiaye et al. 2008; Leu et al. 2012; Arao et al. 2014; Turke et al. 2014; Wu et al. 2014). However, the main drawback limiting wider application of WPCs is their high flammability, which is because the two main components (wood-flour or fiber and plastic) are themselves flammable (Li et al. 2010; Arao et al. 2014; Pan et al. 2014). Thus, the development of flame-retarding WPCs is of great importance.

The most effective, expeditious method to enhance the flame retardancy of WPCs is to treat them with flame retardants (FRs), among which intumescent flame retardants (IFRs) have been considered promising and are widely used because of their halogen-free nature, low smoke generation, low toxicity, and high efficiency (Bourbigot et al. 2004; Demir et al. 2005; Arao et al. 2014; Bai et al. 2014).

The most typical, effective IFR system is the combination of ammonium polyphosphate (APP) and pentaerythritol (PER), in which APP acts as both the acid source and the blowing agent and PER is the char forming agent. These additives play an important role in forming a carbonaceous char. The reaction process of the IFR system was extensively studied in 1980s and 1990s by Bourbigot et al.(1993, 1995) and Camino et al. (1984a,b,c,d; 1985a,b). Most of the investigations focused on the IFR system in polyolefins (Camino et al. 1984a,b,c,d; 1985a,b; Delobel et al. 1993; Bourbigot et al. 2004; Xia et al. 2014), and the optimal APP/PER ratio (weight ratio of APP-to-PER) for the flame retardancy of the polymer matrix was proposed in several studies. However, few studies have focused on the typical IFR system present in WPCs and the corresponding flame retardancy mechanism.

In this work, IFR systems with different APP/PER ratios (4/1, 3/1, and 2/1) were used for the flame retardancy modification of wood-flour/polypropylene composites. The effect of PER on the thermal degradation behavior of the flame-retarding WPCs was investigated by thermogravimetric analysis (TGA). The flame retardancy of the WPCs was evaluated by limiting oxygen index (LOI) and cone calorimetry tests. The surface residues of the WPCs at the end of the cone calorimetry tests were investigated by scanning electron microscopy (SEM) and the corresponding flame retardant mechanism was speculated. In addition, the effect of PER on the mechanical properties of the flame-retarding WPCs was also investigated.

EXPERIMENTAL

Materials

The materials were all made in China. Poplar wood flour (Populus tomentasa Carr., particle sizes between 60- and 80-mesh) was kindly provided by Gaocheng Xingda Wood Flour Company. PP (K8303, copolymer, melting point 165 °C, melt-flow rate 1.5 g/10 min) was obtained from Beijing Yanshan Petrochemical Co. APP (average polymerization degree n > 1000) was obtained from Shenzhen Jingcai Chemical Co.. PER (chemically pure) was obtained from Shanghai Sinopharm Chemical Reagent Co.

Methods

Preparation of WPCs

The wood-flour was oven-dried at 105 °C until its weight was stable. Then, APP and PER were added into PP and wood-flour (PP/wood-flour ratio of 6/4) at constant weight percentages (Table 1). Each group of raw materials was mixed in a high-speed mixer at a mixing speed of 2900 rpm for 4 min followed by melt-blending in a co-rotating twin-screw extruder (KESUN KS-20, Kunshan, China). The corresponding temperatures in the extruder barrel were controlled to 165, 170, 175, 180, and 175 °C from the hopper to the die zones, respectively, and the screw speed was 167 rpm. Then, the extrudates were cut into small particles about 5 mm in size and dried again at 105 °C for 3 h before being removed for hand matting. A hot press (SYSMEN-ll, China Academy of Forestry, Beijing, China) was used to produce WPCs by compressing the mat under 4 MPa pressure at 180 °C for 6 min. After hot pressing, the mat formed was cooled under 4 MPa pressure at room temperature for another 6 min in a cold press. The control WPC (WPC-0), without IFR, was prepared similarly. The dimensions of the WPCs were 270 × 270 × 3 mm3 with a target density of 1.0 g/cm3.

Table 1. Formulation of WPCs

Analytical tests

All TGA curves were recorded using a Q50 TGA analyzer (TA Instruments, USA) at a linear heating rate of 10 °C/min under a pure nitrogen atmosphere. The temperature ranged from ambient to 600°C. Each sample was kept within 5 to 8 mg in an open platinum pan.

The LOIs of the all WPCs were measured using an HC-2 oxygen index meter (Jiangning Analysis Instrument Company, China) with the sheets (135 × 6.5 × 3 mm3) according to ASTM D2863-77. Fifteen replicates were tested for each group.

Combustion experiments were conducted with a cone calorimeter (Stanton Redcroft, UK) in accordance with ISO 5660 procedures. Each specimen (100 × 100 × 3 mm3) was wrapped in aluminum foil and exposed horizontally to 35 kW/m2 external heat flux. Three replicates were tested for each group.

The morphologies of the WPC combustion residues were investigated by a Hitachi S-3400 SEM analyzer (Philips, Japan) with an acceleration voltage of 5 kV.

Mechanical property tests

The flexural properties, including the flexural strength (MOR) and flexural elasticity (MOE), were measured as specified by Chinese standard GB/T 9341-2008, which involves a three-point bending test at a crosshead speed of 5 mm/min. Six replicates (60 × 25 × 3 mm3) from each group were tested and the standard deviations (SDs) were calculated.

The tensile properties, including the tensile strength and elongation at break, were measured according to Chinese standard GB/T 1040.2-2006 at a testing speed of 2 mm/min. Six replicates (75 × 13 × 3 mm3) from each group were tested and the SDs were calculated.

Unnotched Izod impact tests were performed in accordance with Chinese standard GB/T 1843-2008. Six unnotched replicates (80 × 10 × 3 mm3) from each group were tested to calculate the Izod impact strength.

RESULTS AND DISCUSSION

Thermal Degradation Analysis

The TGA and derivative thermogravimetry (DTG) curves of the WPCs are shown in Figs. 1a and b, respectively, and the related DTG data are listed in Table 2. The thermal degradation of WPC-0 and WPC-1 was composed of two steps. The Tmax1 of WPC-1 was lower than that of WPC-0, while Tmax2 was higher (Table 2), indicating that the incorporation of APP significantly accelerated the decomposition of the WPCs, which was consistent with the findings of a previous study (Delobel et al. 1993). When WPCs were incorporated with PER, they exhibited three decomposition steps, as shown in Fig. 1 (WPC-2, WPC-3, and WPC-4). The first decomposition step (from about 200 to 250 °C) was attributed to a series of possible esterification reactions (Fig. 2) between APP and PER (Xia et al. 2014). With more PER incorporation, WPCs exhibited slightly lower Tmax1, which could be attributed to the comparatively lower decomposition temperature of PER (about 200 oC) (Camino et al. 1984a; Wang et al. 2009). Therefore, the more PER added to the WPCs, the comparatively lower the Tmax1 was. The second step (from 250 to 350 °C) represented the decomposition of part of the PP and APP, hemicellulose (225 to 325 °C), and cellulose (325 to 375°C) in the wood-flour, and further esterification reactions between APP and PER (Arao et al. 2014). The carbonaceous foam, a phosphate-carbon mixture containing both soluble phosphorous moieties and insoluble C-rich chars, formed during these two decomposition steps (Vandersall 1971; Camino et al. 1984a,b). The soluble phosphorous moieties were phosphorous degradation products from the APP-PER system, which could be defined as PDPs. This carbonaceous foam, with a mixture of rich chars and PDPs, could effectively protect underlying materials from further thermal degradation. Thus, the flame-retarding WPCs containing PER decomposed more slowly and exhibited higher thermal stability than WPC/APP in the last decomposition step and left much more char residue (about 45%) at 600 °C, especially in WPC-3 (47.2%).

Fig. 1. TGA (a) and DTG (b) curves of WPCs

Table 2. TGA Data of WPCs

Fig. 2. Possible esterification reactions between APP and PER

Fire Performance of WPCs

LOI tests

LOI tests were used to evaluate the flame retardancy of WPCs, and the results are shown in Table 3. As can be seen, the incorporation of APP increased the LOI value of the WPCs by 17.6% from 20.4 (WPC-0) to 24.0 (WPC-1), indicating that APP imparted the WPCs with better flame retardancy. With further addition of PER, the LOI value of the WPCs was increased by 5.4% (WPC-2) and 6.3% (WPC-3), as compared with WPC-1 (24.0). However, with more PER added to the composites, the LOI value of WPC-4 (25.2) was decreased slightly. It is well known that PER acts as the char forming agent in the IFR system, so the amount of char formed could increase with increasing PER incorporation, thus enhancing the efficiency of heat insulation and increasing the LOI value. However, the results of the LOI tests suggest that there should exist an optimal acid source (or blowing agent)/char forming agent ratio (APP/PER ratio) suitable to effectively achieve the synergistic effect of elemental P/C/N and produce carbonaceous foaming char with a certain hole size (Xia et al. 2014). Therefore, 3/1 (WPC-3) could be the optimal APP/PER ratio for the flame retardancy of WPCs.

Table 3. LOI data of WPCs

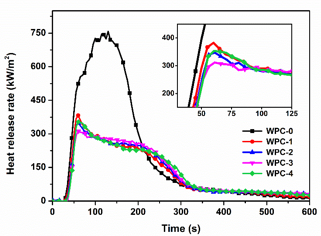

Cone calorimetry tests

Cone calorimetry can well simulate the behavior of a material in a real fire and was used to further interpret the results of the LOI tests. The ignition time (IT), peak-heat release rate (Pk-HRR), average-heat release rate (Av-HRR), average mass loss rate (Av-MLR), total heat release (THR), average specific extinction area (Av-SEA), and residue weight at the end of the tests are the main parameters to evaluate the combustion behavior of materials. They are summarized in Table 4. The HRR is one of the most significant parameters for flame retardancy evaluation, which is shown in Fig. 3. As can be seen, the composite without flame retardants (WPC-0) burned quickly after ignition and its Pk-HRR was 757.92 kW/m2. However, other composites exhibited dramatically lower HRR peaks. The THR value of WPC-1 (77.13 MJ/m2) was slightly lower than those of WPC-2, WPC-3, and WPC-4, which may be because that the actual amount of APP in composites played the important role in decreasing the THR, and WPC-1 contained more APP (30 wt. %) than the other WPCs (Tang et al. 2013). Comparatively, HRR, MLR, and SEA data showed the corresponding trends with the LOI data (Table 3). WPC-3 exhibited the lowest HRR, MLR, SEA values, demonstrating that WPC-3 displayed better flame retardancy than the other flame-retarding WPCs. In addition, WPC-2, WPC-3, and WPC-4 yielded much higher residue weights at the end of the test compared with WPC-1, illustrating that PER indeed acted as a char forming agent and promoted the formation of char residues in a real fire.

Fig. 3. HRR curves versus burning time of WPCs

Table 4. Cone Calorimetry Data of WPCs

Flame Retardant Mechanism

Figure 4 shows the SEM morphology of the surface residues of the flame-retarding WPCs at the end of the cone calorimetry tests. The surfaces of all the residues were covered by an expanded char network. The char residue of WPC-1 contained a large number of channels or gaps which could allow combustible gases and melting polymer to overflow, resulting in further combustion (Wang et al. 2015). Compared with that of WPC-1, the chars of WPC-2 and WPC-3 were swollen and there were some successive and randomly scattered bubbles that resulted from the decomposition of APP and the release of volatile gases, including NH3 and H2O. These gases could decrease the concentration of O2 on the surface of the burning materials, playing a positive role in the gas-phase flame retardant mechanism (Fig. 5a). On the other hand, the incorporation of PER promoted the formation of a honeycomb-like, intumescent char, which could prevent the transfer of heat and O2 between the surface of the burning materials and the underlying matrix, thus decreasing further pyrolysis reactions and improving the flame retardancy of the WPCs (Camino et al. 1984a; Wu et al. 2008) (Fig. 5b). Therefore, PER had a positive effect on the condensed-phase flame retardant mechanism. However, WPC-4 performed some discontinuous or broken intumescent char network, which may not prevent the transfer of the heat and O2. These morphologies could further demonstrate the lower flame-retardancy of WPC-4 than that of WPC-2 and WPC-3, which corresponded with the results of LOI and cone calorimetry tests.

Fig. 4. SEM images of the surface formation char of WPCs

Fig. 5. Possible intumescent flame-retarding process in WPC/APP/PER system

Mechanical Performance of WPCs

The mechanical performance, including the tensile properties, flexural properties, and impact strength of the WPCs, is shown in Table 5. The data presented are the average of six replicates. It was obvious that both the tensile properties and the impact strength of the WPCs decreased with the addition of APP, which was consistent with the findings of the previous reports (Canimo et al. 1984a; Ayrilmis et al. 2012; Wang et al. 2014). In addition, the MOR also decreased with the addition of APP into the WPCs, while the MOE increased. This was because APP had poor compatibility with the WPC matrix, but they could act as rigid particles in the matrix and enhance the MOE of the WPCs to some extent. WPC-1 contained more APP (30 wt. %) than the other flame-retarding WPCs, as a result, it performed the highest MOE value. When PER was incorporated, the mechanical performance of the WPCs decreased as compared with WPC-1, and further decreased with the increment PER in the WPCs. This may be due to the fact that PER had poor compatibility with PP because of their different polarities. On the other hand, the comparatively larger PER particles, with uneven dispersion, had a negative effect on the interfacial bonding between the matrix materials and acted as a site of stress concentration (Mareri et al. 1998), reducing the mechanical properties of the WPCs.

Table 5. Mechanical Properties of the WPCs

CONCLUSIONS

- Composites containing both APP and PER exhibited higher LOI values and lower HRRs, and left more char residues after combustion than the composites only containing APP (WPC-1), especially WPC-3 with an APP/PER ratio of 3/1, which left 42.3% more residues than WPC-1.

- The incorporation of PER improved the flame retardancy of WPCs, especially WPC-3 according to the LOI and cone calorimetry tests.

- The SEM morphologies of the residues from the WPCs indicated that PER promoted the formation of a honeycomb-like intumescent char and had a positive effect on the condensed-phase flame retardant mechanism.

- The addition of PER decreased the mechanical performance of the flame-retarding WPCs. Therefore, to extend the application of PER, further studies should be focused on improving the interfacial compatibility between PER and the composite matrix.

ACKNOWLEDGMENTS

The authors are grateful for the support of the Beijing Natural Science Foundation (2151003) and the Fundamental Research Funds for the Central Universities (BLYJ201511).

REFERENCES CITED

Arao, Y., Nakamura, S., Tomita, Y., Takakuwa, K., Umemura, T., and Tanaka, T. (2014). “Improvement on fire retardancy of wood flour/polypropylene composites using various fire retardants,” Polymer Degradation and Stability 100, 79-85. DOI:10.1016/j.polymdegradstab.2013.12.022

Ashori, A. (2008). “Wood-plastic composites as promising green-composites for automotive industries,” Bioresource Technology99(11), 4661-4667. DOI:10.1016/j.biortech.2007.09.043

Ayrilmis, N., Akbulut, T., Dundar, T., White, R. H., Mengeloglu, F., Buyuksari, U., Candan, Z., and Avci, E. (2012). “Effect of boron and phosphate compounds on physical, mechanical, and fire properties of wood-polypropylene composites,” Construction and Building Materials 33, 63-69. DOI:10.1016/j.conbuildmat.2012.01.013

Bai, G., Guo, C., and Li, L. (2014). “Synergistic effect of intumescent flame retardant and expandable graphite on mechanical and flame-retardant properties of wood flour-polypropylene composites,”Construction and Building Materials 50(15), 148-153. DOI:10.1016/j.conbuildmat.2013.09.028

Bourbigot, S., Le Bras, M., and Delobel, R. (1993). “Carbonization mechanisms resulting from intumescence association with the ammonium polyphosphate pentaerythritol fire retardant system,” Carbon 31(8), 1219-1230. DOI:10.1016/0008-6223(93)90079-P

Bourbigot, S., Le Bras, M., and Delobel, R. (1995). “Carbonization mechanisms resulting from intumescence – Part II. Association with an ethylene terpolymer and the ammonium polyphosphate-pentaerythritol fire retardant system,” Carbon 33(3), 283-294. DOI:10.1016/0008-6223(94)00131-I

Bourbigot, S., Le, B. M., Duquesne, S., and Rochery, M. (2004). “Recent advances for intumescent polymers,” Macromolecular Materials and Engineering 289(6), 499-511. DOI: 10.1002/mame.200400007

Camino, G., Costa, L., and Trossarelli, L. (1984a). “Study of the mechanism of intumescence in fire retardant polymers: Part I–Thermal degradation of ammonium polyphosphate-pentaerythritol mixtures,” Polymer Degradation and Stability 6(4), 243-252. DOI:10.1016/0141-3910(84)90004-1

Camino, G., Costa, L., and Trossarelli, L. (1984b). “Study of the mechanism of intumescence in fire retardant polymers: Part II – Mechanism of action in polypropylene ammonium polyphosphate-pentaerythritol mixtures,” Polymer Degradation and Stability 7(1), 25-31. DOI:10.1016/0141-3910(84)90027-2

Camino, G., Costa, L., and Trossarelli, L. (1984c). “Study of the mechanism of intumescence in fire retardant polymers: Part III – Effect of urea on the ammonium polyphosphate-pentaerythritol system,” Polymer Degradation and Stability 7(4), 221-229. DOI:10.1016/0141-3910(84)90098-3

Camino, G., Costa, L., and Trossarelli, L. (1984d). “Study of the mechanism of intumescence in fire retardant polymers: Part IV – Evidence of ester formation in ammonium polyphosphate-pentaerythritol system,” Polymer Degradation and Stability 8(1), 13-22. DOI:10.1016/0141-3910(84)90068-5

Camino, G., Costa, L., and Trossarelli, L. (1985a). “Study of the mechanism of intumescence in fire retardant polymers: Part V – Mechanism of formation of gaseous products in the thermal degradation of ammonium polyphosphate,” Polymer Degradation and Stability 12(3), 203-211. DOI:10.1016/0141-3910(85)90089-8

Camino, G., Costa, L., and Trossarelli, L. (1985b). “Study of the mechanism of intumescence in fire retardant polymers: Part VI – Mechanism of ester formation in ammonium polyphosphate-pentaerythritol mixtures,” Polymer Degradation and Stability 12(3), 213-228. DOI:10.1016/0141-3910(85)90090-4

Delobel, R., Bourbigot, S., Le Bras, M., Schmidt, Y., and Leroy, J. M. (1993). “Invariant values of kinetic parameters e evaluation of fire retardancy application to the PP-APP/PER system,” Macromolekulare Chemie. Macromolecular Symposia 74(1), 59-69. DOI: 10.1002/masy.19930740108

Demir, H., Arkìs, E., Balköse, D., and Ülkü, S. (2005). “Synergistic effect of natural zeolites on flame retardant additives,” Polymer Degradation and Stability 89(3), 478-483. DOI:10.1016/j.polymdegradstab.2005.01.028

García, M., Hidalgo, J., Garmendia, I., and Garcıa-Jaca, J. (2009). “Wood-plastic composites with better fire retardancy and durability performance,” Composites: Part A 40(11), 1772-1776. DOI:10.1016/j.compositesa.2009.08.010

Leu, S. Y., Yang, T. H., Lo, S. F., and Yang, T. H. (2012). “Optimized material composition to improve the physical and mechanical properties of extruded wood-plastic composites (WPCs),” Construction and Building Materials 29, 120-127. DOI:10.1016/j.conbuildmat.2011.09.013

Li, H. Y., Song, K. L., Zhou, D. G., and Wu, Q. L. (2014). “Effect of durability treatment on moisture sorption properties of wood-plastic composites,” BioResources 9(4), 6397-6407. DOI: 10.15376/biores.9.4.6397-6407

Li, S.M., Ren, J., Yuan, H., Yu. T., and Yuan. W.Z. (2010). “Influence of ammonium polyphosphate on the flame retardancy and mechanical properties of ramie fiber-reinforced poly(lactic acid) biocomposites,” Polymer International 59, 242-248. DOI: 10.1002/pi.2715

Mareri, P., Bastide, S., Binda, N., and Crespy, A. (1998). “Mechanical behavior of polypropylene composites containing fine mineral filler: Effects of filler surface treatment,” Composite Science and Technology 58(5), 747-752. DOI:10.1016/S0266-3538(97)00156-5

Ndiaye, D., Fanton, E., Morlat-Therias, S., Vidal, L., Tidjani, A., and Gardette, J.-L. (2008). “Durability of wood polymer composites: Part 1. Influence of wood on the photochemical properties,” Composites Science and Technology 68(13), 2779-2784. DOI:10.1016/j.compscitech.2008.06.014

Pan, M.Z., Mei, C.T., Du, J., and Li, G.C. (2014). “Synergistic effect of nano silicon dioxide and ammonium polyphosphate on flame retardancy of wood fiber-polyethylene composites,” Composites: Part A 66, 128-134. DOI: 10.1016/j.compositesa.2014.07.016

Stark, N. M., White, R. H., Mueller, S. A., and Osswald, T. A. (2010). “Evaluation of various fire retardants for use in wood flour-polyethylene composites,” Polymer Degradation and Stability 95(9), 1903-1910. DOI:10.1016/j.polymdegradstab.2010.04.014

Tang, Q. B., Wang, B. B., Shi, Y. Q., Song, L., and Hu, Y. (2013). “Microencapsulated ammonium polyphosphate with glycidyl methacrylate shell: Application to flame retardant epoxy resin,” Industrial & Engineering Chemistry Research 52(16), 5640-5647. DOI: 10.1021/ie302591r

Turke, I., Nikolaeva, M., and Kärki, T. (2014). “The effect fire retardants on the flammability, mechanical properties, and wettability of co-extruded PP-based wood-plastic composites,” BioResources9(1), 1539-1551. DOI: 10.15376/biores.9.1.1539-1551

Vandersall, H.L. (1971). “Intumescent coating systems, their development and chemistry,” Journal of Fire Flammability 2(9), 97-140.

Wang, W., Zhang, W., Zhang, S. F., and Li, J. Z. (2014). “Preparation and characterization of microencapsulated ammonium polyphosphate with UMF and its application in WPCs,” Construction and Building Materials 65(29), 151-158. DOI:10.1016/j.conbuildmat.2014.04.106

Wang, W., Zhang, W., Chen, H., Zhang, S. F., and Li, J. Z. (2015). “Synergistic effect of synthetic zeolites on flame-retardant wood-flour/polypropylene composites,” Construction and Building Materials 79(15), 337-344. DOI:10.1016/j.conbuildmat.2015.01.038

Wang, Z. Z., Lv, P., Hu, Y., and Hu, K. L. (2009). “Thermal degradation study of intumescent flame retardants by TG and FTIR: Melamine phosphate and its mixture with pentaerythritol,” Journal of Analytical and Applied Pyrolysis 86(1), 207-214. DOI: 10.1016/j.jaap.2009.06.007

Wu, K. Wang, Z. Z., and Hu, Y. (2008). “Microencapsulated ammonium polyphosphate with urea-melamine-formaldehyde shell: Preparation, characterization, and its flame retardance in polypropylene,” Polymer Advanced Technology 19(8), 1118-1125. DOI: 10.1002/pat.1095

Wu, G. F., and Xu, M. (2014). “Effects of boron compounds on the mechanical and fire properties of wood-chitosan and high-density polyethylene composites,” BioResources 9(3), 4173-4193. DOI: 10.15376/biores.9.3.4173-4193

Xia, Y., Jin, F. F., Mao, Z. M., Guo, Y., and Zheng, A. (2014). “Effects of ammonium polyphosphate to pentaerythritol ratio on composition and properties of carbonaceous foam deriving from intumescent flame-retardant polypropylene,” Polymer Degradation and Stability 107, 64-73. DOI:10.1016/j.polymdegradstab.2014.04.016

Article submitted: May 26, 2015; Peer review completed: July 20, 2015; Revised version received and accepted: July 22, 2015; Published: August 31, 2015.

DOI: 10.15376/biores.10.4.6917-6927