Abstract

To predict the resin absorbing content of bamboo bundle fiber, a model relating to the soaking time and mass ratio of polyvinyl acetate (PVAC) adhesive to phenol formaldehyde (PF) resin defined on the basis of the Lucas-Washburn equation was proposed. Various dipping times and different PVAC/PF ratios were investigated in the experiment. Variance analysis revealed that the resin absorbing content was significantly associated with the ratio of PVAC/PF. However, the soaking time had a significant effect on bamboo fiber resin absorbing content from 0 s to 70 s and had an insignificant effect after 70 s. The results showed that the model proposed could accurately predict the resin absorbing content for bamboo bundle fiber impregnated in different PVAC/PF levels. The comparison of theoretical calculations with experimental results revealed that the residual sum of square and root mean squared error were relatively low, and the correlation coefficients and coefficients of determination were all over 0.95.

Download PDF

Full Article

Large-span Bamboo Fiber-based Composites, Part I: A Prediction Model based on the Lucas-Washburn Equation Describing the Resin Content of Bamboo Fiber Impregnated with Different PVAC/PF Concentrations

Haidong Li, Fuming Chen,* Haitao Cheng,* Jianchao Deng, Ge Wang, and Fengbo Sun

To predict the resin absorbing content of bamboo bundle fiber, a model relating to the soaking time and mass ratio of polyvinyl acetate (PVAC) adhesive to phenol formaldehyde (PF) resin defined on the basis of the Lucas-Washburn equation was proposed. Various dipping times and different PVAC/PF ratios were investigated in the experiment. Variance analysis revealed that the resin absorbing content was significantly associated with the ratio of PVAC/PF. However, the soaking time had a significant effect on bamboo fiber resin absorbing content from 0 s to 70 s and had an insignificant effect after 70 s. The results showed that the model proposed could accurately predict the resin absorbing content for bamboo bundle fiber impregnated in different PVAC/PF levels. The comparison of theoretical calculations with experimental results revealed that the residual sum of square and root mean squared error were relatively low, and the correlation coefficients and coefficients of determination were all over 0.95.

Keywords: Bamboo bundle fiber; Lucas-Washburn equation; Soaking time; PVA C/PF mass ratio

Contact information: International Centre for Bamboo and Rattan, Beijing, P.R. China, 100102;

* Corresponding authors: chenfuming1985@126.com; htcheng@icbr.ac.cn

INTRODUCTION

Bamboo, as a fast growing and renewable natural resource, has been exploited by humans for thousands of years. Due to its high strength and stiffness, bamboo-based composites, as a new type of engineering structure material have been widely applied in bridges and construction. The application of bamboo in modern structures was considered to be a new breakthrough in the civil engineering field (Xiao et al. 2009). Consequently, some new types of bamboo-based composite construction materials have been extensively promoted in China, such as reconstituted bamboo lumber (RBL), glue-laminated bamboo (GluBam), and bamboo-bundle laminated veneer lumber (BLVL) (Xiao et al. 2008; Yu 2011; Yu et al. 2012). Especially for BLVL, more than 90% of bamboo can be utilized; furthermore, high mechanical properties, superior stability, and uniformity can be obtained at the same time (Chen et al. 2013a; Jiang et al. 2013; Chen et al.2014).

Recently, the demand for long-span building materials has been increasing with the increasing construction of environmentally sustainable buildings (Zhang et al. 2014). In China, many companies do not possess large hot press machines, which largely hampers development of the domestic bamboo industry. Fortunately, this problem has been solved by researchers at the International Centre for Bamboo and Rattan (ICBR). A new technology, named intermittent cold-hot-cold pressing technology, has been proposed to manufacture long-span bamboo engineering materials. This approach mainly includes two steps: one is prepress densification technology and the other is re-hot pressing (Chen et al. 2013b). By dipping a mixture of polyvinyl acetate (PVAC) and phenol formaldehyde (PF) resin, the PVAC/PF resin attaches to the surface of bamboo fiber and the board prepressing process can be realized. The prepress technology mainly determines the quality of large span BLVL products. Therefore, it is essential to investigate the effect of prepress densification technology on the properties of BLVL. Attention should be especially focused on the key technical parameter of the resin absorbing content of bamboo bundle fiber.

Bamboo-bundle laminated veneer lumber (BLVL) could function as indoor beams and outdoor wall material because of its superior weathering ability and mechanical properties obtained from the PF resin and manufacturing process. PF resin is a type of thermosetting resin, while polyvinyl acetate (PVAC) resin is a thermoplastic adhesive that is sensitive to moisture and temperature. To achieve preprocessing densification technology, a mixture of PF and PVAC resin was adopted. However, as the PVAC/PF ratio increased, the weather resistant property of BLVL decreased. If the added content of PVAC was low for bamboo fiber, the bonding performance of preprocessing densification board would be weakened. Therefore, a reasonable adding ratio of PVAC plays an important role in preprocessing densification technology.

Many studies have focused on impregnation characteristics, physical, and mechanical properties of bamboo-based composites with different resin impregnations (Meng et al. 2011; Ren et al. 2012; Feng et al. 2013). However, only a limited number of studies have been conducted on theoretical models for predicting the absorbing content of mixture of PF resin and PVAC resin for bamboo bundle fiber.

Bamboo bundle fiber can be considered a porous medium, and the process of resin impregnation can be assumed to involve a capillary action in porous media. Capillary rise in porous media has been studied for many years, since the pioneering work of Washburn (Washburn 1921). The theory plays an important role in many industrial and environmental applications including oil recovery, the manufacture of surface coatings, water distribution in soil substrates, the printing of paper, the application of fluid-based paints and lacquers, and the wicking of fibrous materials (Gane et al. 2004). However, limited studies have been conducted that investigate how the Lucas-Washburn equation applies to bamboo bundle fiber absorption.

The objectives of this study were as follows: (1) to model resin absorbing content of bamboo bundle fiber as a function of time and PVAC ratio; and (2) to validate the fitting model by comparing theoretical predictions with experimental results.

EXPERIMENTAL

Materials

Bamboo bundle

Three- to four-year-old Cizhu bamboo (Neosinocalamus affinis) was obtained from Yibin, Sichuan Province, China. Upon arrival at the International Centre for Bamboo and Rattan (ICBR), the bamboo tubes were first split into four pieces of approximately the same size and the bamboo nodes were removed with a hatchet. Then, the bamboo chips were broomed and rolled into a loosely laminated reticulate sheet by an untwining machine. The bamboo bundle sheet used in this study was nearly similar in thickness (about 4 to 5 mm), maintaining the original bamboo fiber arrangement. The bamboo bundle sheets were cut to 300 mm in length, and then air-dried to a moisture content (MC) within the range 10% to 12%. All research was conducted in a key laboratory under permit from the state forestry administration.

Adhesive

Phenol-formaldehyde resin (PF) with thermosetting properties was provided by Taier (Dynea) Corporation (Beijing, China). The solid content of the resin was 45.53%, and the pH value was 10.5. The viscosity of the PF resin was 48 mPa·s.

A commercial polyvinyl acetate emulsion adhesive (PVAC) was obtained from the Hangao Corporation (Shanghai, China). The solid content of the adhesive was 27.25% and the viscosity was 14.2 mPa·s.

Methods

Two plastic containers were used to dilute the PF resin and PVAC adhesive to an appropriate solid content. The two adhesives were mixed fully with a blender. A basin with mesh on the bottom was used, so the redundant adhesive could discharge timely through the mesh. Time and weights were measured using a timer and electronic balance, respectively.

The PF resin and PVAC adhesive were diluted with water to a solids content of 17%. Then the diluted PF resin and PVAC adhesive were mixed with mass ratios of 2:1, 4:1, 6:1, 8:1, 10:1, and 14:1. Pure PF resin served as the control. A blender was used to blend the different level of PVAC/PF mixture uniformly. For convenience, the mixture of PF resin and PVAC adhesive was abbreviated as PVAC/PF.

Before the bamboo bundle was immersed in PVAC/PF, the weight of the cut pieces was measured. The soaking times were 5, 25, 60, 180, 300, 420, 540, and 660 s. Each impregnated bamboo bundle was then moved to a basin containing mesh. In addition, in order to ensure the adhesive did not drip from the bamboo bundle, the impregnating pieces were vertically positioned on the basin for about 10 min. The weight of the impregnated bamboo bundle was recorded again. Each treatment was repeated 10 times, and the resin absorbing content of bamboo bundle fiber was calculated in Eq. 1,

(1)

where W is the resin absorbing content of bamboo bundle fiber; MR is the weight of the impregnated bamboo bundle; m is the weight of the bamboo bundle before impregnation; n is the solid content of the PF/PVAC mixture; and a is the moisture content (MC) of the bamboo bundle before impregnation. The impregnation process for bamboo bundle fiber with PF/PVAC resin is shown in Fig. 1.

The Theoretical Basis

After the vascular bundle and parenchyma cells of bamboo bundle fiber had been separated, a large amount of tiny pores and cracks was generated in the surface and inside of cellulose. In this case, the water-soluble adhesive could infiltrate, permeate, and spread through the cracks with nanoscale sizes, pits, microcapillaries, and large capillaries composed of fibers, vessels, and intercellular space. In an ideal situation, when the adhesive molecules move through the capillary and other porous materials either horizontally or vertically, the major determinant of the dynamic is capillary pressure. The capillary pressure can be described by the Laplace equation (Miller and Young 1975; Hsieh and Yu 1992; Adamson and Gast 1997) in Eq. 2,

![]() (2)

(2)

where P is the capillary pressure; is the surface tension of the liquid and θ is the contact angle between the liquid and the capillary wall; R is the capillary radius.

Fig. 1. Impregnation process for bamboo bundle fiber with PF/PVAC resin. (a) Glue preparation, (b) blending, (c) dipping, and (d) drying

The pioneering work of Lucas (1918) and Washburn (1921) proposed a commonly used equation that is the theory of liquids in capillary, and is usually described by the Lucas-Washburn equation (Zhmud et al. 2000; Schoelkopf et al. 2002; Dimitrov et al. 2009),

(3)

where L is the length of liquid penetration in a straight-line capillary and t is the permeation time and the viscosity.

It is unusually complicated to model the bamboo bundle porous systems in detail. To characterize the system, an assumption was made that the contact angle did not change during the imbibition process, and bamboo bundle fiber was modeled as a bundle of uniform capillaries. Thus, the resin absorbing content of bamboo bundle fiber per unit area can be described as follows,

(4)

where M is the resin absorbing content of bamboo bundle fiber per unit area; N is the number of bamboo bundle fibers per unit area; D is the equivalent radius of bamboo bundle fiber; Vr andVf are the volume fraction of capillary tube and bamboo bundle fiber respectively. Moreover, Vr is defined as: Vr=1-Vf. Substituting Eq. 3 into Eq. 4, one obtains:

(5)

The volume fraction of bamboo bundle fiber is defined as Vf, and the bamboo bundle fiber capillary radius as Rf. The bamboo bundle fibers were also assumed as a bundle of uniform capillaries. Therefore, the equivalent radius of a single capillary is assumed to be:

(6)

Substituting Eq. 6 in Eq. 5 yields,

(7)

where α is the viscosity coefficient of PF/PVAC mixture; α has a linear relationship with c, and c is defined as the mass ratio coefficient of the PF resin with PVAC adhesive.

Hence, Eq. 7 can be simplified as:

(8)

For better calculation, it was assumed that the weight of the single bamboo bundle fibers was m, the resin absorbing content was mr, and the solid content of the mixture was n. The resin absorbing content of bamboo bundle fiber should satisfy the following equation:

(9)

The solid content of the mixture (i.e., n) has a relationship with the mass ratio coefficient of the PF/PVAC mixture (i.e., c). Therefore, it was assumed that the PF/PVAC mixture had been mixed well and the bamboo bundle fibers had been soaked evenly. Therefore, the resin absorbing content of the single bamboo bundle fibers can be used for calculating that of the whole bamboo bundle fibers. The m and n are constants, which can be defined as follows:

(10)

Finally, the resin absorbing content of bamboo bundle fiber was defined as the revised Lucas-Washburn equation and was therefore calculated as,

(11)

where W is the resin absorbing content of bamboo bundle fiber and Q is the parameter of the mass ratio coefficient of the PF resin with PVAC adhesive.

The Lucas-Washburn equation (Lucas 1918; Washburn 1921) is widely utilized in wicking kinetics for predicting the relationship between saturated zone wicking lengths and wicking time. However, the Lucas-Washburn equation is not accurate if the unsaturated zone is taken into account. This is due to the humidity effects of porous media and the lock-in effects during the process of capillary rise of a liquid. Researchers have different opinions about the parameter of permeation time. The study of Laughlin and Davies (1961) on the capillary absorption in fibrous textile wicking indicated that the parameter of permeation time is less than 0.5. In this study the coefficient of viscosity of the PF/PVAC mixture has been changed, because of different PF/PVAC mixture ratio. Hence, the parameter of permeation time has been changed, and Eq. 12 was found to approximate this situation,

(12)

where W is the resin absorbing content of bamboo bundle fiber; Q is the parameter of the mass ratio coefficient of the PF resin with PVAC adhesive; is the parameter of permeation time; however Q and

are variable and have a relationship with the ratio of PF/PVAC mixture.

Statistics

Data were analyzed by a one-way analysis of variance (ANOVA) with the Duncan test using SPSS 18 software (SPSS, Inc., Chicago, IL). Probability values of less than 5% were considered to be significant. Nonlinear fitting was applied by 1stOpt software (7D-SoftHigh Technology Inc.; Beijing, China) and graphs were drawn by origin 8.0 software (Originlab Corp.; Northampton, MA).

RESULTS AND DISCUSSION

The resins absorbing content vs. time for bamboo bundle fiber under different mass ratio curves is shown in Fig. 2, and the statistical analysis of resin absorbing content by different adding mass of PVAC is summarized in Table 1.

Fig. 2. Relationship between resin absorbing content and permeation time for bamboo bundle fiber with various mass ratios of PVAC/PF

As shown in Fig. 2, over the time 0 to 70 s, the curves of resin absorbing content vs. time for bamboo bundle fibers impregnated with different PVAC/PF levels generally agreed with the Lucas-Washburn equation. From 70 to 300 s, the rate of resin absorbed by bamboo fiber increased gradually. At the time 300 to 420 s, the resin absorbing content reached a peak, whereas after 420 s the resin absorbing content leveled off. Therefore, we recommend the permeation time of 6 min to 7 min in future work. The impregnation time of resin was consistent with a previous study by Chen et al. (2014). According to the parallel contrast between experimental and control groups, the resin absorbing content of bamboo bundle fiber increased with adding ratio of PVAC/PF showing a “step” increase trend. This could be partly due to an increase in the proportion of the PVAC adhesive. After the PVAC adhesive had been mixed into PF resin, the viscosity of PF resin was decreased because the PVAC adhesive had lower viscosity. The addition of PVAC would lead to greater decrease of PF resin viscosity. When the viscosity of the resin decreases, the length of liquid penetration would increase easily at a certain time according to Eq. 3.

Table 1. Statistical Analysis of Resin Absorbing Content by Different Adding Weight of PVAC

Table 1 shows that the resin absorbing content of bamboo bundle fiber increased with the extension of time and the added ratio of PVAC/PF. Variance analysis showed that the resin absorbing content increased significantly compared with the control groups. Moreover, multiple comparison analysis showed that the adding ratios of 1/14 and 1/10, 1/10 and 1/8, 1/6 and 1/4 could be divided into the same subset, respectively. The adding ratio of 1/2 for resin absorption content was regarded as a separate subset. In the same subset, the resin absorption content for a different level of PVAC/PF could be replaced. Soaking times of 60, 180, 300, and 420 s; 180, 300, 420, and 540 s; and 300, 420, 540, and 660 s could be placed in the same subsets. Therefore, the resin content of bamboo fiber for the above subset groups was statistical equal. The resin absorbed content for the groups of 5 and 25 s was insignificant, as shown by analysis of the data in Table 1. The overall trend of the statistical results indicates that the resin absorbing content of bamboo fiber may vary significantly with PVAC ratio. In contrast, the soaking time had a significant effect on bamboo fiber resin absorbing content from 0 s to 70 s, while an insignificant effect after 70 s.

Modeling for Predicting Resin Absorbing Content

Nonlinear fitting was applied by software using Eq. 12. Seven curves with high degrees of fit were obtained by an optimization algorithm combining Levenberg-Marquardt (Zhang and Geng 2009) with Universal Global Optimization (Yuan and He 2010) (Fig. 3). In addition, the parameter of the mass ratio coefficient of the PF resin with PVAC adhesive (Q) and the parameter of permeation time () were obtained (Table 2).

Fig. 3. Fitting curves of the relationship between resin absorbing content and permeation time for bamboo bundle fiber with various mass ratios of PVAC/PF

According to Table 2, the low value of root mean squared error (RMSE) of the fitting equation indicated that the errors between actual values and fitted values were relatively low. Moreover, the residual sum of square (SSE) was also low, and the correlation coefficient and the coefficient of determination for fitting equation were over all 0.95. This suggests that the fitting model for the bamboo fiber impregnated in the mixture of PVAC/PF had relatively high precision.

Table 2. Statistical Analysis of Absorbing Resin Content with Different PVAC Adding Levels

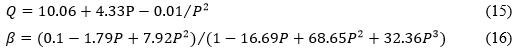

According to the data shown in Table 2, a model for a relationship between the parameter of mass ratio coefficient (Q) and the mass ratio (P) was established (Fig. 4). In Fig. 4, as the mass ratio (P) increased, there was an upward trend in the parameter of mass ratio coefficient (Q). The fitted equation was as follows,

y=p1+p2*x+p3/x2 (13)

where p1 = 10.06, p2 = 4.33, and p3 = -0.01.

When the model parameters values were used, the root mean square error (RMSE) of nonlinear fitting had a minimum value. The 3-D contour plots of response value between RMSE and fitting parameters are shown in Fig. 5. Residual sum of squares (SSE) was low, and the correlation coefficient (R) and the coefficient of determination (R2) were more than 0.995 for the fitted model, shown in Fig. 5. These demonstrated that the model was suitable for modelling the variance of resin absorption.

Fig. 4. Fitting curve of the relationship between the mass ratio of PVAC/PF (P) and parameter of mass ratio coefficient (Q)

Fig. 5. 3-D contour plots of response value between RMSE and fitting parameters

Similarly, as shown in Fig. 6, a model for the relation between the parameter of permeation time () and the mass ratio (P) was established. The fitted equation was:

y = (p1+p3*x+p5*x2)/ (1+p2*x+p4*x2+p6*x3) (14)

where p1 = 0.10, p2 = -16.69, p3 = -1.79, p4 = 68.65, p5 = 7.92, and p6 = 32.36.

When the model parameters values were used, the root mean square error (RMSE) of nonlinear fitting and the residual sum of square (SSE) were low. In addition, the correlation coefficient (R) and the coefficient of determination (R2) were above 0.999. This indicated that the analog effect of the model was reliable and performed to a higher fitting degree. In contrast with the mass ratio coefficient (Q), the relationship between the mass ratio (P) and the parameter of permeation time () was not obvious.

Fig. 6. Fitting curve of the relationship between the adding ratio of PVAC (P) and parameter of permeation time (β)

By statistical analysis of the above-mentioned data, the relationship between P vs. Q, and P vs. was defined as follows:

Substituting Eq. 15 and Eq. 16 into Eq. 12, and taking the logarithm of both sides gives,

(17)

where W is the resin absorbing content of bamboo bundle fiber, tis the permeation time, and P is the mass ratio of PVAC adhesive to PF resin.

CONCLUSIONS

- The model provided a very good predictor of the resin absorbing content of bamboo fiber impregnated in different level of PVAC/PF ratios, and the model can be used in practice.

- The relationship between resin absorbing content and soaking time for bamboo bundle fiber was studied by adding different ratios of PVAC/PF. It was found that the soaking time has a significant effect on bamboo fiber resin absorbing content from 0 s to 70 s, while an insignificant effect after 70 s. The resin absorbing content of bamboo bundle fiber increased with an additional ratio of PVAC/PF showing a “step” increase trend.

- The permeation time should be confirmed as 6 to 7 min in future experiments.

ACKNOWLEDGMENTS

The financial support by the National Forestry Public Welfare Scientific Research Program (201204701) and the Fundamental Research Funds for the International Centre for Bamboo and Rattan (1632013001), which made this research possible, is gratefully acknowledged. The constructive comments from the anonymous reviewers are also greatly appreciated.

REFERENCES CITED

Adamson, A. W., and Gast, A. P. (1997). Physical Chemistry of Surfaces, Wiley-InterScience, Hoboken, NJ.

Chen, F. M., Jiang, Z. H., Wang, G., Shi, S. Q., and Liu, X. E. (2013a). “Bamboo bundle corrugated laminated composites (BCLC). Part I. Three-dimensional stability in response to corrugating effect,” The Journal of Adhesion 89(3), 225-238.

Chen, F. M., Zhang, D., and Wang, G. (2013b). “Prepress densification technology for manufactured bamboo bundle laminated veneer lumber and its properties,” China Forest Products Industry 40(5), 52-54.

Chen, F. M., Deng, J. C., Jiang, Z. H., Wang, G., Zhang, D., Zhao, Q. C., Cai, L. P., and Shi, Q. S. (2014). “Evaluation of the uniformity of density and mechanical properties of bamboo-bundle laminated veneer lumber (BLVL),” BioResources 9(1), 554-565.

Dimitrov, D. I., Milchev, A., and Binder, K. (2009). “Capillary rise in nanotubes coated with polymer brushes,” Annals of the New York Academy of Sciences 1161(1), 537-548.

Feng, M. Z., Zhao, R. L., Gao, L., and Zhang, S. B. (2013). “Influence of resin contents on properties of silver ply bamboo,” China Wood Industry 27(3), 54-56.

Gane, P. A., Ridgway, C. J., and Schoelkopf, J. (2004). “Absorption rate and volume dependency on the complexity of porous network structures,” Transport in Porous Media 54(1), 79-106.

Hsieh, Y. L., and Yu, B. (1992). “Liquid wetting, transport, and retention properties of fibrous assemblies: Part I: Water wetting properties of woven fabrics and their constituent single fibers,” Textile Research Journal 62(11), 677-685.

Jiang, Z. H., Chen, F. M., Wang, G., Liu, X. E., Shi, Q. S., and Yu, Z. X. (2013). “Bamboo bundle corrugated laminated composites (BCLC). Part II. Damage analysis under low velocity impact loading,” BioResources 8(1), 923-932.

Laughlin, R. D., and Davies, J. E. (1961). “Some aspects of capillary absorption in fibrous textile wicking,” Textile Research Journal 31(10), 904-910.

Lucas, R. (1918). “Ueber das Zeitgesetz des kapillaren Aufstiegs von Flüssigkeiten,” Colloid & Polymer Science 23(1), 15-22

Meng, F. D., Yu, Y. L., Zhu, R. X., Zhang, Y. H., and Yu, W. J. (2011). “Effect of resin impregnation rate on physical and mechanical properties of laminated bamboo fibrillated veneer lumber,” China Wood Industry 25(2), 1-3.

Miller, B., and Young, R. A. (1975). “Methodology for studying the wettability of filaments,” Textile Research Journal 45(5), 359-365.

Ren, Y. P., Wang, Z., Gao, L., and Guo, W. J. (2012). “Impregnation characteristics of 3 types of sympodial bamboo wools from Sichuan Province,” Journal of Fujian College of Forestry 32(4), 376-380.

Schoelkopf, J., Gane, P. A., Ridgway, C. J., and Matthews, G. P. (2002). “Practical observation of deviation from Lucas-Washburn scaling in porous media,” Colloids and Surfaces A: Physicochemical and Engineering Aspects 206(1), 445-454.

Washburn, E. W. (1921). “The dynamics of capillary flow,” Physical Review 17(3), 273-283.

Xiao, Y., Shan, B., Chen, G., Zhou, Q., and She, L. Y. (2008). “Development of a new type of glulam-GluBam,” Modern Bamboo Structures, CRC, London, 41-47.

Xiao, Y., Zhou, Q., and Shan, B. (2009). “Design and construction of modern bamboo bridges,” Journal of Bridge Engineering 15(5), 533-541.

Yu, W. J. (2011). “Development of bamboo-fiber based composites,” China Wood Industry 25(1), 6-8.

Yu, Z. X. (2012). Processing Technology of Laminated Bamboo-bundle Veneer Lumber and its Application Performance, Ph.D. Dissertation, Chinese Academy of Forestry, Beijing.

Yuan, W. P., and He, Z. X. (2010). “Application of global optimization based on 1stopt in tractor’s final transmission design” Tractor & Farm Transporter 37(6), 28-30.

Zhang, D., Wang, G., and Ren, W. H. (2014). “Effect of different veneer-joint forms and allocations on mechanical properties of bamboo-bundle laminated veneer lumber,” BioResources 9(2), 2689-2695.

Zhang, H. Y., and Geng, Z. (2009). “Novel interpretation for Levenberg-Marquardt algorithm,” Computer Engineering and Applications 45(19), 5-8.

Zhmud, B. V., Tiberg, F., and Hallstensson, K. (2000). “Dynamics of capillary rise,” Journal of Colloid and Interface Science 228(2), 263-269.

Article submitted: May 28, 2014; Peer review completed: August 17, 2014; Revised version received and accepted: August 26, 2014; Published: September 8, 2014.