Abstract

The goal of this study was to develop an operational steam explosion pretreatment for effective modification of rice straw chemical structure in order to improve its biodegradability and methane yield. The parameters of pressure (5 bar to 15 bar), moisture (0% to 70%), and time (1 min to 15 min) were studied in steam explosion pretreatment. The steam explosion efficiency was investigated according to the changes in crystallinity structure and chemical composition on rice straw, as well as the methane yield from straw. Steam explosion changed the structure linkages between the lignin and carbohydrate, which was indicated by a reduction in the peak intensities in the bonds from 1648 cm-1 to 1516 cm-1. After pretreatment, the crystallinity index of the rice straw in the 10 bar-10 min cycle with no moisture and 15 bar-10 min cycle with 70% moisture increased from 22.9% to 28.3% and 28.6%, respectively. Steam explosion efficiently decreased the lignin. The highest reduction in the amount of lignin was observed with the 10 bar-10 min cycle, which reached from 18.6% to 13.0%. The methane yield increased with the cycles 10 bar-10 min and 15 bar-15 min with 35% moisture, and 15 bar-10 min with 70% moisture by 113%, 104%, and 147% compared to that of the untreated straw, respectively. Moreover, the highest biodegradation percent of the rice straw was obtained in these cycles.

Download PDF

Full Article

Effect of Steam Explosion on the Structural Modification of Rice Straw for Enhanced Biodegradation and Biogas Production

Abolfazl Lotfi Aski,a,d,* Alimohammad Borghei,a Ali Zenouzi,b Nariman Ashrafi,c and Mohammad J. Taherzadeh d

The goal of this study was to develop an operational steam explosion pretreatment for effective modification of rice straw chemical structure in order to improve its biodegradability and methane yield. The parameters of pressure (5 bar to 15 bar), moisture (0% to 70%), and time (1 min to 15 min) were studied in steam explosion pretreatment. The steam explosion efficiency was investigated according to the changes in crystallinity structure and chemical composition on rice straw, as well as the methane yield from straw. Steam explosion changed the structure linkages between the lignin and carbohydrate, which was indicated by a reduction in the peak intensities in the bonds from 1648 cm-1 to 1516 cm-1. After pretreatment, the crystallinity index of the rice straw in the 10 bar-10 min cycle with no moisture and 15 bar-10 min cycle with 70% moisture increased from 22.9% to 28.3% and 28.6%, respectively. Steam explosion efficiently decreased the lignin. The highest reduction in the amount of lignin was observed with the 10 bar-10 min cycle, which reached from 18.6% to 13.0%. The methane yield increased with the cycles 10 bar-10 min and 15 bar-15 min with 35% moisture, and 15 bar-10 min with 70% moisture by 113%, 104%, and 147% compared to that of the untreated straw, respectively. Moreover, the highest biodegradation percent of the rice straw was obtained in these cycles.

Keywords: Rice straw; Steam explosion pretreatment; Lignin; Crystallinity index; Anaerobic digestion; Methane yield

Contact information: a: Department of Biosystem Mechanical Engineering, Islamic Azad University Tehran Science and Research Branch, Tehran, Iran; b: Iranian Research Organizations for Science and Technology (IROST), Tehran, Iran; c: Department of Mechanical and Aerospace Engineering, Islamic Azad University Tehran Science and Research Branch, Tehran, Iran; d: Swedish Center for Resource Recovery, University of Borås, Sweden; *Corresponding author: lotfi_aski.abolfazl@hb.se

INTRODUCTION

Biogas is an important renewable fuel that has begun to be used as energy for transportation fuel, cooking, and power generation in recent years. Biogas is generated from different types of organic waste, agricultural residues, and wastewater treatment sludge, as well as energy crops (Teghammar et al. 2012; Kabir et al. 2014). One of the most produced agricultural residues around the world is related to rice straw. The estimated yearly global rice production in 2017 was approximately 759 million tons, where 1 kg to 1.5 kg of straw was obtained per 1 kg of rice crop (FAO 2017). Rice straw burning is the dominant removal method used by farmers to clean the farm for the next cultivation. Open burning of straw poses threats to the global environment because of the release of noxious greenhouse gases and short-lived pollutants into the air (Kaur et al. 2017). Additionally, rice straw is not suitable as an animal feed because of its low digestibility (Rodríguez et al. 2010). Straw consists of cellulose, hemicellulose, lignin, and ash. Generally, the cellulose chains in lignocelluloses are bound together by hydrogen bonds, in a mainly crystalline form in microfibrils. Microfibrils are covered by a matrix that includes hemicellulose, lignin, and other polymers, where lignin limits the accessibility of the carbohydrates to hydrolytic bacteria (Chen et al. 2011).

Another characteristic of rice straw is the presence of silica in the cell wall. This straw contains high amounts of silica. The first limiting factor in rice straw anaerobic digestion is silica, followed by lignin (Van Soest 2006). Lignin is not an independent polymer in the cell wall of rice straw (Abraham et al. 2016). Due to these properties, lignin is a hard and sturdy component in rice straw. Therefore, the high lignin content in rice straw results in a greater resistance to degradation.

The polysaccharides of rice straw are an appropriate source for renewable fuel production (Dehghani et al. 2015). The cellulose in rice straw is not easily accessible to microorganisms because of the complex nature of this substrate. Therefore, pretreatment is necessary prior to anaerobic digestion for the destruction of the lignin layer for effective digestion of the substrate (Taherzadeh and Karimi 2008). There are different pretreatment techniques, such as biological, chemical, and physical. A key step in removing hemicellulose, lignin, and silica from rice straw is the selection of economic, efficient, and environmentally friendly pretreatment techniques prior to anaerobic digestion (Kabir et al. 2014). Steam explosion is one of the most useful pretreatment methods for disrupting the lignocellulose structure. Rice straw is pretreated with hot steam under a high pressure, followed by a sudden pressure drop. The sudden pressure drop causes the degradation of the rigid structure of the biomass fibers, which results in better accessibility to the cellulose for fermentation by microorganisms and enzymes (Kitani et al. 1989; Zhou et al. 2016).

Several studies have reported that steam explosion pretreatment of lignocelluloses is an effective method for improving the enzymatic hydrolysis and bioethanol production. This pretreatment technique has also been used to pretreat several different biomasses to increase the biogas production yield (Ma et al. 2014). Steam explosion has been used to increase the methane production yield from wheat straw. The methane yield was improved by 20% to 30% compared to that of an untreated sample (Bauer et al. 2009). The conditions of steam explosion pretreatment were improved to obtain the highest methane production from bulrush. The highest methane production was obtained at 17 bar, 8.14 min, and a 11% moisture content, and was 24% higher compared to that of an untreated sample (Wang et al. 2010). Steam explosion with NaOH and H2O2 was used for pretreatment of paper tube residues and had positive effects on the methane production. Steam explosion pretreatment was conducted at 15 bar and 20 bar (190 °C to 220 °C) for 10 min and 30 min. The best result was observed at 220 °C and 10 min, and the production was 107% higher compared to that of the untreated sample (Teghammar et al. 2010). Zhou et al. (2016) reported that steam explosion pretreatment led to the distribution of special and clear differences in the population and earlier presence of bacteria during anaerobic digestion. Pretreatment at the conditions of 200 °C and 120 s resulted in the highest biogas production of 328.7 mL/g TS, which led to a 51% increase in the methane production compared to that of the unpretreated sample. Kobayashi et al. (2004) studied the methane yield from steam-exploded bamboo under various steaming times of 1 min, 3 min, 5 min, 10 min, and 20 min at a pressure of 35 bar. Vivekanand et al. (2012) examined the effect of steam explosion on the methane yield from brown seaweed. The thawed seaweed was treated at 130 °C, 160 °C, and 210 °C for 10 min.

Usually, the pretreatment pressure is studied within the range of 5 to 40 bar (160 to 280 °C), and the retention time is from several seconds to a few minutes. Most studies have examined a limited range of steam explosion parameters, and the moisture content in the feedstock has also been poorly considered in steam explosion pretreatment. Therefore, there is not a lot of data on using the steam explosion method with wider range of parameters to modify the structure of rice straw for methane production. Hence, rice straw was pretreated in a steam explosion reactor at pressures of 5 bar to 15 bar. The rice straw was kept at different pressures inside of the pressure vessel for 1 min to 15 min; moreover, the rice straw was investigated with three moisture contents (0%, 35%, and 70%).

The main goal of this investigation was to modify the structure of rice straw with steam explosion pretreatment techniques to increase the biodegradability. Finally, the impacts of the pretreatment on the composition and structure of the rice straw were investigated by performing anaerobic batch digestion. This study aimed to enhance the digestibility of rice straw for an optimum methane yield.

EXPRIMENTAL

Materials

Rice straw, acquired from Rice Research Institute of Iran (Amol, Iran), was used as the substrate for anaerobic digestion. Rice straw as the blank sample was dried in an oven at 105 °C for 24 h to decrease the moisture level to less than 5%. Thereafter, the straw was cut into 3-mm sections with a pair of scissors. The inoculum used in this case study was obtained from the municipal wastewater treatment plant in Tehran, Iran. The inoculum was centrifuged to enhance the total solids (TS) from 9.0 to 19.8% and was then activated at 37 °C for 4 d prior to use.

Methods

Steam explosion pretreatment

The steam explosion reactor was constructed with an operating pressure of up to 40 bar and a temperature of 280 °C. It consisted of a steam generator, pressure vessel, and vacuum tank. A steam generator was used, with a 20-L capacity for pressure and heat production. The pressure vessel had a capacity of 3 L. Each treatment cycle used up to 100 g of rice straw. During pretreatment, the steam penetrated the pores of the rice straw. Using a solenoid valve control key on the control panel, steam was directed to the pressure vessel until the desired pressure was reached. Pressures from 5 bar to 15 bar, moisture contents from 0% to 70%, and times of 1 min to 15 min were studied. This resulted in a total of 36 pressure/time/moisture combinations. After the high pressure pretreatment, the pressure was released through the vacuum tank (200 L) by opening the angle valve, which created a sudden pressure drop. After the sudden pressure drop, a pressure difference was created between the inside of the fibers and surrounding environment; therefore, the rice straw was exploded.

Anaerobic digestion

Anaerobic digestion conditions were used with mesophilic bacteria (inoculum) at 37.5 °C in batch reactors. The reactors were glass bottles with a 118-mL total volume that were closed with butyl rubber seals and aluminum caps (Hansen et al. 2004). The pretreated rice straw was considered to be the substrate for methane production. The volatile solids (VS) percentage was 83% and 10.4% in the rice straw and inoculum, respectively. Each reactor was based on VSinoculum: VSsubstrate ratio (2:1) contained 1.64 g VS of inoculum and 0.83 g VS of pretreated rice straw. The total volume of the reactor reached 25 mL by adding a certain amount of deionized water. To determine the methane production from the inoculum, a blank sample containing inoculum and deionized water was analyzed. The mixture of the pretreated rice straw and inoculum was the control sample. To obtain an anaerobic state in the reactor, the headspace was flushed with pure nitrogen for 2 min. All of the experimental tests were performed in triplicate. The reactors were kept in an incubator at 37.5 °C for 60 d. During incubation, the reactors were shaken once a day. Biogas samples were taken from each reactor with a syringe, and the methane yield was measured by gas chromatography.

Analyzing the chemical composition of the rice straw

The chemical components of the rice straw were identified by NREL methods, and their values were compared to each other. The TS, VS, and ash contents were measured by drying the samples at 105 °C for 24 h in an oven and then heating them in a furnace at 550 °C for 4 h (Sluiter et al. 2008a,b). The amount of biogas produced in each reactor was measured on a daily basis using a syringe. The methane produced from the reactors during incubation was measured using a gas chromatograph (Auto System, Perkin Elmer, Waltham, U.S.A.). The data analysis was performed as explained by Teghammar et al. (2010).

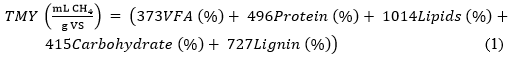

The theoretical methane yield was determined using the organic composition with Eq. 1 (Triolo et al. 2011):

The biodegradability (BD%) of the samples was calculated with Eq. 2 (Li et al. 2013):

![]()

Analysis of the structural changes

Intensity changes and band shifts in the untreated and pretreated rice straw were identified using Fourier transform infrared (FTIR) spectroscopy (Impact 410, Nicolet Instrument Corp., Madison, WI, USA) by direct transmittance using the KBr pellet technique. The peaks were analyzed using the Essential FTIR software (Version 3.2, Madison, WI, USA). The FTIR spectra of the rice straw were recorded in the absorption range of 600 cm-1 to 4000 cm-1 with a resolution of 4 cm-1 and 32 scans.

X-ray diffraction (XRD) analysis

The crystalline phase was identified using X-ray diffraction (PW 1710, Philips, Amsterdam, Netherlands) with Cu Kα radiation. Radial scans of the intensity were recorded at the scattering 2θ angles of 5° to 40° (step size = 0.02°, scanning rate = 2 s/step) using radiation (λ = 1.54 A°). The crystallinity index (CrI) of the rice straw was determined with the following empirical equation,

CrI (%) = [(I002 – Iam) / I002] × 100% (3)

where I002 is the intensity of the diffraction at 2θ values of 22° to 23° for cellulose I, and Iam is the intensity of the diffraction at 2θ values of 18° to 19°, which represent the amorphous part of lignocellulose.

Statistical analysis

The values shown were the means of triplicates with the standard deviation. The data were statistically analyzed with 95% confidence intervals using the Minitab software package (Version 17, Pennsylvania, U.S.A.). The response surface was considered by a linear model analysis of variance (ANOVA) to determine the parameters’ effects on the methane yield (anaerobic digestion process) after steam explosion. The effect of the pressure and moisture variables at three levels and the effect of the time at four levels resulted in a total of 36 experimental runs.

RESULTS AND DISCUSSION

Steam explosion pretreatment of rice straw with different cycles is a complicated physical-chemical reaction that causes changes to the rice straw structure. These structural changes lead to increased VS and TS contents after pretreatment. Furthermore, steam explosion pretreatment degrades the crystalline structure of rice straw, which causes the microorganism accessibility to carbohydrates to increase (Zheng et al. 2014).

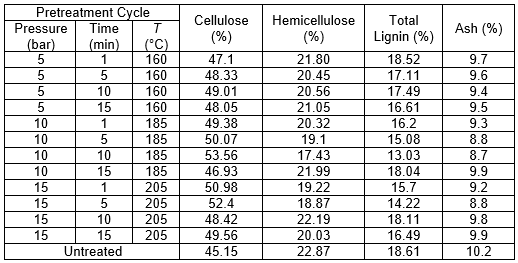

Effects of the Pretreatment on the Chemical Composition of the Rice Straw

The untreated rice straw consisted of cellulose (45.2%), hemicellulose (22.9%), lignin (18.6%), and ash (10.2%). The results of the chemical composition analysis of the pretreated rice straw are presented in Table 1. According to the results, the cellulose content increased in the pretreated rice straw compared to that in the untreated rice straw with an increasing pressure and retention time. However, the other components (lignin, hemicellulose, and ash) were noticeably reduced. This analysis demonstrated that in the 10 bar-10 min cycle with a 0% moisture content and the 15 bar-1 min and 15 bar-5 min cycles, there was more lignin and ash removal. After the pretreatment, a reduction in the hemicellulose amount was observed in the pretreated rice straw. Pretreatment with a pressure of 5 bar and a low retention time led to approximately the same lignin, ash, and carbohydrate contents as in the untreated sample (Table 1).

Table 1. Chemical Compositions of the Untreated and Pretreated Rice Straw

The results demonstrated that the pretreatment technique is able to remove lignin and hemicellulose under high pressure conditions.

Pressure is the most important parameter in steam explosion pretreatment, other than the moisture and time (Xiao et al. 2014). During steam explosion pretreatment, hemicellulose is first damaged, followed by lignin when the temperature is greater than 150 °C (Ma et al. 2014). In addition to removing hemicellulose, steam explosion causes major modifications to the lignin structure. Lignin degrades in the temperature range of 120 °C to 200 °C. It divides into smaller particles and is separated from the cellulose (Fan et al. 2016). Steam explosion damaged the cell walls of the rice straw by disrupting the lignin structure.

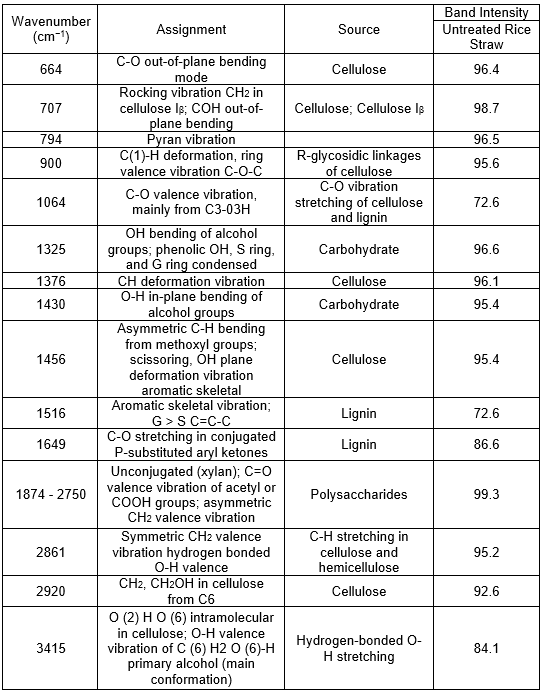

Table 2. TS and VS Contents of the Pretreated and Untreated Rice Straw

The analysis showed that the pretreated rice straw contained 91.8% TS and 83% VS on a wet weight basis, which increased with different pretreatment cycles. Table 2 shows the VS and TS contents in the pretreated rice straw. According to the results, an increase in the pressure increased the VS content. This was an indication of a higher carbohydrate content in the pretreated rice straw (Dehghani et al. 2015).

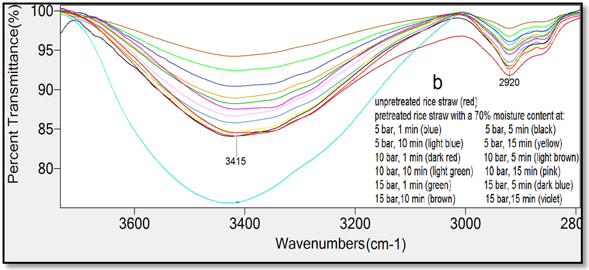

Effects of the Pretreatment on the Rice Straw Structure

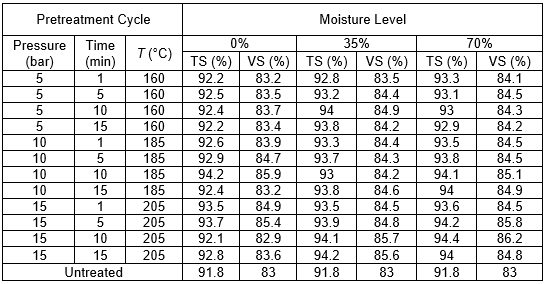

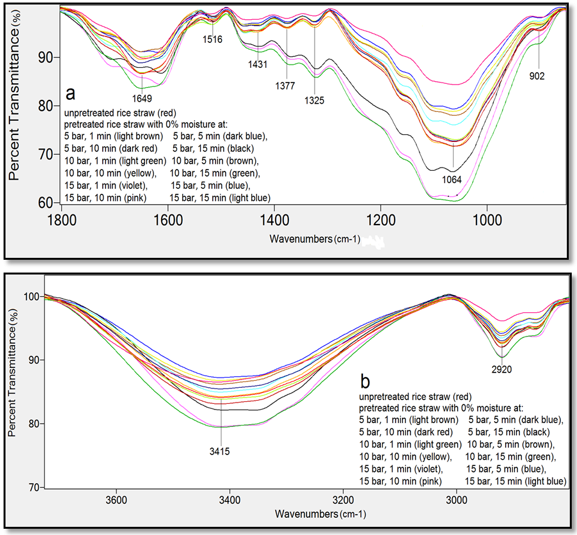

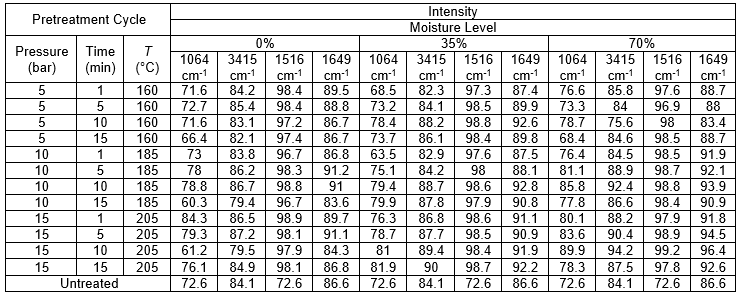

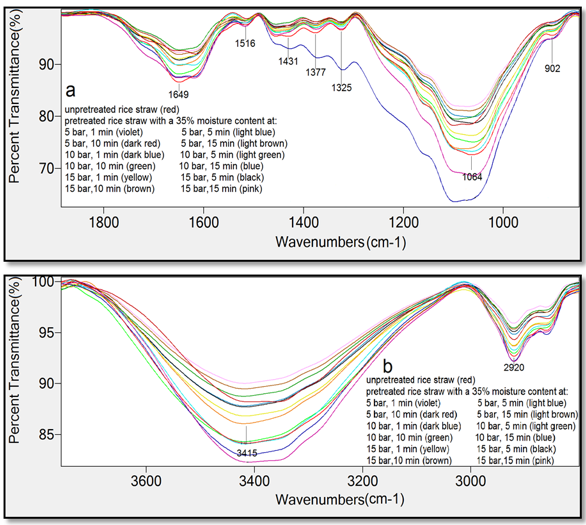

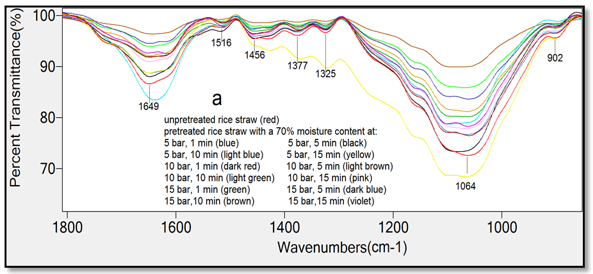

Absorption bands in the rice straw were found in the range from 450 cm-1 to 3600 cm-1 (Table 3). The results for the changes in the functional groups and structure of the rice straw are shown in Table 4. The band between 3600 cm-1 and 3100 cm-1 was related to OH stretching vibration present in cellulose, hemicellulose, and lignin (Rahnama et al. 2013). The intensity of the band at 3415 cm-1 decreased as a result of the high-pressure steam explosion pretreatment, namely at 10 bar for 5 min and 10 min and 15 bar for 1 min and 5 min with a 0% moisture content, 15 bar for 10 min and 15 min and 10 bar for 10 min with a 35% moisture content, and 15 bar for 5 min and 10 min with a 70% moisture content (Table 4) (Figs. 1 to 3). Therefore, it was indicated that hydrogen bonds were degraded. This is a key step for increasing the accessibility of enzymes and microorganisms to cellulose (He et al. 2008).

Table 3. Group Frequency of the Absorption Bands for the Pretreated Rice Straw

The peaks at 2920 cm-1 and 2861 cm-1 were related to the C-H stretching vibration. The intensity of the peaks indicated that they were hemicellulose and cellulose (methyl and methylene). The intensity of the bands was reduced after the pressure increased (Kazeem et al. 2017). The loss of aromatic units and changes in the lignin were identified by changes in the intensity of the band at 1649 cm-1. The aromatic ring changes in the lignin were revealed by the intensity of the band at 1516 cm-1 (Isroi et al. 2012). The intensity of both bands was reduced with an increased pretreatment pressure, including 10 bar for 5 min and 10 min and 15 bar for 1 min and 5 min with a 0% moisture content, 10 bar for 10 min and 15 bar for 10 min and 15 min with a 35% moisture content, and 10 bar for 5 min and 10 min and 15 bar for 5 min and 10 min with a 70% moisture content (Table 4) (Figs. 1 to 3). This was an indication of lignin structural changes.

Fig. 1. FTIR spectra of the unpretreated rice straw and pretreated with 0% moisture, (a) wavenumbers between 800 and 1800 cm-1; (b) wavenumbers between 2800 and 3800 cm-1

The band at 1064 cm-1 is usually attributed to structural specifications of cellulose and hemicelluloses (Rahnama et al. 2013). It was clear that the band at 1064 cm-1 had lower intensity compared to that in the untreated rice straw. The decrease in this band intensity was related to the decreased hemicellulose content after the steam explosion pretreatment cycles with 10 bar for 5 min and 10 min and 15 bar for 1 min and 5 min with a 0% moisture content, 10 bar for 10 min and 15 min and 15 bar for 10 min and 15 min with a 35% moisture content, and 10 bar for 10 min and 15 min and 15 bar for 1 min, 5 min, and 10 min with a 70% moisture content (Table 4) (Figs. 1 to 3). The increase in the intensity of this band might have been because of the dissolution of non-cellulose components, which caused an increase in the cellulose content in the rice straw (Ang et al. 2012). The absorption band at 1430 cm-1 was related to amorphous cellulose (Kazeem et al. 2017). The intensity of the band at 1430 cm-1 was reduced after the steam explosion pretreatment, which meant the amorphous part of the structure was degraded, especially after lignin structural changes occurred.

Table 4. Intensity Changes of the Absorption Bands for the Structural Changes in the Pretreated Rice Straw

Fig. 2. FTIR spectra of the unpretreated rice straw and pretreated with 35% moisture content: (a) wavenumbers between 800 and 1900 cm-1; (b) wavenumbers between 2800 and 3800 cm-1

The lignin structure was degraded in the cycles with 10 bar for 5 min and 10 min and 15 bar for 1 min and 5 min with a 0% moisture content, 15 bar for 10 min and 15 min with a 35% moisture content, and 15 bar for 5 min and 10 min with a 70% moisture content.

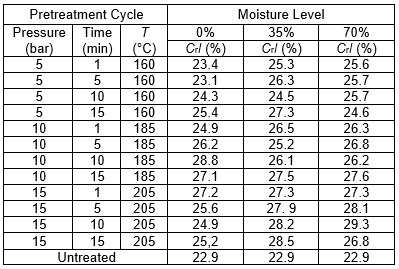

Lignocelluloses contain amorphous and crystalline regions. The amorphous part consists of hemicelluloses and lignin, while the crystalline part consists of cellulose (Sakdaronnarong and Jonglertjunya 2012). The cellulose crystallinity, generally between 30 and 80%, refers to the percentage of all the cellulose occupied in the crystalline region (Chen 2014). The crystallinity index of both the untreated and pretreated rice straws is shown in Table 5. Two peaks were observed at 2θ values of 18° to 19° and 22° to 23°, which were related to the amorphous and crystalline regions in the rice straw, respectively. According to the results, the crystallinity index increased in all of the pretreated rice straw samples compared to the untreated sample. The highest crystallinities of the pretreated rice straw were 28.8%, 28.6%, and 29.3% in the cycles 10 bar-10 min with a 0% moisture content, 15 bar-15 min with a 35% moisture content, and 15 bar-10 min with a 70% moisture content, respectively, which were higher than for the untreated rice straw (22.9%). In all of the pretreated samples, the crystalline cellulose region was higher compared to the amorphous region (Table 5). During the steam explosion pretreatment, hemicellulose and lignin were hydrolyzed by the increased pressure, which mainly constitutes the amorphous part. This led to an increase in the crystallinity index after pretreatment.

Table 5. Crystallinity Index of the Untreated and Pretreated Rice Straw

Previous research has also suggested that the crystallinity index of rice straw could be enhanced by other thermal pretreatments, while not negatively affecting fermentation (Kshirsagar et al. 2015). The increase in the crystallinity index was because of the increased effect of steam explosion in the amorphous part than in the crystalline part. Rahnama et al. (2013) reported an enhancement in the crystallinity index from 50.8% to 61.4% in alkali-pretreated rice straw. The crystallinity index in the rice straw pretreated with microwaves and acid increased to 61.4% from 52.2% for pretreated rice straw (Singh et al. 2014).

Fig. 3. FTIR spectra of the unpretreated rice straw and pretreated with 70% moisture content: (a) wavenumbers between 800 and 1900 cm-1; (b) wavenumbers between 2800 and 3800 cm-1

Fig. 4. X-ray diffraction of (a) unpretreated rice straw, (b) pretreated 10 bar, 10 min, 0% moisture, (c) pretreated 10 bar, 15 min, 0% moisture, (d) pretreated 15 bar, 10 min, 35% moisture, (e) pretreated 15 bar, 15 min, 35% moisture, (f) pretreated 15 bar, 5 min, 70% moisture, and (g) pretreated 15 bar, 15 min, 70% moisture

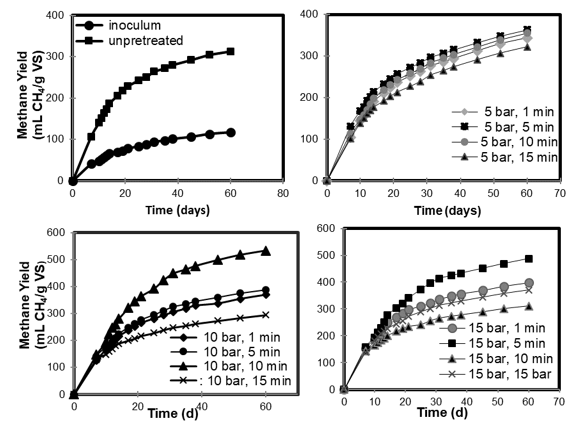

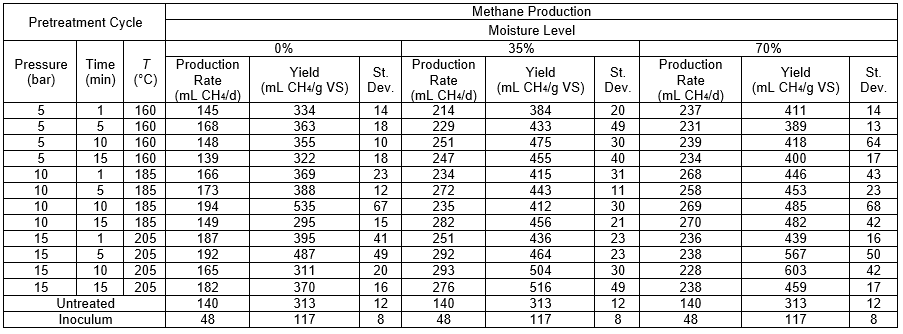

Effect of the Steam Explosion Pretreatment on the Biogas Production

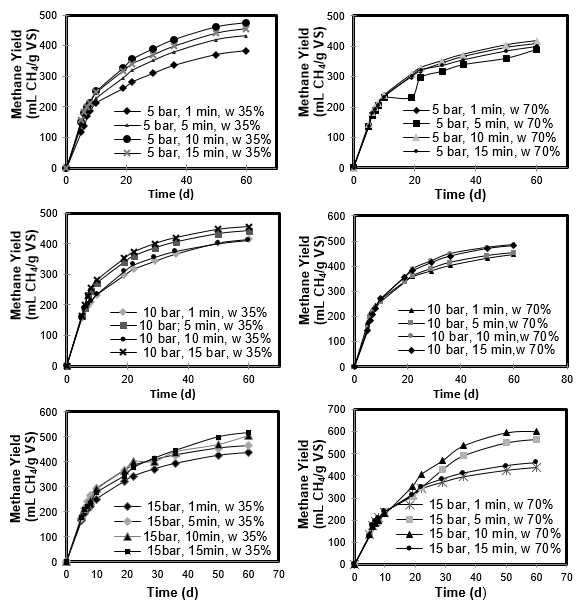

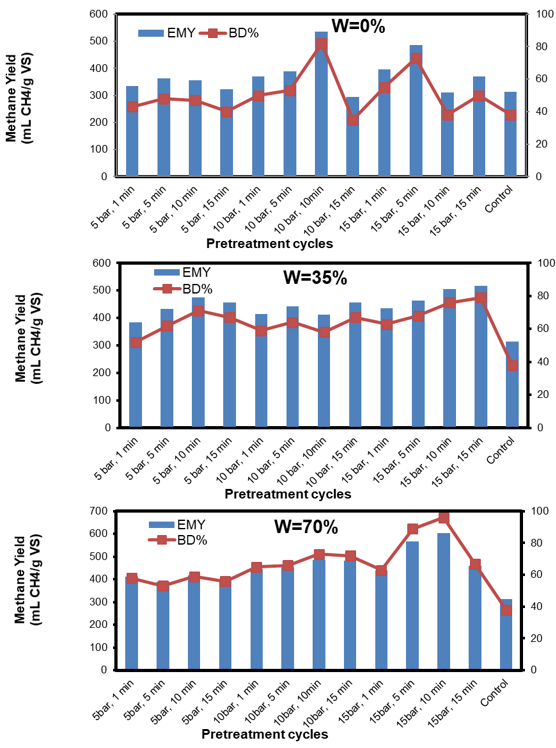

The total methane produced from the pretreated rice straw after 60 d of incubation is presented in Table 6. The time, pressure, and moisture levels were investigated as variable pretreatment parameters, and the impacts of the pretreatment were evaluated with the methane yield as the response variable. The average amount of methane produced per day was measured during the first 10 d of the anaerobic digestion process as the initial production rates. The results are shown in Table 6. The theoretical methane yield was calculated using Eq. 1 and was 503 mL/g VS for the untreated rice straw. The biodegradability was determined for pretreated rice straw. The results are shown in Fig. 6.

The methane produced by the inoculum was deducted from the total methane produced from each sample. The highest initial production rate was obtained for the 0% moisture content after pretreatment of the rice straw with the 10 bar-10 min cycle, with an increase of 59% from 92 mL/g VS for the untreated straw to 146 mL/g VS and then 144 mL/g VS (Fig. 5). The pretreated rice straw in the cycles with a low pressure and time led to almost similar initial production rates compared to that of the untreated rice straw (Fig. 5 and Table 6). The highest initial production rate was obtained for the 35% moisture content in the pretreated rice straw with the 15 bar-10 min cycle, with an increase of 166% from 92 mL/g VS to 245 mL/g VS and then 244 N mL/g VS (Fig. 6). The maximum initial production rate was obtained for the 70% moisture content after pretreatment with the 10 bar-15 min cycle. It increased by 141% from 92 mL/g VS to 222 mL/g VS and then 221 mL/g VS (Fig. 6).

Fig. 5. Total methane produced from the pretreated rice straw with a 0% moisture content

The highest methane yield for the 0% moisture content was observed for the pretreated rice straw with the 10 bar-10 min and 15 bar-5 min cycles, with values of 418 mL/g VS and 370 mL/g VS, respectively (untreated = 196 mL/g VS) (Table 6, Fig. 5). This was a 114% increase in the methane yield. The rice straw pretreated with the 15 bar for 15 min and 10 min cycles resulted in the highest methane production yields for the 35% moisture content, with values of 399 mL/g VS and 387 mL/g VS, respectively (Fig. 6). The methane production yield increasing from 196 mL/g VS to 399 mL/g VS was an increase of 104% (Table 6). The highest methane production yields for the 70% moisture content were obtained with the rice straw after pretreatment with the 15 bar for 10 min and 5 min cycles, with values of 486 mL/g VS and 450 mL/g VS, respectively (Fig. 6).

The methane production yield increasing from 196 mL/g VS to 486 N mL/g VS was an increase of 147% (Table 6). The highest increase in the biodegradability was observed with the cycles 10 bar-10 min and 15 bar-10 min with a 35% moisture content and 10 bar-15 min with a 70% moisture content (Fig. 7). According to the increase in the methane production yield, the structure of the rice straw was changed by the steam explosion pretreatment; therefore, the methane production increased during the first days of the anaerobic digestion process. According to the initial production rate of the pretreated rice straw, the cycles 10 bar-10 min and 15 bar-15 min with a 35% moisture content, and 15 bar-10 min with a 70% moisture content had methane production yields of approximately 35%, 57%, and 37%, which occurred in the first 10 d of incubation, respectively.

Table 6. Total Methane Produced and Initial Rate of Methane Production from the Pretreated Rice Straw With Different Moisture Contents

Fig. 6. Total methane produced from the pretreated rice straw with 35% and 70% moisture contents

The lowest initial production rate for the 0% moisture content was observed with the 5 bar-15 min cycle, which led to a methane yield of 91 mL/g VS. This was similar to that of the untreated rice straw (92 mL/g VS) (Fig. 5). The lowest methane production for the 0% moisture content was with the 10 bar-15 min cycle, which led to a methane production yield of 178 mL/g VS. This was less than that of the untreated rice straw (196 mL/g VS) (Fig. 5).

Fig. 7. Biodegradability (BD%) and methane production yields (EMY)

The lowest initial production rate and methane production yield for the 35% moisture content were observed with the rice straw pretreated with the 5 bar-1 min cycle, which led to a methane production rate and yield of 166 mL/g VS and 267 mL/g VS that were higher than that of the untreated sample at 92 mL/g VS and 196 mL/g VS, respectively (Fig. 6). The rice straw pretreated with the 15 bar-10 min cycle resulted in the initial production rate of 180 mL/g VS, which was the lowest for the 70% moisture content (Fig. 6). The lowest methane production yield for the 70% moisture content was with the 5 bar-5 min cycle, which led to a methane production of 272 mL/g VS (Table 6).

According to the positive effects of steam explosion, the lignin removal and structural changes in the rice straw increased the methane yield. The best results were obtained with the cycles 10 bar-10 min with a 0% moisture content, 15 bar-15 min with a 35% moisture content, and 15 bar-10 min with a 70% moisture content, which increased the methane yield by 104% to 147% compared to that of the untreated straw. Also, these pretreatment cycles led to a noticeable increase in the biodegradability of the rice straw.

The most important parameter was the pressure, followed by the moisture content and time for steam explosion pretreatment. The results of the methane produced from the pretreated rice straw showed that increasing the pressure from 5 bar to 10 bar and 15 bar imcreased the methane yield. The effect of the retention time was dependent upon the pressure and moisture content. When the moisture level was 0% with the high pressure cycle, the high retention time (15 min) caused a complete destruction of the rice straw structure and had a negative effect on the methane production (Table 6). However, with a similar cycle condition and an increased moisture content, the rice straw resistance was enhanced against heating and burning, which prevented the complete destruction of the rice straw structure. The increase in the moisture content had a positive impact on the methane yield (Table 6).

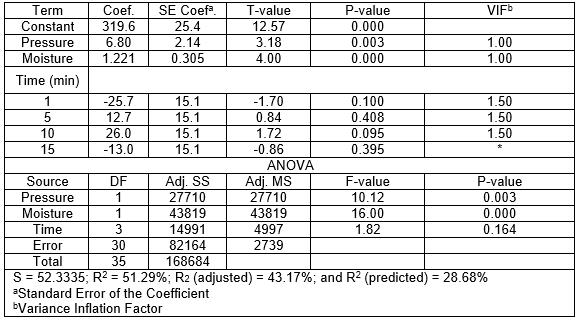

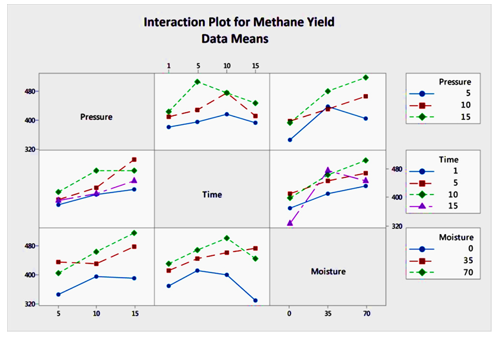

Table 7. General Linear Model ANOVA to Determine the Parameter Effect of Steam Explosion with the Methane Yield as the Variable Response

For the effects of the parameters, the confidence intervals of the steam explosion were calculated for the anaerobic digestion experiments. The response surface following the steam explosion pretreatment had two levels for each parameter. The parameters were used as covariates to determine the impacts of the pretreatment. The investigated parameters were significant when the probability (p-value) was less than 0.05. The ANOVA analysis (Table 7) showed that the pressure and moisture were the significant factors that increased the methane yield, and the time was not statistically significant (Fig. 8).

Fig. 8. Interaction plots for the methane yield

According to the results of the fits and diagnostics for the unusual observations, the 10 bar-10 min and 15 bar-10 min cycles with a 0% moisture content were the best and worst pretreatment conditions, considering the standard residuals of 2.50 and -2.91 and fits of 413.6 and 447.5, respectively.

CONCLUSIONS

The steam explosion pretreatment was effective in removing lignin and hemicellulose, and also changed the crystalline structure of the rice straw before the anaerobic digestion process. The steam explosion pretreatment was effective in modifying the structure of the rice straw

According to the results, the most important parameter was the pressure, followed by the moisture content and time in steam explosion pretreatment.

Steam explosion with the cycles of high pressure (10 bar and 15 bar) and a long retention time was more effective in modifying the rice straw structure.

Steam explosion is a suitable technique to improve the biogas production yield as a pretreatment for rice straw. The pretreatments with 10 bar-10 min and 15 bar-10 min were the best and worst cycles, respectively.

The biodegradability of the rice straw was noticeably increased using steam explosion. The initial production rates were increased by factors of 1.59, 2.66, and 2.41 compared to that of the untreated rice straw.

Steam explosion is a suitable pretreatment method for improving biogas production. The methane gas yields obtained after 60 d were 535 mL/g VS, 516 mL/g VS, and 613 mL/g VS, which were increases by factors of 2.14, 2.04, and 2.47 compared to that of the untreated rice straw, respectively. This demonstrated the ability of the steam explosion pretreatment to modify the rice straw structure.

ACKNOWLEDGMENTS

The authors wish to thank Amir Mahboubi Soufiani and Regina Patinvoh for their help with editing. The financial support from University of Borås is acknowledged.

REFERENCES CITED

Abraham, A., Mathew, A. K., Sindhu, R., Pandey, A., and Binod, P. (2016). “Potential of rice straw for bio-refining: An overview,” Bioresource Technol. 215, 29-36. DOI: 10.1016/j.biortech.2016.04.011

Ang, T. N., Ngoh, G. C., Chua, A. S. M., and Lee, M. G. (2012). “Elucidation of the effect of ionic liquid pretreatment on rice husk via structural analyses,” Biotechnol. Biofuels 5(1), 67. DOI: 10.1186/1754-6834-5-67

Bauer, A., Bösch, P., Friedl, A., and Amon, T. (2009). “Analysis of methane potentials of steam-exploded wheat straw and estimation of energy yields of combined ethanol and methane production,” J. Biotechnol. 142(1), 50-55. DOI: 10.1016/j.jbiotec.2009.01.017

Chen, H. Z. (2014). Biotechnology of Lignocellulose: Theory and Practice, Chemical Industry Press, Beijing and Springer Dordrecht Publisher. DOI: 10.1007/978-94-007-6898-7

Chen, X., Yu, J., Zhang, Z., and Lu, C. (2011). “Study on structure and thermal stability properties of cellulose fibers from rice straw,” Carbohyd. Polym. 85(1), 245-250. DOI: 10.1016/j.carbpol.2011.02.022

Dehghani, M., Karimi, K., and Sadeghi, M. (2015). “Pretreatment of rice straw for the improvement of biogas production,” Energ. Fuel. 29(6), 3770-3775. DOI: 10.1021/acs.energyfuels.5b00718

Fan, S., Zhang, P., Li, F., Jin, S., Wang, S., and Zhou, S. (2016). “A review of lignocellulose change during hydrothermal pretreatment for bioenergy production,” Curr. Org. Chem. 20(26), 2799-2809. DOI: 10.2174/1385272820666160513154113

FAO (2017). Rice Market Monitor (Volume XX, Issue No. 2), Food and Agriculture Organization of the United Nations (FAO), Rome, Italy.

Hansen, T. L., Schmidt, J. E., Angelidaki, I., Marca, E., Jansen, J. l. C., Mosbæk, H., and Christensen, T. H. (2004). “Method for determination of methane potentials of solid organic waste,” Waste Manage. 24(4), 393-400. DOI: 10.1016/j.wasman.2003.09.009

He, Y., Pang, Y., Liu, Y., Li, X., and Wang, K. (2008). “Physicochemical characterization of rice straw pretreated with sodium hydroxide in the solid state for enhancing biogas production,” Energ. Fuel. 22(4), 2775-2781. DOI: 10.1021/ef8000967

Isroi, Ishola, M. M., Millati, R., Syamsiah, S., Cahyanto, M. N., Niklasson, C., and Taherzadeh, M. J. (2012). “Structural changes of oil palm empty fruit bunch (OPEFB) after fungal and phosphoric acid pretreatment,” Molecules 17(12), 14995-15012. DOI: 10.3390/molecules171214995

Kabir, M. M., Niklasson, C., Taherzadeh, M. J., and Horváth, I. S. (2014). “Biogas production from lignocelluloses by N-methylmorpholine-N-oxide (NMMO) pretreatment: Effects of recovery and reuse of NMMO,” Bioresource Technol. 161, 446-450. DOI: 10.1016/j.biortech.2014.03.107

Kaur, D., Bhardwaj, N. K., and Lohchab, R. K. (2017). “Prospects of rice straw as a raw material for paper making,” Waste Manage. 60, 127-139. DOI: 10.1016/j.wasman.2016.08.001

Kazeem, M. O., Shah, U. K. M., Baharuddin, A. S., and Abdul Rahman, N. A. A. (2017). “Influence of high-pressure steam pretreatment on the structure of rice husk and enzymatic saccharification in a two-step system,” Bioresources 12(3), 6207-6236. DOI: 10.15376/biores.12.3.6207-6236

Kitani, O., Hall, C. W., and Wagener, K. (1989). Biomass Handbook, Gordon and Breach Science Publishers, New York, NY.

Kobayashi, F., Take, H., Asada, C., and Nakamura, Y. (2004). “Methane production from steam-exploded bamboo,” J. Biosci. Bioeng. 97(6), 426-428. DOI: 10.1016/S1389-1723(04)70231-5

Kshirsagar, S. D., Waghmare, P. R., Loni, P. C., Patil, S. A., and Govindwar, S. P. (2015). “Dilute acid pretreatment of rice straw, structural characterization and optimization of enzymatic hydrolysis conditions by response surface methodology,” RSC Adv. 5(58), 46525-46533. DOI: 10.1039/C5RA04430H

Li, Y., Zhang, R., Liu, G., Chen, C., He, Y., and Liu, X. (2013). “Comparison of methane production potential, biodegradability, and kinetics of different organic substrates,” Bioresource Technol. 149, 565-569. DOI: 10.1016/j.biortech.2013.09.063

Ma, X. J., Yang, X. F., Zheng, X., Lin, L. H., Chen, L. H., Huang, L. L., and Cao, S. L. (2014). “Degradation and dissolution of hemicelluloses during bamboo hydrothermal pretreatment,” Bioresource Technol. 161, 215-220. DOI: 10.1016/j.biortech.2014.03.044

Rahnama, N., Mamat, S., Md Shah, U. K., Ling, F. H., Abdul Rahman, N. A., and Ariff, A. B. (2013). “Effect of alkali pretreatment of rice straw on cellulase and xylanase production by local Trichoderma harzianum SNRS3 under solid state fermentation,” BioResources 8(2), 2881-2896. DOI: 10.15376/biores.8.2.2881-2896

Rodríguez, A., Sánchez, R., Requejo, A., and Ferrer, A. (2010). “Feasibility of rice straw as a raw material for the production of soda cellulose pulp,” J. Clean. Prod. 18(10-11), 1084-1091. DOI: 10.1016/j.jclepro.2010.03.011

Sakdaronnarong, C., and Jonglertjunya, W. (2012). “Rice straw and sugarcane bagasse degradation mimicking lignocellulose decay in nature: An alternative approach to biorefinery,” ScienceAsia 38(4), 364-372. DOI: 10.2306/scienceasia1513-1874.2012.38.364

Singh, R., Tiwari, S., Srivastava, M., and Shukla, A. (2014). “Microwave assisted alkali pretreatment of rice straw for enhancing enzymatic digestibility,” J. Energy 2014, 1-7. DOI: 10.1155/2014/483813

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., and Templeton, D. (2008a). Determination of Ash in Biomass (NREL/TP-510-42622), National Renewable Energy Laboratory, Golden, CO.

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D., and Crocker, D. (2008b). Determination of Structural Carbohydrates and Lignin in Biomass (NREL/TP-510-42618), National Renewable Energy Laboratory, Golden, CO.

Taherzadeh, M. J., and Karimi, K. (2008). “Pretreatment of lignocellulosic wastes to improve ethanol and biogas production: A review,” Int. J. Mol. Sci. 9(9), 1621-1651. DOI: 10.3390/ijms9091621

Teghammar, A., Karimi, K., Horváth, I. S., and Taherzadeh, M. J. (2012). “Enhanced biogas production from rice straw, triticale straw and softwood spruce by NMMO pretreatment,” Biomass Bioenerg. 36, 116-120. DOI: 10.1016/j.biombioe.2011.10.019

Teghammar, A., Yngvesson, J., Lundin, M., Taherzadeh, M. J., and Horváth, I. S. (2010). “Pretreatment of paper tube residuals for improved biogas production,” Bioresource Technol. 101(4), 1206-1212. DOI: 10.1016/j.biortech.2009.09.029

Triolo, J. M., Sommer, S. G., Møller, H. B., Weisbjerg, M. R., and Jiang, X. Y. (2011). “A new algorithm to characterize biodegradability of biomass during anaerobic digestion: Influence of lignin concentration on methane production potential,” Bioresource Technol. 102(20), 9395-9402. DOI: 10.1016/j.biortech.2011.07.026

Van Soest, P. J. (2006). “Rice straw, the role of silica and treatments to improve quality,” Anim. Feed Sci. Tech. 130(3-4), 137-171. DOI: 10.1016/j.anifeedsci.2006.01.023

Wang, J., Yue, Z.-B., Chen, T.-H., Peng, S.-C., Yu, H.-Q., and Chen, H.-Z. (2010). “Anaerobic digestibility and fiber composition of bulrush in response to steam explosion,” Bioresource Technol. 101(17), 6610-6614. DOI: 10.1016/j.biortech.2010.03.086

Vivekanand, V., Eijsink, V. G. H., and Horn, S. J. (2012). “Biogas production from the brown seaweed Saccharina latissima: Thermal pretreatment and codigestion with wheat straw,” J. Appl. Phycol. 24(5), 1295-1301. DOI: 10.1007/s10811-011-9779-8

Xiao, X., Bian, J., Li, M.-F., Xu, H., Xiao, B., and Sun, R.-C. (2014). “Enhanced enzymatic hydrolysis of bamboo (Dendrocalamus giganteus Munro) culm by hydrothermal pretreatment,” Bioresource Technol. 159, 41-47. DOI: 10.1016/j.biortech.2014.02.096

Zheng, Y., Zhao, J., Xu, F., and Li, Y. (2014). “Pretreatment of lignocellulosic biomass for enhanced biogas production,” Prog. Energ. Combust. 42, 35-53. DOI: 10.1016/j.pecs.2014.01.001

Zhou, J., Yan, B. H., Wang, Y., Yong, X. Y., Yang, Z. H., Jia, H. H., Jiang, M., and Wei, P. (2016). “Effect of steam explosion pretreatment on the anaerobic digestion of rice straw,” RSC Adv. 6(91), 88417-88425. DOI: 10.1039/C6RA15330E

Article submitted: August 31, 2018; Peer review completed: October 30, 2018; Revised version received and accepted: November 15, 2018; Published: November 28, 2018.

DOI: 10.15376/biores.14.1.464-485