Abstract

Bamboo hardness test standards are not available. This study developed a new test method for bamboo indentation hardness with the U-shaped cylindrical and V-shaped compression heads in bamboo rings with different lengths. The mechanical behaviors of bamboo rings under two kinds of compression heads were analyzed. The results showed that U-shaped indentation hardness and V-shaped indentation hardness were closely correlated with compression strength and that the difference between U-shaped indentation hardness and V-shaped indentation hardness was significant. However, the bamboo rings with different lengths showed no significant difference in indentation hardness.

Download PDF

Full Article

Indentation Hardness Test Methods for Bamboo

Xiaomeng Yang,# Yuan Chai,# Zhengjun Sun, Huanrong Liu,* and Zehui Jiang *

Bamboo hardness test standards are not available. This study developed a new test method for bamboo indentation hardness with the U-shaped cylindrical and V-shaped compression heads in bamboo rings with different lengths. The mechanical behaviors of bamboo rings under two kinds of compression heads were analyzed. The results showed that U-shaped indentation hardness and V-shaped indentation hardness were closely correlated with compression strength and that the difference between U-shaped indentation hardness and V-shaped indentation hardness was significant. However, the bamboo rings with different lengths showed no significant difference in indentation hardness.

Keywords: Moso bamboo; Indentation hardness; Compression strength; Behavior

Contact information: International Centre for Bamboo and Rattan, Beijing, China, 100102;

# Co-First Author: Yuan Chai, equal contributors as first author

* Corresponding authors: Jiangzehui@icbr.ac.cn; liuhuanrong@icbr.ac.cn

INTRODUCTION

In many countries, especially in Asia, bamboo is an important natural resource. Due to its rapid growth rate and excellent flexibility and machinability, bamboo is widely used as a material in construction, furniture, pulping, and handicraft works. It resembles a hollow cylinder with many nodes (circular discs inserted into the hollow cylinder). The function of these nodes is to prevent buckling caused by bending. In addition, they may also act as axial crack arresters. Compared with wood, bamboo has a unique structure.

Hardness reflects the ability of a material to resist the entry of other rigid bodies. It is the common parameter in testing the mechanical properties of materials (Tsoumis 1991). This property is particularly important in processing and utilization of wood and bamboo. For bamboo products such as flooring, hardness is a very important strength standard (Berndsen et al. 2014).

The indentation method is derived from the hardness test. By establishing the connection between the partial indentation test and the conventional mechanical test, the characteristics of the material can be obtained. The main application in the field of wood is the nano-indentation technology, which has the advantages of simplicity and rapidity (Oliver and Pharr 1992; Yu et al. 2007). The mechanical properties of the cell walls and the hardness of the fibers at the cell level were obtained. However, bamboo is a porous, layered, and heterogenous natural polymer biomaterial with a multistage structure, and it has different mechanical properties on the macro scale. Nano-indentation characterization determines the mechanical behavior of a single fiber at the microscopic scale.

At present, the international standard of wood hardness testing is ISO3350 (1975), and Chinese National Standard is GB/T-1941 (2009), which is a revision of the international standard. The principle of the standard is the Janka hardness testing method. The hemispherical head of 11.28 mm is pressed into the wood, and the maximum load value is the hardness. However, because of its heterogeneity, large differences in the outer and inner wall, and wall thickness limitations, it is not suitable to use wood hardness testing directly. There are no international standards, Chinese national standards, or industry standards in bamboo hardness testing methods.

To date, wood hardness and half pressure hardness have been used as reference for radial hardness of bamboo (Dong et al. 2009; Ge et al. 2012; Trujillo and Jangra 2016). However, because of the thickness limit of the bamboo and its own arc, the loading of the end and the tangential direction is difficult, and the specimens easily crack when the contact surface is the bamboo green in the radial loading. Thus, there is no definite method for measuring the hardness of the end face of bamboo.

In this paper, a new method was used to study the macro hardness indentation of bamboo based on previous studies and the hardness and compression tests of wood in relevant standards. Based on the traditional material processing machine, according to the principle of depth measurement pressure, a pressure machine was developed for the macro depth measurement instrument. This study developed an indentation hardness test method to provide a fast testing and grading method for bamboo culm.

EXPERIMENTAL

Materials

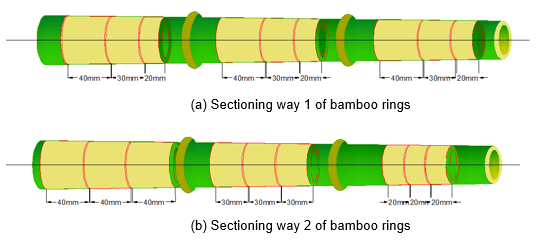

Nine four-year-old moso bamboo (Phyllostachys pubescens Mazel) culms with a total height of about 13 m and the diameter at the breast height of 9 to 15 cm were harvested from Huoshan Town, Anhui Province, China. The specimens were exclusively taken from three successive internode sections of the fresh culms at the height of 1.3 to 2.0 m. Bamboo rings at three different heights were obtained in two methods (Fig. 1(a)-(b)).

Fig. 1. Schematic diagram of specimens cut in two sectioning ways

To explore the effect of the height of bamboo on the indention hardness, bamboo with the heights of 20 mm, 30 mm, and 40 mm were cut successively from the bottom to the top of the three internodes. Nine bamboo rings for each height were obtained from three culms according to each sampling method. A total eighteen specimens for each height were obtained.

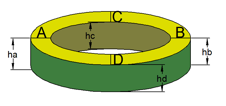

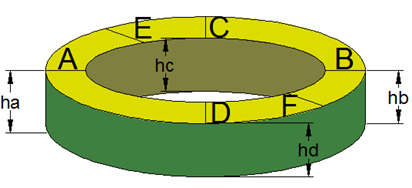

The upper and lower surfaces of all the specimens were absolutely smooth and parallel to each other and both perpendicular to the axial direction. The height of each bamboo ring was measured at four points, which were respectively in the longest axis and the shortest axis (Fig. 2). The measurement error was controlled within 5%. The moisture content was measured immediately after the test. The average moisture content of all specimens was 42%.

Fig. 2. Height measurement of a bamboo ring

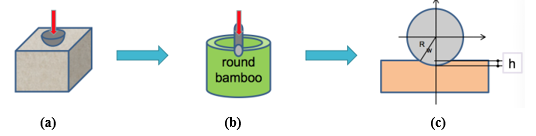

Indention hardness tests were performed on a universal testing machine (TENSON, WDW-T50, Jinan, China) equipped with a load cell with a capacity of 10 KN. According to ASTM D143-14 (2014), wood hardness was determined by with a ball-shaped compression head with a diameter of 11.3 mm (Fig. 3(a)). Bamboo is a hollow cylinder, so to consider the properties of bamboo more completely, a roller compressing head was used across the end of bamboo (Fig. 3(b)-(c)).

Fig. 3. Determination flow chart of round bamboo indentation test: (a) wood hardness test model; (b) round bamboo indentation test model; (c) indentation dimension

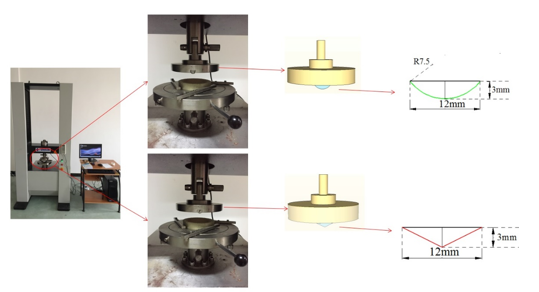

Fig. 4. Schematic diagram of round bamboo indentation test system

Fig. 5. Centering device of the specimen

For the pipe shape of bamboo culm with thin culm walls, indention hardness of bamboo was tested by U-shaped and V-shaped compressing heads as shown in Fig. 4. The U-shaped and V-shaped compressing heads were fixed on a compression platen. The height of both heads was 3 mm. The surface of platen was smooth. Before the test, the specimen was fixed at the center of the pressure plate, and the position was adjusted using a centering device (Fig. 5).

Indentation Hardness

For each specimen, three indices were tested. Six points (A, B, C, D, E, and F) were marked along three axes of each bamboo ring. The three axes pass through the center of bamboo ring. The AB axes were long axes for the U-shaped indentation test, and the CD axes were short axes for the V-shaped indentation test. Immediately after the indentation tests, the bamboo ring specimens were sewed at the points of E and F for the longitudinal compression test (Fig. 6).

Fig. 6. Indentation test position on specimen

First, indentation hardness was tested on each specimen with U-shaped and V-shaped compressing heads. The specimens used in compression strength tests with the dimensions of 20 mm (longitudinal) × 20 mm (tangential) × t mm (radial) were obtained at E and F points after indentation hardness tests. Compression strength was tested according to GB/T 15780 (1995). Before the tests, the height and thickness of bamboo ring at four points (A, B, C, and D) was measured. The longitudinal, tangential, and radial dimensions were measured for compression strength tests.

In indentation hardness tests, the specimen was fixed on the bottom platen with the centering device. The specimens were loaded at a displacement rate of 3 mm/min until the head was completely embedded in culm wall. The corresponding load and displacement values were recorded. The indentation hardness was calculated as follows,

![]()

where σ is indentation hardness at indentation depth of 3 mm (MPa, precision of 0.1 MPa), and P is the indentation load when it is pressed into the depth of 3 mm, N, as shown in Fig. 8, Pmax. S is the indentation area when it was pressed into the depth of 3 mm, in mm2 and can be calculated as follows,

![]()

where w is the width of indentation in the tangential direction of bamboo culm; t is bamboo wall thickness at the indentation, mm.

Compression Strength

In compression strength tests, the small specimen was set at the center of bottom platen and compressed by the top smooth platen. The specimens were loaded at a displacement rate of 3 mm/min until the failure. Compression strength was calculated according to GB/T 15780 (1995). The average value of 18 specimens was calculated.

RESULTS AND DISCUSSION

Effects of Bamboo Ring Height on Indentation Hardness

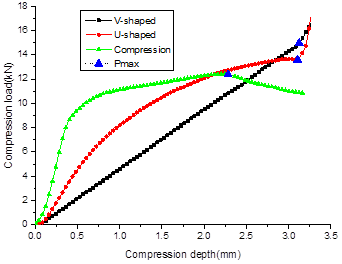

Higher bamboo rings increase the preparation difficulty, but short bamboo rings do not represent the property completely. In order to confirm the effects of bamboo ring height on the indentation hardness, the indentation hardness of three bamboo rings with different

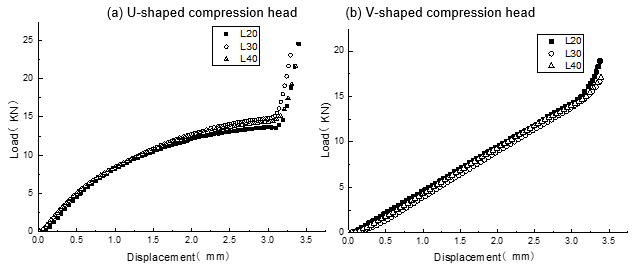

heights was tested with U-shaped and V-shaped compression heads. The representative load-displacement curves of the specimens are shown in Fig. 7.

Fig. 7. Load-displacement curves of bamboo rings in different lengths (L20: Bamboo ring length is 20 mm, L30: Bamboo ring length is 30 mm, L40: Bamboo ring length is 40 mm)

The load-displacement curves of three rings with different heights were similar. The load increased with the increase of the displacement. However, the increasing trends of the curves obtained with U-shaped and V-shaped compression heads were different. The curves of three rings with different heights obtained with the V-shaped compression head were linear curves, and the compression load increased linearly with the increase in the displacement. However, in the curves obtained with the U-shaped compression head, the load linearly increased at first and then it increased nonlinearly when the displacement exceeded 0.5 mm due to the stiff opposite response. Compared with the contact area in the V-shaped compressing head method, the contact area was larger in the U-shaped compressing head method, and the circular surface presented the slight yield response.

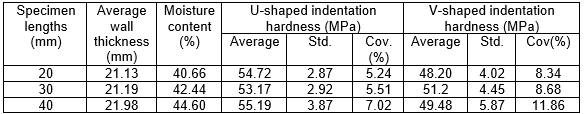

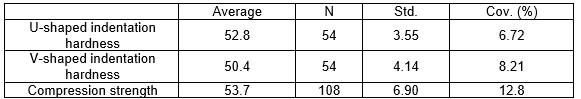

Table 1. Indentation Hardness of Bamboo Rings in 3-Different Length under U and V Shaped Compression Head

Std., standard deviation; and Cov., coefficient of variation

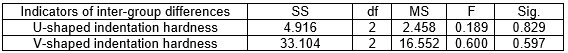

Table 2. Significant Difference Analysis at the Level of 0.05

SS, sum of squares; df, degree of freedom; and MS, mean square.

Table 1 shows the indentation hardness of three kinds of bamboo rings. Indentation hardness obtained with the U-shaped compression head was slightly higher than that obtained with the V-shaped compression head for all the specimens. However, there was no great difference in indentation hardness at different heights. As shown in Table 2, the indentation hardness of bamboo rings at different heights showed no statistically significant difference. Although the height showed no significant influence on indentation hardness, bamboo ring at the height of 20 mm was selected in the subsequent analysis of indentation. The indentation hardness of all the 54 specimens with three different heights was tested in this study.

Compression Strength and Indentation Hardness of Bamboo

A total of 54 specimens were used to test indentation hardness, and 108 specimens were used to test compression strength. The indentation hardness obtained with U-shaped and V-shaped compression heads was lower than compression strength (Table 3). Compression strength was 53.7 MPa, which was slightly lower than corresponding values in previous reports (Wang 2002; Li 2009). The difference might be interpreted as follows. The moisture content in the testing specimen was higher than the saturation moisture content, and the mechanical properties decreased with the increase in moisture content. Though the indentation compression process was similar to the standardized grain compression test method, compression loads were different in the two test methods. The maximum compression load was the compression load at the failure point in the compression strength test, whereas the maximum compression load was the compression load under the displacement of 3 mm in the indentation hardness test. Moreover, the compression strength values of different specimens were also different. In compression strength tests, each specimen was separately tested, and their cross sections were compressed completely.

The U-shaped indentation hardness was compared with the V-shaped indentation hardness in Table 3. U-shaped indentation hardness and the grain compression strength were greater than the V-shaped indentation hardness. According to the paired specimen test in Table 4, there was a significant difference between U-shaped and V-shaped indentation hardness. The difference may be interpreted as follows. In the indentation process, the end face of the bamboo ring obtained with U-shaped compression head and in CIS compression process has a larger yield area than that obtained with V-shaped compression head. In the displacement-load curve obtained with V-shaped compression head, the slope of the rear part of the linear segment is slightly smaller, indicating that the slight yield. In summary, the yield area obtained with V-shaped compression head was smaller and the overall yield area was smaller. Therefore, V-shaped indentation hardness was lower than U-shaped indentation hardness and the compressive strength.

Table 3. Paired Specimen Statistics of U-shaped Indentation Hardness and V-Shaped Indentation Hardness

N, number; Std., standard deviation; Cov, coefficient of variation

Table 4. Paired Specimen Test of U-shaped Indentation Hardness and V-shaped Indentation Hardness

Std., standard deviation; df, degree of freedom.

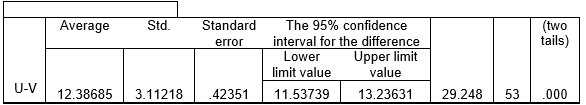

The correlation between indentation hardness obtained with the U-shaped and V-shaped compression heads and compression strength is shown in Fig. 8. The coefficient of determination between V-shaped indentation hardness and compression strength (R2 = 0.6924) was higher than that between U-shaped indentation hardness and compression strength (R2 = 0.558), indicating that V-shaped indentation hardness test was more similar to standardized grain compression tests. Therefore, V-shaped indentation hardness was used to grade bamboo rings in subsequent tests.

Fig. 8. Relationship between the U-shaped (a) and V-shaped (b) indentation hardness and the compressive strength

Compression Behaviors

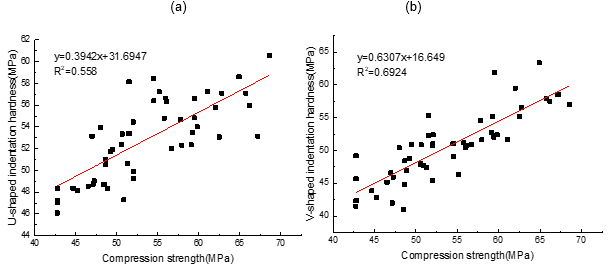

The representative load-displacement curves of the specimens obtained in three compression methods are shown in Fig. 9. These curves were different in the curve shape and trend. Three representative compression load-displacement curves of bamboo in three different compression head are presented in Fig. 9, which contained three typical segments: linear elasticity segment, non-linear viscoelasticity segment, and failure non-linear segment. The long non-linear segment indicated a long-term deformation behavior until the failure under a maximum load.

Fig. 9. Load-displacement- curves of bamboo in three different compression heads.

In contrast, the load-displacement curve obtained in V-shaped indentation test method only had the linear segment until the critical point. However, the load-displacement curve obtained with the U-shaped compression head was similar to that obtained with the V-shaped compression head except that the former curve was smooth, whereas the latter curve was the linear curve. The load-displacement curve could be divided into two segments: the first linearly increasing segment and the second gently increasing segment.

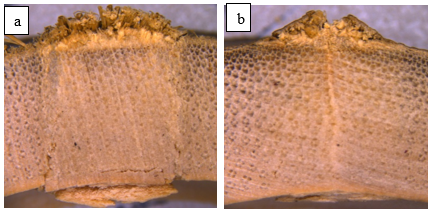

Fig. 10. Indentation under U-shaped compression head (a) and V-shaped compression head (b)

The characters of these curves reflected their compression behaviors. In compression tests, only elastic deformation corresponding to the linear segment in the curve occurred. The viscoelasticity was evaluated under the increasing load within a longer period. Finally, the specimen was crushed under the critical load. The failure modes of bamboo included rupturing the inner layer and humping the outer layer (Fig. 10).

The special failure characteristics of bamboo rings in U-shaped indentation tests were the circular column indentation, the shear rupture of the inner layer, and the brooming of the outer layer (Fig. 10(a)). The failure mode was associated with the circular surface of compression head.

The failure mode of bamboo in V-shaped indentation tests involved V-shaped indentation on the cross section, which was similar to the circular indentation in U-shaped indentation tests. However, the lowest middle line of V indentation was deep. The outer layer was ruptured and the inner layer was crushed on the line (Fig. 10(b)).

According to bamboo indentation modes and compression characteristics in three compressing tests, the outer part of bamboo culm with a high fiber volume fraction (~50%) (Zhang 2000; Li 2014) exhibited the excellent compression property. The stiff fibre bundles mainly bore the axial compression load. The inner part of bamboo culm with the lower fiber volume fraction and higher volume fraction of parenchyma tissues presented a slightly weak structure. The inner layer with silicon mainly bore the compression load, but it was slightly weaker than that of the outer layer.

CONCLUSIONS

Indentation hardness of bamboo was tested in two kinds of compression heads. In order to clarify the effect of bamboo ring height on the indentation hardness, specimens with three different heights were tested.

The difference in indentation hardness between bamboo rings with different heights was not significant. Considering the measurement accuracy of specimens, the specimens at the height of 20 mm were used for indentation hardness tests.

Indentation hardness values were different in U-shaped and V-shaped indentation tests. U-shaped indentation hardness was slightly higher than V-shaped indentation hardness. However, indentation hardness in V-shaped indentation tests was correlated with compression strength and its load-displacement curve could well describe the compression properties of bamboo.

The specimens showed different failure characteristics in the compression strength test and U-shaped and V-shaped indentation harness tests. The bending of the outer layer was the main failure characteristics in compression strength test. Circle indentation of the inner layer and crushing of the outer layer was main failure characteristics in U-shaped indentation hardness tests. Triangle indentation of the outer layer rupture was the main failure characteristics in V-shaped indentation harness tests. In compression strength tests and U-shaped and V-shaped indentation hardness tests, the stiff fiber bundles bore the compression load in the axial direction. The outer layer with more fiber bundles was stiffer and bore the more compression loads in compression strength tests.

ACKNOWLEDGMENTS

This research was financially supported by the 13th Five Years Plan-Study National Key Research & Development Program of China (Grant No. 2016YFD0600905).

REFERENCES CITED

ASTM D143-14 (2014). “Standard test methods for small clear specimens of timber,” ASTM International, West Conshohocken, PA.

Berndsen, R. S., Klitzke, R. J., Batista, D. C., Nascimento, E. M. D., and Ostapiv, F. (2014). “Mechanical resistance of moso bamboo (Phyllostachys pubescens) Part 2: Axial tensile strength, hardness and wear resistance,” Floresta 44(3), 505. DOI: 10.5380/rf.v44i3.33311

Dong, D. Y., Guan, M. J., Zhu, Y. X., Mo, C. Z., and Mo, X. F. (2009). “The hardness test and analysis solidness of moso bamboo in different ages,” ( In Chinese) Journal of Forestry Engineering 2009(5), 48-50.

GB/T 1941 (2009). “Wood hardness testing method,” Standardization Administration of China, Beijing.

GB/T 15780 (1995). “Test method of physical and mechanical properties of bamboo,” Standardization Administration of China, Beijing.

GB/T 21838.1 (2008). “Instrumented indentation test for hardness and material parameters of metal materials,” Standardization Administration of China, Beijing.

Ge, J. C., Tong, T. P., Sun M. Y., Yan, W., Guan, M. J., and Zhu, Y. X. (2012). “Hardness properties of bamboo based on indentation loading curve,” J. Bamboo Res. 31 (4), 28-30. DOI: 10.3969/j.issn.1000-6567.2012.04.007

ISO 3350 (1975). “Wood – Determination of static hardness,” International Organization for Standardization, Geneva, Switzerland.

Li, X. Z. (2009). Research on Mechanics and Failure Properties of Moso Bamboo, Ph.D. Dissertation, Chinese Academy of Forestry, Beijing.

Oliver, W. C., and Pharr, G. M. (1992). “An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments,” J. Mater. Res. 7(6), 1564-1583. DOI: 10.1557/JMR.1992.1564

Trujillo, D., and Jangra, S. (2016). Grading of Bamboo–INBAR Working Paper 79, International Network for Bamboo and Rattan, Beijing.

Tsoumis, G. (1991). Science and Technology of Wood: Structure, Properties and Utilization, Van Nostrand Reinhold, New York.

Wang, Z. H. (2001) Study on the Relationship between Variation of Wood Properties and Processing and Utilization, Ph.D. Dissertation, Chinese Academy of Forestry, Beijing.

Yu, Y., Fei, B. H., Zhang, B., Yu, X. (2007) “Cell-wall mechanical properties of bamboo investigated by in-situ imaging nanoindentation,” Wood Fiber Sci. 39(4), 527-535. DOI: 10.1088/0953-8984/18/18/S03

Zhang, J. Y., Yu, T. X., Kim, J. K., Sui, G. X. (2000) “Static indentation and impact behaviour of reformed bamboo/aluminium laminated composites,” Compos. Struct. 50(2), 207-216. DOI: 10.1016/S0263-8223(00)00104-5

Article submitted: October 23, 2018; Peer review completed: November 30, 2018; Revisions accepted: December 10, 2018; Published: December 11, 2018.

DOI: 10.15376/biores.14.1.954-964