Abstract

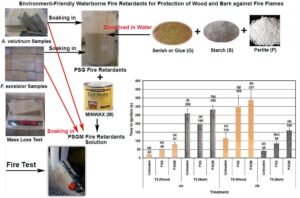

Flame retardancy was induced in maple (Acer velutinum) and ash (Fraxinus excelsior) wood and bark by means of mixtures consisting of bio-based materials such as starch (S) and glue (G) and water-based paint, MINWAX (M) in two different combined formulations with perlite (P) as the main fire retardant. The selected wood species as solid wood with two different treatable surfaces (with and without bark) were examined. The lowest and the highest mass loss occurred in the untreated-ash and untreated-maple wood samples with bark, while the lowest weight percent gain was related to PSGM-treated ash wood samples with bark, and the highest weight percent gain was related to PSGM-treated maple wood samples without bark. The lowest time to ignition and glowing point time were measured in the untreated-maple wood samples without bark, and the highest of them were measured in the PSGM-treated ash wood samples without bark. The effect of bark in the treated- and untreated-maple samples on the time to ignition and glowing point time was greater than the bark of treated- and untreated-ash samples, respectively. There was not any significant relationship between actual retention, weight percent gain, and mass loss for all treatments. However, there was significant difference between the individual and interaction agents on fire retardancy of treated and untreated samples.

Download PDF

Full Article

Environment-Friendly Waterborne Fire Retardants for Protection of Wood and Bark against Fire Flames

Sayed Khosrow Hosseinashrafi,a,* Seyyed Khalil Hosseinihashemi,a,* Pedram Gorji,a and Maliheh Akhtari b

Flame retardancy was induced in maple (Acer velutinum) and ash (Fraxinus excelsior) wood and bark by means of mixtures consisting of bio-based materials such as starch (S) and glue (G) and water-based paint, MINWAX (M) in two different combined formulations with perlite (P) as the main fire retardant. The selected wood species as solid wood with two different treatable surfaces (with and without bark) were examined. The lowest and the highest mass loss occurred in the untreated-ash and untreated-maple wood samples with bark, while the lowest weight percent gain was related to PSGM-treated ash wood samples with bark, and the highest weight percent gain was related to PSGM-treated maple wood samples without bark. The lowest time to ignition and glowing point time were measured in the untreated-maple wood samples without bark, and the highest of them were measured in the PSGM-treated ash wood samples without bark. The effect of bark in the treated- and untreated-maple samples on the time to ignition and glowing point time was greater than the bark of treated- and untreated-ash samples, respectively. There was not any significant relationship between actual retention, weight percent gain, and mass loss for all treatments. However, there was significant difference between the individual and interaction agents on fire retardancy of treated and untreated samples.

DOI:10.15376/biores.18.4.7681-7699

Keywords: Fire retardants; Maple and ash; Wood and bark; Time to ignition; Glowing point

Contact information: a: Department of Wood Science and Paper Technology, Karaj Branch, Islamic Azad University, Karaj, Iran; b: Department of Wood and Paper Sciences and Technology, Bojnourd Branch, Islamic Azad University, Bojnourd, Iran;

*Corresponding authors: khosrowashrafi@gmail.com and hashemi@kiau.ac.ir

GRAPHICAL ABSTRACT

INTRODUCTION

Fire is one of the most important physically destructive factors of solid wood. Therefore, wood as a raw material must be protected against the fire. Wood as an eco-friendly and renewable natural material has been extensively protected through various fire retardants (FRs) and antiseptic fire resistance (Elvira-León et al. 2016; Gazizov et al. 2018a, b; Gazizov and Ivanchina 2018; Kmeťová et al. 2022). Protection of solid wood against fire are performed with help of two methods, such as superficial and deep impregnation with special compositions containing FRs, as well as it is also common to use fire-resistant coatings (Östman et al. 2010).

Deep impregnation is more effective than surface impregnation, so that deeper penetration of fireproof solutions into the surface layers of wood is possible via hot and cold baths, as well as processing with help of industrial apparatus or autoclave in the mode of successive increase in pressure or alternation of vacuum and increased pressure (vacuum impregnation) (Khvatov et al. 2019).

Currently, the use of natural mineral fillers, such as perlite, vermiculite, and expanded perlite and vermiculite (Wang et al. 2016; Szadkowski et al. 2020; Lanzón et al. 2022), and binders, such as gypsum, geopolymers, and starch, are also effective and have significant effects on flame retardancy of bio-based composite panels and wood (Manzello et al. 2007; Bumanis et al. 2020).

The characteristics of perlite are light weight, thermal insulation, and fire resistance. These characteristics prompt its use in applications such as heat storage (Zhang et al. 2016) and dye decolourisation (Pezzella et al. 2014). Therefore, perlite has been applied to prepare waterborne fire resistive coatings (Huang et al. 2020), and expanded perlite may decrease the plaster fire protection, especially if used in high doses (Lanzón et al. 2022).

Tsuyumoto et al. (2011) found a significant flame retardancy effect from starch and sodium polyborate (SPB) mixtures. They prepared the effective mixture as a flame retardant by simple coating with rigid polyurethane foam, nonwoven polyethylene terephthalate/ethylene vinyl alcohol copolymer, and nonwoven polypropylene.

One of the applications of FR paints is in combustible materials, such as wood, foam, and plastic, which are considered to reduce the rate of flame spread. These materials are based on silicone, casein, or vinyl resins. They are similar in paints, and their formulation is such that the tools used for them (brush, roller, or spray) should be the same as paints (Kusumgar et al. 2007).

The plant glue (Serish) is taken from the plants of the Asphodelaceae family. The root of Eremurus persicus plant (Serish) is a well-known glue of plant origin in Iran that has been used for centuries as natural glue in the textile, carpentry, binding, and book restoration industries. Thin layer chromatographic (TLC) analysis of ethanolic extract of E. persicus root showed that it contains polyphenols, flavonoids, and naphthoquinones (Beiranvand and Beiranvand 2021). People traditionally collected the roots, dried and powdered them, and mixed them with water to make glue (Koohkesh et al. 2020). Additionally, these materials are economical compared to chemical materials and can be easily purchased as raw materials in the market. The E. persicus essential oil is rich in terpenes and oxygenated terpene derivatives. Individually, limonene (16.2%), geranylgeraniol (15.2%), n-nonanal (9.5%), geranyl acetone (9.1%), benzene acetaldehyde (8.5%), linalool (7.9%), α-pinene (6.9%), and 1,8-cineol (5.2%) were the most abundant volatile compounds (Salehi et al. 2017). The roots of Eremurus species are rich of oligo and polysaccharides, including branched arabinogalactan, linear galactomannan, and short chains of fructose units with a single d-glucosyl unit at the nonreducing end that accumulate during their growth (Flamm et al. 2001; Karaman et al. 2011; Muhidinov et al. 2020; Pourfarzad et al. 2015; Smirnova et al. 2001).

Maple wood has a special place in the furniture and upholstery industry, and it is also suitable for flooring and making plywood and shoe molds, covering large surfaces of walls and tabletops, and sculpting (Golbabaei and Ebrahimi 2015; Naghdi et al. 2016). Common ash (Fraxinus excelsior L.) is a medium-sized deciduous hardwood tree and belongs to the Oleaceae family. This tree is mostly native to Europe and is distributed in northern Scandinavia and the southern Iberian Peninsula. Its bark is smooth and gray at first, then it has vertical cracks in the middle and its color becomes blackish gray. Ash wood has good strength and hardness and good elasticity (Azadi 2005; Beck et al. 2016).

The bark protects the tree from weather conditions, insect pests, and browsing, and it also has a crucial role in wood fires. Much research has been conducted on this subject. Schafer et al. (2015), Catry et al. (2010), Lawes et al. (2011), Wang and Wangen (2011), Do Vale and Elias (2014), Dickinson and Johnson (2001), and Dickinson (2002) established that the relative thickness of the bark significantly influences the survival of trees in a fire. Bauer et al. (2010) and Hengst and Dawson (1993) examined the probability of survival for a tree if its surface is exposed to fire. They found that the fire resistance of the bark depends on thickness and moisture content, and that the different physical qualities of tree species have a negligible influencing role. Bauer et al. (2010) mentioned that the transfer potential provided for biomimetic heat insulation and fire-stopping behavior is found in many species of tree bark.

This study aims to evaluate the effect of perlite (P), starch (S), glue (G), and plastic paint, MINWAX (M) in combined formulations on the fire behavior of wood that are compared to control samples. This matter has received little attention in previous studies. It is not clear whether the use of two different formulations of natural compounds: 1) mixture of P, S, and G in water solution; 2) mixture of P, S, G, and M in soluble to water, are beneficial for the protection of wood and cellulosic materials against fire. The authors’ hypothesis is that in order to delay the fire, the fluid slurry resulting from the potential formulation of these materials can be easily applied and sprayed on standing trees in the forest and close to the house, pastures, and grasslands before and during exposure to fire.

In this study, the fire retardancy properties, such as mass loss (ML), flame point or time to ignition (TTI), glowing point time (GPT), weight percent gain (WPG), actual retention (AR) of velvet maple- and common ash-treated wood with environment-friendly waterborne FRs in two treatable surfaces with bark and without bark, were evaluated and compared with control samples.

EXPERIMENTAL

Materials

Perlite, starch, glue, and MINWAX

Raw perlite (3 kg) as the one of fire retardants was supplied and prepared from the Pars Chemical Company, Tehran, Iran (Fig. 1a). The material was air-dried for several days and ground into small pieces (powder) and sieved between 60- and 80-mesh screens. Then, it was weighed and bagged, so that the moisture content of perlite powder was around 10 ± 2% when used. The ingredients of perlite are: 70 to 75% silicon dioxide (SiO2), 12 to 15% aluminium oxide (Al2O3), 3 to 4% sodium oxide (Na2O), 3 to 5% potassium oxide (K2O), 0.5 to 2% iron oxide (Fe2O3), 0.2 to 0.7% magnesium oxide (MgO), 0.5 to 1.5% calcium oxide (CaO), and 3 to 5% loss on ignition (chemical/combined water) (Arifuzzaman and Kim 2017).

In this research, corn starch polymer produced by Mehshad Company, Yazd, Iran, with a melt flow index of 3 g/10 min and a density of 1.3 g/cm3 was used (Fig. 1b). Glue is also a natural binder that is extracted from plant and animal elements. The plant glue (Serish powder) used in this study has also been used by gluing industries (Fig. 1c). The water-based paint with MINWAX trademark was used in this study (Fig. 1d).

Fig. 1. The materials used in this study: a: perlite; b: starch; c: glue (Serish); d: MINWAX paint

Preparation of Test Specimens

Defect-free maple (Acer velutinum Boiss.) (AV) and ash (Fraxinus excelsior L.) (FE) woods with and without bark were first cut into 20 × 15 × 1 cm3 (L × T × R) blocks and prepared according to the EN ISO 11925-2 (2010) standard (Fig. 2). All specimens were oven-dried at 103 ± 2 ºC for 48 h before and after treatment.

Fig. 2. Preparation of wood specimens with and without bark from the log

Independent variables and their levels were as follows:

– Species: maple (A. velutinum Boiss.) and ash (F. excelsior L.)

– Treatable surfaces: wood with bark and wood without bark

– Fire retardants: 1) Formulation PSG with a concentration of 22.5%; 2) formulation PSGM with a concentration of 42.5% as the treating materials and untreated (UT) as the control samples were used (Table 1).

The prepared specimens were impregnated with two different solutions having the abovementioned compositions. Preparation of specimens and measurement of the fire retardancy parameters of wood were completed according to JISA-1322 (1982) and BS 476-6 (1997) standards, respectively. The fire test was a single flame source test.

Manufacturing Process

The initial experiments were done by trial and error to achieve an effective natural formulation that has the best efficiency in delaying the TTI point (flaming time) and GPT on wood. In this way, a new combination of perlite with bio-based binder materials such as starch and a natural adhesive material such as glue (Serish powder) was obtained by dissolving in a certain volume of water. This natural compound is easily dissolved in water and a simple formulation with flame retardant properties was obtained.

Changes were made in the amount of P, S, G, and M in the formulation of flame retardant. In experiment number 1, the untreated samples were tested. In experiment number 2, the samples were treated with a solution of P (as the main flame retardant) and starch (as the first adhesive). In experiment number 3, the samples were treated with a solution of P and glue (as the second adhesive). In experiment number 4, the samples were treated with a solution of perlite, starch, and glue. In the final experiment, perlite, starch, glue, and MINWAX plastic paint were used in the treatment of the samples. After giving the result of each experiment, in the next experiment, attention was paid to the favorable effect of the previous experiment along with the adjustment in the compositions and the experiment of the effect of another additive.

Preparation of Treatment Solutions and Impregnation

Formulation with a concentration of 22.5%, including a mixture of perlite (100 g), starch (10 g), and glue (15 g) in 1000 mL water; and formulation with a concentration of 42.5%, including a mixture of perlite (100 g), starch (10 g), glue (15 g), and water-based paint, MINWAX (200 g) in 1000 mL water, were prepared.

The FRs test specimens were treated (T) with solution at a concentration of 22.5% and 42.5%. Four sets of 10 specimens were immersed in the PSG solution, and four sets of 10 specimens were also immersed in the PSGM solution for 24 h according to Table 1. Four sets of 10 specimens were not treated with treatment solutions; these were the control. In total, 120 specimens were tested for fire retardancy parameters according to the JISA-1322 (1982) standard.

Table 1. FRs Treatment for Protection of Maple and Ash Wood Samples with and without Bark against Fire

After the impregnation operations, each group of samples was placed in the laboratory environment conditions for 2 weeks to reach the equilibrium moisture content (10 ± 2%), so that the FR solutions underwent the diffusion, penetration, and fixation processes well, and then the samples were weighed to determine the amount of treating solution absorbed. All treatments used in the present study are summarized in Table 1.

After impregnation, actual retention (AR) and weight percent gain (WPG) of the treated samples was determined according to the literature (Tascioglu et al. 2012; Simsek et al. 2013; Mohammadnia Afrouzi et al. 2015; Ahmet et al. 2017; Nayeri et al. 2017; Gupta et al. 2021) and by the following Eqs. 1 and 2,

AR= ((G × C)/V) × 10 (1)

where G is the difference between sample weight after impregnation and sample weight before impregnation (kg), C is the concentration (%), and V is the sample volume (m3).

WPG (%)= ((M2-M1)/M1) × 100 (2)

In Eq. 2, M2 is the mass (g) after treatment, and M1 is the mass (g) before treatment.

Fire Test

The treated and untreated samples were fixed in the device clamp according to Fig. 3, and the flame was placed on the end of the sample at 45°. The distance between wood and device was 10 cm. The time to ignition (TTI) was recorded with a timer in seconds (s). After the sample reached the flame point, the flame was set aside, and the glowing point time (GPT) after removing the fire nozzle was recorded in s.

Fig. 3. Measuring the flammability of building materials by JISA-1322 (1982) standard

Mass Loss Test

Mass loss test of samples was performed according to KS F ISO 5660-1 (2003) standard guidelines. In this method, the mass of each test sample was measured with a digital scale with an accuracy of 0.001 g before and after the fire test. After testing the average value of 10 tested specimens have to be defined. The mass loss (P, %) was calculated according to the literature (Ozcifci et al. 2007; Sled 2012) and following Eq. 3,

P (%)= (P1-P2/P1) × 100 (3)

where P1, mass of specimen before testing, in g; P2, mass of specimen after testing, in g.

Statistical Analysis

A univariate analysis of variance was conducted using the IBM SPSS statistics for Windows, version 24.0, software package (SPSS Inc., IBM Corp., Armonk, NY, USA) (p< 0.05 and p< 0.01) to evaluate the effect of the different species, treatable surfaces, and FRs treatment on ML, TTI, GPT, AR, and WPG, as the fire retardancy parameters. Significant difference among the average values of the FR-treated and untreated specimens were determined using Duncan’s multiple range test (DMRT).

RESULTS AND DISCUSSION

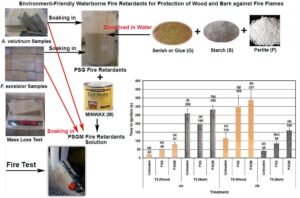

Mass Loss of Untreated and FR-Treated Samples Duo to Combustion

Statistically, results showed that the interaction between the variables wood species, treatable surfaces, and FRs was negative and had a significant effect on the mass loss (ML) of samples.

According to a statistical analysis, the individual effect of variables wood species, treatable surfaces, and FRs showed significant effects on the ML measured. The interaction between wood species and treatable surfaces was negative and indicated a significant effect on the ML factor within the range of 95% and 99% confidence for the experimental FRs investigated. But the interactions between wood species and FRs and treatable surfaces and FRs were positive and did not have any significant effect on the ML factor.

Results indicated that the lowest ML value (0.39%) due to combustion was obtained in the UT-FE wood samples with bark and the highest ML (2.06%) was found in the UT-AV wood samples with bark (Fig. 4). Because the FE bark is thicker than the AV bark, it can be said that the bark of FE showed more resistance to ML than the AV bark. Thus, it was apparent that the fire resistance of the bark depends on thickness, density, and moisture content and that the different physical qualities of tree species have a negligible influencing role (Hengst and Dawson 1993; Bauer et al. 2010). Researchers have stated that the bark thickness is a better predictor of resistance to cambial injury from fires than either bark moisture or density (Lawes et al. 2011).

Compared to the samples that are treated with FRs, the best material regarding mass reduction is a mixture of perlite, starch, glue, and water-based paint.

The average ML values of untreated and FR-treated samples showed that ML in the AV (1.45%) was higher than the FE (0.95%) as the species; ML in the samples without bark (1.30%) was higher than the samples with bark (1.09%) as the treatable surfaces; and ML in the untreated samples (1.35%) was higher than the PSG-treated samples with a concentration of 22.5% (1.20%), and ML in the PSG-treated samples was higher than the PSGM-treated samples with a concentration of 42.5% (1.04%) as the FRs.

Lublóy et al. (2023) examined the fire performance of Norway spruce- and Scots pine-treated wood with 7 different precautions such as 1.09 g IPBC + 0.35 g propiconazole, 1.09 g IPBC + 0.35 g propiconazole, 80 g tebuconazole + 0.50 g IPBC + 0.15 g cypermethrin, 80 g tebuconazole + 0.50 g IPBC + 0.15 g cypermethrin, 0.8 g IPBC + 0.8 g propiconazole + 0.15 g cypermethrin, 15 g boric acid + 1.53 g borax, and 44.0 g boric acid + 0.8 g Alcyl-dimethyl, benzyl ammonium chloride. The ML percentages were 7.54, 7.49, 7.50, 7.65, 7.65, 5.94, and 6.69% for Norway spruce-treated wood; 8.14 and 8.07% for untreated wood, respectively, while the ML percentages were 10.53, 9.76, 10.95, 9.78, 10.54, 7.00, and 9.14% for Scots pine-treated wood; 11.43 and 10.70% for untreated wood, respectively.

Fig. 4. Mean values ± standard deviation of the mass loss of untreated and FR-treated samples. Different letters in each column indicate a statistical difference (p<0.05) among the treatment groups

Free-extractives Pinus taeda wood exhibits a more significant weight loss at approximately 20 °C higher than when the extractives are present in wood, whilst for the Eucalyptus grandis a more pronounced degradation process occurs only at approximately 10 °C higher when the extractives are present in wood (Poletto 2016). This occurs because extractives are compounds with low molecular weight and may promote wood degradation at relative low temperatures (Guo et al. 2010; Kilulya et al. 2014), reducing wood thermal stability.

The standard defines a flame retardant as effective if mass loss does not exceed 1.5 g for surface-treated wood and 2.5 g for impregnated wood (Lublóy et al. 2023). The ML of untreated and FR-treated samples were classified according to Sled (2012): ML≤9% – The class I of fire retardant efficiency is given; 9%≤ML≤25% – The class II of fire retardant efficiency is given; and ML>25% – this treatment is not providing the fireproofing effect and is not the fire retardant. According to the classification of ML by Sled (2012), all untreated and FR-treated samples in this research were placed in class I of ML≤9% – thus, the I class of fire retardant efficiency is given.

Time to Ignition of Untreated and FR-Treated Samples

Statistically, it was shown that the interaction between the variables wood species, treatable surfaces, and FRs was positive and exhibited no significant effect on the time to ignition (TTI) of samples. According to a statistical analysis, the individual effect of variables wood species, treatable surfaces, and FRs showed significant effects on the TTI measured. The interaction between wood species and treatable surfaces, wood species and FRs, as well as treatable surfaces and FRs were negative and had a significant effect on the TTI factor within the range of 95% and 99% confidence for the experimental FR-treated samples investigated.

Results indicated that the PSGM-treated FE wood samples without bark and UT-AV wood samples without bark had the highest and lowest TTI, so that the formulation with a mixture of P, S, G, and M with a concentration of 42.5% delays the fire point (TTI) by 337 s (Fig. 5). This time in the UT-samples is low; especially regarding UT-AV, the reduction is very considerable, so that the TTI reach to 22 s (Fig. 5).

Fig. 5. Mean values ± standard deviation of the time to ignition of untreated and FR-treated samples. Different letters in each column indicate a statistical difference (p<0.05) among the treatment groups

The average TTI values of untreated and FR-treated samples showed that TTI in the FE (173 s) was higher than the AV (148 s) as the species; TTI in the samples with bark (170 s) was higher than the samples without bark (151 s) as the treatable surfaces; TTI in the PSGM-treated samples with a concentration of 42.5% (215 s) was higher than the PSG-treated samples with a concentration of 22.5% (157 s) as the FRs; and TTI in the PSG-treated samples was higher than the untreated samples (109 s).

The TTI of untreated- and treated-AV wood sample with bark was higher than the untreated- and treated-AV wood sample without bark. According to the Fengel and Wegener (2003) theory, tree barks contain relatively high amounts of extractives (20% to 30%). Additionally, Kain et al. (2013) found that tree bark has interesting properties for use as an insulation material, namely relatively low thermal conductivity and high heat storage capacity.

The flame-retardant mechanism of the bark cement-boards was investigated by researchers. According to their findings, a mineral-enriched matrix in the composites was the main reason for their flame retardancy. Cement as a non-combustible building material and bark as a natural barrier of tree against fire plays an important role in flame retardancy (Pacher et al. 2022). Tree bark contains the phenolic compounds that provide fire-retardant properties to such composites, together with the protective role of bark as fire-stopping, is found in many species (Bauer et al. 2010). Starch is a bio-based polymeric component derived from renewable and widely available biomass resources. In addition, starch was chosen as the main component of FR systems in the other studies because of its good adhesion to wooden surfaces (Tretsiakova-McNally et al. 2021).

The investigation results of Seo et al. (2017) on fire properties of Pinus densiflora utilizing fire-retardant chemicals based on borated and phosphorus showed that for time to ignition (TTI), there was no noticeable difference between the untreated and fire-retardant treated wood (FRTW)-vacuum specimens. On the other hand, the FRTW-pressure specimen was ignited on the surface of the material after a testing time of 688 s. The mass loss rate (MLR) curves of the untreated and FRTW-vacuum specimens showed an initial rapid mass loss, which continued after 300 s. The MLR in the FRTW-pressure specimen remained similar at the 400 s mark of the test time. Also, after 700 s the MLR of the FRTW-pressure specimen decreased. To modify the flammability of wood-plastic composites (WPC), Umemura et al. (2014) were added various fire retardants, such as ammonium polysphosphate (APP), melamine polyphosphate (MPP), and aluminum hydroxide (Al(OH)3) to WPCs. The results illustrated that the ignition time of PP, WPC with 50 wt% wood flour, WPC + APP, WPC + MPP, and WPC + Al(OH)3 was 31.6, 21.4, 19.6, 20.4, and 24.8 s, respectively.

Final values of mass loss and time to ignition of untreated and HR-Prof-retardant-treated spruce wood samples by painting, spraying, immersion, or vacuum method was determined by Mitterová (2022). He measured the mass loss of samples in interior, protected exterior, and exterior environments about 68, 85, and 90% for untreated samples, while for treated samples was 48, 71, and 89%. The ignition time for untreated samples was 95, 61, and 37 s, whilst for treated specimens was 155, 92, and 37 s.

Glowing Point Time of Untreated and FR-Treated Samples

Glowing time can be defined as the time in seconds that a specimen continues to glow under the conditions of these test methods after it has ceased to flame. Statistically, results showed that the interaction between the variables wood species, treatable surfaces, and FRs was positive and had no significant effect on the glowing point time (GPT) of samples.

According to a statistical analysis, the individual effect of variables wood species, treatable surfaces, and FRs showed significant effects on the GPT measured. The interaction between wood species and treatable surfaces, wood species, and FRs, as well as treatable surfaces and FRs were negative and had a significant effect on the GPT factor within the range of 95% and 99% confidence for the experimental FR-treated samples investigated.

Results indicated that the PSGM-treated FE wood samples without bark and UT-AV wood samples without bark had the highest and lowest GPT, respectively, so that the formulation with a mixture of P, S, G, and M with a concentration of 42.5% delayed the glowing point time (GPT) by 529 s (Fig. 6). This time in the UT-samples was low; especially regarding UT-AV, the reduction was very considerable, so that the GPT reach to 49 s (Fig. 6) with the exception of UT-AV wood samples with bark (500 s).

The average GPT values of untreated and FR-treated samples showed that GPT in the FE (319 s) was higher than the AV (282 s) as the species; GPT in the samples with bark (330 s) was higher than the samples without bark (271 s) as the treatable surfaces; GPT in the PSGM-treated samples with a concentration of 42.5% (365 s) was higher than the PSG-treated samples with a concentration of 22.5% (310 s) as the FRs; and GPT in the PSG-treated samples was higher than the untreated samples (227 s).

Fig. 6. Mean values ± standard deviation of the glowing point time of untreated and FR-treated samples. Different letters in each column indicate a statistical difference (p<0.05) among the treatment groups

It is probable that the main components of AV bark in UT- and treated wood samples that inhibit fire are graphite, inserted and distorted graphite-graphene aggregates (Tributsch and Fiechter 2008), and polyphenols (tannins), because the tannins contribute to the generation of graphite during charring. Furthermore, tannins are high molecular weight (up to 20,000) compounds that form complexes with proteins and alkaloids, which precipitate. The likely mechanism of action is as follows: The tannins are able to neutralize radicals due to their endowment to donate electrons (Hemingway and Lacks 1992) and via electron donation, as well as through forming a protective layer against the heat and against diffusion to the flame of combustible volatile compounds (Pacher et al. 2022). Tannins determine reduction of heat power, which could retard and slow down the fire.

One of the most abundant chemical compounds in the AV wood that was identified by Vaysi et al. (2019) is benzaldehyde (48%). The degree of hydrophobicity contributed by the phenyl group from benzaldehyde is low, so the hydroxyl group plays the main role in the solubility of benzaldehyde-based Novolac (Nemoto et al. 2009).

Fengel and Wegener (1989) reported that organic solvents usually extract lipophilic extractives, such as sterols, terpenoids, fatty acids, resin acids, and waxes, which play a role in influencing the ignitability of biomass because of their volatility.

Homovanillic acid, palmitic acid, and stigmasta-3,5-dien-7-one were identified in the bark extracts from sugar maple (SM) trees in addition to the compounds identified in the wood extracts, with the exception of xanthene-9-carboxylic acid. Palmitic acid has been previously observed in SM extractives (Miller et al. 1990; Goundalkar et al. 2010). Sinapaldehyde was also found in the SM wood and bark extracts, but quantification was not possible because of poor peak separation in the bark.

The fact is that the starch acted as an appropriate binder substance. Tsuyumoto et al. (2011) has used it along with SPB fire retardant. A high flame-retardant effect of the SPB on starch can be caused by the carbonized layer formation due to the dehydration of cellulose-based material such as wood, paper, and cotton cooperating with the flame retardancy, and this matter should apply to other general carbohydrates. Thus, it is expected that the flame retardancy is caused by the synergistic effect of carbonized layer formation along with the binding effect of starch.

Commercial corn starch was added for the adhesive formulations with poplar bark for enhanced resistance to fire the bark-based panel bonded with clay (Tudor et al. 2020). Kebke et al. (2020) found that the smoldering time is shorter for all starch FR samples than for untreated wood fiber and also the application of well-soluble additives has a positive effect on fire and smoldering protection.

Paint systems contribute considerably to weather protection are usually needed to maintain the fire performance properties of fire retardant-treated (FRT) wood products for exterior applications (Östman and Tsantaridis 2016).

Actual Retention of FR-Treated Samples

Statistically, results showed that the interaction between the variables wood species, treatable surfaces, and FRs is positive and did not have any significant effect on the actual retention (AR) of samples. The individual effect of variables wood species, treatable surfaces, and FRs showed significant effects on the measured AR. The interaction between wood species and treatable surfaces, wood species and FRs, as well as treatable surfaces and FRs were negative and exhibited a significant effect on the AR factor within the range of 95% and 99% confidence for the experimental FR-treated samples investigated.

Table 2 shows that the lowest AR values of FR-treated samples observed by the treatment of 22.5% PSG-treated AV wood samples without bark (33.2 kg/m3) and the highest AR values of FR-treated samples showed by the treatment of 42.5% PSGM-treated AV wood samples without bark (144.7 kg/m3).

Table 2. Mean Values ± Standard Deviation of the Actual Retention (AR) of FR-treated Samples at Different Concentration Levels

Different letters in each column indicate a statistical difference (p<0.05 and p<0.01) among the treatment groups

The average AR values of FR-treated samples showed that AR in the AV (72.9 kg/m3) was higher than the FE (55.2 kg/m3) as the species, AR in the samples without bark (69.4 kg/m3) was higher than the samples with bark (58.7 kg/m3) as the treatable surfaces, and AR in the PSGM (83.2 kg/m3) with a concentration of 42.5% was higher than the PSG (44.9 kg/m3) with a concentration of 22.5% as the FRs.

Weight Percent Gain of FR-Treated Samples

Statistically, results showed that the interaction between the variables wood species, treatable surfaces, and FRs was negative and had significant effect on the weight percent gain (WPG) of samples. According to a statistical analysis, the individual effect of the variables wood species, treatable surfaces, and FRs showed significant effects on the WPG measured. The interaction between wood species and treatable surfaces, the interaction between wood species and FRs, as well as the interaction between wood species and FRs were negative and had a significant effect on the WPG factor within the range of 95% and 99% confidence for the experimental FRs investigated.

Table 3 shows that the lowest WPG values of FR-treated samples observed by the treatment of 42.5% PSGM-treated FE wood samples with bark (0.87%) and the highest WPG values of FR-treated samples shown by the treatment of 42.5% PSGM-treated AV wood samples without bark (10.32%).

The average WPG values of FR-treated samples showed that WPG in the AV (4.8%) was higher than the FE (2.5%) as the species; WPG in the samples without bark (5.3%) was higher than the samples with bark (2.0%) as the treatable surfaces; and WPG in the PSGM (4.2%) with a concentration of 42.5% was higher than the PSG (3.1%) with a concentration of 22.5% as the FRs.

Table 3. Mean Values ± Standard Deviation of the WPG of FR-treated Samples at Different Concentration Levels

Different letters in each column indicate a statistical difference (p<0.05 and p<0.01) among the treatment groups

Overall, the type of species, the treatable surfaces, the presence of treating materials, and its concentration can affect the ML, TTI, GPT, AR, and WPG of FR-treated samples compared to the untreated samples against fire flame. According to the findings in the previous literatures and the current results, apparently whole properties of wood and bark, such as anatomical, morphological, physical, and thermal properties, the content and the type of extractives, as well as the type of different species, could be affected the fire retardancy parameters.

CONCLUSIONS

1. According to the findings of this study, fire-retardant (FR) chemicals had a favorable effect on the measured parameters of fire retardancy and provided a certain amount of protection against combustion.

2. As a result of this study, the type of species, the treatable surfaces, the type of treating materials, and its concentration can be affected in the retention of FRs. The average actual retention (AR) values in the Acer velutinum Boiss. (AV) were higher than the Fraxinus excelsior L. (FE) as the species, AR in the samples without bark was higher than the samples with bark as the treatable surfaces, as well as AR in the perlite-starch-glue-MINWAX (PSGM) formulation with a concentration of 42.5% was higher than the PSG with a concentration of 22.5% as the FR.

3. The weight percentage gain (WPG) in the AV was higher than the FE as the species; WPG in the samples without bark was higher than in the samples with bark as the treatable surfaces, as well as WPG in the PSGM with a concentration of 42.5% was higher than the PSG with a concentration of 22.5% as the FR.

4. Compared to the samples that were treated with FRs, the best material regarding mass reduction is a mixture of perlite, starch, glue, and water-based paint, MINWAX. The average mass loss (ML) values in the AV were higher than the FE as the species, and the ML in the samples without bark was higher than in the samples with bark as the treatable surfaces.

5. Results indicated that the formulation with a mixture of P, S, G, and M with a concentration of 42.5% delayed the time to ignition (TTI) and glowing point time (GPT). These times in the UT-samples were very low; especially regarding UT-AV, the reductions were very considerable.

6. According to the authors’ observations, the findings were consistent with the findings of other researchers. This means a high flame-retardant effect of the perlite on starch, glue, and paint can be caused by the strong carbonized layer formation due to the dehydration of surface layers of wood and bark cooperating with the flame retardancy. It is probable that the high flame retardancy is caused by the synergistic effect of carbonized layer formation along with the binding effect of starch, glue, and paint.

ACKNOWLEDGMENTS

The authors are grateful for the support of the Department of Wood Science and Paper Technology, Karaj Branch, Islamic Azad University.

REFERENCES CITED

Ahmet, C., İsmail, Ö., Wojcıech, G., and Eser, S. (2017). “Improvement of fire performance of impregnated wood with copper based chemicals,” in: 28th ICWST International Conference on Wood Science and Technology, Zagreb, Croatia, pp. 21-27.

Arifuzzaman, M., and Kim, H. S. (2017). “Prediction and evaluation of density and volume fractions for the novel perlite composite affected by internal structure formation,” Constr. Build. Mater. 141, 201-215. DOI: 10.1016/j.conbuildmat.2017.03.015

Azadi, R. (2005). “Notes on the Oleaceae family in Iran,” Iran. J. Bot. 11(1), 41-47.

Beck, P., Caudullo, G., Tinner, W., and de Rigo, D. (2016). “Fraxinus excelsior in Europe: Distribution, habitat, usage and threats,” in: European Atlas of Forest Tree Species, J. San-Miguel-Ayanz, D. de Rigo, G. Caudullo, T. Houston Durrant, and A. Mauri (eds.), EU Publications: Publ. Off., Luxembourg, pp. e0181c0.

Bauer, G., Speck, T., Blömer, J., Bertling, J., and Speck, O. (2010). “Insulation capability of the bark of trees with different fire adaptation,” J. Mater. Sci. 45, 5950-5959. DOI: 10.1007/s10853-010-4680-4

Beiranvand, M., and Beiranvand, F. (2021). “Iranian plant Eremurus persicus: An overview of botany, traditional uses, phytochemistry and pharmacology,” Nat. Prod. Res. 36(10), 2692-2705. DOI: 10.1080/14786419.2021.1916744

BS 476-6 (1997). “Fire tests on building materials and structures – Part 2: Method of test for fire propagation for products,” British Standards Institution, London, UK.

Bumanis, G., Vitola, L., Pundiene, I., Sinka, M., and Bajare, D. (2020). “Gypsum, geopolymers, and starch—alternative binders for bio-based building materials: A review and life-cycle assessment,” Sustainability 12(14), article ID 5666. DOI: 10.3390/su12145666

Catry, F. X., Rego, F., Moreira, F., Fernandes, P. M., and Pausas, J. G. (2010). “Post-fire tree mortality in mixed forests of central Portugal,” Forest Ecol. Manag. 260(7), 1184-1192. DOI: 10.1016/j.foreco.2010.07.010

Dickinson, M. B. (2002). “Heat transfer and vascular cambium necrosis in the boles of trees during surface fires,” in: Proceedings, Forest Fire Research and Wildland Fire Safety, D. X. Viegas (ed.), Millpress, Rotterdam, Netherlands, pp. 1-10.

Dickinson, M. B., and Johnson, E. A. (2001). “Fire effects on trees,” in: Forest Fires: Behavior and Ecological Effects, E. A. Johnson, and K. Miyanishi (eds.), Academic Press, New York, NY, USA, pp. 477-525. DOI: 10.1016/b978-012386660-8/50016-7

Do Vale, A. T., and Elias, P. S. (2014). “Bark thermal protection level of four tree species and the relationship between bark architecture and heat transfer,” Ciênc. Florest. 24(4), 979-987. DOI: 10.5902/1980509816611

Elvira-León, J. C., Chimenos, J. M., Isábal, C., Monton, J., Formosa, J., and Haurie, L. (2016). “Epsomite as flame retardant treatment for wood: Preliminary study,” Constr. Build. Mater. 126, 936-942. DOI: 10.1016/j.conbuildmat.2016.09.107

EN ISO 11925-2 (2010). “Reaction to fire tests – Ignitability of products subjected to direct impingement of flame – Part 2: Single-flame source test,” European Committee for Standardization, Brussels, Belgium.

Fengel, D., and Wegener, G. (1989). Wood–Chemistry, Ultrastructure, Reactions, Walter de Gruyter, Berlin, Germany.

Fengel, D., and Wegener, G. (2003). Wood–Chemistry, Ultrastructure, Reactions, Walter de Gruyter, Berlin, Germany.

Flamm, G., Glinsmann, W., Kritchevsky, D., Prosky, L., and Roberfroid, M. (2001). “Inulin and oligofructose as dietary fiber: A review of the evidence,” Crit. Rev. Food Sci. Nutr. 41(5), 353-362. DOI: 10.1080/20014091091841

Gazizov, A. M., Sinegubova, E. S., and Kuznetsova, O. V. (2018a). “Study of fire resistance of composite materials,” Materials XIII Int. Eurasian Symp. Woodworking: Technologies, Equipment, Management of the XXI century, Yekaterinburg, Russia, pp. 73-76.

Gazizov, A. M., Kuznetsova, O. V., Sharafutdinov, A. A., and Enikeev, M. I. (2018b). “Increasing the resistance of composite wood material,” Oil and Gas Business 4, 182-193.

Gazizov, A. M., and Ivanchina, U. E. (2018). “Assessment of the impact of fire on the environment,” Proceedings, The Academy of GPS EMERCOM of Russia II International Scientific and Practical Conference, Moscow, Russia, pp. 103.

Golbabaei, F., and Ebrahimi, G. (2015). “The mechanical properties of Acer velutinum var. glabrescens wood growing in different regions of Caspian forests,” Iran. J. Wood Pap. Ind. 7(1), 79-90.

Goundalkar, M. J., Bujanovic, B., and Amidon, T. E. (2010). “Analysis of non-carbohydrate based low-molecular weight organic compounds dissolved during hot water extraction of sugar maple,” Cellul. Chem. Technol. 44, 27-33.

Guo, X., Wang, S., Wang, K., Liu, Q., and Luo, Z. (2010). “Influence of extractives on mechanism of biomass pyrolysis,” J. Fuel Chem. Technol. 38(1), 42-46. DOI: 10.1016/S1872-5813(10)60019-9

Gupta, H., Sharma, K. R., and Sharma, J. N. (2021). “Economically feasible wood biopreservation platform in Lannea coromandelica (Houtt.) Merr. against wood rotting fungus through bio-prospecting weed extracts,” Front. Plant Sci. 12, article ID 696747. DOI: 10.3389/fpls.2021.696747

Hemingway, R. W., and Lacks, P. E. (1992). Plant Polyphenols: Synthesis, Properties, Significance, Plenum Press: New York, NY, USA.

Hengst, G. E., and Dawson, J. O. (1993). “Bark thermal properties of selected central hardwood species,” in: Proceedings, 9th Central Hardwood Forest Conference, A. R. Gillespie, G. R. Parker, P. E. Pope, and G. Rink (eds.), West Lafayette, IN, USA, pp. 55-75.

Huang, H., Ge, X., Zhang, Z., Li, P., and Zhang, T. (2020). “Effect of perlite on fire protection of waterborne coatings for steel structure,” J. Mat. Sci. Chem. Eng. 8(12), 1-7. DOI: 10.4236/msce.2020.812001

JISA 1322 (1982). “Testing method in combustibility of thin materials for building,” Japanese Industrial Standards, Tokyo, Japan.

Kain, G., Barbu, M.-C., Hinterreiter, S., Richter, K., and Petutschnigg, A. (2013). “Using bark as a heat insulation material,” BioResources 8(3), 3718-3731. DOI: 10.15376/biores.8.3.3718-3731

Karaman, K., Polat, B., Ozturk, I., Sagdic, O., and Ozdemir, C. (2011). “Volatile compounds and bioactivity of Eremurus spectabilis (Ciris), a Turkish wild edible vegetable,” J. Med. Food 14(10), 1238-1243. DOI: 10.1089/jmf.2010.0262

Kebke, S., Thümmler, K., Sonnier, R., Tech, S., Wagenführ A., and Fischer, S. (2020). “Flame retardancy of wood fiber materials using phosphorus‐modified wheat starch,”Molecules 25(2), article 335. DOI: 10.3390/molecules25020335

Khvatov, A. V., Sakharov, P. A., Lomakin, S. M., Varfolomeev, S. D., Lukanina, Y. K., Minikh, A. A., Glinushkin, A. P., Seraya, L. G., and Demin, D. V. (2019). “Study of antiseptic properties of the flame retardant solution provided by oxidized plant waste with regard to wood staining and mold micromycetes,” IOP Conf. Ser.: Mat. Sci. Eng. 525, article ID 012103. DOI: 10.1088/1757-899X/525/1/012103

Kilulya, K., Msagati, T. A. M., Mamba, B. B., Ngila, J. C., and Brush, T. (2014). “Effect of site, species and tree size on the quantitative variation of lipophilic extractives in Eucalyptus woods used for pulping in South Africa,” Ind. Crop. Prod. 56, 166-174. DOI: 10.1016/j.indcrop.2014.02.017

Kmeťová, E., Kačík, F., Kubovský, I., and Kačíková, D. (2022). “Effect of expandable graphite flakes on the flame resistance of oak wood,” Coatings 12(12), article ID 1908. DOI: 10.3390/coatings12121908

Koohkesh, N., Samanian, K., and Afsharpour, M. (2020). “Eliminating color from Serish (Eremurus) paste for paper conservation and restoration,” J. Cult. Heritage. 44, 53-62. DOI: 10.1016/j.culher.2019.11.009

KS F ISO 5660-1 (2003). “Reaction to fire – Heat release, smoke production and mass loss rate – Part 1: Heat release rate (Cone calorimeter method),” Korean Standards Association, Gangnam, Seoul, Korea.

Kusumgar, M., Nerlfi, S., and Growney, M. (2007).“Fire safety with specialty coatings,” JCT Coatings Tech. 4(9), 78-84.

Lanzón, M. Castellón, F. J., and Ayala, M. (2022). “Effect of the expanded perlite dose on the fire performance of gypsum plasters,” Constr. Build. Mater. 346, article ID 128494. DOI: 10.1016/j.conbuildmat.2022.128494

Lawes, M. J., Richards, A., Dathe, J., and Midgley, J. J. (2011). “Bark thickness determines fire resistance of selected tree species from fire-prone tropical savanna in north Australia,” Plant Ecol. 212(12), 2057-2069. DOI: 10.1007/s11258-011-9954-7

Lublóy, É., Mészáros, D. T., Takács, L. G., Cimer, Z., and Norbert, H. (2023). “Examination of the fire performance of wood materials treated with different precautions,” J. Therm. Anal. Calorim. 148, 4129-4140. DOI: 10.1007/s10973-023-12050-2

Manzello, S. L., Gann, R. G., Kukuck, S. R., and Lenhert, D. B. (2007). “Influence of gypsum board type (X or C) on real fire performance of partition assemblies,” Fire Mater. 31, 425-442. DOI: 10.1002/fam.940

Miller, D., Sutcliffe, R., and Thauvette, J. (1990). “Sticker stain formation in hardwoods: Isolation of scopoletin from sugar maple (Acer saccharum Marsh.),” Wood Sci. Technol. 24, 339-344. DOI: 10.1007/BF00227054

Mitterová, I. (2022). “Wood in building structures and its fire protection,” Fire Protec. Saf. Sci. J. 16(2), 15-23. DOI: 10.17423/delta.2022.16.2.111

Mohammadnia Afrouzi, Y., Marzbani, P., and Omidvar, A. (2015). “The effect of moisture content on the retention and distribution of nano-titanium dioxide in the wood,” Maderas. Cienc. Tecnol. 17(2), 385-390. DOI: 10.4067/S0718-221X2015005000036

Muhidinov, Z. K., Boboklonov, J. T., Ismoilov, I. B., Strahan, G. D., Chau, H. K., Hotchkiss, A. T., and Liu, L. S. (2020). “Characterization of two types of polysaccharides from Eremurus hissaricus roots growing in Tajikistan,” Food Hydrocoll. 105, article 105768. DOI: 10.1016/j.foodhyd.2020.105768

Naghdi, R., Solgi, A., Labelle, E. R., and Zenner, E. K. (2016). “Influence of ground-based skidding on physical and chemical properties of forest soils and their effects on maple seedling growth,” Eur. J. For. Res. 135, 949-962. DOI: 10.1007/s10342-016-0986-3

Nayeri, H. R., Tarmian, A., Abdulkhani, A., and Ebrahimi, G. (2017). “Decay resistance of wood impregnated with monoethanolamine and sodium bisulfite pulping black liquors,” Maderas. Cienc. Tecnol. 19(4), 507-516. DOI: 10.4067/S0718-221X2017005000043

Nemoto, T., Mir, I. A., and Onishi, G. K. (2009). “Synthesis and properties of a high-molecular-weight organosoluble bisphenol A novolac,” Polym. J. 41(4), 338-342. DOI: 10.1295/polymj.PJ2008199

Östman, B., and Tsantaridis, L. (2016). “Durability of the reaction to fire performance for fire retardant treated (FRT) wood products in exterior applications – a ten years report,” in: MATEC Web of Conferences 46, article ID 05005. DOI: 10.1051/matecconf/20164605005

Östman, B., Mikkola, E., Stein, R., Frangi, A., König, J., Dhima, D., Hakkarainen, T., and Bregulla, J. (2010). Fire Safety in Timber Buildings – Technical Guideline for Europe (SP Report 19), SP Technical Research Institute, Boras, Sweden.

Ozcifci, A., Toker, H., and Baysal, E. (2007). “Fire properties of laminated veneer lumber treated with some fire retardants,” Wood Res. 52(4), 37-46.

Pacher, T., Barbu, M. C., Urstöger, J., Petutschnigg, A., and Tudor, E. M. (2022). “Fire retardancy of cementitious panels with larch and spruce bark as bio-admixtures,” Polymers 14(07), article ID 1469. DOI: 10.3390/polym14071469

Pezzella, C., Russo, M. E., Marzocchella, A., Salatino, P., and Sannia, G. (2014). “Immobilization of a Pleurotus ostreatus laccase mixture on perlite and its application to dye decolourisation,” Biomed. Res. Int. 2014(8), article ID 308613. DOI: 10.1155/2014/308613

Poletto, M. (2016). “Effect of extractive content on the thermal stability of two wood species from Brazil,” Maderas. Cienc. Tecnol. 18(3), 435-442. DOI: 10.4067/S0718-221X2016005000039

Pourfarzad, A., Najafi, M. B. H., Khodaparast, M. H. H., and Khayyat, M. H. (2015). “Characterization of fructan extracted from Eremurus spectabilis tubers: A comparative study on different technical conditions,” J. Food Sci. Technol. 52(5), 2657-2667. DOI: 10.1007%2Fs13197-014-1310-1

Salehi, B., Ayatollahi, S. A., Segura-Carretero, A., Kobarfard, F., Contreras, M. D. M., Faizi, M., Sharifi-Rad, M., Tabatabai, S. A., and Sharifi-Rad, J. (2017). “Bioactive chemical compounds in Eremurus persicus (Joub. & Spach) Boiss. essential oil and their health implications,” Cell. Mol. Biol. 63(9), 1-7. DOI: 10.14715/cmb/2017.63.9.1

Schafer, J. L., Breslow, B. P., Hohmann, M. G., and Hoffmann, W. A. (2015). “Relative bark thickness is correlated with tree species distribution along a fire frequency gradient,” Fire Ecol. 11(1), 74-87. DOI: 10.4996/fireecology.1101074

Seo, H. J., Hwang, W., and Lee, M. C. (2017). “Fire properties of Pinus densiflora utilizing fire-retardant chemicals based on borated and phosphorus (I) – Combustion characteristics,” BioResources 12(3), 5417-5427. DOI: 10.15376/biores.12.3.5417-5427

Sled, I. (2012). Protection of Wood. Fire Tests, Bachelor Thesis, Saimaa University of Applied Sciences Technology, Lappeenranta Double Degree Program in Civil and Construction Engineering, Karelia, Finland.

Simsek, H., Baysal, E., Yilmaz, M., and Culha, F. (2013). “Some mechanical properties of wood impregnated with environmentally-friendly boron and copper based chemicals,” Wood Res. 58(3), 495-504. DOI: 10.5072/ZENODO.26800

Smirnova, N., Mestechkina, N., and Shcherbukhin, V. (2001). “The structure and characteristics of glucomannans from Eremurus iae and E. zangezuricus: assignment of acetyl group localization in macromolecules,” Appl. Biochem. Microbiol. 37, 287-291. DOI: 10.1023/A:1010237419780

Szadkowski, B., Marzec, A., Rybiński, P., Żukowski, W., and Zaborski, M. (2020). “Characterization of ethylene–propylene composites filled with perlite and vermiculite minerals: Mechanical, barrier, and flammability properties,” Materials 13(3), article ID 585. DOI: 10.3390/ma13030585

Tascioglu, C., Yalcin, M., De Troya, T., and Sivrikaya, H. (2012). “Termiticidal properties of some wood and bark extracts used as wood preservatives,” BioResources 7(3), 2960-2969. DOI: 10.15376/biores.7.3.2960-2969

Tretsiakova-McNally, S., Douarin, A. L., Joseph, P., and Arun, M. (2021). “Passive fire protection of Taeda pine wood by using starch-based surface coatings,” Polymers 13(21), article ID 3841. DOI: 10.3390/polym13213841

Tributsch, H., and Fiechter, S. (2008). “The material strategy of fire-resistant tree barks,” WIT Trans. Built. Environ. 97, 43-52. DOI: 10.2495/HPSM080051

Tsuyumoto, I., Miura, Y., Nirei, M., Ikurumi, S., and Kumagai, T. (2011). “Highly flame retardant coating consisting of starch and amorphous sodium polyborate,” J. Mater. Sci. 46, 5371-5377. DOI: 10.1007/s10853-011-5475-y

Tudor, E. M., Scheriau, C., Barbu, M. C., Réh, R., Kristak, L., and Schnabel, T. (2020). “Enhanced resistance to fire of the bark-based panels bonded with clay,” Appl. Sci. 10(16), article ID 5594. DOI: 10.3390/app10165594

Umemura, T., Arao, Y., Nakamura, S., Tomita, Y., and Tanaka, T. (2014). “Synergy effects of wood flour and fire retardants in flammability of wood-plastic composites,” Energy Procedia 56, 48-56. DOI: 10.1016/j.egypro.2014.07.130

Vaysi, R. (2019). “A study on the possibility of identification and comparison of metallic ions and chemical components in wood of Persian maple and Caucasian maple tree by atomic absorption and GC-MS methods,” Iran. J. Wood Paper Sci. Res. 34(3), 361-371.

Wang, F., Gao, Z., Zheng, M., and Sun, J. (2016). “Thermal degradation and fire performance of plywood treated with expanded vermiculite,” Fire Mater. 40(3), 427-433. DOI: 10.1002/fam.2297

Wang, G. G., and Wangen, S. R. (2011). “Does frequent burning affect longleaf pine (Pinus palustris) bark thickness?,” Can. J. Forest Res. 41(7), 1562-1565. DOI: 10.1139/x11-074

Zhang, X., Wen, R., Tang, C., Wu, B., Huang, Z., Min, X., Huang, Y., Liu, Y., Fang, M., and Wu, X. (2016). “Thermal conductivity enhancement of polyethylene glycol/expanded perlite with carbon layer for heat storage application,” Energy Build. 130, 113-121. DOI: 10.1016/j.enbuild.2016.08.049

Article submitted: August 9, 2023; Peer review completed: September 16, 2023; Revised version received and accepted: September 19, 2023; Published: September 27, 2023.

DOI: 10.15376/biores.18.4.7681-7699