Abstract

Chemical production from crude oil represents a substantial percentage of the yearly fossil fuel use worldwide, and this could be partially offset by renewable feedstocks such as woody biomass and energy crops. Past techno-economic and environmental analyses have been conducted for isolated feedstocks on a regional or national scope. This study encompasses complete supply chain logistics analysis, delivered cost financial analysis, national availability, and environmental life cycle assessment (LCA) for 18 selected cellulosic feedstocks from around the world. A biochemical conversion route to monomeric sugars is assumed for estimated sugar yields and biosugar feedstock cost analysis. US corn grain was determined to have the highest delivered cost, while rice hulls in Indonesia resulted in the lowest cost of the feedstocks studied. Monomeric sugar yields from literature ranged from 358 kg BDMT-1 for US forest residues to 700 kg BDMT-1 for corn syrup. Environmental LCA was conducted in SimaPro using ecoinvent v2.2 data and the TRACI 2 impact assessment method for mid-point impacts cradle-to-incoming biorefinery gate. Carbon absorption during biomass growth contributed most substantially to the reduction of net global warming potential. Rice hulls and switchgrass resulted in the highest global warming potential, followed closely by corn and Thai sugarcane bagasse. Contribution analysis shows that chemical inputs such as fertilizer use contribute substantially to the net environmental impacts for these feedstocks.

Download PDF

Full Article

Environmental LCA and Financial Analysis to Evaluate the Feasibility of Bio-based Sugar Feedstock Biomass Supply Globally: Part 1. Supply Chain Analysis

Carter W. Reeb,a Richard Venditti,a,* Tyler Hays,a Jesse Daystar,b Ronalds Gonzalez,a and Stephen Kelley a

Chemical production from crude oil represents a substantial percentage of the yearly fossil fuel use worldwide, and this could be partially offset by renewable feedstocks such as woody biomass and energy crops. Past techno-economic and environmental analyses have been conducted for isolated feedstocks on a regional or national scope. This study encompasses complete supply chain logistics analysis, delivered cost financial analysis, national availability, and environmental life cycle assessment (LCA) for 18 selected cellulosic feedstocks from around the world. A biochemical conversion route to monomeric sugars is assumed for estimated sugar yields and biosugar feedstock cost analysis. US corn grain was determined to have the highest delivered cost, while rice hulls in Indonesia resulted in the lowest cost of the feedstocks studied. Monomeric sugar yields from literature ranged from 358 kg BDMT-1 for US forest residues to 700 kg BDMT-1 for corn syrup. Environmental LCA was conducted in SimaPro using ecoinvent v2.2 data and the TRACI 2 impact assessment method for mid-point impacts cradle-to-incoming biorefinery gate. Carbon absorption during biomass growth contributed most substantially to the reduction of net global warming potential. Rice hulls and switchgrass resulted in the highest global warming potential, followed closely by corn and Thai sugarcane bagasse. Contribution analysis shows that chemical inputs such as fertilizer use contribute substantially to the net environmental impacts for these feedstocks.

Keywords: Biomass supply feasibility; Supply chain analysis; Life cycle assessment; Delivered cost

Contact information: a: Department of Forest Biomaterials, North Carolina State University, Campus Box 8001, NCSU Campus, Raleigh, NC 27695 USA; b: Center for Sustainability and Commerce, Nicholas School of the Environment, Duke University, Durham, NC 27708;

*Corresponding author: Richard_Venditti@ncsu.edu

INTRODUCTION

Bio-based chemicals are poised to play an integral role in the chemical industry at large and to contribute to decreasing the net climate change impacts through reductions in the use of petroleum feedstocks for chemical production. Production of non-fuel chemicals from crude oil currently represents roughly 5.5% of petroleum use in the U.S. (EIA 2015). A few key factors to consider when commercializing the products of such a chemical production system include chemical product choice, conversion pathway, the location of the biorefinery, biorefinery scale, and feedstock choice. These scenario conditions are instrumental to the feasibility of the modeled production system and competitiveness of a bio-based product entering an existing market. Many academic and industry studies have analyzed end product choice (Jang et al. 2012; Liao and Hu 2012), compared conversion pathways (Baskar et al. 2012; Shabbir et al. 2012; Tay and Ng 2012), optimized biorefinery location (Stephen et al. 2013), and supply chain logistics (Akgul et al. 2012; Awudu and Zhang 2012; Čuček et al. 2012), and have determined the most appropriate biorefinery scale (Argo et al. 2013). Other biomass-to-bioproducts studies have been conducted (Kim et al. 2011), though typically for a single country (Gonzalez-Garcia et al. 2009; Yu and Tao 2009; Stephen et al. 2010; Gonzalez et al. 2011; Daystar et al. 2014), for limited feedstock options (Giarola et al. 2011; You et al. 2012), or for other than a biorefinery scale (U.S. DOE 2001).

In the literature, there is an explicit gap in models that practically and objectively compare biomass feedstocks in an integrated manner, including technical, financial, and environmental concerns for a bio-based chemical refinery across multiple continents, irrespective of conversion pathway. This research would be helpful for those intending to construct and operate a biomass-to-monomeric sugar biorefinery to understand the impact of biomass type, biorefinery scale, location, and other parameters on the feasibility of successful biosugar commercialization. Additionally, a complete financial analysis would identify major cost drivers and a single feedstock delivered cost per bone-dry metric tonne (BDMT) for pertinent biomass feedstocks, biorefinery locations (country), and biorefinery scales.

Herein, we compared 18 biomass feedstocks from three different continents, calculated the delivered cost and environmental impacts per BDMT, provided estimated feedstock-specific monomeric sugar yields assuming a biochemical conversion process, and estimated the regional biomass availability. While the range of biomass feedstocks surveyed herein is by no means exhaustive, this study includes those feedstocks most commonly explored in the literature. The comparison of these biomass feedstocks using such measures enabled the authors to compare feedstocks objectively, to identify the parameters of each feedstock supply chain that could be optimized, and to discuss the realistic feasibility of commercialization of a bio-based economy.

METHODS

Biomass feedstock supply chain models were developed to determine the techno-economic and environmental feasibility of supplying a centralized biorefinery with biomass for a biomass-to-sugar production platform. Feedstocks analyzed were chosen based on preliminary research that indicated high potential availability and adequacy for conversion (Table 1). A biorefinery production scale of 500,000 BDMT yr-1 was chosen for analysis (Daystar et al. 2014; Reeb et al. 2014). The time horizon for supply chain and financial analysis was thirty project years and environmental impacts were analyzed on a 100-year time frame. US dollar values are presented as inflation-adjusted 2014 dollars.

The technical results include the form of delivery, biomass density, embodied energy content, chemical composition, and moisture content. The transport distances were calculated based on estimates of covered area and feedstock yield per hectare. The delivered cost includes the cost of biomass purchase or production, the cost of loading, transport to the biorefinery, and storage, as well as yield losses due to biomass degradation during storage. Environmental impacts of the cradle-to-gate feedstock supply chain were calculated by modeling necessary chemical, fuel, fertilizer, herbicide, pesticide and irrigation inputs and wastes for the establishment, maintenance, harvest, collection, loading, transport, and storage of the biomass feedstocks prior to the biorefinery gate (Khanchi 2012). The system boundary includes upstream and downstream impacts of mass and energy inputs, but no infrastructure impacts. Mass allocation was used for all scenario co-products (Appendix Table A3, Reeb et al. 2014).

Table 1. Overview of Biomass Feedstocks Chosen for Analysis, the Country Assumed for Each Biomass Type, and the Primary Literature Sources Used for Data Collection

*Indicates a residue co-product biomass type

Feedstock Supply Chains

Excel-based feedstock supply chain models were used to systematically model biomass production inputs, feedstock characteristics, and supply chain parameters. All data were collected from literature as referenced in Table 1. In order to facilitate more objective comparisons between scenarios, feedstock supply chains were separated into life cycle stages, including: land use change, establishment, maintenance, harvest, transportation, and storage. Feedstocks classified as ‘residues’ do not include land use change, establishment, maintenance or harvest life cycle stages as these impacts and costs are allocated to the main product of biomass production, though collection of the residues was modeled. The life cycle stages, major inputs and outputs to the system, and system boundary for each feedstock are outlined in Fig. 1.

Fig. 1a. Supply system scope and boundary for corn grain, corn syrup, corn stover, and Genera corn stover

Fig. 1b. Supply system scope and boundary for softwoods, US eucalyptus, and Brazilian eucalyptus. Adapted from Daystar et al. (2014)

Fig. 1c. Supply system scope and boundary for unmanaged hardwoods, forest residues, and Indonesian rice hulls. Adapted from Daystar et al. (2014).

Fig. 1d. Supply system scope and boundary for switchgrass, sweet sorghum, Genera biomass sorghum, and Genera biomass sorghum. Adapted from Daystar et al. (2014).

Fig. 1e. Supply system scope and boundary for Malaysian empty fruit bunches

Fig. 1f. Supply system scope and boundary for Thai sugarcane bagasse

Fig. 1g. Supply system scope and boundary for Brazilian sugarcane and Brazilian sugarcane bagasse

Delivered Cost

The major outputs of the supply chain analysis include delivered cost and the feedstock production life cycle inventory (all material and energy consumption and production along with emissions). Delivered cost was calculated as the sum of establishment, maintenance, harvest, biomass purchase, loading and transportation, as applicable for each feedstock. The bases of feedstock cost were US$ per BDMT of biomass delivered, per metric tonne of carbohydrates delivered, per million British Thermal Units (MBTU) delivered, and per metric tonne of monomeric sugars subsequently produced. A more complete discussion of the methodology used for calculating the delivered cost is provided by Daystar et al. (2014) and Reeb et al. (2014).

Life Cycle Assessment

Greenhouse gas (GHG) accounting was accomplished through the use of a carbon balance and reported using a carbon dioxide equivalency (CO2-eq.) based upon the Inter-governmental Panel on Climate Change (IPCC 2013) 100-year timeframe characterization factors for equivalency between CO2 and other GHG molecules to the CO2 baseline impact factor of 1.00. With respect to GHG accounting, plant growth was treated as a negative emission based on the proximate and ultimate analysis of each biomass type, and assuming a 3.667 carbon to CO2 stoichiometric balance (Daystar et al. 2014; Reeb et al. 2014). The bases of analysis for GHG accounting and for life cycle assessment include a mass basis (per BDMT), a carbohydrate basis (per MT carbohydrates), and a biosugar basis (per MT monomeric sugar).

In addition to GHG accounting for the cradle-to-gate biomass feedstock life cycles, a full life cycle inventory (LCI) was developed and the life cycle impact assessment (LCIA) was conducted using SimaPro 7.3 (PRé 2013), ecoinvent v2.2 (Frischknecht et al. 2005), and the LCA methodology outlined by the International Organization for Standardization (ISO 2010). In order to maintain a basis for comparison between the feedstocks analyzed, the Tool for the Reduction and Assessment of Chemical and other Environmental Impacts 2, version 3.01 (TRACI, Bare et al. 2002) was used to consistently calculate mid-point environmental impacts for the different biomass types (Table 2).

Table 2. Table of TRACI Impact Categories and Acronym Used

TRACI was used for all LCAs because it is of great importance to compare feedstocks consistently, though not all feedstocks are produced in the US and non-US LCI data was used for non-domestic feedstock supply models. Details about the GHG accounting method used and the LCA method, TRACI impact assessment method, and other parameters of the environmental assessment were outlined in detail by Reeb et al. (2014). Mass allocation data for coproducts are described in Appendix Table A3 and Appendix Figure A1.

RESULTS AND DISCUSSION

Supply Chain Analysis

The supply chain logistics for eighteen biomass feedstocks of interest for the potential bio-based economy were modeled at commercial scale. The characteristics of the selected biomass types that contribute to their selection include high carbohydrate content, relatively high yield, low cost, and sufficient availability (existing or projected) for the proposed biorefinery scale of 500,000 bone-dry metric tonnes (BDMT). Relevant assumptions about the analyzed biomasses and the modeled supply chains are further detailed in Table 3. A breakdown of the feedstock dry-mass composition is provided in Fig. 2 and in the Appendix (Table A2). These supply chain assumptions are important to take into account when comparing the biomass feedstocks because differences in delivered cost between feedstocks can likely be explained by yield differences, transport distances, required storage due to harvest window differences, covered area, and other factors.

Another factor which may impact the appropriateness of a biomass type for commercial-scale biorefinery feedstock supply is the availability of this feedstock within a financially-feasible transportation distance. In the case of some North American feedstocks the covered area is 10%, which, when coupled with low yields such as for unmanaged hardwoods, can contribute to very high maximum transportation distances. Assumptions about covered area and transport distance can be found in Table 3 and the results of the availability study in Table 4.

Fig. 2. Biomass feedstock composition on a dry-mass basis for the biomass types analyzed

Composition and supply chain logistics vary greatly for the various biomass types, as shown in Table 3 and Fig. 1. Other important factors and assumptions drawn from the literature include transportation distance (Gonzalez et al. 2011; Daystar et al. 2014; Reeb et al. 2014), a 1.31 tortuosity factor (Ravula 2007; Sultana and Kumar 2014), compositional analysis (Reeb et al. 2014; Daystar et al. 2015), and moisture content (Daystar et al. 2013). National biomass feedstock availability was estimated from literature and national agricultural production databases for each feedstock in each country of analysis (Table 4). Other important sources used throughout this study include: Allan et al. (2005), Rausch and Belyea (2006), Nguyen and Gheewala (2008), Lois-Correa et al. (2010), Couto et al. (2011), Prasera-A and Grant (2011), Shinners et al. (2011), Thao et al. (2011), Bolin (2012), Cavalett et al. (2012), Sakdaronnarong and Jonglertjunya (2012), Shafie et al. (2012), Munoz et al. (2013), Stephen et al.(2013), Vadas and Digman (2013), Daystar (2014), Daystar et al. (2014), and Reeb et al. (2014). Primary data regarding the three Genera feedstocks (corn stover, switchgrass, and biomass sorghum) were collected through personal communication with Genera Energy (Tiller 2015).

Table 3. Overview of Biomass Feedstock Options Chosen for Analysis and Relevant Feedstock Characteristics

Table 4. National Annual Availability Estimate for Each Biomass Feedstock Type Analyzed

Delivered Cost

The delivered cost can be defined as the sum of land preparation, planting, maintenance, harvesting, loading, and transport costs for feedstocks that are a primary product in their system. Alternatively, delivered cost can be defined as the sum of biomass purchase price in the “field,” cost of collection, loading costs, and transport costs for feedstocks which are a waste co-product of their system. Values for chemical use, yield, irrigation, harvest activities, transport distance, and other cost drivers were calculated using the methods more extensively outlined by Daystar et al. (2014) and Reeb et al.(2014). Table 5 gives a breakdown of costs by life cycle stage and the aggregate delivered cost per metric dry tonne of biomass and per metric tonne of carbohydrates. Cost data per metric tonne of carbohydrates and the total annual carbohydrate delivery potential for each feedstock within each studied country are provided below (Table 5 and Fig. 3).

Table 5. Total Delivered Cost Per BDMT, Per Metric Tonne (MT) of Carbohydrates and Per Million British Thermal Units (MBTU) Embodied Energy for Each Biomass Feedstock Type by Life Cycle Stage

Fig. 3. Biomass feedstock delivered cost per MT carbohydrates and major cost drivers for each feedstock, assuming 500,000 BDMT yr-1. Where biomass purchase price is not available, it is taken as equal to establishment, maintenance, and harvest costs for that biomass type.

As Brazilian sugarcane bagasse does not currently occupy an organized, consistent market as a biomass type, valuation of a market average price, spot price, or other purchase price equivalent was not possible. Therefore, the embodied energy content was used to calculate the expected electricity production potential from burning bagasse in an industrial power boiler. The value of that electricity in the Brazilian electricity grid was calculated using a 2014 average price per kWh in 2014 US dollars. This lack of market price data means that the estimate herein of $59 BDMT-1 might be higher than what biorefineries would encounter under actual contract terms at commercial scale.

It is clear from delivered cost calculations that South American and Southeast Asian biomass types can be supplied to a biorefinery at a lower cost than most North American biomass types. This is primarily due to the high purchase price of biomass in North America and the high cost of feedstock harvesting in the case of woody biomass types. Corn also requires a substantial agrochemical investment for establishment and maintenance of the prepared, planted field. The feedstocks that will deliver the most carbohydrates for the least cost, not taking into account the monomeric sugar conversion rate of these feedstocks, are, in descending order, rice hulls, empty fruit bunch, Brazilian sugarcane, sweet sorghum, corn stover, and Brazilian eucalyptus. Depending upon the unit of measure for delivered cost, some biomass types might not seem as financially feasible relative to other biomass types that are cheaper on a per unit mass basis. Accounting for carbohydrate content and hypothetical biosugar yield can help identify the tradeoffs between biomass types more pragmatically from the perspective of the biorefinery.

While these delivered cost values are specific to the 500,000 BDMT yr-1 biorefinery scale, the increase or decrease in refinery scale does not greatly impact scale-equivalent technology comparisons. Although bio-refinery CAPEX and other pro forma financial values would likely be impacted by scale changes, biosugar conversion economics are not examined herein. This nth-year financial analysis shows that non-North American feedstocks can provide a lower cost biomass carbohydrate supply to a biorefinery. These biomass types include rice hulls, Genera biomass sorghum, corn stover, Genera corn stover, Malaysian empty fruit bunch, and all Brazilian biomass types studied. This analysis does not account for biosugar yields, or bio-based chemical yields, or biorefining costs.

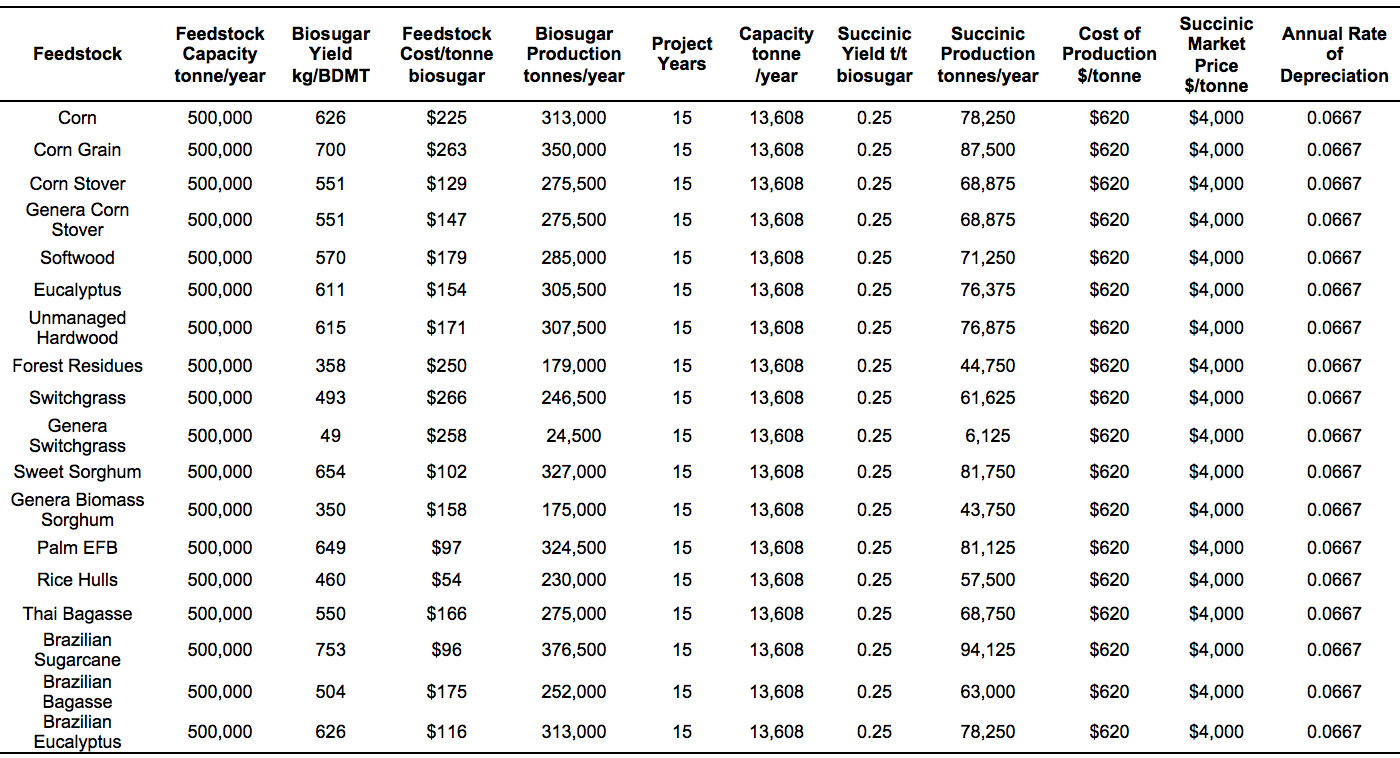

In addition to the availability, delivered cost, and environmental impacts caused by biomass feedstock supply, the monomeric sugar biochemical conversion yield for each biomass type was also explored. Dilute acid pretreatment was assumed for initial disaggregation followed by enzymatic hydrolysis to facilitate the production of dilute monomeric sugars in solution. A review of literature provided conversion efficiency factors used for analysis of the technical feasibility of biochemical conversion for each feedstock (Table 6). These values were validated using WinGEMS biochemical conversion models.

It is important to note that rice hulls, and to some extent switchgrass and Genera switchgrass, are higher in ash content and lower in carbohydrate content, which reduces the attractiveness of these biomass types as feedstock for monomeric sugar production through biochemical conversion. Some feedstocks, such as corn, corn syrup, switchgrass and Genera switchgrass have a high carbohydrate cost, while others, such as forest residues, Brazilian sugarcane, and Brazilian sugarcane bagasse, have a lower sugar cost due in part to high sugar yield and low delivered cost. Switchgrass has both a low carbohydrate concentration and therefore a higher carbohydrate cost, but also a low carbohydrate-to-monomeric sugar yield, which results in a high estimated feedstock cost per tonne of monomeric sugar produced.

Table 6. Carbohydrate Cost and Content, Monomeric Sugar Yield, and Calculated Feedstock Cost Per Tonne of Sugar Produced for Each Feedstock Type, Based on Conversion Efficiency Estimates

Note: Brazilian Sugarcane refers to conversion of whole plant (extractable sugars and subsequently bagasse).

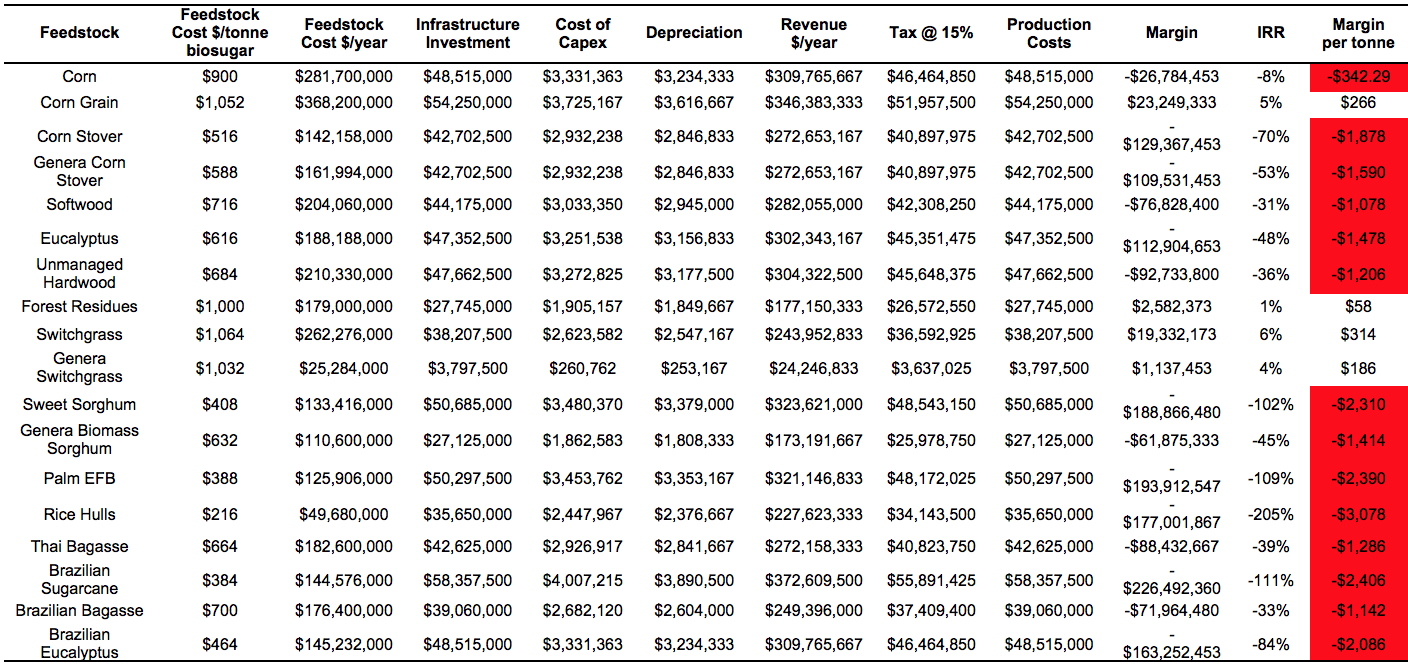

For the purposes of determining financial viability of biorefining, the transport distance, and therefore the growth yield and maximum geographical growth density, may significantly impact the financial viability of the biochemical biosugar platform for certain biomass types. For example, assume that the biosugar platform is employed to produce succinic acid, with a conversion yield from biosugar of 0.25 g/g sugar (Geraili et al. 2013; Wang et al. 2013), the market price of succinic acid is $4.00 kg-1 (Taylor 2010 RSC), the capital and overhead cost is $0.46 per kg and conversion cost is $0.62 per kg (Luo et al. 2010; Claypool 2013; Efe et al. 2013), for a 15-year project term assuming 3% interest on capital, straight-line depreciation, a 15% tax rate, and US$ in 2015. In this scenario only corn grain, forest residues, switchgrass, and Genera switchgrass will be financially viable feedstocks for a biosugar-to-succinic acid biorefinery, though with internal rates of return ranging from 1% to 6% (Appendix Tables A5 and A6).

Although this discussion has focused on the biochemical conversion route to this point, one alternative is a thermochemical conversion route, for which yield is not strictly correlated to polysaccharide content, but instead correlates well with carbon content, moisture content, and ash content (Daystar et al. 2013).

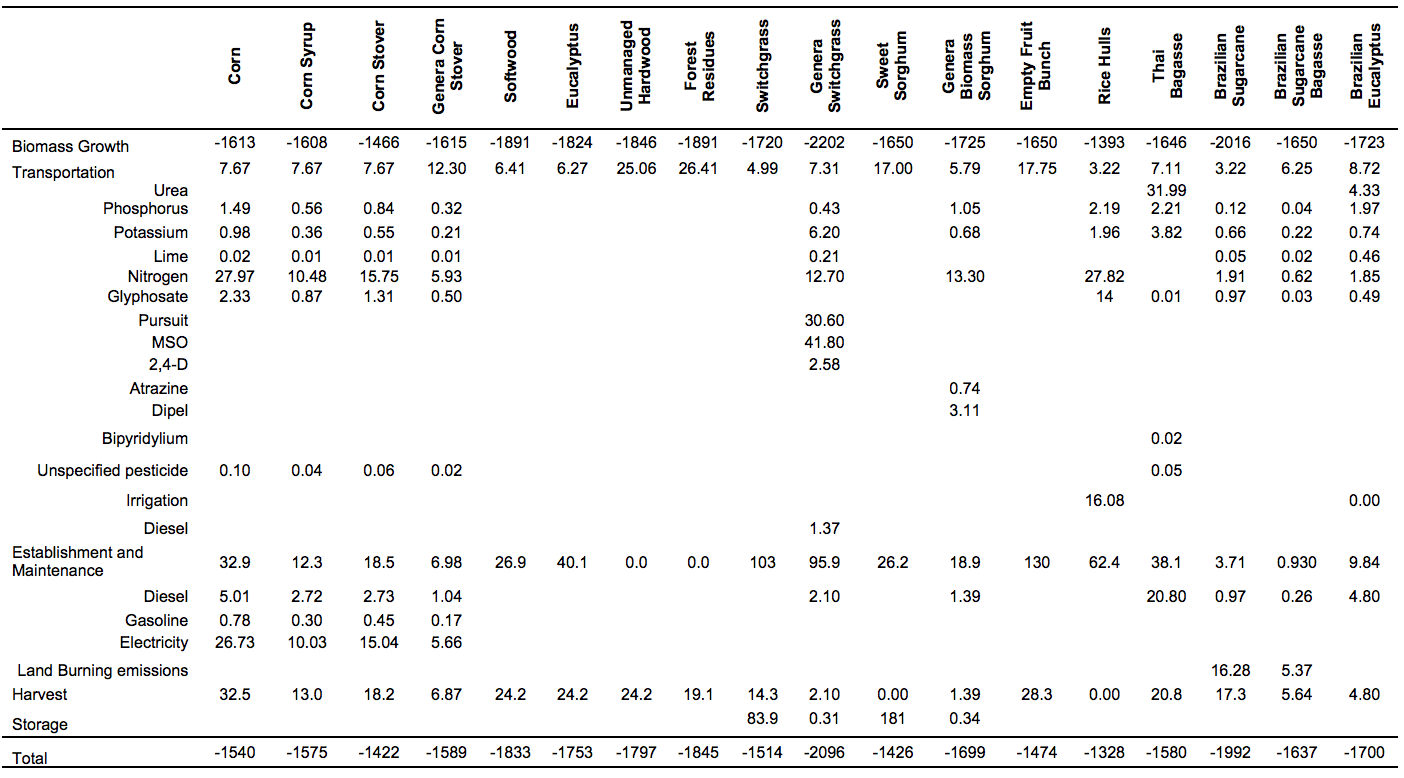

Table 7. Major Inputs and Outputs Allocated to the Feedstock Production, Harvest, Storage, and Transportation Life Cycle for Delivery of a BDMT Biomass to the Biorefinery, Assuming a 500,000 BDMT yr-1 Scale

Note, mass allocation methods used for feedstocks with coproducts are described in Appendix Table A3.

While forest residues, switchgrass, softwood and rice hulls are less feasible than other studied feedstocks for the biochemical conversion route, these feedstocks may be more appropriate for a thermochemical conversion pathway, as outlined by various researchers from the National Renewable Energy Laboratory (NREL; Dutta et al. 2011).

Life Cycle Assessment

The feedstock production and supply chain material and energy flow data related to chemical, energy and fuel use, transport distance, and degradation during storage were modeled using SimaPro 7.3 (PRé 2013) to generate the life cycle inventory (LCI). Upstream and downstream emission and resource use data were calculated using ecoinvent v2.2 (Frischknecht et al. 2005). Process data generated using the supply chain models and from literature for each cradle-to-gate feedstock production system are shown in Table 7.

Fig. 4. Global warming potential (GWP) per BDMT biomass delivered and the life cycle stage-wise contributions. Please note the y-axis has an axis break at approximately -1000 kg CO2-eq and two scales, for above and below the origin. The positive bars indicate the actual non-biogenic emissions based GWP impact without the biomass growth contribution.

To conduct the life cycle impact assessment (LCIA) the TRACI 2 impact assessment method was used to calculate mid-point impacts based upon the LCI developed in SimaPro. The typical output of such analysis is raw LCIA values in table form (Table A2 of Appendix) and normalized to the scenario with the highest impact for each impact category (Fig. A2 of Appendix). Herein, the global warming potential and other values were given as raw values (Fig. 4) and all TRACI impacts were presented using a heat map method (Fig. 5), developed using Tableau software (2014).

It is important to note that while the transportation distances vary greatly and in some cases contributed substantially to the delivered cost value for each feedstock, the transport emissions contribute only minimally to the net environmental burden for each feedstock supply system. Other important factors include the use of pre-harvest burning for sugarcane in Brazil and Thailand, which can directly impact the global warming potential (GWP) for each feedstock. Land use change (LUC) impacts were not included in the main TRACI impact assessment, but other studies by the authors have determined that LUC impacts can greatly impact the net GWP impact cradle-to-gate (Daystar 2014; Daystar et al. 2014; Reeb et al. 2014). Global warming potential values for feedstock production and supply are also provided per kg of bio-based sugar produced (Appendix Fig. A2 and A3).

Fig. 5. TRACI impact assessment results for all feedstocks cradle-to-gate. Larger squares indicate higher environmental impact within a category per BDMT. Raw TRACI impact values in table form can be found in Appendix Table A2. For the GWP impact category all of the scenario values were negative; in this plot the size of the square is larger for those scenarios with larger net GWP impacts.

From the TRACI results, and for the scenario assumptions used here, it is clear that simply because a feedstock is a residue co-product within a system does not mean that it inherently results in lower environmental and human health impacts. For example, the agricultural by-product rice hulls result in the highest environmental impacts for GWP. The second-highest GWP impact was attributed to sweet sorghum, an energy crop. Rice hulls were most impactful for global warming potential, eutrophication, ecotoxicity, and carcinogenics, while switchgrass was most impactful for acidification, ozone depletion, and photochemical oxidation. It should be noted that the environmental impacts of rice hull were mass allocated between rice grain and the rice hull; it is acknowledged that the rice grain is the driver that motivates the rice plant growth. For some feedstocks economic allocation may be more appropriate, however mass allocation was used throughout this study so that results would be comparable. Sweet sorghum resulted in the highest non-carcinogenics impact, and corn resulted in the largest respiratory effect.

This analysis is a cradle-to-gate comparison between feedstocks for a bio-refinery model. When combined with sugar yield, energy of conversion, cost of biorefining, and other factors, an educated determination of which feedstock and bio-refinery conversion pathway is least costly and least environmentally burdensome is possible. Where competing feasibility criteria exist, trade-offs must be taken into account during decision making. Part 2 of this manuscript explores methods for comparing competing criteria.

CONCLUSIONS

- Several biomass types have been identified that have sufficient availability to satisfy the ongoing demand of an operating bio-based sugar refinery at 500,000 BDMT yr-1.

- From among biomass feedstock types studied, those produced in Southeast Asia and South America generally resulted in a lower delivered cost than those produced in North America.

- The major cost drivers for most biomass types were transportation and biomass purchase price.

- Optimizing biomass supply systems for transport improves the cost position, but does not appreciably reduce global warming potential impacts.

- Calculating sugar yield enables the calculation of a yield-adjusted feedstock cost per metric tonne of biosugar produced, a more meaningful measure of feedstock cost to produce sugars than delivered mass cost or delivered carbohydrate cost.

- Rice hull biomass has the lowest delivered cost but a low carbohydrate content, a potential issue for storage, transportation and processing feasibility.

- Rice hulls, empty fruit bunch, sweet sorghum, and corn stover resulted in the highest global warming potential, followed closely by Genera corn stover, corn, corn syrup, switchgrass, and Thai sugarcane bagasse. Contribution analysis shows that chemical inputs such as fertilizer use contribute substantially to an increase in the net global warming impacts for these feedstocks.

- Biorefining for chemicals such as bio-succinic acid production may be financially feasible, depending upon the biomass type chosen, feedstock purchase or production cost, conversion yield, and the implications of throughput capacity on scale-related capital costs.

ACKNOWLEDGMENTS

The authors are grateful for financial support from Eastman Chemical Company and input from Barclay Satterfield, Lauren Johnson, Rebecca Glaspie, and Randy Waymire. Additionally, some helpful primary source data was provided by Kelly Tiller, Genera Energy.

REFERENCES CITED

Akgul, O., Shah, N., and Papageorgiou, L. G. (2012). “An optimization framework for a hybrid first/second generation bioethanol supply chain,” Computers & Chemical Engineering 42, 101-114. DOI: 10.1016/j.compchemeng.2012.01.012

Allan, G. G., Rattanaviwatpong, P., Guyette, E. B., Ho, T. C. S., Mallari, J. C., and Pfeif, A. (2005). “Sugar-cellulose composites VII. A comparative assessment of corn syrup as a fiber substitute in paper,” Bioresource Technology 96(15), 1645-1649. DOI: 10.1016/j.biortech.2004.12.029

Alvarez, P., Burken, J. G., Coan, J. D., de Oliveira, M. E. D., Dominguez-Faus, R., Gomez, D. E., Jaffe, A. M., Medlock III, K. B., Powers, S. E., Soligo, R., and Smulcer, L. A. (2010). “Fundamentals of a sustainable U.S. biofuels policy,” Department of Civil and Environmental Engineering, Rice University, Houston, TX. URL: http://www.ascension-publishing.com/BIZ/Baker134.pdf

Argo, A. M., Tan, E. C. D., Inman, D., Langholtz, M. H., Eaton, L. M., Jacobson, J. J., Wright, C. T., Muth Jr., D. J., Wu, M. M., Chiu, Y.-W., et al. (2013). “Investigation of biochemical biorefinery sizing and environmental sustainability impacts for conventional bale system and advanced uniform biomass logistics designs,” Biofuels, Bioproducts and Biorefining 7(3), 282-302. DOI: 10.1002/bbb.1391

Awudu, I., and Zhang, J. (2012). “Uncertainties and sustainability concepts in biofuel supply chain management: A review,” Renewable and Sustainable Energy Reviews 16(2), 1359-1368. DOI: 10.1016/j.rser.2011.10.016

Azar, C., and Larson, E. D. (2000). “Bioenergy and land-use competition in Northeast Brazil,” Energy for Sustainable Development 4(3), 64-71. DOI: 10.1016/j.rser.2011.10.016

Banerji, A., Balakrishnan, M., and Kishore, V. V. N. (2013). “Low severity dilute-acid hydrolysis of sweet sorghum bagasse,” Applied Energy 104, 197-206. DOI: 10.1016/j.apenergy.2012.11.012

Bare, J. C., Norris, G. A., Pennington, D. W., and McKone, T. (2002). “TRACI: The tool for the reduction and assessment of chemical and other environmental impacts,” Journal of Industrial Ecology6(3-4), 49-78. DOI: 10.1162/108819802766269539

Baskar, C., Baskar, S., and Dhillon, R. S. (2012). Biomass Conversion: The Interface of Biotechnology, Chemistry and Materials Science, Springer, New York, NY.

Bauen, A. (1999). Gasification-based Biomass Fuel Cycles: An Economic and Environmental Analysis at the Regional Level, Ph.D. dissertation, King’s College London, University of London, London, UK.

Bergqvist, M. M., Wárdh, K. S., Das, A., and Ahlgren, E. O. (2008). “A techno-economic assessment of rice husk-based power generation in the Mekong River Delta of Vietnam,” International Journal of Energy Research 32(12), 1136-1150. DOI: 10.1002/er.1451

Benjamin, Y., Cheng, H., and Görgens, J. F. (2013). “Evaluation of bagasse from different varieties of sugarcane by dilute acid pretreatment and enzymatic hydrolysis,” Industrial Crops and Products 51, 7-18. DOI: 10.1016/j.indcrop.2013.08.067

Bernardes, A. D. P., Tremblay, G. F., Bélanger, G., Brégard, A., Seguin, P., and Vanasse, A. (2015). “Sugar yield of sweet pearl millet and sweet sorghum as influenced by harvest date and delays between biomass chopping and pressing,” BioEnergy Research 8(1), 100-108. DOI: 10.1007/s12155-014-9504-y

Betters, D. R., Wright, L. L., and Couto, L. (1991). “Short rotation woody crop plantations in Brazil and the United States,” Biomass & Bioenergy 1(6), 305-316. DOI: 10.1016/0961-9534(91)90011-Z

Bolin, C. A. (2012). “Sustainable preservative-treated forest products, their life cycle environmental impacts, and end of life management opportunities: A case study,” in: Life Cycle Assessment Handbook: A Guide for Environmentally Sustainable Products, M. A. Curran (ed.), Scrivener Publishing, Beverly, MA, pp. 291-310.

Bonner, I. J., Muth Jr., D. J., Koch, J. B., and Karlen, D. L. (2014). “Modeled impacts of cover crops and vegetative barriers on corn stover availability and soil quality,” BioEnergy Research 7(2), 576-589. DOI: 10.1007/s12155-014-9423-y

Cabrera, E., Muñoz, M. J., Martín, R., Caro, I., Curbelo, C., and Díaz, A. B. (2014). “Alkaline and alkaline peroxide pretreatments at mild temperature to enhance enzymatic hydrolysis of rice hulls and straw,” Bioresource Technology 167, 1-7. DOI: 10.1016/j.biortech.2014.05.103

Cavalett, O., Junqueira, T. L., Dias, M. O. S., Jesus, C. D. F., Mantelatto, P. E., Cunha, M. P., et al.(2012). “Environmental and economic assessment of sugarcane first generation biorefineries in Brazil,” Clean Technologies and Environmental Policy 14(3), 399-410. DOI: 10.1007/s10098-011-0424-7

Chungsangunsit, T., Gheewala, S. H., and Patumsawad, S. (2004). “Environmental assessment of electricity production from rice husk: A case study in Thailand,” International Energy Journal 6(1): 347-356. ISSN: 1513-718X

Claypool, J. T. (2013). Development, Validation, and Use of a Spreadsheet-Based Tool for Early-Stage Technoeconomic Evaluation of Industrial Biotechnologies, M.S. thesis, Report No. 13135, Iowa State University, Ames, IA.

Contreras, A. M., Rosa, E., Pérez, M., Van Langenhove, H., and Dewulf, J. (2009). “Comparative life cycle assessment of four alternatives for using by-products of cane sugar production,” Journal of Cleaner Production 17(8), 772-779. DOI: 10.1016/j.jclepro.2008.12.001

Corredor, D. Y., Salazar, J. M., Hohn, K. L., Bean, S., Bean, B., and Wang, D. (2009). “Evaluation and characterization of forage sorghum as feedstock for fermentable sugar production,” Applied Biochemistry and Biotechnology 158(1), 164-179. DOI: 10.1007/s12010-008-8340-y

Couto, L., Nicholas, I., and Wright, L. (2011). “Short rotation eucalyptus plantations for energy in Brazil,” IEA Bioenergy Task 43: 2011:02.

Cromer, R. N., Cameron, D. M., Rance, S. J., Ryan, P. A., and Brown, M. (1993). “Response to nutrients in Eucalyptus grandis. 1. Biomass accumulation,” Forest Ecology and Management 62(1), 211-230. DOI: 10.1016/0378-1127(93)90051-N

Cubbage, F., Mac Donagh, P., Júnior, J. S., Rubilar, R., Donoso, P., Ferreira, A., Hoeflich, V., Olmos, V. M., Ferreira, G., Balmelli, G., et al. (2007). “Timber investment returns for selected plantations and native forests in South America and the southern United States,” New Forests 33(3), 237-255. DOI: 10.1007/s11056-006-9025-4

Čuček, L., Varbanov, P. S., Klemeš, J. J., and Kravanja, Z. (2012). “Total footprints-based multi-criteria optimization of regional biomass energy supply chains,” Energy 44(1), 135-145. DOI: 10.1016/j.energy.2012.01.040

Cui, X., Zhao, X., Zeng, J., Loh, S. K., Choo, Y. M., and Liu, D. (2014). “Robust enzymatic hydrolysis of Formaline-pretreated oil palm empty fruit bunches (EFB) for efficient conversion of polysaccharide to sugars and ethanol,” Bioresource Technology 166, 584-591. DOI: 10.1016/j.biortech.2014.05.102

Cunningham, M. W., and Tamang, B. (2014). “Eucalyptus,” in: Cellulosic Energy Cropping Systems, First Edition, D. L. Karlen (ed.), John Wiley & Sons, West Sussex, UK, pp. 149-159. ISBN: 978-1-119-99194-6

Daystar, J. S. (2014). Environmental Impacts of Cellulosic Biofuels Made in the South East: Implications of Impact Assessment Methods and Study Assumptions, Ph.D. dissertation, Department of Forest Biomaterials, North Carolina State University, Raleigh, NC.

Daystar, J. S., Venditti, R. A., Gonzalez, R., Jameel, H., Jett, M., and Reeb, C. W. (2013). “Impacts of feedstock composition on alcohol yields and greenhouse gas emissions from the NREL thermochemical ethanol conversion process,” BioResources 8(4), 5261-5278. DOI: 10.15376/biores.8.4.5261-5278

Daystar, J. S., Gonzalez, R., Reeb, C. W., Venditti, R. A., Treasure, T., Abt, R., and Kelley, S. (2014). “Economics, environmental impacts, and supply chain analysis of cellulosic biomass for biofuels in the southern US: Pine, eucalyptus, unmanaged hardwoods, forest residues, switchgrass, and sweet sorghum,” BioResources 9(1), 393-444. DOI: 10.15376/biores.9.1.393-444

Daystar, J. S., Reeb, C. W., Gonzalez, R., Venditti, R., and Kelley, S. S. (2015). “Environmental life cycle impacts of cellulosic ethanol in the Southern US produced from loblolly pine, eucalyptus, unmanaged hardwoods, forest residues, and switchgrass using a thermochemical conversion pathway,” Fuel Processing Technology 138: 164-174. DOI: 10.1016/j.fuproc.2015.04.019

de Moraes Rocha, G. J., Martin, C., Soares, I. B., Maior, A. M. S., Baudel, H. M., and de Abreu, C. A. M. (2011). “Dilute acid-mixed pretreatment of sugarcane bagasse for ethanol production,” Biomass & Bioenergy 35(1), 663-670. DOI: 10.1016/j.biombioe.2010.10.018

Diaz-Balteiro, L., and Rodriguez, L. C. E. (2006). “Optimal rotations on Eucalyptus plantations including carbon sequestration – A comparison of results in Brazil and Spain,” Forest Ecology and Management 229(1), 247-258. DOI: 10.1016/j.foreco.2006.04.005

Dube, F., Couto, L., Silva, M. L., Leite, H. G., Garcia, R., and Araujo, G. A. A. (2002). “A simulation model for evaluating technical and economic aspects of an industrial Eucalyptus-based agroforestry system in Minas Gerais, Brazil,” Agroforestry Systems 55(1), 73-80. DOI: 10.1023/A:1020240107370

Dutta, A., Talmadge, M., Hensley, J., Worley, M., Dudgeon, D., Barton, D., Groenendijk, P., Ferrari, D., Stears, B., Searcy, E. M., et al. (2011). “Process design and economics for conversion of lignocellulosic biomass to ethanol: Thermochemical pathway by indirect gasification and mixed alcohol synthesis,” NREL/TP-5100-51400, National Renewable Energy Laboratory, Golden, CO.

Efe, T., van der Wielen, L. A. M., and Straathof, A. J. J. (2013). “Techno-economic analysis of succinic acid production using adsorption from fermentation medium,” Biomass & Bioenergy 56, 479-492. DOI: 10.1016/j.biombioe.2013.06.002

Finkbeiner, M. (2011). Towards Life Cycle Sustainability Management, Springer Science+Business Media, New York, NY.

Frischknecht, R., Jungbluth, N., Althaus, H.-J., Doka, G., Dones, R., Heck, T., Hellweg, S., Hischier, R., Nemecek, T., Rebitzer, G., et al. (2005). “The ecoinvent database: Overview and methodological framework,” International Journal of Life Cycle Assessment 10(1), 3-9. DOI: 10.1065/lca2004.10.181.1

Garivait, S., Chaiyo, U., Patumsawad, S., and Deakhuntod, J. (2006). “Physical and chemical properties of Thai biomass fuels from agricultural residues,” Proceedings of the 2nd Joint International Conference on Sustainable Energy and Environment, November 23-December 1, 2006, Bangkok, Thailand.

Garlock, R. J., Balan, V., Dale, B. E., Pallapolu, V. R., Lee, Y. Y., Kim, Y., Mosier, N. S., Ladisch, M. R., Holtzapple, M., Falls, M., et al. (2011). “Comparative material balances around pretreatment technologies for the conversion of switchgrass to soluble sugars,” Bioresource Technology 102(24), 11063-11071. DOI: 10.1016/j.biortech.2011.04.002

Giarola, S., Zamboni, A., and Bezzo, F. (2011). “Spatially explicit multi-objective optimization for design and planning of hybrid first and second generation biorefineries,” Computers & Chemical Engineering 35(9), 1782-1797. DOI: 10.1016/j.compchemeng.2011.01.020

Glassner, D. A., Hettenhaus, J. R., and Schechinger, T. M. (1998). “Corn stover collection project,” Proceedings of BioEnergy ’98: Expanding BioEnergy Partnerships, Volume 2, pp. 1100-1110.

Gonzalez, R., Wright, J., and Saloni, D. (2008). “The business of growing Eucalyptus for biomass,” Biomass Magazine 4, 52-55.

Gonzalez, R., Phillips, R., Saloni, D., Jameel, H., Abt, R., Pirraglia, A., and Wright, J. (2011a). “Biomass to energy in the southern United States: Supply chain and delivered cost,” BioResources6(3), 2954-2976. DOI: 10.15376/biores.6.3.2954-2976

Gonzalez, R., Treasure, T., Wright, J., Saloni, D., Phillips, R., Abt, R., and Jameel, H. (2011b). “Exploring the potential of Eucalyptus for energy production in the Southern United States: Financial analysis of delivered biomass. Part I,” Biomass & Bioenergy 35(2), 755-766. DOI: 10.1016/j.biombioe.2010.10.011

González-García, S., Berg, S., Feijoo, G., and Moreira, M. T. (2009). “Comparative environmental assessment of wood transport models: A case study of a Swedish pulp mill,” Science of the Total Environment 407(11), 3530-3539. DOI: 10.1016/j.scitotenv.2009.02.022

Groot, W. J., and Borén, T. (2010). “Life cycle assessment of the manufacture of lactide and PLA biopolymers from sugarcane in Thailand,” International Journal of Life Cycle Assessment 15(9), 970-984. DOI: 10.1007/s11367-010-0225-y

Kadam, K. L., and McMillan, J. D. (2003). “Availability of corn stover as a sustainable feedstock for bioethanol production,” Bioresource Technology 88(1), 17-25. DOI: 10.1016/S0960-8524(02)00269-9

Hamelinck, C. N., van Hooijdonk, G., and Faaij, A. P. C. (2005). “Ethanol from lignocellulosic biomass: Techno-economic performance in short-, middle- and long-term,” Biomass & Bioenergy28(4), 384-410. DOI: 10.10016/j.biombioe.2004.09.002

Hess, J. R., Kenney, K. L., Wright, C. T., Perlack, R., and Turhollow, A. (2009). “Corn stover availability for biomass conversion: Situation analysis,” Cellulose 16(4), 599-619. DOI: 10.1007/s10570-009-9323-z

Hislop, D., and Hall, D. O. (1996). “Biomass resources for gasification power plant,” ETSU B/M3/00388/31/REP, Kings College, University of London, London, UK.

Holtzapple, M. T., Davison, R. R., Ross, M. K., Aldrett-Lee, S., Nagwani, M., Lee, C.-M., Lee, C., Adelson, S., Kaar, W., Gaskin, D., et al. (1999). “Biomass conversion to mixed alcohol fuels using the MixAlco process,” Applied Biochemistry and Biotechnology 77-79, 609-631. DOI: 10.1385/ABAB:79:1-3:609

Holzmueller, E. J., and Jose, S. (2012). “Biomass production for biofuels using agroforestry: Potential for the North Central Region of the United States,” Agroforestry Systems 85(2), 305-314. DOI: 10.1007/s10457-012-9502-z

Huang, H. (2013). Characterization of Chemical Composition, Milling Properties and Carbon Dioxide Diffusivity Resulting from Early Harvest Corn and Corn Stover, Ph.D. dissertation, Department of Agricultural and Biological Engineering, University of Illinois at Urbana-Champaign, Urbana, IL.

Inter-governmental Panel on Climate Change [IPCC]. (2013). Climate Change 2013 – The Physical Science Basis, IPCC Fifth Assessment Report, T. F. Stocker, D. Qin, G.-K. Plattner, M. Tignor, S. K. Allen, J. Boschung, A. Nauels, Y. Xia, V. Bex, and P. M. Midgley. (eds.), Cambridge University Press, Cambridge, UK.

International Organization for Standardization [ISO]. (2010). ISO 14044:2006, Environmental management – Life cycle assessment – Requirements and guidelines, International Organization for Standardization, Geneva, Switzerland, pp. 1-46.

Jang, Y., Kim, B., Shin, J. H., Choi, Y. J., Choi, S., Song, C. W., Lee, J., Park, H. G., and Lee S. Y. (2012). “Bio-based production of C2-C6 platform chemicals,” Biotechnology and Bioengineering109(10), 2437-2459. DOI: 10.1002/bit.24599

Janzon, R., Schutt, F., Oldenburg, S., Fischer, E., Korner, I., and Saake, B. (2014). “Steam pretreatment of spruce forest residues: Optimal conditions for biogas production and enzymatic hydrolysis,” Carbohydrate Polymers 100, 202-210. DOI: 10.1016/j.carbpol.2013.04.093

Jung, J. H., Vermerris, W., Gallo, M., Fedenko, J. R., Erikson, J. E., and Altpeter, F. (2013). “RNA interference suppression of lignin biosynthesis increases fermentable sugar yields for biofuel production from field-grown sugarcane,” Plant Biotechnology Journal 11(6), 709-716. DOI: 10.1111-pbi.12061

Kadam, K. L., and McMillan, J. D. (2003). “Availability of corn stover as a sustainable feedstock for ethanol production,” Bioresource Technology 88(1), 17-25. DOI: 10.1016/S09608524(02)00269-9

Kasmaprapruet, S., Paengjuntuek, W., Saikhwan, P, and Phungrassami, H. (2009). “Life cycle assessment of milled rice production: Case study in Thailand,” European Journal of Scientific Research 30(2), 195-203. ISSN: 1450-216X

Khanchi, A. (2012). Drying and Storage of Switchgrass, Ph.D. dissertation, Oklahoma State University, Stillwater, OK.

Kim, M., and Day, D. F. (2011). “Composition of sugar cane, energy cane, and sweet sorghum suitable for ethanol production at Louisiana sugar mills,” Journal of Industrial Microbiology and Biotechnology 38(7), 803-807. DOI: 10.1007/s10295-010-0812-8

Kim, S., Dale, B. E., and Jenkins, R. (2009). “Life cycle assessment of corn grain and corn stover in the United States,” International Journal of Life Cycle Assessment 14(2), 160-174. DOI: 10.1007/s11367-008-0054-4

Kim, J., Realff, M. J., and Lee, J. H. (2011). “Optimal design and global sensitivity analysis of biomass supply chain networks for biofuels under uncertainty,” Computers & Chemical Engineering35(9), 1738-1751. DOI: 10.1016/j.compchemeng.2011.02.008

Laclau, J.-P., Bouillet, J.-P., Gonçalves, J. L. M., Silva, E. V., Jourdan, C., Cunha, M. C. S., Moreira, M. R., Saint-André, L., Maquère, V., Nouvellon, Y., and Ranger, J. (2008). “Mixed-species plantations of Acacia mangium and Eucalyptus grandis in Brazil. 1. Growth dynamics and aboveground net primary productivity,” Forest Ecology Management 255(12), 3905-3917. DOI: 10.1016/j.foreco.2007.10.049

Laclau, J.-P., Ranger, J., Gonçalves, J. L. M., Maquère, V., Krusche, A. V., M’Bou, A. T., Nouvellon, Y., Saint-André, L., Bouillet, J.-P., Piccolo, M. D. C., and Deleporte, P. (2010). “Biogeochemical cycles of nutrients in tropical Eucalyptus plantations: Main features shown by intensive monitoring in Congo and Brazil,” Forest Ecology and Management 259(9), 1771-1785. DOI: 10.1016/j.foreco.2009.06.010

Laopaiboon, P., Thani, A., Leelavatcharamas, V., and Laopaiboon, L. (2010). “Acid hydrolysis of sugarcane bagasse for lactic acid production,” Bioresource Technology 101(3), 1036-1043. DOI: 10.1016/j.biortech.2009.08.091

Li, C., Sun, L., Simmons, B. A., and Singh, S. (2013a). “Comparing the recalcitrance of Eucalyptus, Pine, and Switchgrass using ionic liquid and dilute acid pretreatments,” BioEnergy Research 6(1), 14-23. DOI: 10.1007/s12155-012-9220-4

Li, C., Tanjore, D., He, W., Wong, J., Gardner, J. L., Sale, K. L., Simmons, B. A., and Singh, S. (2013b). “Scale-up and evaluation of high solid ionic liquid pretreatment and enzymatic hydrolysis of switchgrass,” Biotechnology for Biofuels 6(154), 1-14. DOI: 10.1186/1754-6834-6-154.

Liao, J. C., and Hu, W. (2012). “Bio-based chemical engineering,” Current Opinion in Chemical Engineering 1(4), 353-354. DOI: 10.1016/j.coche.2012.09.011

Lim, W.-S., and Lee, J.-W. (2013). “Effects of pretreatment factors on fermentable sugar production and enzymatic hydrolysis of mixed hardwood,” Bioresource Technology 130, 97-101. DOI: 10.1016/j.biortech.2012.11.122

Ling, T. P., Hassan, O., Badri, K., Maskat, M. Y., and Mustapha, W. A. W. (2013). “Sugar recovery of enzymatic hydrolysed oil palm empty fruit bunch fiber by chemical pretreatment,” Cellulose 20(6), 3191-3203. DOI: 10.1007/s10570-013-0033-1

Lingga, V. (2009). “Rice husk waste turned into cheap energy for cooking,” The Jakarta Post, Jakarta, Indonesia, published online: 28 January 2009. URL: http://www.thejakartapost.com/news/2009/01/28/rice-husk-waste-turned-cheap-energy-cooking.html

Lloyd, T. A., and Wyman, C. E. (2005). “Combined sugar yields for dilute sulfuric acid pretreatment of corn stover followed by enzymatic hydrolysis of the remaining solids,” Bioresource Technology96(18), 1967-1977. DOI: 10.1016/j.biortech.2005.01.011

Lois-Correa, J., Flores-Vela, A., Ortega-Grimaldo, D., and Berman-Delgado, J. (2010). “Experimental evaluation of sugar cane bagasse storage in bales system,” J. Appl. Res. Tech. 8(3), 365-377.

Luo, L., van der Voet, E., and Huppes, G. (2010). “Biorefining of lignocellulosic feedstock – Technical, economic and environmental considerations,” Bioresource Technology 101(13), 5023-5032. DOI: 10.1016/j.biortech.2009.12.109

Mabee, W. E., McFarlane, P. N., and Saddler, J. N. (2011). “Biomass availability for lignocellulosic ethanol production,” Biomass & Bioenergy 35(11), 4519-4529. DOI: 10.1016/j.biombioe.2011.06.026

Marx, S., Ndaba, B., Chiyanzu, I., and Schabort, C. (2014). “Fuel ethanol production from sweet sorghum bagasse using microwave irradiation,” Biomass & Bioenergy 65, 145-150. DOI: 10.1016/j.biombioe.2013.11.019

Meier, E. (2014). “Loblolly pine,” The Wood Database, URL: http://www.wood-database.com/lumber-identification/softwoods/loblolly-pine/ (accessed: 2 September 2014).

Munoz, I., Flury, K., Jungbluth, N., Rigarlsford, G., Canals, L. M., and King, H. (2013). “Life cycle assessment of bio-based ethanol produced from different agricultural feedstocks,” International Journal of Life Cycle Assessment 19(1), 109-119. DOI: 10.1007/s11367-013-0613-1

Nguyen, T. L. T., and Gheewala, S. H. (2008). “Life cycle assessment of fuel ethanol from cane molasses in Thailand,” International Journal of Life Cycle Assessment 13(4), 301-311. DOI: 10.1007/s11367-008-0011-2

Nguyen, T. L. T., Gheewala, S. H., and Garivait, S. (2008). “Full chain energy analysis of fuel ethanol from cane molasses in Thailand,” Applied Energy 85(8), 722-734. DOI: 10.1016/j.apenergy.2008.02.002

Nguyen, T. L. T., Gheewala, S. H., and Sagisaka, M. (2010). “Greenhouse gas savings potential of sugar cane bio-energy systems,” Journal of Cleaner Production 18(5), 412-418. DOI: 10.1016/j.jclepro.2009.12.012

Ou, C.-S. (2007). Sustainable Infrastructure Materials: A Life Cycle Assessment Approach, Ph.D. dissertation, Department of Civil, Environmental and Architectural Engineering, University of Colorado, Boulder, CO.

Pattra, S., Sangyoka, S., Boonmee, M., and Reungsang, A. (2008). “Bio-hydrogen production from the fermentation of sugarcane bagasse hydrolysate by Clostridium butyricum,” International Journal of Hydrogen Production 33(19), 5256-5265. DOI: 10.1016/j.ijhydene.2008.05.008

Perlack, R. D., and Turhollow, A. F. (2003). “Feedstock cost analysis of corn stover residues for further processing,” Energy 28(14), 1395-1403. DOI: 10.1016/S0360-5442(3)00123-3

Petrolia, D. R. (2008). “The economics of harvesting and transporting corn stover for conversion to fuel ethanol: A case study for Minnesota,” Biomass & Bioenergy 32(7), 603-612. DOI: 10.1016/j.biombioe.2007.12.012

Phillips, R. B., Jameel, H., and Chang, H.-M. (2013). “Integration of pulp and paper technology with bioethanol production,” Biotechnology for Biofuels 6(1), 1-13. DOI: 10.1186/1754-6834-6-13

Prasara-A, J., and Grant, T. (2011). “Comparative life cycle assessment of uses of rice husk for energy purposes,” International Journal of Life Cycle Assessment 16(6), 493-502. DOI: 10.1007/s11367-011-0293-7

Prasertsri, P. (2013). “Thailand annual sugar report,” U.S. Department of Agriculture, Foreign Agricultural Service, Global Agricultural Information Network. GAIN Report Number: TH3037. URL: http://gain.fas.usda.gov/Recent%20GAIN%20Publications/Sugar%20Annual_Bangkok_Thailand_4-17-2013.pdf

PRé Consultants. (2014). “SimaPro v. 7.2 Life Cycle Assessment Software,” Amersfoort, The Netherlands.

Rausch, K. D., and Belyea, R. L. (2006). “The future of coproducts from corn processing,” Applied Biochemistry and Biotechnology 128(1), 47-86. DOI: 10.1385/ABAB:128:1:047

Ravula, P. (2007). Design, Simulation, Analysis and Optimization of Transportation System for a Biomass to Ethanol Conversion Plant, Ph.D. dissertation, Virginia Polytechnic Institute and State University, Blacksburg, VA.

Reeb, C. W., Hays, T., Venditti, R., Gonzalez, R., and Kelley, S. (2014). “Supply chain analysis, delivered cost and life cycle assessment of oil palm empty fruit bunch biomass for green chemical production in Malaysia,” BioResources 9(3), 5385-5416. DOI: 10.15376/biores.9.3.5385-5416

Rosillo-Calle, F. (2006). Biomass Energy – An overview, Landolf-Bornstein Handbook Publisher, Springer.

Roy, P., Shimizu, N., Okadome, H., Shiina, T., and Kimura, T. (2007). “Life cycle of rice: Challenges and choices for Bangladesh,” Journal of Food Engineering 79(4), 1250-1255. DOI: 10.1016/j.foodeng.2006.04.017

Sakdaronnarong, C., and Jonglertjunya, W. (2012). “Rice straw and sugarcane bagasse degradation mimicking lignocellulose decay in nature: An alternative approach to biorefinery,” Science Asia 38(4), 364-372. DOI: 1.2306/scienceasia1513-1874.2012.38.364

Sarlls, C. E., and Oladosu, G. (2010). “A comparison of empirical and theoretical Eucalyptus yields in Brazil,” Poster presentation, 95th Ecological Society of America Conference, August 1-6, 2010, Pittsburgh, PA. URL: http://web.ornl.gov/sci/ees/cbes/Trip%20Reports/P2%20Oladosu%20and%20Sarlis%202010%20POSTER%20Eucalypts%20Productivity%20Theory%20vs%20Empirical%20%20Compatibility%20Mode.pdf (accessed: 26 August 2014).

Schmer, M. R., and Dose, H. L. (2014). “Cob biomass supply for combined heat and power and biofuel in the north central USA,” Biomass & Bioenergy 64, 321-328. DOI: 10.1016/j.biombioe.2014.03.051

Schmidt, M., Onyango, V., and Palekhov, D. (2011). Implementing Environmental and Resource Management, Springer-Verlag, New York, NY.

Schwietzke, S., Kim, Y., Ximenes, E., Mosier, N. and Ladisch, M. (2009). “Ethanol production from maize,” in: Biotechnology in Agriculture and Forestry, Vol. 63, Springer Science+Business Media, New York, NY. pp. 347-364. DOI: 10.1007/978-3-540-68922-5_23

Shabbir, Z., Tay, D. H. S., and Ng, D. K. S. (2012). “A hybrid optimization model for the synthesis of sustainable gasification-based integrated biorefinery,” Chemical Engineering Research and Design90(10), 1568-1581. DOI: 10.1016/j.cherd.2012.02.015

Shafie, S. M., Mahlia, T. M. I, Masjuki, H. H., and Rismanchi, B. (2012). “Life cycle assessment (LCA) of electricity generation from rice husk in Malaysia,” Energy Procedia 14, 499-504. DOI: 10.1016/j.egypro.2011.12.965

Sharp, B. E. (2013). Assessing Potential Environmental Impacts According to Probable Patters of Switchgrass Adoption in the Southeastern US, Ph.D. dissertation, Department of Environmental Engineering and Science, Clemson University, Clemson, SC.

Shi, J., Ebrik, M. A., and Wyman, C. E. (2011). “Sugar yields from dilute sulfuric acid and sulfur dioxide pretreatments and subsequent enzymatic hydrolysis of switchgrass,” Bioresource Technology102(19), 8930-8938. DOI: 10.1016/j.biortech.2011.07.042

Shinners, K. J., Wepner, A. D., Muck, R. E., and Weimer, P. J. (2011). “Aerobic and anaerobic storage of single-pass, chopped corn stover,” Bioenergy Research 4(1), 61-75. DOI: 10.1007/S12155-010-9101-7

Singh, A. (2007). Bioadhesives from Distiller’s Dried Grains with Solubles (DDGS) and Studies on Sustainability Issues of Corn Ethanol Industries, M.S. thesis, School of Packaging, Michigan State University, Lansing, MI.

Singh, V., Johnston, D. B., and Neoh, S. L. (2010). “Enzymatic corn wet milling process: Enzyme optimization & commercial trial,” Industrial Biotechnology 6(1), 34-40. DOI: 10.1089/ind.2010.6.034

Stape, J. L., Binkley, D., Ryan, M. G., Fonseca, S., Loos, R. A., Takahashi, E. N., Silva, C. R., Silva, S. R., Hakamada, R. E., Ferreira, J. M. D. A., et al. (2010). “The Brazil Eucalyptus Potential Productivity Project: Influence of water, nutrients and stand uniformity on wood production,” Forest Ecology and Management 259(9) 1684-1694. DOI: 10.1016/j.foreco.2010.01.012

Stephen, J. D., Sokhansanj, S., Bi, X., Sowlati, T., Kloeck, T., Townley-Smith, L., and Stumborg, M. A. (2010). “Analysis of biomass feedstock availability and variability for the Peace River region of Alberta, Canada,” Biosystems Engineering 105(1), 103-111. DOI: 1.1016/j.biosystemseng.2009.09.019

Stephen, J. D., Mabee, W. E., and Saddler, J. N. (2013). “Lignocellulosic ethanol production from woody biomass: The impact of facility siting on competitiveness,” Energy Policy 59, 329-340. DOI: 10.1016/j.enpol.2013.03.043

Sultana, A. and Kumar, A. (2014). “Development of tortuosity factor for assessment of lignocellulosic biomass delivery cost to a biorefinery,” Applied Energy 119, 288-295. DOI: 10.1016/j.apenergy.2013.12.036

Sun, T. T. W. (2013). Impact of Pretreatment Methods on Enzymatic Hydrolysis of Softwood, M.S. thesis, University of Toronto, Toronto, Canada.

Tableau Software (2014). “Tableau Desktop v. 8.3 Data Analysis Software,” Seattle, WA.

Tay, D. H. S., and Ng, D. K. S. (2012). “Multiple-cascade automated targeting for synthesis of a gasification-based integrated biorefinery,” Journal of Cleaner Production 34, 38-48. DOI: 10.1016/j.jclepro.2011.11.006

Thao, P. T. M., Kurisu, K. H., and Hanaki, K. (2011). “Greenhouse gas emission mitigation potential of rice husks for An Giang province, Vietnam,” Biomass & Bioenergy 35(8), 5656-5666. DOI: 10.1016/j.biombioe.2011.05.023

Tiller, K. (2015). Personal Communication with Kelly Tiller, Genera Energy, Vonore, TN.

U.S. Census Bureau [USCB]. (2012). “Forestry, fishing and mining,” Statistical Abstracts of the United States, Section 18, pp. 559-580.

U.S. Department of Agriculture. (2013). “Crop production,” National Agricultural Statistics Service, URL: http://www.usda.gov/nass/PUBS/TODAYRPT/crop1113.pdf

U.S. Department of Energy. (2001). “U.S. billion-ton update: Biomass supply for a bioenergy and bioproducts industry,” R. D. Perlack and B. J. Stokes (leads), ORNL/TM-2011/224, Oak Ridge National Laboratory, Oak Ridge, TN.

U.S. Department of Energy. (2014). “National Agricultural Statistics Service,” URL: http://www.nass.usda.gov/

U.S. Environmental Protection Agency. (2002). “Tool for the reduction and assessment of chemical and other environmental impacts,” Impact assessment method, provided by GreenDelta GmbH under license (accessed: 10 June 2014).

Vadas, P. A., Barnett, K. H., and Undersander, D. J. (2008). “Economics and energy of ethanol production from alfalfa, corn, and switchgrass in the Upper Midwest, USA,” BioEnergy Research 1(1), 44-55. DOI: 10.1007/s12155-008-9002-1

Vadas, P. A., and Digman, M. F. (2013). “Production costs of potential corn stover harvest and storage systems,” Biomass & Bioenergy 54, 133-139. DOI: 10.1016/j.biombioe.2013.03.028

Van Eylen, D., van Dongen, F., Kabel, M., and de Bont, J. (2011). “Corn fiber, cobs and stover: Enzyme-aided saccharification and co-fermentation after dilute acid pretreatment,” Bioresource Technology 102(10), 5995-6004. DOI: 10.1016/j.biortech.2011.02.049

Vidal, R. Martínez, P., and Garraín, D. (2009). “Life cycle assessment of composite materials made of recycled thermoplastics combined with rice husks and cotton linters,” International Journal of Life Cycle Assessment 14(1), 73-82. DOI: 10.1007/S11367-008-043-7

Wakamura, Y. (2003). “Utilization of bagasse energy in Thailand,” Mitigation and Adaptation Strategies for Global Change 8(3), 253-260. DOI: 10.1023/B:MITI.0000005642.56625.9a

Wibulswas, P., and Tamnanthong, N. (1988). “Thermal energy analysis in a sugar mill,” RERIC International Energy Journal 10(2), 11-22.

Xu, F., Shi, Y.-C., Wu, X., Theerarattananoon, K., Staggenborg, S., and Wang, D. (2011). “Sulfuric acid pretreatment and enzymatic hydrolysis of photoperiod sensitive sorghum for ethanol production,” Bioprocess and Biosystems Engineering 34(4), 485-492. DOI: 10.1007/S00449-010-0492-9

You, F., Tao, L., Graziano, D. J., and Snyder, S. W. (2012). “Optimal design of sustainable cellulosic biofuel supply chains: Multiobjective optimization coupled with life cycle assessment and input-output analysis,” AIChE Journal 58(4), 1157-1180. DOI: 10.1002/aic.12637

Yu, S. and Tao, J. (2009). “Simulation-based life cycle assessment of energy efficiency of biomass-based ethanol fuel from different feedstocks in China,” Energy 34(4), 476-484. DOI: 10.1016/j.energy.2008.12.015

Zhang, C., Zhu, J. Y., Gleisner, R., and Sessions, J. (2012). “Fractionation of forest residues of Douglas-fir for fermentable sugar production by SPORL pretreatment,” BioEnergy Research 5(4), 978-988. DOI: 10.1007/S12155-012-9213-3

Zhang, Q., Zhang, P., Pei, Z. J., Xu, F., Wang, D., and Vadlani, P. (2015). “Effects of ultrasonic vibration-assisted pelleting on chemical composition and sugar yield of corn stover and sorghum stalk,” Renewable Energy 76, 160-166. DOI: 10.1016/j.renene.2014.10.057

Zhou, W., Yang, M., Wang, C., Liu, J., and Xing, J. (2014). “Changes in plant cell-wall structure of corn stover due to hot compressed water pretreatment and enhanced enzymatic hydrolysis,” World Journal of Microbiology and Biotechnology 30(8), 2325-2333. DOI: 10.1007/S11274-014-1651-y

Zhuang, Q., Qin, Z., and Chen, M. (2013). “Biofuel, land and water: Maize, switchgrass or Miscanthus?” Environmental Research Letters 8(1), 015020. DOI: 10.1088/1748-9326/8/1/015020

Zych, D. (2008). “The viability of corn cobs as a bioenergy feedstock,” report from the West Central Research and Outreach Center, University of Minnesota, August 2008.

Article submitted: June 19, 2015; Peer review completed: September 4, 2015; Revised version received: October 5, 2015; Accepted: October 6, 2015; Published: October 26, 2015.

DOI: 10.15376/biores.10.4.8098-8134

APPENDIX

Table A1. Chemical Composition of Studied Feedstock Biomass Species

Table A2. Environmental and Human Health Impacts, per Bone-Dry Metric Tonne of Biomass Delivered, for Each Feedstock by TRACI Impact Category.

Units for impact categories are: GWP (kg CO2-eq.), AC (moles of H+-eq), EU (kg N-eq.), EC (kg 2,4-D-Eq), OZ (kg CFC-11-Eq), PO (kg NOx-Eq), CA (kg benzene-Eq), NC (kg toluene-Eq), and RE (kg PM2.5-Eq).

Table A3. Primary and Coproducts for Feedstock Supply Systems and Mass Allocation Ratios Used

Fig. A1. Mass balance of the corn grain, corn syrup, and corn stover co-production system

Fig. A2. TRACI impacts normalized to 100% of the greatest impact for each category

Fig. A3. Global warming contribution analysis for feedstock production and delivery per bone-dry metric tonne of biomass delivered; biomass growth is not included

Fig. A4. Global warming contribution analysis for feedstock production and delivery per metric tonne of biosugar produced; biomass growth is included here

Table A4. Global Warming Potential, in kg CO2-Eq. per Bone-Dry Metric Tonne of Biomass Delivered, and Contribution by Chemical and Life Cycle Stage for Each Biomass Feedstock

Table A5. Parameters for Preliminary Financial Analysis of Bio-Succinic Acid Production Based on Literature Values and Feedstock Costs Described Herein

Table A6. Results of Preliminary Financial Analysis of Bio-Succinic Acid Production Based on the Parameters in Table A5 and Literature Values.

Margin values in red indicate negative net earnings per tonne succinic acid produced for that feedstock conversion scenario. Production level assumed to vary based upon sugar yield from 500,000 bone-dry metric tonnes of biomass converted per year. Tax rate is assumed to be 15%, debt/equity ratio assumed to be 40%/60%. Infrastructure cost assumed to vary linearly with feedstock processing capacity.