Abstract

Copper azole type B (CAz-B) preservative and polyphosphatic carbamate (PPC) fire retardants were impregnated in succession into green (97% MC) and kiln-dried (18% MC) Japanese cedar (Cryptomeria japonica (L.f.) D.Don) lumber by the passive impregnation method to prolong the period of lumber use by increasing its resistance to fire and biological degradation. Lumber was dried with a kiln or by air-drying. Total chemical retention, penetration, leaching, decay resistance (JIS K 1571), and fire retardancy (ISO 834-1 standard, 20 minutes) tests were performed according to the mentioned standards. Preservative retention was higher in the green lumber (4.97 kg/m3) compared with the kiln-dried (4.88 kg/m3) lumber. However, fire retardant retention was similar for both lumber types (107 and 111 kg/m3). Leaching was higher in kiln-dried lumber (21.8%) compared to air-dried lumber (14.4%), although there were no significant differences in the decay resistance test between these two lumber types. The fire performance of both lumber types was similar in the fire resistance test. Therefore, the passive impregnation method can be used effectively for impregnation of both preservatives and fire retardants into wood.

Download PDF

Full Article

Impregnation of Preservative and Fire Retardants into Japanese Cedar Lumber by Passive Impregnation

Md Nazrul Islam,a,* Keisuke Ando,a Hidefumi Yamauchi,b Daisuke Kamikawa,c Toshiro Harada,c and Nobuaki Hattori a

Copper azole type B (CAz-B) preservative and polyphosphatic carbamate (PPC) fire retardants were impregnated in succession into green (97% MC) and kiln-dried (18% MC) Japanese cedar (Cryptomeria japonica (L.f.) D.Don) lumber by the passive impregnation method to prolong the period of lumber use by increasing its resistance to fire and biological degradation. Lumber was dried with a kiln or by air-drying. Total chemical retention, penetration, leaching, decay resistance (JIS K 1571), and fire retardancy (ISO 834-1 standard, 20 minutes) tests were performed according to the mentioned standards. Preservative retention was higher in the green lumber (4.97 kg/m3) compared with the kiln-dried (4.88 kg/m3) lumber. However, fire retardant retention was similar for both lumber types (107 and 111 kg/m3). Leaching was higher in kiln-dried lumber (21.8%) compared to air-dried lumber (14.4%), although there were no significant differences in the decay resistance test between these two lumber types. The fire performance of both lumber types was similar in the fire resistance test. Therefore, the passive impregnation method can be used effectively for impregnation of both preservatives and fire retardants into wood.

Keywords: Air drying; Copper azole; Laser incision; Leaching; Mass loss

Contact information: a: Department of Environmental and Natural Resource Science, Tokyo University of Agriculture and Technology, 3-5-8 Saiwai-cho, Fuchu, Tokyo 183-8509, Japan; b: Institute of Wood Technology, Akita Prefectural University, Akita, Japan; c: Wood Protection Laboratory, Forestry and Forest Products Research Institute (FFPRI), Matsunosato 1, Tsukuba, Ibaraki 305-8687 Japan; *Corresponding author: nazrul@cc.tuat.ac.jp; nazrul17@yahoo.com

INTRODUCTION

Wood is one of the most worthy and widely used natural resources for many uses such as furniture and construction. Worldwide environmental problems and natural resource crises are becoming more serious, and wood is receiving more attention because of its unique renewability and environmentally-friendly nature. However, insufficient durability limits the use of wood, because of its biodegradability and flammability. The lack of durability can be overcome when proper protection is applied to wood.

Wood protection has been practiced for almost as long as wood has been used (Richardson 1978). Over the years numerous processes have been introduced, and existing processes have been improved. The goal of modern wood preservation is to ensure deep, uniform penetration with a reasonable cost and without endangering the environment. The most widespread impregnation processes today are those that use artificial pressure to effectively treat many different types of wood; however, several wood species are resistant to impregnation because of their structure. To overcome issues related to low impregnability of different wood species, a passive impregnation method was developed, in which no direct pressure is applied to impregnate preservative into wood (Hattori et al. 2005). In this method, steam is injected into the lumber by a steam injection press through CO2 laser-incised pinholes; the lumber is then dipped into a preservative. Effective preservation of all timber species with any moisture content can be achieved by this method (Islam et al. 2011; 2009a,b; 2008; 2007; Ando et al. 2012; 2011; Hattori et al. 2005). This method is also very good with respect to cost (Islam et al. 2008) and time (Ando et al. 2012). However, for all previous studies, only preservative was impregnated into lumber by the passive impregnation method.

The wood preservation industry has been working to manufacture effective wood preservatives that are environmentally more acceptable. Consequently, since the end of the 1990s, novel biocides such as copper azole (CuAz) and ammoniacal copper quaternary (ACQ) have become predominant choices worldwide as wood preservation systems (Nicholas and Schultz 1994). Improving the fireproofing capability of the wooden material has become an important issue and has attracted more attention than ever before (Jiang et al. 2010). The combustibility of wood can be reduced with flame- or fire-retardant materials (Mitchell 1993; Ellis and Rowell 1989), which also need to impregnate into the wood. A variety of chemicals including phosphates are widely used in fire-retardant-treated wood materials (Wladyka-Przybylak and Kozlowski 1999; Su et al. 1997; Ostman and Tsantaridis 1995). In the study by Ogawa and Siina (1993), poly-phosphatic carbamate, which is a widely known fire retardant, was impregnated into wood following copper azole preservative impregnation by the passive impregnation method.

The objective of this study was to impregnate preservatives and fire retardants into green and kiln-dried Japanese cedar posts by the passive impregnation method. This study also aimed to determine the treated wood’s performance after preservative and fire retardant impregnation.

EXPERIMENTAL

Both green (96 % MC & 0.36 g cm-3 dry density) and kiln-dried (10 % MC & 0.41 g cm-3 dry density) commercially available Japanese cedar (Cryptomeria japonica (L.f.) D.Don) lumber samples were used in this study. Long posts of a square cross-section (12 × 12 cm) were cut to a length of 65 cm and used as specimens for successful preservative (Copper azole type B) and fire retardant (polyphosphatic carbamate) impregnation into the wood. Both specimen ends were sealed with urethane resin prior to steam injection to prevent liquid penetration. For each experiment there were 24 specimens, of which half were kiln dried and half were green. Three independent experiments were performed for this study.

A through-hole laser incision was first performed with a 1.5 kW CO2 laser (Rofin-Sinar DC 025) on the specimen’s radial surface (Islam et al. 2008; 2007). The incising density was 2,500 holes m-2 and the incising pattern is shown in Fig. 1. Moisture content was measured before and after treatment by the oven drying method (JIS Z 2101, 1994).

In the second step of the passive impregnation method, steam was injected into the incised kiln-dried specimens for 20 minutes (D20) and into the green lumber for 840 minutes (G840) by a steam injection press (Kitagawa Seiki Co. Ltd; VH2-1449). The steam temperature was 110 °C, the hot plate temperature was 140 °C, and the steam pressure was 0.05 MPa above atmospheric pressure.

Fig. 1. Incising pattern (where a = 8 cm)

Immediately following the steam injection, specimens were dipped into a 1.03% copper azole type B (CuAz-B) solution for 6 h. After preservative impregnation, specimens were re-dried by steam injection in the same manner as described above for 10 h. Immediately following 10 h of re-drying, specimens were dipped into 25% polyphosphatic carbamate (NH2CO-(OPO(ONH4))n-OCNH2) (PPC) fire retardant solution for 6 h. The undiluted PPC solution pH was 5 to 7, and the degree of polymerization was 5 to 10. After impregnation of the fire retardant, half of the specimens (six D20K and six G840K) were kiln dried using the Japanese Industrial Standard (JIS) Japanese cedar kiln-drying schedule. The other half of the samples (D20A-G840A) were air dried.

Total chemical retention (kg m-3) was calculated using chemical concentrations and solution uptake, which was determined by pre- and post-treatment sample weight (Islam et al. 2009a). Samples for penetration analysis and leaching tests were collected from the center of each treated specimen. Preservative penetration was measured based on color indicators on the freshly cut wood surface of the treated timber, as described by the American Wood Preservers’ Association (AWPA 1993). Measurements were performed on both longitudinal (radial) and cross-sectional surfaces for all of the samples with a scanner and Adobe Photoshop software (Islam et al. 2009a).

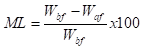

Eight samples (2 from each category – D20K, G840K, D20A, and G840A) with similar preservative retention levels were selected for leaching and decay resistance tests. The samples were sealed in a plastic bag and conditioned for 4 weeks at room temperature after treatment. The sample size was 2 (T) x 2 (R) x 1 (L) cm in dimension. Leaching and decay resistance tests were analyzed according to the JIS K 1571 (JIS, 2004) standards for severe weathering conditions. The specimen for fire testing was performed with samples (32 x 12 x 12 cm) having no leaching and decay resistance tests in a preheated kiln by a small-scale fire test according to the ISO 834-1 standard. The MC was less than 20% for all specimens (18 ± 1 %) in the fire test. The heating time was 20 minutes, and the glowing time was 60 minutes. The test specimen mass losses after the fire test were calculated with the following equation,

(1)

(1)

where ML is Mass loss, Wbf is the weight (g) of a wood specimen before the fire test, and Waf is the weight (g) of a wood specimen after the fire test.

After cutting the specimen in the center for a fresh surface, the remaining cross-section (%) after the fire resistance test was calculated with a scanner and Adobe Photoshop software.

Statistical analyses (t-test/F-test) were performed using R software (version 2.15.0) with the α-level set to 0.05. A flow diagram of the experimental process is shown in Fig. 2.

Fig. 2. Flow diagram of the experimental process. The data in parentheses are the numbers of samples.

RESULTS AND DISCUSSION

As reported by Ando et al. (2012), minute surface cracking and slight darkening were observed when Japanese cedar specimens were dried by superheated steam after preservative impregnation. Surface cracking during drying is common for Japanese cedar lumber (Nakada et al. 1998), and kiln drying of this lumber is a problem facing the Japanese wood industry (Obataya et al. 2006). However, surface cracking and darkening phenomenon were not severe in the present study, because the samples were dried with superheated steam before fire retardant impregnation, followed by either kiln or air drying.

Preservative and Fire Retardant Retention and Penetration

The results of the preservative and fire retardant retention studies in Japanese cedar specimens displayed small differences between green and dry lumber (Fig. 3). The preservative retention was slightly higher in green specimens (4.97 kg m-3) compared with the kiln-dried specimens (4.88 kg m-3); however, fire retardant retention was higher in the kiln-dried specimens (111 kg m-3) compared with the green specimens. There were no significant differences in preservative retention (t = ± 1.9) and fire retardant retention (t = ± 2.17) between green and kiln-dried lumber. The average dry densities of all of the studied specimens were similar, which ensured uniform porosity (fractional void volume) among the treatment groups, which might have led to the similar preservative and fire retardant retention. In earlier studies using the passive impregnation method (Islam et al. 2011), the total chemical retention was reportedly similar to or greater than the prescribed retention level (4.97 kg m-3) for permanent wood foundations or structures in most hazardous conditions (AWPA 2010). The fire retardant (polyphosphatic carbamate) retention was higher than the Japanese Building Standard Law retention requirement (80 kg m-3) for fire-retardant material (Harada et al. 2003, 2009). Harada et al. (2003, 2009) found similar or higher retention depending on the polyphosphatic carbamate concen-tration and sample type that was used.

Fig. 3. Preservative and fire retardant retention by initial kiln-dried and green Japanese cedar lumber

As expected with the passive impregnation method, the preservative penetration (Cu) for all specimens was almost 100 % in the longitudinal direction (Fig. 4), as measured by color indicator method described by AWPA (AWPA 1993). Longitudinal penetration is common for the passive impregnation method, as reported by earlier works (Islam et al. 2011; 2009a,b; 2008; 2007; Ando et al. 2012; 2011). Preservative penetration on the longitudinal/radial surfaces was also greater than 93% at any depth that was cut, and the outer surfaces that were 0 and 12 cm from the laser-irradiating surface had higher penetration than the inner surfaces, which were 3, 6, and 9 cm from the surface. The penetration was more than 97 % at cross-section. This phenomenon is normal because the preservative moves from the outside to the inside of the wood during dipping. Similar results were reported by Islam et al. (2009a,b; 2008; 2007) for the passive impregnation method.

Fig. 4. Cross sectional and radial surface preservative penetration area for different types of lumber

Leaching and Decay Resistance Tests

It was observed that leaching was very high for all sample types (Fig. 5). Leaching was significantly higher (F = 3.56) in the green samples compared with the kiln-dried samples. When the final drying methods were compared, leaching was significantly higher (F = 4.87) in the kiln-dried samples compared with the air-dried samples. Similar to most other fire-retardant chemicals (FRCs), polyphosphatic carbamate is water-soluble and washes out of wood by absorbing moisture (Harada et al. 2007; 2009) during leaching, which might be a cause for the increased leaching in all of the samples.

Fig. 5. Preservative leaching from different lumber types

Efflorescence is a common problem of the fire retardant, in which impregnated chemicals form white crystals. Efflorescence was severe in the kiln-dried samples because the wood dried more quickly compared with the samples that were air dried, which might be a cause for the increased leaching in the kiln-dried samples. Chemicals redistribute during rapid drying, which also leads to higher proportions of leach-susceptible components (Hingston et al. 2001). These results are also supported by previous works, in which the final drying condition considerably affects fixation and chemical leaching (Kartal et al. 2009; Kang et al. 2008; Humara et al. 2006), although the results differ depending on experimental conditions. In earlier studies using the passive impregnation method, the leaching results were much lower than in this study, where only preservative was impregnated into the wood (Ando et al. 2012; 2011).

Mass loss in the course of the decay resistance test was reduced when preservative retention was increased (Table 1), and in some samples, there was no mass loss after the decay resistance test. There were little or no differences in mass losses during the decay resistance test for the different sample types. However, the mass loss was increased in the final kiln-dried samples. This result validates that leaching was increased in this study compared with previous studies (Ando et al. 2012), since leachable fire retardants and preservative were retained in the wood, even after the leaching test.

Table 1. Mean Mass Loss (%) of Japanese Cedar Lumber at Different Conditions after 12-week Exposure to Trametes versicolor and Fomitopsis palustris

The data in parentheses are the standard deviations.

Sample Fire Performance

To analyze fire performance, mass loss and sample cross-section (%) retention were evaluated. Mass loss was significantly higher in the control samples compared with the treated samples (F = 30.9). However, there were no significant differences in mass losses (F = 0.08) between green and kiln-dried samples. Mass losses were also similar when comparing air and kiln drying as the final drying methods (F = 1.18) (Fig. 6). The cross-section retention (%) after treatment was also significantly higher (F = 17.49) in treated samples compared with the control. The cross-section retention (%) was also significantly higher in the green samples compared with the initial kiln-dried samples (F = 4.23). However, the difference was not significant when kiln and air drying were compared as final drying methods (F = 1.9) (Fig. 6). The color of the retained cross-section of the control specimen was darker compared with the treated specimens. Harada et al. (2003) found that total heat release decreased linearly as PPC fire retardant impregnation increased from 0 to 120 kg/m3, which satisfies the flammability criteria for a fire-retardant material. It is clear from the study that a fixed amount or percentage of fire retardant chemicals is lost in leaching. However, ceramic coating after preservative and fire retardant impregnation can minimize this problem (Harada et al. 2007). This area of fire-retardant-treated wood weathering, both natural and artificial, needs further investigation.

Fig. 6. Mass loss (%) and cross-section retention (%) for different lumber types after a fire test

CONCLUSION

Using the passive impregnation method, higher amounts of preservative and standard amounts of fire retardant chemicals can be successfully impregnated into Japanese cedar lumber, which ensures that the wood displays both fire retardant and biocidal properties. Retention and penetration of preservative and fire retardant were similar for both green and kiln-dried lumbers. The increased preservative amount satisfies the requirements for wood use in permanent wood foundations and structures in most hazardous conditions, and the amount of the fire retardant chemical fulfills the criteria for a fire retardant material. Leaching was significantly higher in kiln-dried samples compared with the air-dried samples. Preservative leaching was reduced; however, fire retardant leaching was higher. No significant differences between green and kiln-dried samples were found in mass losses for the fire performance test. Further research will ensure that fire retardant is retained in wood and will prolong its effectiveness against fire.

ACKNOWLEDGMENTS

The authors are indebted to the Japan Society for Promotion of Science (JSPS) for providing financial support in the form of a postdoctoral fellowship No. 22248019 (JSPS KAKENHI).

REFERENCES CITED

American Wood Preservers’ Association (AWPA) (1993). Annual Book of Standards, Granbury, TX.

American Wood Preservers’ Association (AWPA) (2010). Annual Book of Standards, Granbury, TX.

Ando, K., Islam, M. N., Yamauchi, H., and Hattori, N. (2011). “Preservative leaching from copper azole–treated lumber: A comparison between the full-cell method and the passive-impregnation method,” Forest Products Journal 61, 270-272.

Ando, K., Islam, M. N., Yamauchi, H., and Hattori, N. (2012). “Effect of steam injection redrying of Japanese cedar on preservative leaching after passive impregnation,” Wood Material Science & Engineering (Online first), DOI:10.1080/17480272.2012.694909.

Ellis, W. D., and Rowell, R. M. (1989). “Flame-retardant treatment of wood with a diisocyanate and an oligomerphosphate,” Wood Fiber Sci. 21(4), 367-375.

Harada, T., Matsunaga, H., Kataoka, Y., Kiguchi, M., and Matsumura, J. (2009). “Weatherability and combustibility of fire-retardant-impregnated wood after accelerated weathering tests,” Journal of Wood Science 55, 359-366.

Harada, T., Nakashima, Y., and Anazawa, Y. (2007). “The effect of ceramic coating of fire-retardant wood on combustibility and weatherability,” Journal of Wood Science 53, 249-254.

Harada, T., Uesugi, S., and Taniuchi, H. (2003). “Evaluation of fire retarding wood treated with polyphosphatic carbamate using cone calorimeter,” Forest Products Journal 53, 81-85.

Hattori, N., Morinaka, Y., Ando, K., Yamauchi, Y., and Kobayashi, Y. (2005). “Passive impregnation of liquid into laser incised lumber,” In: Seventeenth International Wood Machining Seminar, September 26-28, 2005, Germany.

Hingston, J. A., Collins, C. D. Murphy, R. J., and Lester, J. N. (2001). “Leaching of chromated copper arsenate wood preservatives: A review,” Environmental Pollution 111, 53-66.

Humara, M., Zlindra, D., and Pohleven, F. (2006). “Effect of fixation time on leaching of coppereethanolamine based wood preservatives,” Holz als Roh und Werkstoff 65, 329-330.

Islam, M. N., Ando, K., Yamauchi, H., and Hattori, N. (2008). “Comparative study between full cell and passive impregnation method of wood preservation for laser incised Douglas fir lumber,” Wood Science and Technology 42, 343-350.

Islam, M. N., Ando, K., Yamauchi, H., and Hattori, N. (2009a). “Preservative treatment of Douglas-fir lumber by the passive impregnation method with copper azole,” European Journal of Wood and Wood Products 67(1), 77–81.

Islam, M. N., Ando, K., Yamauchi, H., and Hattori, N. (2009b). “Effects of species and moisture content on penetration of liquid in laser incised lumber by the passive impregnation method,” European Journal of Wood and Wood Products 67(2), 129-133.

Islam, M. N., Ando, K., Yamauchi, H., and Hattori, N. (2011). “Change of temperature and pressure in dry and green Douglas-fir and sugi wood during passive impregnation method,” Wood and Fiber Science 43, 305-310.

Islam, M. N., Ando, K., Yamauchi, H., Kobayashi, Y., and Hattori, N. (2007). “Passive impregnation of liquid in impermeable lumber incised by laser,” Journal of Wood Science 53, 436-441.

Japanese Industrial Standards (JIS) (1994). Methods of Test for Woods, JIS Z 2101-1994, Tokyo, Japan.

Japanese Industrial Standards (JIS) (2004). Test Methods for Determining the Effects of Wood Preservatives and Their Performance Requirements, JIS K 1571-2004, Tokyo, Japan.

Jiang, J., Li, J., Hu, J., and Fan, D. (2010). “Effect of nitrogen phosphorus flame retardants on thermal degradation of wood,” Construction and Building Materials 24, 2633-2637.

Kang, S. M., Hwang, I. Y., and Kim, S. M. (2008). “Effect of steam on fixation of Cu-amine preservative treated wood (IRG/WP/08-50251),” The International Research Group on Wood Protection, Stockholm.

Kartal, S. N., Green, F., and Clausen, C. A. (2009). “Do the unique properties of nanometals affect leachability or efficacy against fungi and termites?,” International Biodeterioration and Biodegradation 63, 490-495.

Mitchell, S. (1993). “Fire performance of wood: Test methods and fire retardant treatments,” Proceedings of the 4th annual BCC Conference on Flame Retardancy, Stamford, CT, Norwalk, CT; Business Communications Co, 18-20 May, pp. 36-43.

Nakada, R., Fujisawa, Y., Hirakawa, Y., and Yamashita, K. (1998). “Longitudinal change of the green moisture content in the stem of Cryptomeria japonica D. Don (in Japanese),” Mokuzai Gakkaishi (Japanese) 44, 395-402.

Nicholas, D. D., and Schultz, T. P. (1994). “Biocides that have potential as wood preservatives – An overview,” Proceeding from the Conference sponsored by the Forest Products Society, Georgia, USA, pp. 169-173.

Obataya, E., Shibutani, S., Hanata, K., and Doi, S. (2006). “Effects of high temperature kiln drying on the practical performances of Japanese cedar wood (Cryptomeria japonica), I: changes in hygroscopicity due to heating,” Journal of Wood Science 52, 33-38.

Ogawa, Y., and Siina, N. (1993). “Fire-retardant chemicals of wood (in Japanese),” Mokuzai Hozon (Japanese) 19(5), 235-249.

Ostman, B. A. L., and Tsantaridis, L. D. (1995). “Heat release and classification of fire retardant wood products” Fire and Materials 19(6), 253-258.

Richardson, B. A. (1978). Wood Preservation, Penarth Research Centre, The Construction Press, Lancester, London. New York.

Su, W., Subiyakto, Y., Hata, T., Imamura, Y., and Ishihara, S. (1997). “Improvement of the fire retardaney of strandboard by surface treatment with melamine and boric or phosphoric acids” Mokuzai Gakkaishi (Japanese) 43(l), 75-81.

Wladyka-Przybylak, M., and Kozlowski, M. (1999). “The thermal characteristics of different intumescent coatings,” Fire and Materials 3(l), 33-43.

Article submitted: September 11, 2012; Peer review completed: October 20, 2012; Revised version received: November 25, 2012; Accepted: November 26, 2012; Published: November 29, 2012.