Abstract

Cellulose fibers’ complex and compact structure hinders the quantitative extraction of residual hemicelluloses from the fiber wall. In this study, hardwood kraft paper pulp was subjected to refining with a Hollander beater at different refining loads (3, 4.5, and 5.5 kg) in order to assess the impact of refining load on xylan removal by cold caustic extraction. The refined pulp showed high water retention values and specific surface area, which increased accessibility and a correspondingly high degree of xylan removal. Coupling refining and cold caustic extraction (100 g/L soda) achieved over 50% more xylan removal than the unrefined pulp (3% against 7%, respectively). Furthermore, an improvement in xylan removal (79%) was achieved by implementing a one-pot simultaneous refining and cold caustic extraction treatment at half the time required for the sequential treatment and low soda concentration (60 g/L). Finally, the benefit of beating was also observed for xylanase treatment. Overall, the combined extractions made it possible to remove 85% of xylan from a conventional hardwood paper pulp giving rise to a high purity cellulose pulp with unimodal and narrow molecular mass distribution.

Download PDF

Full Article

Influence of Hollander Beater Refining on Xylan Extraction from Hardwood Paper Pulp by Cold Caustic Extraction and Xylanase Treatment

Gloria I. Ngene,* Jean-Claude Roux, and Dominique Lachenal

Cellulose fibers’ complex and compact structure hinders the quantitative extraction of residual hemicelluloses from the fiber wall. In this study, hardwood kraft paper pulp was subjected to refining with a Hollander beater at different refining loads (3, 4.5, and 5.5 kg) in order to assess the impact of refining load on xylan removal by cold caustic extraction. The refined pulp showed high water retention values and specific surface area, which increased accessibility and a correspondingly high degree of xylan removal. Coupling refining and cold caustic extraction (100 g/L soda) achieved over 50% more xylan removal than the unrefined pulp (3% against 7%, respectively). Furthermore, an improvement in xylan removal (79%) was achieved by implementing a one-pot simultaneous refining and cold caustic extraction treatment at half the time required for the sequential treatment and low soda concentration (60 g/L). Finally, the benefit of beating was also observed for xylanase treatment. Overall, the combined extractions made it possible to remove 85% of xylan from a conventional hardwood paper pulp giving rise to a high purity cellulose pulp with unimodal and narrow molecular mass distribution.

DOI: 10.15376/biores.17.1.908-921

Keywords: Paper-grade pulp; Hollander beater refining; Cold caustic extraction; Xylanase treatment; Dissolving pulp; One-pot refining; Alkaline treatment

Contact information: Univ. Grenoble Alpes, CNRS, Grenoble INP*, LGP2, F-38000 Grenoble, France

* Corresponding author: gloria-ifunanya.ngene@grenoble-inp.fr

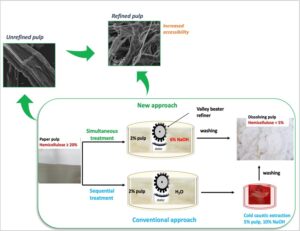

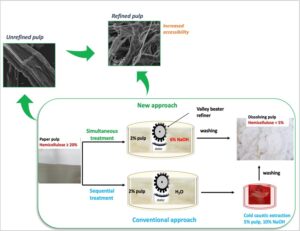

GRAPHICAL ABSTRACT

INTRODUCTION

Recent market studies show that the demand for wood dissolving pulp, a material used to produce regenerated cellulose and cellulose derivatives, is increasing. This trend could be attributed to several factors including availability and sustainability of this raw material, biodegradability of cellulose products, possibility of its use as a sustainable alternative for the manufacture of fossil-based materials, and foreseen dramatic increase of textile demand worldwide (Cherubini 2010; Kumar and Christopher 2017). This explains the impetus for the lignocellulose-based research carried out to explore and realize its great potentials. However, the biggest challenge remains the lengthy process of extraction, purification, and the lack of a cost-effective and environmentally friendly dissolution process for cellulose (Sixta 2006; Gehmayr et al. 2011; Hutterer et al. 2016).

Processes have been developed for separating cellulose from other wood components and the subsequent purification of the resulting cellulose fibers. The separation of cellulose begins with wood cooking or pulping. The kraft cooking process is the most prevalent chemical pulping method globally, especially for papermaking applications. This is because of the superior strength properties of the isolated cellulose fibers and the quantitative recovery of the cooking chemicals. The production of dissolving pulp is currently performed by the kraft and sulfite processes (Sixta 2006; Duan et al. 2015). Contrary to paper pulp, dissolving pulp must have a very low hemicellulose content (<5%), implying that the hemicellulose extraction must be achieved by performing specific treatments in addition to the traditional pulping process. Production of dissolving pulp by the kraft process is typically realized by implementing a hemicellulose extraction stage before the kraft cook known as auto-hydrolysis or pre-hydrolysis (Curmi et al. 2018); however, another promising approach for the production of dissolving pulp via the kraft cook is to carry out an alkaline post-treatment of the kraft fibers (Ibarra et al. 2009). The cold caustic extraction (CCE) effectively removes part of the residual hemicellulose from the paper-grade pulp. The mechanism involves the swelling of cellulose fibers in an alkaline environment, making way for the solubilization of hemicellulose (lower molecular weight fraction of the pulp). The advantages of the CCE over the prehydrolysis kraft (PHK) are as follows: (i) The dissolving pulp produced has higher alpha-cellulose and narrower molecular weight distribution; (ii) The additional digester capacity required for the PHK is not required for the CCE; (iii) The CCE enables better chemical recovery by avoiding pH control problems associated with PHK; (vi) The hemicelluloses extracted via the CCE, especially xylan, are obtained in their polymeric form, which has potential in some applications; and (v) The possibility of an easy shift from paper pulp to dissolving pulp production for pulp mills, depending on the fluctuations in market demand (Pinto et al. 2005; Köpcke 2010; Gehmayr et al. 2011; Stoklosa and Hodge 2012; Hutterer et al. 2016; Gong et al. 2017).

The main question in upgrading paper pulp to dissolving pulp is how the high hemicellulose content (18 to 29% depending on wood type) in the paper pulp can be sufficiently reduced (Gehmayr et al. 2012; Arnoul-Jarriault et al. 2014; Dou and Tang 2017; Kim et al. 2019). Some studies available in the literature suggested applying a mechanical pretreatment prior to CCE (Duan et al. 2015; Zhao et al. 2017). For instance, Li et al. (2015) studied the effect of PFI refining (10,000 revolutions) on the alkaline extraction of softwood sulfite pulp carried out at (10% pulp consistency, 25 °C, 30 min reaction time). The authors found that coupling of the refining with CCE (4% NaOH) resulted in a reduction of hemicellulose from 9.5% to 5%, while CCE implemented alone led to a decrease of 9.5% to 7.8%. This study highlights the benefit of refining prior to the cold caustic extraction process, which is plausibly due to better accessibility. However, the full potential of refining is not known, considering that there exist different technologies to refine/beat pulp and that several intensities may be applied. For example, the refining mechanisms of the PFI and laboratory Hollander beater are quite different. The prominent effect of refining with the PFI is fibrillation, and that of the Hollander beater has a greater amount of cutting and fines generation (Gharehkhani et al. 2015; Motamedian et al. 2019), the likelihood exists that pulps treated by the PFI refiner and Valley beater might respond differently to chemical and enzymatic hemicellulose extraction. Some reports exist in the literature on the influence of mechanical refining (using the PFI mill) on hemicellulose removal (Duan et al. 2015; Li et al. 2015; Zhao et al. 2017; Kim et al. 2019).

The present study aims to provide information on the effect of pulp modification via the laboratory Hollander beater at different refining loads and the impact of such morphological changes on the removal of hemicellulose from regular hardwood kraft pulp containing around 20% xylan. The approaches considered in this study to achieve quantitative removal of hemicellulose from the pulp is the sequential refining pretreatment followed by CCE and a new approach involving simultaneous refining and CCE. In addition, the influence of Hollander beater refining on xylanase treatment was investigated since enzymes reactivity is highly susceptible to accessibility and may produce complementary extraction.

EXPERIMENTAL

Materials

Bleached mixed hardwood kraft dry sheets were supplied by Fibre Excellence St-Gaudens, a paper mill in France. The xylan content and degree of polymerization of the pulp before treatment were 20% and 1294, respectively. No other hemicelluloses were present in a significant amount. β-xylanase was purchased from Megazyme (Bray, Ireland), and other chemicals used were NaOH (≥ 99 % for analysis, Roth, Karlsruhe, Germany), sulfuric acid (95-97% for analysis, Roth), dimethylacetamide (≥ 99 % for analysis, Roth), lithium chloride (≥ 99 %, Sigma Aldrich, St. Louis, MO, USA), and cupriethylene diamine solution (1.0 M, Sigma Aldrich).

Methods

Mechanical refining

Mechanical treatment was performed with the Valley laboratory Hollander beater (Voith, Heidenheim, Germany). An equivalent of 440 g (oven dried weight) of pulp was soaked in 2 L tap water overnight and then drained and disintegrated with a pulper for 10 min. The disintegrated pulp correctly diluted to 22 L was then transferred into the beater and refined to the desired Schopper Riegler value (degrees SR). The refined pulp was then centrifuged to remove excess water, moved into a polyethylene bag, and stored in the fridge. Three refining loads, 3, 4.5, and 5.5 kg, were selected and tested to determine the load that would produce morphological modifications best suited for optimum hemicellulose removal.

Fiber characterization

The fiber quality (length, width, fibrillation index, and fines content) was determined by the Morfi fiber analyzer (Techpap, Grenoble, France). The water retention value was determined by centrifugation of test pads at an acceleration of 3000 g for 15 min. Pulp specific surface area and total pore volume were determined by the Brunauer-Emmett-Teller (BET) analysis of nitrogen adsorption. The measurements were carried out using the Nova 2200e device from Quantachrome (Grenoble, France). Samples were degassed under vacuum at 105 °C for 16 hours to remove water molecules adsorbed on the porous surface of the sample prior to determination. Fiber images were acquired by environmental scanning electron microscopy ESEM (FEI, Tokyo, Japan).

Cold caustic extraction

The cold caustic extraction of hemicelluloses was carried out at NaOH concentrations of 20, 40, 60, and 100 g/L. Other conditions chosen for the extraction were pulp consistency of 5%, residence time of 30 minutes, and temperature of 25 °C. At the end of the reaction, the pulp was washed with deionized water to a pH of 8. The resulting pulp was dried by lyophilization. A schematic representation of the approach introduced in this study for alkaline extraction of hemicellulose is shown in Fig. 1.

Xylanase treatment

For the enzymatic extraction of hemicelluloses, pulp samples were treated with xylanase (50, 300, and 500 U/g) at 3% consistency in a 0.1M sodium phosphate buffer solution. The pH of the buffer was 6, and the reaction was carried out in a plastic bag. The enzyme was first introduced into the buffer solution and thoroughly mixed before pulp addition to ensuring uniform distribution. After the homogenization of the pulp/xylanase suspension, it was incubated in a controlled water bath at 50 °C for 2 h. The pulp/xylanase suspension was filtered and mixed with deionized water at 90 °C. It was then placed in a water bath maintained at 90 °C for 30 min to deactivate the enzyme. The pulp was washed with deionized water and stored at 4 °C.

Fig. 1. Schematic representation of the novel approach developed in the study

Analytical techniques

The degree of polymerization was determined before and after treatment by dispersing the pulp in deionized water and subsequent dissolution in cupriethylenediamine solution (CED) according to the TAPPI T230 om-13 (2013). The molecular weight distribution of pulp samples was determined by dissolving in 8% LiCl/DAMc solution and analyzed by gel permeation chromatography (GPC) equipped with a multi-angle light scattering (MALLS) detection system (Dupont 2003). According to the NREL procedure, a two-step acid hydrolysis was used to determine the hemicellulose composition (Sluiter et al. 2008).

RESULTS AND DISCUSSION

Fiber Modification with Hollander Beater Refining

The modification of the fiber morphology during refining is achieved by controlled exposure to shear and compression forces. This results in fiber cutting, internal and external fibrillation, fiber delamination, and generation of fines (Gharehkhani et al. 2015; Li et al. 2015; Roux et al. 2017; Motamedian et al. 2019). The modifications ultimately lead to increased specific surface area (SSA), increased water retention value (WRV), increased pore size and volume, and decreased crystallinity index. All these factors should increase reactivity of the pulp towards hemicellulose removal or dissolution of cellulose (Hakala et al. 2014; Tian et al. 2014; Duan et al. 2015; Li et al. 2015; Zhou et al. 2018).

Fig. 2. (a) The Hollander beater; (b) evolution of drainage resistance determined by the Schopper Riegler value (SR) with refining time and refining load

The laboratory Hollander beater (Fig. 2a) is operated at a low pulp consistency of ≤ 2%. The energy applied to the pulp suspension can be adjusted by the loading level and the refining time. The refining action takes place between the bedplate and the rotor. The bedplate is fixed and has slightly inclined bars and grooves, unlike the PFI mill, which is smooth. The refining mechanism of the Hollander beater has been reported to favor fiber cutting and external fibrillation to internal fibrillation and swelling observed in the PFI mill (Kerekes 2005).

The parameter used to evaluate the extent of refining or degree of refining in this study was the Schopper Riegler (degrees SR). From the result presented in Fig. 2b, the evolution of pulp drainage resistance represented by the Schopper Riegler degrees at the different loading levels of 3, 4.5, and 5.5 kg followed a similar trend, but the time it took to reach the target SR value (85) was different. The refining energy applied at the different loading levels was estimated to be 344, 400, and 480 kWh/t for 3, 4.5, and 5.5 respectively. Therefore, the order of refining intensity for the loading levels was 5.5 kg > 4.5 kg > 3 kg. As the refining mechanism is influenced by the refining intensity, among other factors, it can be imagined that the mechanism of refining at the different loading conditions varies. For instance, lower intensity refining (occurring at a low loading levels) is characterized by a more gentle impact or refining action, unlike high-intensity refining (occurring at high loading levels). Besides, high intensity refining is associated with an aggressive or harsh treatment of the fibers, resulting in fiber cutting, while a gentle refining action promotes fibrillation (Abitz and Luner 1989). Table 1 shows a significant reduction in fiber length and increases in fines content with refining. This indicates that Hollander beater refining promotes fiber cutting, especially at a high loading. Similarly, the WRV increased more than twofold with refining, and the highest increase was recorded at 4.5 kg load. Also, the fibrillation index, specific surface area SSA, and pore volume dramatically increased with refining. The high refining loads gave the most increase in SSA.

Table 1. Influence of Hollander Beater Refining on Fiber Morphology

Fig. 3. SEM images of (a) unrefined pulp, (b) refined pulp – 3kg load, (c) refined pulp – 4.5 kg load, and (d), refined pulp – 5.5 kg load

The scanning electron microscopy images were used to highlight the structural modification of fibers with refining. As shown in Fig. 3, the effect of refining is evident when the unrefined fibers are compared to the refined fibers. Although a clear difference is not visible between the morphology at the different loadings, the fibers refined with the 4.5 and 5.5 kg loads showed more external fibrillation, fragmentation of the fibers, and the presence of fibrillated fines surrounding the fibers. All these structural changes constitute favorable conditions that enhance the accessibility of chemicals and enzymes to active sites. Consequently, the 4.5 kg refining load was preferred for further investigation.

Performance of Cold Caustic Extraction with Hollander Beater Refining

In the context of paper pulp upgrade to dissolving pulp, the cold caustic extraction method shows promise (Sixta 2006; Hutterer et al. 2016; Li et al. 2016; Friebel et al. 2019). Several factors affect the solubilization of hemicellulose fraction in alkali-treated pulp, including extraction temperature, residence time, pulp consistency, and alkali concentration (Sixta 2006; Hutterer et al. 2016). To better monitor the effect of the alkali charge on the extraction process, other parameters apart from the alkali concentration were kept constant. The temperature was 25 °C, the residence time 30 min, and the pulp consistency was kept at 5%. The choice of a short residence time of 30 min was made because longer treatment time resulted in yield losses (Li et al. 2017) and 5% consistency was to ensure uniformity in mixing and the practicality for industrial application (Sixta 2006). Biphasic extraction of hemicellulose from pulp during the cold caustic extraction process has been reported (Hutterer et al. 2016; Li et al. 2017). The first phase occurs at the onset of the extraction process at a lower alkaline charge within the first few minutes. It involves the rapid extraction of the easily accessible xylan with low molecular weight, while the second phase occurs at a lower rate and extracts the inaccessible high molecular weight hemicelluloses. More so, the latter phase requires the use of a high alkaline charge to obtain a good extraction.

Fig. 4. Xylan extraction performance of the cold caustic extraction treatment at various soda concentrations on unrefined and Hollander beater refined pulp at (3 kg, 4.5 kg and 5.5 kg loads) evaluated by the residual xylan content after treatment

Figure 4 shows the xylan extraction performance of the cold caustic extraction treatment at various soda concentrations on unrefined and refined pulp. A 20 g/L NaOH concentration showed no significant xylan extraction even when refining was applied before the alkaline treatment. This means that the concentration was too low to allow the swelling process that initiates the first phase of xylan solubilization. As expected, a rapid phase of hemicellulose solubilization occurred between 40 and 60 g/L NaOH concentrations for both unrefined and refined pulps. The influence of refining, although noticeable, is not particularly relevant in the first phase of the xylan dissolution process, as evidenced by the degree of xylan removal at both concentrations (40 and 60 g/L NaOH), being respectively 34% and 58% for unrefined pulp and 39% and 68% for refined pulp (4.5 kg load). However, in the second phase of extraction, a considerable difference in the performance of the CCE is observed for refined pulp compared to the unrefined pulp. The results show that a soda concentration of 100 g/L removed 50% more xylan compared to the unrefined pulp, indicating a greater synergy between the high alkali charge and fiber wall modifications due to refining.

Simultaneous Refining and Cold Caustic Extraction

The hypothesis was that mechanical pulp refining could be considered as a rigorous mixing process occurring at neutral pH, resulting in disruption and modification of the structural properties of the pulp. Therefore, increasing the pH during refining would allow for rapid fiber modifications occurring alongside cellulose fiber swelling, resulting in accelerated accessibility of chemicals to hard-to-reach regions of the fiber, ultimately improving xylan solubilization and extraction. The simultaneous refining-CCE was conducted on the Hollander beater at a soda concentration of 60 g/L and refining load of 4.5 kg for about 60 min (Fig. 1). At the end of the treatment, the resulting pulp was washed until neutral pH. The result presented in Fig. 5 showed a 79% xylan removal degree for the simultaneous treatment against 68% obtained for the sequential refining and CCE treatment performed at the same soda concentration of 60 g/L. The simultaneous refining-CCE treatment efficiency could be attributed to the intense mixing effect achieved in the process. Since pulp swelling occurs instantaneously in a soda solution (Sixta 2006), creating new surfaces during refining coupled with an alkaline environment ultimately results in more effective xylan removal.

Fig. 5. Performance of xylan removal with CCE at 60 g/L for unrefined pulp, sequential treatment (refining prior to CCE at 60 g/L) and simultaneous treatment (refining-CCE at 60 g/L.)

Dinand et al. (2002) reported that the impact of mercerization was more intense for individual fibrils than bundles. In addition to that, they suggested that the outer layer of the cellulose cell wall had a somewhat loose structure. As expected, refining allows the separation of fibrils from bundles (fibrillation) and the structural modifications that enable the exposure of hidden layers of the cell wall, which explains the efficiency of this approach. Notably, the xylan removal degree achieved by the simultaneous treatment was similar to results obtained for sequential treatment at a higher soda concentration (100 g/L), making it a more attractive process. Besides, the soda concentration employed limits the transformation of native cellulose to cellulose II.

The possibility of upscaling this process industrially on disc refiners exists and would be more interesting if the spent alkali is recycled.

Performance of Xylanase Treatment with Hollander Beater Refining

Recently, the use of enzymes in pulp processing has gained popularity due to (i) the mild conditions in which they are applied, (ii) the biodegradable nature of the proteins, (iii) their non-polluting and eco-friendly nature, (iv) their highly specific reactions and, as a result, the absence of yield losses due to side reactions. However, xylan removal by xylanase is generally much lower than that brought about by alkaline treatment. This was attributed to the large size of the enzyme, which could hinder it from penetrating the pores and reaching the active site (Köpcke et al. 2008; Zhao et al. 2017). Also, the saturation of the hydrolysis products in the reaction medium has been considered as a limiting factor (Dhiman et al. 2008; Hutterer et al. 2017). Therefore, to overcome the problem of accessibility, Hollander beater refining pretreatment was applied prior to the xylanase treatment. The unrefined pulp was treated at various xylanase dosages ranging from 0 to 500 U/g to determine the optimum enzyme concentration required to extract xylan from the pulp. A reduction in the initial xylan content of the pulp was observed with xylanase treatment and increasing the enzyme dosage slightly increased the xylan removal. The best result was obtained at a xylan dosage of 500 U/g with about 25% of the initial xylan content release. Surprisingly, the performance of the xylanase treatment alone in unrefined pulp was lower than values reported in the literature (Köpcke 2008; Hutterer et al. 2017; Zhao et al. 2017). The plausible explanation for the poor performance of the xylanase treatment might be the hornification effects associated with dried-rewetted pulp sheets and the process history.

Fig. 6. (a) Xylan content of the bleached hardwood pulp in response to the xylanase dosage at an incubation temperature and time of 50 °C and 2 h, respectively. (b) Comparing the effect of CCE on unrefined pulp (UR-6%CCE), and refined pulp (VB-6%CCE) and (VB-simul) with the effect of coupling CCE with a sequential xylanase treatment at dosage of 500 U/g in unrefined pulp (UR-X_6%CCE), Hollander beater refined pulp (VB-X_6%CCE), and simultaneous Hollander beater refining and CCE (VB-simul_X) {6%CCE refers to cold caustic extraction performed at 60 g/L NaOH}

The effect of Hollander beater refining prior to xylanase treatment was assessed (Fig. 6a). Refined pulp was treated with xylanase at various concentrations ranging from 0 to 500 U/g dry pulp. The maximum xylan removal was 38%, which was achieved at a xylanase dosage of 500 U/g. Although an improvement in xylan removal was observed with refining, it remained rather weak. The improvement in xylan removal with refining is an indicator of the structural changes associated with refining that ultimately increases accessibility.

Because xylanase treatment alone was insufficient to achieve quantitative removal of xylan from wood pulp, a coupling of both xylanase and alkaline extraction was implemented. The result of the coupling with alkaline extraction at a soda concentration of 60 g/L is shown in Fig. 6b. In the unrefined pulp, the benefit of adding xylanase treatment prior to CCE was marginal. However, substantial xylan extraction was achieved when refining was performed before the xylanase treatment, followed by the CCE stage, leading to approximately 80% xylan removal. More so, implementing a sequential xylanase treatment on the simultaneous refining -CCE treated pulp produced the best result with 85% total xylan removal. These findings once again support the new approach of xylan extraction in which the refining and CCE is done simultaneously.

Molecular Weight Distribution and Degree of Polymerization

The degree of polymerization (DPv) of the pulp, which is determined by the viscosity of the pulp in cupriethylenediamine (CED) solution indicated that a slight breakdown of the cellulose chain occurred during refining (Tian et al. 2014; Duan et al. 2015; Zhou et al. 2018; Kim et al. 2019). Although the removal of residual xylan during the alkaline treatment resulted in an overall gain in degree of polymerization (since the xylan molecules (short-chain) were removed), the effect of the slight degradation of cellulose chains remains evident when comparing the DPv values of the alkaline extracted unrefined and refined pulps (Fig. 7(a)).

Fig. 7. (a) Effect of refining and soda concentration on the degree of polymerization (DPv) determined by the capillary viscosity in CED. (b) Molecular weight distribution profile of starting pulp without any treatment (reference pulp), after simultaneous refining-6% CCE (Simul-R-6% CCE), unrefined pulp with 10% CCE (UR-10% CCE), and refined pulp with 10% CCE (R-10% CCE)

As shown in Fig. 7(b), the molecular weight distribution (MWD) profile for the starting pulp was remarkably different from pulps treated by refining and CCE. The disappearance of the small peak (which signals hemicellulose loss) to form a unimodal distribution agrees with what has been reported. The simultaneous refining-CCE presented the best profile (narrow MWD), which fully satisfies the dissolving pulp requirement. The shift from the high molecular weight region to the center indicates a slight degradation of long cellulose chains when simultaneous refining-CCE treatment is performed. The change in DPv with refining and molecular weight could facilitate the dissolution of the cellulose obtained from this process.

CONCLUSIONS

- The importance of mechanical refining with the laboratory Hollander beater in producing high purity pulp from paper grade pulp was illustrated in this study. The study showed that fiber morphology could be influenced by controlling the refining load, which corresponds to the xylan extraction performance. Structural modifications included increased water retention values (WRV), specific surface area (SSA), and fiber cutting. These were associated with mechanical refining with the Hollander beater, especially at a loading of 4.5 kg. Such refining was shown to facilitate the extraction of residual xylan from the pulp by cold caustic extraction (CCE) and xylanase treatment.

- A new approach consisting of a one-pot simultaneous refining and the cold caustic extraction process was introduced, leading to 79% xylan removal and a narrower molecular weight distribution (MWD) profile. The performance of the novel approach could be attributed to the treatment mechanism, which involves exposing new surfaces during refining in an alkaline environment. Such treatment promotes rapid penetration of the chemical into the difficult-to-reach area of the fiber wall, thereby improving mass transfer. Therefore, with this treatment, a low alkaline load of (6% NaOH) achieved a xylan removal capacity similar to performing a sequential treatment (refining prior to CCE) at a higher alkaline load (10% NaOH).

- The coupling of mechanical refining with xylanase treatment followed by alkaline extraction (6% NaOH) resulted in a pulp of high purity that satisfies the hemicellulose requirement for dissolving pulp (≤ 5%). The advantage of xylan extraction at low alkali load is that it saves chemical consumption, and secondly, it prevents the challenges associated with reactivity due to cellulose II.

ACKNOWLEDGMENTS

This research was made possible thanks to the facilities of the TekLiCell platform funded by the Région Rhône-Alpes (ERDF: European regional development fund) with support from Glyco@Alps.

REFERENCES CITED

Abitz, P., and Luner, P. (1989). “The effect of refining on wet fiber flexibility and its relationship to sheet properties,” in: Transactions of the 9th Fundamental Research Symposium, Cambridge, UK, pp. 67-86. DOI: 10.15376/frc.1989.1.67.THE

Arnoul-Jarriault, B., Lachenal, D., Chirat, C., and Heux, L. (2014). “Upgrading softwood bleached kraft pulp to dissolving pulp by cold caustic treatment and acid-hot caustic treatment,” Industrial Crops & Products 65, 565-571. DOI: 10.1016/j.indcrop.2014.09.051

Cherubini, F. (2010). “The biorefinery concept: Using biomass instead of oil for producing energy and chemicals,” Energy Conversion and Management 51(7), 1412-1421. DOI: 10.1016/j.enconman.2010.01.015

Curmi, H., Chirat, C., Brochier Salon, M. C., and Lachenal, D. (2018). “Effect of autohydrolysis on alkaline delignification of mixed hardwood chips and on lignin structure,” Holzforschung 72(8), 631-636. DOI: 10.1515/hf-2017-0196

Dhiman, S. S., Sharma, J., and Battan, B. (2008). “Industrial applications and future prospects of microbial xylanases: A review,” BioResources 3(4), 1377-1402. DOI: 10.15376/biores.3.4.1377-1402

Dinand, E., Vignon, M., Chanzy, H., and Heux, L. (2002). “Mercerization of primary wall cellulose and its implication for the conversion of cellulose I → cellulose II,” Cellulose 9(1), 7-18. DOI: 10.1023/A:1015877021688

Dou, X., and Tang, Y. (2017). “The influence of cold caustic extraction on the purity, accessibility and reactivity of dissolving-grade pulp,” ChemistrySelect 2(35), 11462-11468. DOI: 10.1002/slct.201701551

Duan, C., Li, J., and Ma, X. (2015). “Comparison of acid sulfite ( AS ) – and prehydrolysis kraft ( PHK )-based dissolving pulps,” Cellulose 22, 4017-4026. DOI: 10.1007/s10570-015-0781-1

Duan, C., Verma, S. K., Li, J., Ma, X., and Ni, Y. (2015). “Combination of mechanical, alkaline and enzymatic treatments to upgrade paper-grade pulp to dissolving pulp with high reactivity,” Bioresource Technology 200, 458-463. DOI: 10.1016/j.biortech.2015.10.067

Dupont, A. (2003). “Cellulose in lithium chloride / N,N-dimethylacetamide optimisation of a dissolution method using paper substrates and stability of the solutions,” Cellulose 44, 4117-4126. DOI: 10.1016/S0032-3861(03)00398-7

Friebel, C., Bischof, R. H., Schild, G., Fackler, K., and Gebauer, I. (2019). “Effects of caustic extraction on properties of viscose grade dissolving pulp,” Processes 7(3), 122. DOI: 10.3390/pr7030122

Gehmayr, V., Potthast, A., and Sixta, H. (2012). “Reactivity of dissolving pulps modified by TEMPO-mediated oxidation reactivity of dissolving pulps modified by TEMPO-mediated oxidation,” Cellulose 19, 1125-1134. DOI: 10.1007/s10570-012-9729-x

Gehmayr, V., Schild, G., and Sixta, H. (2011). “A precise study on the feasibility of enzyme treatments of a kraft pulp for viscose application,” Cellulose 18, 479-491. DOI: 10.1007/s10570-010-9483-x

Gharehkhani, S., Sadeghinezhad, E., Kazi, S. N., Yarmand, H., Badarudin, A., Safaei, M. R., and Zubir, M. N. M. (2015). “Basic effects of pulp refining on fiber properties – A review,” Carbohydrate Polymers 115, 785-803. DOI: 10.1016/j.carbpol.2014.08.047

Gong, C., Shi, Y., Ni, J., Yang, X., Liu, Y., and Tian, C. (2017). “Integration of hemicellulose recovery and cold caustic extraction in upgrading a paper-grade bleached kraft pulp to a dissolving grade,” Journal of Bioresources and Bioproducts 2(1), 20-23. DOI: 10.21967/jbb.v2i1.103

Hakala, T. K., Kamppuri, T., Gro, S., Ha, T., Liitia, T., Vehvila, M., Maloney, T., and Suurna, A. (2014). “Fibre porosity development of dissolving pulp during mechanical and enzymatic processing,” Cellulose 21, 3667-3676. DOI: 10.1007/s10570-014-0352-x

Hutterer, A. C., Kliba, G., Punz, M., Fackler, K., and Potthast, A. (2017). “Enzymatic pulp upgrade for producing high-value cellulose out of a kraft paper pulp,” Enzyme and Microbial Technology 102, 67-73. DOI: 10.1016/j.enzmictec.2017.03.014

Hutterer, C., Schild, G., and Potthast, A. (2016). “A precise study on effects that trigger alkaline hemicellulose extraction efficiency,” Bioresource Technology 214, 460-467. DOI: 10.1016/j.biortech.2016.04.114

Ibarra, D., Larsson, P. T., and Ek, M. (2009). “Optimization of treatments for the conversion of eucalyptus kraft pulp,” Polymers from Renewable Resources 1(1), 17-34. DOI: 10.1177/204124791000100102

Kerekes, R. J. (2005). “Characterizing refining action in PFI mills,” Tappi Journal 4(3), 9-14.

Kim, C. H., Lee, J., Treasure, T., Skotty, J., Floyd, T., Kelley, S. S., and Park, S. (2019). “Alkaline extraction and characterization of residual hemicellulose in dissolving pulp,” Cellulose 26, 1323-1333. DOI: 10.1007/s10570-018-2137-0

Köpcke, V. (2008). Improvement on Cellulose Accessibility and Reactivity of Different Wood Pulps, Licentiate Thesis, KTH Royal Institute of Technology, Stockholm.

Köpcke, V. (2010). Conversion of Wood and Non-wood Paper- grade Pulps to Dissolving-grade Pulps, Ph.D. Dissertation, KTH Royal Institute of Technology, Stockholm.

Köpcke, V., Ibarra, D., and Ek, M. (2008). “Increasing accessibility and reactivity of paper grade pulp by enzymatic treatment for use as dissolving pulp,” Nordic Pulp & Paper Research Journal 23(4), 363-368.

Kumar, H., and Christopher, L. P. (2017). “Recent trends and developments in dissolving pulp production and application,” Cellulose 24, 2347-2365. DOI: 10.1007/s10570-017-1285-y

Li, J., Hu, H., Li, H., Huang, L., Chen, L., and Ni, Y. (2017). “Kinetics and mechanism of hemicelluloses removal from cellulosic fibers during the cold caustic extraction process,” Bioresource Technology 234, 61-66. DOI: 10.1016/j.biortech.2017.03.026

Li, J., Liu, Y., Duan, C., Zhang, H., and Ni, Y. (2015). “Mechanical pretreatment improving hemicelluloses removal from cellulosic fibers during cold caustic extraction,” Bioresource Technology 192, 501-506. DOI: 10.1016/j.biortech.2015.06.011

Li, J., Ma, X., and Duan, C. (2016). “Enhanced removal of hemicelluloses from cellulosic fibers by poly ( ethylene glycol ) during alkali treatment,” Cellulose 23, (1) 231-238. DOI: 10.1007/s10570-015-0800-2

Motamedian, H. R., Halilovic, A. E., and Kulachenko, A. (2019). “Mechanisms of strength and stiffness improvement of paper after PFI refining with a focus on the effect of fines,” Cellulose 26, 4099-4124. DOI: 10.1007/s10570-019-02349-5

Pinto, P. C., Evtuguin, D. V, and Neto, C. P. (2005). “Structure of hardwood glucuronoxylans: Modifications and impact on pulp retention during wood kraft pulping,” Carbohydrate Polymers 60(4), 489-497. DOI: 10.1016/j.carbpol.2005.03.001

Roux, J., Bloch, J., and Olejnik, K. (2017). “Refining impulse controls the morphological modifications of fibers,” in: Transactions of the XVIth Fundamental Research Symposium, Oxford, UK, pp. 175-194. DOI: 10.15376/frc.2017.1.175

Sixta, H. (ed.) (2006). Handbook of Pulp, Wiley‐VCH Verlag, Weinheim, Germany. DOI: 10.1002/9783527619887

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D., and Crocker, D. (2008). Determination of Structural Carbohydrates and Lignin in Biomass (NREL/TP-510-42618), National Renewable Energy Laboratory, Golden, CO, USA.

Stoklosa, R. J., and Hodge, D. B. (2012). “Extraction, recovery, and characterization of hardwood and grass hemicelluloses for integration into biorefining processes,” Industrial and Engineering Chemistry Research 51(34), 11045-11053. DOI: 10.1021/ie301260w

TAPPI T230 om-13 (2013) “Viscosity of pulp (capillary viscometer method),” TAPPI Press, Atlanta, GA.

Tian, C., Zheng, L., Miao, Q., Cao, C., and Ni, Y. (2014). “Improving the reactivity of kraft-based dissolving pulp for viscose rayon production by mechanical treatments,” Cellulose 21(5), 3647-3654. DOI: 10.1007/s10570-014-0332-1

Zhao, L., Yuan, Z., Kapu, N. S., Chang, X. F., Beatson, R., Trajano, H. L., and Martinez, D. M. (2017). “Increasing efficiency of enzymatic hemicellulose removal from bamboo for production of high-grade dissolving pulp,” Bioresource Technology 223, 40-46. DOI: 10.1016/j.biortech.2016.10.034

Zhou, S., Li, Y., Huang, L., Chen, L., and Miao, Q. (2018). “Enhanced reactivity of kraft-based viscose-grade dissolving pulp by Hollander beating treatment,” BioResources 13(2), 2861-2870. DOI: 10.15376/biores.13.2.2861-2870

Article submitted: October 9, 2021; Peer review completed: December 5, 2021; Revised version received and accepted: December 6, 2021; Published: December 13, 2021.

DOI: 10.15376/biores.17.1.908-921