Abstract

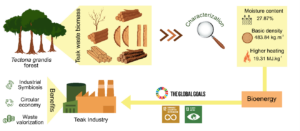

The appropriate use of forest biomass can support the transition to a society with clean and renewable energy. In this context, the research aimed to evaluate the waste biomass from Tectona grandis L.f. for energy purposes. Seven teak wood waste types were used, accessible from the harvesting stage to wood processing. Physical attributes (moisture and basic density) and proximate analysis (volatile materials, ashes, and fixed carbon content) were evaluated, which were used to estimate the energy attributes (higher, lower, and net heating value and energy density). It was found that most waste components had moisture content averages below 30% and did not differentiate statistically. For the basic density, values varied between 366 and 519 kg.m-3. Proximate analysis and energetic attributes of the teak wastes support its feasibility for bioenergy use, focused on trimmings and thin logs. It was concluded that teak waste has the potential for energy purposes if its specific characteristics are considered and appropriate ways of use and conversion are chosen.

Download PDF

Full Article

From Waste to Watts: Investigating Teak Biomass Waste for Bioenergy

Paulo Renato S. Oliveira,a Alfredo J. Santos Júnior,a Allana K. S. Pereira,a Ananias F. Dias Júnior,b Cibelle P. Mourão,a Gabriela F. M. Cupertino,b José O. Brito,a Sueo Numazawa,c and Daniel Saloni d,*

The appropriate use of forest biomass can support the transition to a society with clean and renewable energy. In this context, the research aimed to evaluate the waste biomass from Tectona grandis L.f. for energy purposes. Seven teak wood waste types were used, accessible from the harvesting stage to wood processing. Physical attributes (moisture and basic density) and proximate analysis (volatile materials, ashes, and fixed carbon content) were evaluated, which were used to estimate the energy attributes (higher, lower, and net heating value and energy density). It was found that most waste components had moisture content averages below 30% and did not differentiate statistically. For the basic density, values varied between 366 and 519 kg.m-3. Proximate analysis and energetic attributes of the teak wastes support its feasibility for bioenergy use, focused on trimmings and thin logs. It was concluded that teak waste has the potential for energy purposes if its specific characteristics are considered and appropriate ways of use and conversion are chosen.

DOI: 10.15376/biores.19.2.2883-2900

Keywords: Tectona grandis L.f; Bioenergy; Chemical composition; Heating value

Contact information: a: Department of Forest Sciences, Universidade de São Paulo, Piracicaba, SP 13418-900 Brazil; b: Agricultural Sciences and Engineering Center, Universidade Federal do Espírito Santo, Jerônimo Monteiro, ES 2955-000 Brazil; c: Institute of Agricultural Sciences, Universidade Federal Rural da Amazônia, Belém, PA 66077-830 Brazil; d: Department of Forest Biomaterials, North Carolina State University, Raleigh, NC 27695 USA; *Corresponding author: desaloni@ncsu.edu

GRAPHICAL ABSTRACT

INTRODUCTION

In the last two decades, global governments have implemented measures to address greenhouse gas (GHG) emissions and climate change (Hoang et al. 2022; Malla et al. 2022). Proposals have emerged to replace fossil fuels with renewable sources of energy that are both secure and sustainable, capturing widespread interest among scientists. In 2022, World Energy & Climate Statistics indicated that nearly 30% of global electricity consumption came from renewable sources (Enerdata 2023). However, despite the benefits and potential for substituting fossil fuels, renewable sources remain vulnerable to changes in climate, land use, and vegetative cover (Serrão et al. 2023). Countries such as Brazil must pay attention to these changes, as they emerge with an electrical matrix that is primarily renewable (> 87%) and with a significant share of hydroelectric plants (Empresa de Pesquisa Energética 2023). Thus, expected precipitation deficits in South America (Grimm 2011; Farinosi et al. 2019; Riquetti et al. 2020) and deforestation in important Brazilian biomes (Amazon and Cerrado) negatively impact electricity production. Furthermore, the hydrological seasonality regulates the use of water resources (Queiroz et al. 2019), creating maximum and minimum peaks in energy generation. In this sense, it is essential to diversify renewable sources, also considering their local and seasonal availability.

Brazil is a significant partaker in the bioenergy sector. Among renewable sources, bioenergy contributes 8% to the total share, mainly generating sugarcane bagasse energy (Empresa de Pesquisa Energética 2023). Additionally, there is the potential to enhance the presence of biomass in the energy matrix of developed and developing countries by utilizing waste from planted forests, reinforcing the growing emphasis on building a circular economy, and transitioning towards a decarbonized economy world. In 2022, the total area of trees planted in this country totaled 7.6 million hectares (Indústria Brasileira de Árvores 2023), of which teak (Tectona grandis L. f., Lamiaceae Family) occupies 76 thousand hectares. The latest data on generation in tons of waste are from 2018 and indicate that the sector generated 52 million tons of solid waste, of which 36.9 million (70.9%) were generated by forestry activities and 15.1 million (29.1%) by industries (Indústria Brasiliera de Árvores 2020). For teak, biodegradability is slow (Gupta et al. 2019), and the waste generated can be environmentally passive and difficult to manage. Using these residues in bioenergy production is a sustainable and economically advantageous option.

According to previous research, wood from young trees has a higher heating value than other hardwoods, indicating potential for bioenergetic use (Silva et al. 2015). There is also the prospect of new compounds from the pyrolysis of teak sawdust. Bardalai and Mahanta (2018) performed pyrolysis at 450 ºC to investigate the physicochemical properties of bio-oil for its application in engines, and Balogun et al. (2014) verified several valuable chemical compounds through gas chromatography–mass spectrometry analysis. Even though the teak is a vital timber species established throughout the tropics (Gupta et al. 2019; López-Tobar et al. 2019), few studies have been conducted concerning its physical properties for plantations in Brazil (Chagas et al. 2014). Studies based on chemical and energy properties are still lacking, a gap that this research aims to help fill. Therefore, this study aimed to evaluate the potential of the Tectona grandis L.f. wood wastes for bioenergy generation through the hypothesis that the different wastes have physical-chemical, and energetic attributes compatible with distinct conversion energy pathways. Based on the results, this study provides valuable insights for developing renewable energy alternative sources by reusing wood residues from planted forests, considering their potential positive impacts on the energy and environmental sectors.

EXPERIMENTAL

Location of the Research Area

The field data was collected in the storage yard and teak plantation area. The farm’s headquarters is located at Capitão Poço, Pará – latitude 02°21’17” S and longitude 47°22’19” W (Fig. 1). The property has a total area of 1,300 hectares, of which 833 ha are designated for planting teak for lumber production.

Fig. 1. The location map of the municipality of Capitão Poço, Pará, Brazil

Collection and Preparation of Samples

Table 1 presents the characteristics of the residual biomass studied and the collection sites. The research used seven wastes available at different times of teak wood processing, from the harvesting stage to the timber processing.

Table 1. General Information on the Teak Wastes Studied

Ten repetitions were used to prepare the specimens for the physical tests. Many pieces were weighed in a known volume container for biomass from sawing. One piece was collected from each weighing to compose the repetitions. For the thinned and log tops, 10 logs were used (each one considered a repetition), where three discs (base, middle, and top) were removed and later transformed into wedges to perform the necessary procedures. Ten trees were used to sample the crown, each considered a repetition. The aim was to sample thin and thick branches and stems above the commercial height limit established for the stand. The authors also used small wedges or discs. Each residual component under this study was reduced to chips for the chemical and energetic determinations, and a composite sample was formed, representing the repetitions mentioned above. After that, the biomass was reduced in a Willey-type mill and then classified into 40- and 60-mesh sieves, using the smaller material retained.

Waste Biomass Characterization Tests

Next, the physical (moisture content and basic density), chemical (volatile materials, ashes, and fixed carbon), and energetic parameters (higher, lower, liquid heating value, and energetic density) were analyzed. The gravimetric method was used to determine the moisture content (wet basis), as described in ASTM D1762-84 (2021). The specimens were dried in an oven with forced air circulation at 103 ± 2 °C until constant mass. The mass was considered constant when the difference between two consecutive weightings, with a difference of 24 h, was less than 1 %. The basic density was determined based on NBR 7190 (Associação Brasileira de Normas Técnicas 1997). The specimens were saturated in water with a desiccator and vacuum pump assistance until they reached constant volume. The saturated volume was obtained on a hydrostatic scale by weighing (based on the Archimedes Principle). Subsequently, drying was performed in an oven at 103 ± 2 °C until the mass was stabilized.

The authors used the ASTM D1762-84 (2021) standard for the proximate analysis to determine the volatile matter content, ashes, and fixed carbon. The heating values were estimated from proximate analysis by Eqs. 1, 2, and 3, obtained by modeling the chemical composition and calorific value of several solid biomass with an absolute error of 3.74% (Parikh et al. 2005),

HHV = 0.3536 x CF + 0.1559 x VM – 0.0078 x ASH (1)

LHV = PCS – (2.5116 x 0.09 x H) (2)

NHV = (PCI x (1 – (0.01 x U))) – (2.5116 x 0.01 x U) (3)

where HHV is the higher heating value (MJ.kg-1), LHV represents the lower heating value (MJ.kg-1), NHV is the net heating value (MJ.kg-1), FC is fixed carbon (%), VM is volatile matter content (%), ASH is ash content (%), H is hydrogen content (%), and MC is moisture content (%).

The authors consider the hydrogen content to be 6.42%, as obtained from studies of teak individuals of 5 and 8 years (Blanco-Flórez 2012). The authors determined the energy density (ED) by the product between the lower calorific value in MJ.kg-1 and the basic density in kg.m-3.

Experimental Design and Data Analysis

The random balance design was adopted, with seven treatments, ten repetitions for the physical parameters, and six repetitions for the variables that integrated the chemical and energetic analyses. Waste biomass was considered as a factor. The data residues were performed to the Shapiro-Wilk and Bartlett tests at 95% probability. After proving normality and homogeneity of variance, univariate analysis of variance (ANOVA) was performed and the Tukey test was applied at 5% significance for multiple comparisons of means. The transformation attempted to normalize non-normally distributed and heteroscedastic data, and in cases where the behavior persisted, the authors adopted the non-parametric Kruskall-Wallis test and the Dunn test with Bonferroni correction.

RESULTS AND DISCUSSION

Physical Attributes and Proximate Analysis

In general, teak waste showed an average of 27.9%. As observed in Fig. 2A, log tops contained a higher moisture content, corresponding to 45.9%, followed by the slab with 36.8%. The other components had averages below 30% and did not differentiate statistically. Three groups were distinguished for the basic density values, which ranged between 519 and 366 kg.m-3. Moisture content (MC) is one of the main factors limiting the application of biomass for energy purposes because of its implications on transport costs, storage difficulties, and thermal efficiency reduction during energy conversion (Qi et al. 2021). Water in biomass affects its energy conversion through thermochemical pathways. A high moisture content can cause incomplete combustion and undesirable reaction products, increasing the emission of pollutant gasses (Geronimo et al. 2022). Therefore, values of 30% or less are more suitable for conversion (Zha et al. 2023). For the production of compacts (briquettes and pellets), there is also an ideal range of MC. Excess moisture content can cause explosions due to steam formation. However, excessively dry raw material makes the bonding mechanisms between the particles difficult, as its plasticity is reduced, and friction during compaction increases (Song et al. 2023). According to the literature, MC between 5 and 15% is ideal (Nath et al. 2023).

Fig. 2. Physical attributes of the different teak wastes: (A) moisture content (%) and (B) basic density (kg.m-3)

The moisture content is sensitive to climatic conditions during the storage period due to the hygroscopic nature of the wood, that is, its capacity to retain and lose water to the environment. As a rule, there is a hygroscopic equilibrium point, where each pair of temperature and relative humidity values of the air in the environment will provide a certain moisture content in the wood (Riaz et al. 2022). When considering that biomass’ different sizes and storage periods influence the speed and intensity of changes to their properties (Brand et al. 2014a), the heterogeneity of values and formation of statistically distinct groups is understandable for this research. Smaller biomass pieces, such as edgings and trimming, were observed to have the lowest moisture content. A similar effect was observed for the crown, which, although it had a larger volume than the wastes mentioned above, had diameters smaller than 10 cm and a relatively long length of stay in the field. The thinning and the deteriorated logs were large pieces, and it is not possible to attribute their low contents to the volume of the pieces, but the storage time, from approximately six months to more than two years, respectively, may have contributed to this moisture content. All the components studied presented lower moisture content than those found in residual biomass already used for bioenergy generation. For example, the branches of Eucalyptus sp., whose average value was 48.3% (Santiago and Rezende 2014), and the crown, acicules, and twigs of Pinus taeda, with a moisture content varying between 56 and 65% (Brand et al. 2014b; Ferreira et al. 2016), even though those values are from newly felled trees.

The teak waste was found to have an average basic density of 484 kg.m-3. In Fig. 2B, it can be observed that all wastes, except for deteriorated logs, had densities ranging between 584 and 442 kg.m-3, which was similar to that of teak wood aged 5 and 8 years, respectively (Silva et al. 2015). It is natural that density increases with age (Costa et al. 2020); however, the difference between the values obtained in this research cannot be exclusively explained by this factor. The authors know that the different biomass from sawing does not pass through a grouping criterion; that is, wastes from trees of different ages were placed together, making it only possible to identify the age of the top and thinned logs (8 years). In contrast, the proportion of juvenile and adult wood within the biomass studied could help to understand the values found. Garcia and Marinonio (2016) observed that the basic density decreased in the pith-bark direction for teak cultivated at 5 x 2 m2 spacing. Such variation may result from the wood anatomy and imply physical variations as well as density (Lima et al. 2011). This hypothesis could only be confirmed by studies of wood from the wastes.

The edgings and crowns had a larger fraction of juvenile wood because they were removed from the periphery of the log or are younger components. However, the trimmings came from pieces made in more central regions. The thinned logs, log tops, and slabs represent juvenile and mature wood material, which could be inferred from their average basic density values. The deteriorated logs presented lower basic density, indicating that the deterioration level could influence its structural components (lignin, cellulose, and hemicelluloses) and decrease its mass per volume unit.

It is known that the higher the basic density, the greater the availability of energy per volume unit of wood (Protásio et al. 2019). Thus, the biomass from the group with higher average values has the potential for charcoal production. This biofuel is in high demand by the steel industry, which already consumes charcoal from eucalyptus plantations with basic densities similar to the values obtained in this research. Studies with clones of the genus Corymbia and Eucalyptus showed values between 400 and 520 kg.m-3 (Lopes et al. 2017), and for clones of Eucalyptus urophylla x Eucalyptus grandis, this value was even lower, from 360 to 410 kg.m-3 (Sereghetti et al. 2015). Due to lower basic density and smaller size, other biomasses could produce other solid biofuels, such as briquettes and pellets. To verify the economic feasibility of this use, it is necessary to consider many variables, such as quantity, location, availability, and energy quality, of the biomass (Nones et al. 2017). The present research acts in the qualitative characterization of these biomasses.

Figure 3 shows the values obtained from the proximate analysis of the biomass studied. Tukey’s test (5% probability) differentiated three groups for VM and four for ASH, which did not occur for the FC characteristic, even the analysis of variance indicating a statistical difference between the different biomasses.

Fig. 3. Proximate analysis of the different teak wastes: (A) volatile matter (%), (B) ash (%), and (C) fixed carbon (%)

The volatile matter content is indicative of the ease of ignition of the biomass, the stability of the flame, and its burning rate (Souza et al. 2016). In this research, the logs for thinned logs and log tops had higher percentages, followed by trimmings, edgings, deteriorated logs, and crowns. All averages of the biomass cited were similar to those found for teak 5 and 8 years old (Silva et al. 2015) and were in line with those described in the study by Teixeira et al. (2016) when evaluating Eucalyptus sp. It is possible to verify that the slabs presented lower VM and differed statistically from the group with a higher mean. This difference can be explained by the higher percentage of ash in this biomass. One of the reasons for the increase is associated with the number of impurities from dust and bark, which participate in the protection of the plant and are susceptible to higher inorganic material incrustation (Brand 2010).

The other biomass presented ash levels below 1% and were within the range found for teak wood: 0.98 to 0.40% (Blanco-Flórez 2012; Silva et al. 2015) and close to that for bark and wood of other forest species, such as Eucalyptus and Corymbia clones, with ranges from 0.54 to 0.31% (Lopes et al. 2017). It is worth remembering that the low ash content is positive for energy purposes because the mass of inorganic solid residue is constituted of minerals that do not act in the energy generation process and, instead, can reduce it (Deng et al. 2020), as well as damage the equipment used in the biomass conversion processes (Garcia and Marinonio 2016). For charcoal, biomass with low levels of minerals is also preferred, as these will produce a biofuel of higher mechanical quality, i.e., less friable and prone to fines production (Souza et al. 2016).

Fixed carbon represents the fraction of biomass free of moisture, volatiles, and ash. For the use of biomass in direct combustion, co-incineration, and charcoal production, high values of FC are required (Soares et al. 2014). Combustible materials with high fixed carbon and lower volatile values tend to burn more slowly (Brand 2010). Therefore, the VM/FC ratio assists in the knowledge about the biomass burning time. For chips and sawdust of Pinus sp., the fixed carbon ranged from 12.9 to 17.4% (Protásio et al. 2013; Oliveira et al. 2017); these values are lower than those found in this study.

Similarly, the FC of Eucalyptus sp. sawdust was observed at 14.0% (Protásio et al. 2013). The fixed carbon obtained by Teixeira et al. (2016) was about 19.3%, based on studies with Eucalyptus sp. harvest residues. Eloy et al. (2015), who investigated the bark, branches, and leaves of Eucalyptus grandis, found an average FC of 21.2, 18.9, and 20.9%, respectively. These values were higher than those of biomass derived from sawing but are still within the range observed for the other teak residues studied. These practical considerations underscore the importance of understanding and optimizing the fixed carbon content in biomass to meet the specific demands of different conversion processes and energy applications.

Energy Attributes

The estimated energy attributes are presented in Fig. 4 below. The Kruskall-Wallis test indicates a statistical difference between HHV values. Dunn’s test with Bonferroni correction performed the pairing of all wastes, indicating that only crown–log tops and crown–thinned logs had different HHV values. The other pairings did not show a significant difference between them. It was observed that the lower heating value presented the same behavior due to its closed relationship.

Fig. 4. Estimated energy attributes for the different teak wastes, where (A) higher heating value (MJ.kg-1), (B) lower heating value (MJ.kg-1), (D) net heating value (MJ.kg-1), and (E) energy density (GJ.m-3)

According to the studies of Blanco-Flórez (2012), the average HHV of young teak individuals was 19.9 MJ.kg-1, and Silva et al. (2015) found an average of 19.2 MJ.kg-1. The teak wood analyzed in this study presented an overall average of 19.3 MJ.kg-1. For teak wood sawing wastes, an average of 19.9 MJ.kg-1 was also observed (Balogun et al. 2018). The behavior was similar to wastes from the sawing of Pinus sp. (19.8 MJ.kg-1) (Oliveira et al. 2017). All values were close to those obtained in this research — between 19.7 and 19.1 MJ.kg-1 (Appendix). When evaluating the potential of Eucalyptus sp. forest wastes for thermal and electric energy generation, Santiago and Rezende (2014) obtained higher values than the present study, with an HHV of 20.1 and LHV of 18.8 MJ.kg-1. FC positively affected CWR and EDG wastes but was not responsible for the statistical differentiation into a group with higher HHV for TRM and DTR. In addition, these wastes also presented ash levels between 0.56 and 1%, which may have favored a slight decrease in the HHV and LHV estimates. Regarding the NHV, higher averages for the crown were observed, followed by the logs destined for thinning, trimmings, and edgings. The other biomass types differed statistically, forming distinct groups, and drew attention to their negative impact, as they exhibited the lowest values. This observation underlines the direct influence of elevated moisture content on NHV, emphasizing the practical importance of effectively controlling and managing moisture content in biomass to optimize its heating potential. The energy density differed in four groups: the highest average was observed for trimmings, with 9.59 GJ.m-3; followed by slabs, thinned and log tops, with values between 9.14 to 8.98 GJ.m-3; crown and edgings, with amplitude from 8.66 to 8.56 GJ.m-3; and deteriorated logs with 6.53 GJ.m-3. For Eucalyptus benthamii, at five years, the energy density obtained was 9.23 GJ.m-3 (Silva and Silva 2016), which was close to the highest mean values of ED found for the teak wastes studied. In the studies of Jesus et al. (2017), which evaluated the energy potential of five species of Eucalyptus, the average ED was 6.57 GJ.m-3, which is lower than all the averages mentioned above. In general, basic density values favored energy density, as expected. However, for SLB, although DB values are statistically equal to TRM, the ash content influenced the LHV and, consequently, its final ED value. These results provide valuable insights for selecting and optimizing residual biomass from planted forests for its efficient use as an energy source.

Practical Applications and Future Research

Teak, renowned for its hardwood properties, generates substantial residues across various industries, which can be transformed into a source of clean and accessible energy, contributing to environmental sustainability and addressing energy access challenges (Munsin et al. 2022). Using teak residues for energy generation is a practical strategy aligned with the Sustainable Development Goals (SDGs). The commitment to Climate Action (SDG 13) is strengthened by employing teak residues for energy generation, reducing reliance on non-renewable sources, mitigating greenhouse gas emissions, and facilitating the transition to a low-carbon economy. Embracing the circular economy model, in harmony with Responsible Consumption and Production (SDG 12), redefines teak residues, initially considered waste, as valuable resources for energy production, optimizing resource efficiency and minimizing environmental impacts.

Future research should explore innovations to enhance the circular economy, investigating biomass valorization techniques to diversify the applications of teak residues and potentially generate high-value bio-based products. Through collaborative partnerships between teak waste producers and energy-intensive industries, the emphasis on industrial symbiosis can optimize resource utilization, promoting mutually beneficial relationships and reducing the overall environmental impact (Saghafi and Roshandel 2024). Given the challenges of climate change, it is crucial to concentrate research efforts on developing climate-resilient energy systems. Evaluating the adaptability and sustainability of teak waste-based systems in the face of evolving climatic conditions is essential to ensure long-term viability. Furthermore, analyzing the social implications of teak residue utilization in local communities is imperative. A comprehensive understanding of socio-economic benefits and potential challenges is necessary to ensure that energy projects meet community needs and contribute positively to local and regional development.

CONCLUSIONS

- The pathway to converting teak waste into bioenergy must consider the different characteristics of each waste.

- Moisture content higher than 30% directly affects the waste combustion performance.

- The basic density of all components follows the range found for other biomass for energy purposes, except for deteriorated logs.

- Ash content below 2% of the waste studied implies better conversion equipment performance into other biofuels and efficiency in direct burning.

- The fixed carbon content indicates potential for co-firing and charcoal production.

- Smaller pieces of wastes (crown and edgings) with lower basic density are better suited for producing dense biofuels.

ACKNOWLEDGMENTS

The authors are grateful for the support of the Universidade Federal Rural da Amazônia.

REFERENCES CITED

ABNT NBR 7190. (1997). “Projetos de estruturas de madeira [Wooden structure projects],” Associação Brasileira de Normas Técnicas, Rio de Janeiro, Brazil.

ASTM D1762-84 (2021). “Standard test method for chemical analysis of wood charcoal,” West Conshohocken, PA, USA. DOI: 10.1520/D1762-84R21

Balogun, A. O., Lasode, O. A., and McDonald, A. G. (2014). “Devolatilisation kinetics and pyrolytic analyses of Tectona grandis (teak),” Bioresource Technology 156, 57-62. DOI: 10.1016/j.biortech.2014.01.007

Balogun, A. O., Lasode, O. A., and McDonald, A. G. (2018). “Thermo-physical, chemical and structural modifications in torrefied biomass residues,” Waste and Biomass Valorization 9(1), 131-138. DOI: 10.1007/s12649-016-9787-7

Bardalai, M., and Mahanta, D. K. (2018). “Characterization of pyrolysis oil derived from teak tree saw dust and rice husk,” Journal of Engineering Science and Technology 13(1), 242-253.

Blanco-Flórez, J. (2012). Caracterização Tecnológica da Madeira Jovem de Teca (Tectona grandis L. f) [Technological Characterization of Young Teak Wood (Tectona grandis L. f)], Master’s Thesis, Universidade Federal de Minas Gerais, Lavras, Brazil.

Brand, M. A. (2010). Energia de Biomassa Florestal [Forest Biomass Energy], Editora Interciência, Rio de Janeiro, Brazil.

Brand, M. A., Muñiz, G. I. B., Brito, J. O., and Quirino, W. F. (2014a). “Influências das dimensões da biomassa estocada de Pinus taeda L. e Eucalyptus dunni Maiden na qualidade do combustível para geração de energia [Influences of the dimensions of stored biomass of Pinus taeda L. and Eucalyptus dunni Maiden on the quality of fuel for power generation],” Revista Árvore 38(1), 175-183.

Brand, M. A., Stähelin, T. S. F., Ferreira, J. C., and Neves, M. D. (2014b). “Produção de biomassa para geração de energia em povoamentos de Pinus taeda L. com diferentes idades [Biomass production for energy generation in Pinus taeda L. stands of different ages],” Revista Árvore 38(2), 353-360.

Chagas, S. F., Evangelista, W. V., Silva, J. de C., and Carvalho, A. M. M. L. (2014). “Propriedades da madeira de teca de diferentes idades e oriundas de desbaste [Properties of teak wood of different ages and from thinning],” Revista Ciência da Madeira 5(2), 138-150. DOI: 10.12953/2177-6830.v05n02a08

Costa, S. E. de L., Santos, R. C., Vidaurre, G. B., Castro, R. V. O., Rocha, S. M. G., Carneiro, R. L., Campoe, O. C., Santos, C. P. de S., Gomes, I. R. F., Carvalho, N. F. de O., et al. (2020). “The effects of contrasting environments on the basic density and mean annual increment of wood from eucalyptus clones,” Forest Ecology and Management 458, article ID 117807. DOI: 10.1016/j.foreco.2019.117807

Deng, M., Li, P., Shan, M., and Yang, X. (2020). “Optimizing supply airflow and its distribution between primary and secondary air in a forced-draft biomass pellet stove,” Environmental Research 184, article ID 109301. DOI: 10.1016/j.envres.2020.109301

Eloy, E., Caron, B. O., Silva, D. A., Souza, V. Q., Trevisan, R., Behling, A., and Elli, E. F. (2015). “Energy productivity of forest species in short rotation plantings,” Ciência Rural 45(8), 1424-1431. DOI: 10.1590/0103-8478cr20130177

Empresa de Pesquisa Energética (2023). Brazilian Energy Balance 2023 Year 2022, Ministry of Mines and Energy – MME, Rio de Janeiro, Brazil.

Enerdata. (2023). “World energy & climate statistics – Yearbook 2023,” Enerdata, (https://www.enerdata.net/publications/world-energy-statistics-supply-and-demand.html), Accessed 20 November 2023.

Farinosi, F., Arias, M. E., Lee, E., Longo, M., Pereira, F. F., Livino, A., Moorcroft, P. R., and Briscoe, J. (2019). “Future climate and land use change impacts on river flows in the Tapajós Basin in the Brazilian Amazon,” Earth’s Future 7(8), 993-1017. DOI: 10.1029/2019EF001198

Ferreira, J. C., Stähelin, T. S. F., Valin, M., Brand, M. A., and Muñiz, G. I. B. (2016). “Qualificação da biomassa em povoamentos florestais de Pinus taeda [Biomass qualification in forest stands of Pinus taeda],” Floresta 46(2), 269-276. DOI: 10.5380/rf.v46i2.41208

Garcia, R. A., and Marinonio, G. B. (2016). “Variação da cor da madeira de teca em função da densidade e do teor de extrativos [Variation in teak wood color depending on density and extractive content],” Floresta e Ambiente 23(1), 124-134. DOI: 10.1590/2179-8087.035313

Geronimo, C., Vergara, S. E., Chamberlin, C., and Fingerman, K. (2022). “Overlooked emissions: Influence of environmental variables on greenhouse gas generation from woody biomass storage,” Fuel 319, article ID 123839. DOI: 10.1016/j.fuel.2022.123839

Grimm, A. M. (2011). “Interannual climate variability in South America: Impacts on seasonal precipitation, extreme events, and possible effects of climate change,” Stochastic Environmental Research and Risk Assessment 25(4), 537-554. DOI: 10.1007/s00477-010-0420-1

Gupta, G. K., Gupta, P. K., and Mondal, M. K. (2019). “Experimental process parameters optimization and in-depth product characterizations for teak sawdust pyrolysis,” Waste Management 87, 499–511. DOI: 10.1016/j.wasman.2019.02.035

Hoang, A. T., Foley, A. M., Nižetić, S., Huang, Z., Ong, H. C., Ölçer, A. I., Pham, V. V., and Nguyen, X. P. (2022). “Energy-related approach for reduction of CO2 emissions: A critical strategy on the port-to-ship pathway,” Journal of Cleaner Production 355, Article ID 131772. DOI: 10.1016/j.jclepro.2022.131772

Indústria Brasileira de Árvores. (2023). Relatório Ibá 2023, Brazil, 91.

Indústria Brasiliera de Árvores. (2020). Relatório Ibá 2020, Brazil, 80.

Jesus, M. S., Costa, L. J., Ferreira, J. C., Freitas, F. P., Santos, L. C., and Rocha, M. F. V. (2017). “Caracterização energética de diferentes espécies de Eucalyptus [Energy characterization of different species of Eucalyptus],” Floresta 47(1), 11-16. DOI: 10.5380/rf.v47i1.48418

Lima, I. L. de, Garcia, R., and Longui, E. L. (2011). “Dimensões anatômicas da madeira de Tectona grandis Linn. em função do espaçamento e da posição radial do tronco [Anatomical dimensions of the wood of Tectona grandis Linn. in relation to spacing and radial position in the trunk],” Scientia Forestalis 39(89), 61-68.

Lopes, E. D., Laia, M. L., Santos, A. S., Soares, G. M., Leite, R. W. P., and Martins, N. de S. (2017). “Influência do espaçamento de plantio na produção energética de clones de Corymbia e Eucalyptus [Evaluation Corymbia and Eucalyptus clones under different spacings order to produce bioenergy],” Floresta 47(1), 95-104. DOI: 10.5380/rf.v47i1.47141

López-Tobar, R., López, Y. M., Apuentes, E. S., Pinargote, C. B., and Castro, M. N. (2019). “Incrementos dasométricos en plantaciones de Tectona grandis L. f. (Teca) en la provincia del Guayas: Influencia en el entorno paisajístico de la zona [Dasometric increases in plantations of Tectona grandis L. f. (Teak) in the province of Guayas: Influence in the landscape environment of the area],” Revista Amazónica Ciencia y Tecnología 8(2), 107-113.

Malla, F. A., Mushtaq, A., Bandh, S. A., Qayoom, I., Hoang, A. T., and Shahid-e-Murtaza (2022). “Understanding climate change: Scientific opinion and public perspective,” in: Climate Change, S. A. Bandh (ed.), Springer International Publishing, Cham, Switzerland, pp. 1-20. DOI: 10.1007/978-3-030-86290-9_1

Munsin, R., Udtasri, J., Topaiboul, S., Kowtakul, P., Yeunyongkul, P., Nuntapap, N., Jarupoom, P., Rakyat, M., Laoonual, Y., Srichai, P., et al. (2022). “A study on binderless co-pelletization of industrial rice-powder wastes and teak sawdust at low and elevated temperatures,” Case Studies in Chemical and Environmental Engineering 6, article ID 100250. DOI: 10.1016/j.cscee.2022.100250

Nath, B., Chen, G., Bowtell, L., and Mahmood, R. A. (2023). “Assessment of densified fuel quality parameters: A case study for wheat straw pellet,” Journal of Bioresources and Bioproducts 8(1), 45-58. DOI: 10.1016/j.jobab.2022.10.001

Nones, D. L., Brand, M. A., Ampessan, C. G. M., and Friederichs, G. (2017). “Quantification of agricultural and forestry waste biomass to production of compacts for power generation,” Revista de Ciências Agroveterinárias 16(2), 155-164. DOI: 10.5965/223811711622017155

Oliveira, L. H., Barbosa, P. V. G., Lima, P. A. F., Yamaji, F. M., and Júnior, C. R. S. (2017). “Aproveitamento de resíduos madeireiros de Pinus sp. com diferentes granulometrias para a produção de briquetes [Use of wood residues of Pinus sp. with different granulometry to briquettes production],” Revista de Ciências Agrárias 40(3), 683-691. DOI: 10.19084/rca17010

Parikh, J., Channiwala, S. A., and Ghosal, G. K. (2005). “A correlation for calculating HHV from proximate analysis of solid fuels,” Fuel 84(5), 487-494. DOI: 10.1016/j.fuel.2004.10.010

Protásio, T. de P., Bufalino, L., Tonoli, G. H. D., Junior, M. G., Trugilho, P. F., and Mendes, L. M. (2013). “Brazilian lignocellulosic wastes for bioenergy production: Characterization and comparison with fossil fuels,” BioResources 8(1), 1166-1185. DOI: 10.15376/biores.8.1.1166-1185

Protásio, T. de P., Scatolino, M. V., Araújo, A. C. C., Oliveira, A. F. C. F., Figueiredo, I. C. R., Assis, M. R., and Trugilho, P. F. (2019). “Assessing proximate composition, extractive concentration, and lignin quality to determine appropriate parameters for selection of superior Eucalyptus firewood,” Bioenergy Research 12(3), 626-641. DOI: 10.1007/s12155-019-10004-x

Qi, B., Yan, Y., Zhang, W., and Wang, X. (2021). “Measurement of biomass moisture content distribution in a fluidized bed dryer through electrostatic sensing and digital imaging,” Powder Technology 388, 380-392. DOI: 10.1016/j.powtec.2021.04.096

Queiroz, A. R. de, Faria, V. A. D., Lima, L. M. M., and Lima, J. W. M. (2019). “Hydropower revenues under the threat of climate change in Brazil,” Renewable Energy 133, 873-882. DOI: 10.1016/j.renene.2018.10.050

Riaz, S., Al-Abdeli, Y. M., Oluwoye, I., and Altarawneh, M. (2022). “Torrefaction of densified woody biomass: The effect of pellet size on thermochemical and thermophysical characteristics,” Bioenergy Research 15(1), 544-558. DOI: 10.1007/s12155-021-10319-8

Riquetti, N. B., Mello, C. R., Beskow, S., and Viola, M. R. (2020). “Rainfall erosivity in South America: Current patterns and future perspectives,” Science of The Total Environment 724, article ID 138315. DOI: 10.1016/j.scitotenv.2020.138315

Saghafi, Z., and Roshandel, R. (2024). “Agent-based simulation for technology implementation in an energy-based industrial symbiosis network,” Resources, Conservation & Recycling Advances 21, article ID 200201. DOI: 10.1016/j.rcradv.2023.200201

Santiago, F. L. S., and Rezende, M. A. (2014). “Aproveitamento de resíduos florestais de Eucalyptus spp na indústria de fabricação de celulose para geração de energia térmica e elétrica [Utilization of Eucalyptus forest residues from the cellulose manufacturing industry for thermal and electrical energy generation],” Energia na Agricultura 29(4), 241-253. DOI: 10.17224/EnergAgric.2014v29n4p241-253

Sereghetti, G. C., Lanças, K. P., Sartori, M. S., Rezende, M. A., and Soler, R. R. (2015). “Efeito do espaçamento no crescimento e na densidade básica da madeira de Eucalyptus urophylla x Eucalyptus grandis em florestas de ciclo curto [Effect of spacing on Eucalyptus urophylla x Eucalyptus grandis growth and wood basic density in short cycle plantation],” Energia na Agricultura 30(3), 257-262.

Serrão, E. A. de O., Silva, M. T., Ferreira, T. R., Freitas Xavier, A. C., Dos Santos, C. A., Paiva De Ataide, L. C., Pontes, P. R. M., and Rodrigues Da Silva, V. D. P. (2023). “Climate and land use change: Future impacts on hydropower and revenue for the amazon,” Journal of Cleaner Production 385, article ID 135700. DOI: 10.1016/j.jclepro.2022.135700

Silva, D. A., Christo, E. R., Belhing, A., Mayer, S. L. S., Pelanda, K. A., and Simetti, R. (2015). “Potencial e qualidade da madeira de desbaste de teca para produção de biocombustível [Potential and quality of teak wood from thinning for biofuel production],” Pesquisa Florestal Brasileira 35(83), 299-305. DOI: 10.4336/2015.pfb.35.83.817

Silva, R. L., and Silva, A. M. P. (2016). “Bioenergia da biomassa residual: Potencial energético da combustão da casca de arroz em Dourados-MS e região [Bioenergy from residual biomass: Energy potential from rice husk combustion in dourados-ms and nearby cities],” Revista Brasileira de Energias Renováveis 5, 91-105. DOI: 10.5380/rber.v5i1.43916

Soares, V. C., Bianchi, M. L., Trugilho, P. F., Pereira, A. J., and Höfler, J. (2014). “Correlações entre as propriedades da madeira e do carvão vegetal de híbridos de eucalipto [Correlations between the properties of eucalyptus hybrids wood and charcoal],” Revista Árvore 38(3), 543-549. DOI: 10.1590/S0100-67622014000300017

Song, B., Cooke-Willis, M., Leeuwen, R. van, Fahmy, M., and Hall, P. (2023). “Insights into the swelling behaviors of biomass and biomass/thermoplastic briquettes under water penetration and moisture adsorption,” Biomass and Bioenergy 168, article ID 106673. DOI: 10.1016/j.biombioe.2022.106673

Souza, N. D., Amodei, J. B., Xavier, C. N., Júnior, A. F. D., and Carvalho, A. M. (2016). “Estudo de caso de uma planta de carbonização: Avaliação de características e qualidade do carvão vegetal visando uso siderúrgico [Case study of a carbonization plant: Evaluation of features and quality of charcoal aiming steel use],” Floresta e Ambiente 23(2), 270-277. DOI: 10.1590/2179-8087.106114

Teixeira, C. M. P., Martins, M., Yamamoto, H., Chrisostomo, W. M., and Yamaji, F. (2016). “Chemical characterization of Eucalyptus sp. residues from short-rotation forests for bioenergy production,” Revista Virtual de Química 8(5), 1693-1701. DOI: 10.21577/1984-6835.20160112

Zha, Z., Ge, Z., Wang, S., Li, F., Ma, Y., Wu, Y., Zeng, M., Huang, C., and Zhang, H. (2023). “Biomass combustion behaviors based on online monitoring system: Morphological, thermodynamic and kinetic analysis,” Combustion and Flame 252, article ID 112750. DOI: 10.1016/j.combustflame.2023.112750

Article submitted: February 2, 2024; Peer review completed: March 2, 2024; Revised version received: March 7, 2024; Accepted: March 18, 2024; Published: March 21, 2024.

DOI: 10.15376/biores.19.2.2883-2900

APPENDIX

Supplementary Information

Table S1. Physical Attributes of the Different Teak Wastes

Table S2. Proximate Analysis of the Different Teak Wastes

Table S3. Proximate Analysis of the Different Teak Wastes

Table S4. Estimated Energy Density for the Different Teak Wastes