Abstract

Structural performance of chemically modified oriented strand board (OSB) has drawn great attention from builders, home insurance companies, and panel manufacturers. This study was conducted to provide time-dependent creep and moisture change-induced mechano-sorptive (MS) effect data from borate-treated and randomly formed strand board. The strand boards were lab-fabricated with flakes from southern yellow pine and mixed hardwoods. Commercial liquid phenol-formaldehyde resin was used as the binder. The treatments involved in the study were one level of zinc borate, one level of calcium borate, and two species groups that included separate controls. The load level, equivalent to 25% of the static bending modulus of rupture, was selected as a long-term constant load. Creep at 65% constant relative humidity (RH) developed in a normal time-dependent fashion and the Burger body creep model with four spring-dashpot elements was found appropriate to predict the creep response of borate modified strand board. Noticeable influence of borate modification on the fractional deflection was demonstrated under changing RH for both the absorption and desorption cycles. The measured fractional deflection due to the MS effect followed a linear relationship with moisture content change. The established material constants for various strand boards provided a way to predict the structural performance of treated strand board under varying RH conditions.

Download PDF

Full Article

Mechano-sorptive Deformation of Borate Modified Strand Board for Structural Uses

Guangyao Li,a Xiuxuan Sun,b Sunyoung Lee,c,* and Qinglin Wu b,*

Structural performance of chemically modified oriented strand board (OSB) has drawn great attention from builders, home insurance companies, and panel manufacturers. This study was conducted to provide time-dependent creep and moisture change-induced mechano-sorptive (MS) effect data from borate-treated and randomly formed strand board. The strand boards were lab-fabricated with flakes from southern yellow pine and mixed hardwoods. Commercial liquid phenol-formaldehyde resin was used as the binder. The treatments involved in the study were one level of zinc borate, one level of calcium borate, and two species groups that included separate controls. The load level, equivalent to 25% of the static bending modulus of rupture, was selected as a long-term constant load. Creep at 65% constant relative humidity (RH) developed in a normal time-dependent fashion and the Burger body creep model with four spring-dashpot elements was found appropriate to predict the creep response of borate modified strand board. Noticeable influence of borate modification on the fractional deflection was demonstrated under changing RH for both the absorption and desorption cycles. The measured fractional deflection due to the MS effect followed a linear relationship with moisture content change. The established material constants for various strand boards provided a way to predict the structural performance of treated strand board under varying RH conditions.

Keywords: Borate; OSB; Southern pine; Mixed hardwood; Creep; Mechano-sorptive effect

Contact information: a: School of Engineering, Zhejiang Agriculture and Forestry University, Li An 311300, Zhejiang, China; b: School of Renewable Natural Resources, Louisiana State University Agricultural Center, Baton Rouge, LA 70803, USA; c: Department of Forest Products, Korea National Institute of Forest Science, Seoul, 130-712, Republic of Korea;

* Corresponding authors: wuqing@lsu.edu and nararawood@korea.kr

INTRODUCTION

The time-dependent creep behavior of oriented strand board (OSB) is well-documented (Price 1985; Leichti 1986; Lee et al. 1996). The results of creep studies of wood members have influenced the design specification for buildings made of wood. The current specification provides the creep factor for wood members under normal use conditions (Laufenberg and McNatt 1989). However, when OSB and waferboard are exposed to natural environmental conditions, they have shown much larger values of fractional creep deflection than the recommended creep factor for more than 10 years of service period, due to increased creep deformation under varying moisture contents, which is known as mechano-sorptive (MS) effect (Palka 1993). The mechano-sorption process in wood-based composites is currently not fully understood and causes some discrepancy between the predicted value and the observation.

The influence of moisture content (MC) change on wood creep properties has been recognized since the early 1960s (Armstrong and Christensen 1961; Ranta-Mannus 1975; Van der Put 1989; Wu and Milota 1995). There is a continued interest in providing experimental and theoretical understanding of the MS phenomena for wood and wood-based products (Montero et al. 2012; Ozyhar et al. 2013; Gril 2015; Jin et al. 2016; Pérez-Pena et al. 2016). The MS deformation of composite lumber, plywood, and OSB has been investigated (Szabo and Ifju 1970; Leicester 1971; Schaffer 1972; Yeh 1990; Fridley et al. 1992; Fridley and Tang 1992; Tang et al. 1997; Lee 1999). It is a complex phenomenon involving several factors, such as moisture, hygroscopic swelling, mechanical stress, and the variation of the viscoelastic response of the specimen as a function of time. The MS deformation does not recover by relaxation after loading due to the hysteresis that occurs under the wetting and drying cycle. Furthermore, the stress level varies even under a constant load, due to sample dimensional change under varying relative humidity (RH) conditions. Most MS deformation studies of structural lumber did not reflect the thickness swelling (TS) of specimens in their analysis (Ranta-Maunus 1975; Mukudai and Yata 1988; Hunt 1989; Fridley et al. 1992; Shen and Gupta 1997) due to small TS values. However, it was shown that the TS values of the MS deformation specimens in flatwise bending were not negligible compared with the values of actual MS deflection (Lee et al. 1996). Thus, the deflection that was increased by TS of wood-based composites with relatively large TS becomes significant under sufficiently long exposure to a high RH environment (Lee et al. 1996).

The structural performance of chemically modified oriented strand board (OSB) has attracted much interest from builders, home insurance companies, and structural panel manufacturers, especially for areas that are prone to natural disasters such as flooding and termites (Smith and Wu 2005; Xu et al. 2013). Powder borates are commonly used during OSB manufacturing for added biological protection. A study on the creep properties of chemically-treated solid wood was conducted by Norimoto et al. (1992) using spruce specimens. The chemically modified specimens had a higher MS deformation than that from the controls. However, the modification of OSB with powder-type borate should not necessarily lead to showing similar results. Thus, it is of importance to take an accurate assessment on the MS deflection of borate modified strandboard to provide a more dependable creep factor. The objective of this work is to study the influence of borate modification on creep and MS deformations of structural use strand boards under the combined effect of hygroscopic and mechanical loading.

EXPERIMENTAL

Materials, Board Fabrication, and Basic Analysis

Flakes with target size of 25.4 (width) x76.0 (length) x0.64 (thickness)-mm from wood blocks of nine Louisiana-grown species, i.e., cypress, red oak, hackberry, ash, white oak, pecan, black locust, willow, and southern pine, were fabricated. The obtained green flakes were dried using a cabinet dryer, and the dry flakes were used to make two types of strand boards, one with southern pine (SP) flakes only and the other with eight mixed hardwood (MH) species (of equal weight percentage). The boards were made with 4% commercial liquid phenol-formaldehyde resin (Neste Resins Corp. Dodson, LA), 1% wax emulsion (Neste Resins Corp. Dodson, LA), and two borate compounds (i.e., zinc and calcium borates designated as ZB and CB, respectively) for each panel type. These powder inorganic borates (US Borax Inc., Boron, CA) were pneumatically blown into the drum blender, while the resin and wax were sprayed with separate spray lines. Hand formed single-layer, randomly-oriented flake mats were made and hot-pressed to a dimension of 55.88 cm × 50.8 cm × 1.27 cm. The mats were pressed for 7 min at the maximum pressure of 1,171 MPa to the target thickness of 1.27 cm and platen temperatures were 200 C (Wu et al. 2009). After hot pressing, the boards were cooled down to room temperature and conditioned before testing.

A chemical analysis for determining actual borate loading was performed for each board by using wood powder with particle size smaller than 0.84 mm (20-mesh). Oven-dried wood flour (approximately 5 g) was placed in 100 mg of 2 N HNO3 solution and the mixture was boiled for 2 h at 100 °C (Lee et al. 2004). After the treatment, an Inductively Coupled Plasma spectrograph (Model 200 ICP-OES, PerkinElmer Corp, Waltham, MA) was used to analyze the liquid portion of the mixture. The boron percent in each sample was estimated using the measured boron concentration from the ICP analysis and the oven-dry weight of the wood particles used. The data was presented as BAE (i.e., boric acid equivalent, %).

Methods for Creep and MS Analysis

Determinations of the stress level

Four static bending specimens in the size of 45.72 cm × 7.62 cm ×1.27 cm that were cut from each type of the panels were randomly selected. The bending tests were performed to evaluate their bending modulus of rupture (MOR) according to the ASTM Standard D1037-12 (2006), under the concentrated load applied at the mid-point of the 40.64 cm span. The density and the MC of each specimen were measured before the static bending tests. Using the determined MOR values, the stress levels (SL) for the constant load creep testing were calculated based on the 25% of the static bending MOR for each of the groups (Table 1).

Creep and mechano-sorptive deformation measurement

The creep and MS deformation tests using four matched samples from each group were performed in a climate-controlled room with varied RHs at 25 °C (Fig. 1). Creep testing was first conducted at a constant RH of 65% to determine creep deformation (0 min to 23299 min), which was followed with RH changes from 65% to 95% until equilibrium MC (EMC) was achieved (up to 63882 min). The RH was returned to 65% until the specimen MC reached equilibrium (up to 81855 min) while samples were under the applied load. The creep under a constant RH and mechano-sorptive deformation from both the absorption and desorption cycles were determined.

A load frame shown schematically in Fig. 2a was used for all testing. Two steel pipes were used to support each sample (one at each end). A lead weight was loaded to each creep sample at the central point of the test span. Two linear variable differential transducers (LVDTs) were used to monitor the creep deflections of all samples. The positions of the LVDTs were calibrated against two reference plates prior to each creep deflection measurement. The signals of each LVDT were collected using an in-house designed Visual Basic program (Microsoft Corp, Redmond, WA)

Matched samples from each strand board group were used to follow the actual sample MC and thickness changes during testing. The samples were weighed and thickness measured in the test environment twice a day. The actual sample MCs of loaded specimens at the end of testing were measured using the oven dry method after the creep measurements were completed. Due to the thickness swelling (TS), a correction procedure on the measured deflection was made as shown in Fig. 2b.

Fig. 1. Temperature and relative humidity (RH) history used in the test

Fig. 2. Test setup with creep and MC monitoring using matched samples; a) Schematic of loading frame and b) Effect of TS on neutral plane position with ti and te as initial and end sample thicknesses

Fractional deflection and TS correction

The fractional deflection (FD) is defined as,

(1)

where Y(t) and Y(to) denote the creep deflection at time t (min) and to (taken to be one minute after the load was fully applied). As shown in Fig. 2b, the TS of the specimen made the neutral plane downshifted, because TS could only be measured in the downward direction due to the load applied from the top. The increase of the creep deflection due to the shift of the neutral plane of the specimen, as much as TS/2, was considered in the observed MS deformation. In the absorption stage, the MS deflection increased as the TS increased, while the opposite was true in the desorption stage. The measured TS data as a function of time for each sample group were used to correct the deflection data as described.

RESULTS AND DISCUSSION

Moisture Content and Fractional Deflection

Typical plots that show the moisture history and FD as a function of time under constant and changing RH conditions are shown in Fig. 3 for southern pine strand board and Fig. 4 for mixed hardwood strand board. Some of the key test data are summarized in Table 1. As shown, the entire tests included a creep run under a constant MC (8.5%) for 18 days, a wetting MS test for 28 days, and a drying MS test for 12.5 days under constant loading. The maximum average MC values of the test samples obtained from the wetting cycle were slightly higher from the mixed hardwood strand boards compared with these from the southern pine strand board. There was a noticeable moisture hysteresis after the RH returned to 65% during the desorption cycle (Wu 1999). The actual MC differences (dMCH as shown in Figs. 3 and 4) were 5.06%, 4.44%, and 5.33% for the southern pine group (control, ZB, and CB, respectively) and 4.32%, 4.34%, and 5.08% for the mixed hardwood group (control, ZB, and CB, respectively, as shown in Table 1).

Fractional deflection (FD) increased in a time-dependent manner during initial creep testing (Fig. 3b and Fig. 4b). During the absorption cycle, a large increase in FD was observed after RH change from 65% to 95% due to the MS effect. When the RH was reduced from 95% to 65% during the desorption cycle, FD had a continuously increased trend. This behavior agrees with those observed for wood under moisture cycling (Armstrong and Christensen 1961). The effect of borate treatment on FD for each strand board species group was clear. The CB-treated strand board had the largest FD values among the three groups for each species group.

Creep Properties under the 65% RH Condition

The creep of the modified strand board samples at 8.5% MC developed in an expected time-dependent style (Fig. 3b and Fig. 4b). The fractional deflections after the 18-day testing were 1.87, 1.90, and 1.89 for the SP control, SP 1.80% ZB, and SP 2.0% CB samples, respectively; and 1.67, 1.69, and 1.71 for the MH control, MH 1.75% ZB, and MH 2.05% CB (Table 1), respectively. Thus, the influence of borate type, borate loading, and wood species on creep seemed to be small due to the relatively short testing period and low applied loading level.

Fig. 3. Sample moisture content (a) and fractional deflection (b) of southern pine strand boards as a function of time. ZB-zinc borate, CB-calcium borate, and dMCH-moisture content differences were due to sorption hysteresis.

Fig. 4. Sample moisture content (a) and fractional deflection (b) of mixed hardwood strand board as a function of time. ZB-zinc borate, CB-calcium borate, and dMCH-moisture content differences were due to sorption hysteresis.

Table 1. Initial Properties, Stress Levels Applied, and Fractional Deflections of Various Strand Board Specimens at Different Test Stages

Notes: 1 Boric acid equivalent in percent; 2 Values in the parentheses are the standard deviation of each property based on four samples; 3 Applied stress level (SL) in flexure at the mid-span = 25% MOR; 4 Fractional deflection (FD) and moisture content (MC), A- End of the initial constant RH period (65%); B- End of absorption period (65% to > 95% RH); and C- End of desorption period (95% to > 65%)

Table 2. Creep Model Parameters of Four-element Burger Body Model for Strand Board Specimens Tested under 65% RH Condition

Notes: 1BAE (boric acid equivalent) levels, and 2CV (coefficients of variations = s/) of parameters

The four-element Burger model with springs and dashpots (e.g., Senft and Suddarth 1971) was used to fit the creep data. The model has the following form (Eq. 2),

(2)

where (t) is the creep strain (m/m) under constant load at elapsed time t (min), is the constant applied stress (MPa), Ke, Kk, k, and are, respectively, elastic constant of the Hookean spring, delayed elastic constant of the Kelvin body spring element, the viscoelastic constant of the Kelvin body dashpot, and the viscoelastic constant of the dashpot. For the modeling fitting, the obtained deflection data were reprocessed to calculate actual strains as in Eq. 3,

(3)

where, is the axial strain of the outermost layer in the sample (mm/mm), is the beam curvature (m), M denotes the bending moment applied (N m), EI represents the OSB specimen stiffness (MPa m4), and Y(t) is the deflection of bending (m) at a given time t (min). Table 2 shows the obtained model parameters. The model parameters were used to calculate creep deformation for various samples as a function of time, in separating creep from total deformation data for MS deformation calculations.

Mechano-sorptive Deformation under Varying RH Condition

Noticeable deflection occurred during testing when the MC of the test samples changed (Fig. 3b and Fig. 4b). The effect of borate modification on MS creep deflections was clear in both species groups. It implied that the long-term durability resistance of strand board was remarkably reduced by the borate addition. During the absorption cycle under the applied load (Fig. 3b and Fig. 4b), RH increased to 95%, bringing MC changes of 14.00%, 13.80%, and 15.71% for southern pine group (control, ZB, and CB, respectively); and 15.69%, 14.76%, and 15.64% for the mixed hardwood group (control, ZB, and CB, respectively). The percent increases of the creep deflections (deflection at the equilibrium MC of 95% RH/deflection before RH was increased to 95%) at the absorption process were 306.4%, 358.9%, and 484.1% for the southern pine group (control, ZB, and CB, respectively) and 331.1%, 395.3%, and 440.4% for the mixed hardwood group (control, ZB, and CB, respectively). The desorption process under the applied load led to an additional 9.73%, 9.40%, and 10.6% FD increase for the respective southern pine groups and 14.0%, 7.41, and 15.4% FD increase for the mixed hardwood groups. Such a large creep increase resulted after 28 days and 12.5 days of absorption and desorption periods, respectively, until the specimens reached EMC at each RH condition. It should be pointed out that the setup for the test environment was severe compared with the conditions for normal OSB uses in the field. However, the study was mainly intended for testing a wide MC change range to establish some extreme performance conditions.

Figure 5 shows a plot of the fractional deflection against the moisture content for both the absorption and desoprtion cycles. Linear relationships between FD and MC were seen from both moisture exposure cycles. A linear regression analysis was made to obtain the material constants that described the MS deformation, using Eq. 4,

(4)

where mMS is stress-independent material constant for MS deformation and MMS is the slope of the FD-MC plot.

Fig. 5. Fractional deflection due to mechano-sorptive effect as a function of moisture content; a) Southern pine and b) Mixed hardwood. ZB-zinc borate and CB-calcium borate.

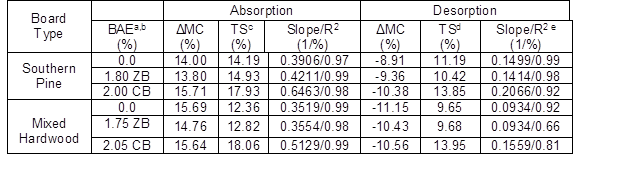

Table 3. Mean Moisture Content (MC) Change, TS, and the Slope of the Fractional Deflection-MC Plots from both Absorption and Desorption Cycles

Notes:a Boric acid equivalent in percent; b ZB – zinc borate, and CB – calcium borate; cTS-thickness swelling from initial sample thickness due to moisture absorption; and dTS- remaining thickness swelling from initial sample thickness after moisture absorption cycle (permanent TS), and e– regression correlation coefficient R2.

Fig. 6. A comparison of the slope data from the FD-MC plots for various strand board samples; a) Absorption and b) Desorption

Table 3 and Fig. 6 show that the slopes of the FD-MC plots had similar values for the control and ZB-treated strand board groups, which indicated similar MS response of the two groups. The slope values for the CB-treated strand board were much larger from both the absorption and desorption cycles. Thus, the CB had more impact on MS deformation of treated strand board. This could have been due to a higher loading rate of CB in strand board and its inherent properties compared with these of ZB. The use of CB led to more thickness swelling, which in turn caused strength reduction of the sample, and led to a reduced load carrying capacity under varying moisture conditions. The slope value was consistently slightly higher in the southern pine group compared with those from the mixed hardwood group, which indicated more MS deformation for a given moisture content change for the southern pine group. Overall, the effect of wood species seemed to be smaller than the effect of borate type. The initial absorption cycle under applied load produced more MS deformation per unit MC change compared with that from the first desorption cycle (Fig. 5).

CONCLUSIONS

Time-dependent creep and moisture change-induced MS deformation from borate modified strand board were studied in this work, using lab-fabricated samples with flakes produced from southern yellow pine and mixed hardwoods. The following conclusions were reached from the study:

- Creep at the constant 65% RH condition developed in a normal time-dependent fashion. The Burger body creep model with four spring-dashpot elements was found to be appropriate in predicting the time-dependent creep response of the modified strand board under the constant 65% RH condition.

- The noticeable influence of powder borate modification on the FDs was demonstrated under the changing environmental condition for both the absorption and desorption cycles. The initial absorption cycle produced more MS deformation per unit MC change compared with that from the first desorption cycle.

- The CB used had more of a negative impact on the sample thickness swelling and MS deformation compared with these from the ZB.

- The measured fractional deflection due to the MS effect followed a linear relationship with moisture content change from both the absorption and desorption cycles.

- Material constants that described the MS deformation for borate modified strand boards were established, which can be made to develop long-term structural performance models for chemically modified strand board.

ACKNOWLEDGES

The authors acknowledge support from the Zhejiang Agriculture and Forestry University, Korea National Institute of Forest Science, and the USDA National Institute of Food and Agriculture McIntire Stennis project [1000017]. The authors also want to thank Dr. Jong N. Lee for his early involvement in the project.

REFERENCES CITED

ASTM D1037-12 (2006). “Standard test methods for evaluating properties of wood-base fiber and particle panel materials,” ASTM International, West Conshohocken, PA.

Armstrong, L. D., and Christensen, G. N. (1961). “Influence of moisture changes on deformation of wood under stress,” Nature 191, 869-870. DOI: 10.1038/191869a0

Fridley, K. J., Tang, R. C., and Soltis, L. A. (1992). “Creep behavior model for structural lumber,” Journal of Structural Engineering 118(8), 2261-2277. DOI: 10.1061/(ASCE)0733-9445(1992)118:8(2261)

Gril, J. (2015). “Modelling mechano-sorption in wood through hygro-locks and other approaches,” in: International Symposium on Wood Science and Technology (IAWPS), Tokyo, Japan.

Hunt, D. G. (1989). “Linearity and non-linearity in mechano-sorptive creep of softwood in compression and bending,” Wood Science and Technology 23(4), 323-333. DOI: 10.1007/BF00353248

Jin, F., Jiang, Z., and Wu, Q. (2016). “Creep behavior of wood plasticized by moisture and temperature,” BioResources 11(1), 827-838. DOI: 10.15376/biores.11.1.827-838

Laufenberg, T. L., and McNatt, J. D. (1989). “Preliminary results of panel products. Creep and creep-rupture program,” in: Proceedings of 23rd International Particleboard/Composite Materials Symposium, Pullman, Washington, pp. 257-266.

Lee, S., Wu, Q., and Smith, W. R. (2004). “Formosan subterranean termite resistance of borate-modified strand board manufactured from southern wood species: a laboratory trial.” Wood Fiber Sci. 36(1), 107-118.

Lee, J. N. (1999). Structural Behavior of Yellow poplar LVL: Effect of Veneer-joint Designs and Environmental Conditions, Ph.D. Dissertation, Auburn University, Auburn, AL.

Lee, J. N., Tang R.C., and Kaiserlik, J. H. (1996). “Effect of adhesive and press types on creep behavior of flakeboards under open-shed environment,” In Proc. the 3rd Pacific rim bio-based composites symposium. Kyoto University, Kyoto, Japan. Dec. 2-5, 1996. pp 124-132.

Leicester, R. H. (1971). “A rheological model for mechano-sorptive deflections of beams,” Wood Science and Technology 5(3), 211-220. DOI: 10.1007/BF00353683

Leichti, R. J. (1986). Assessing the Reliability of Wood Composite I-beams, Ph.D. Dissertation, Auburn University, Auburn, AL.

Montero, C., Gril, J., Legeas, C., Hunt, D. G., and Clair, B. (2012). “Influence of hygromechanical history on the longitudinal mechano-sorptive creep of wood,” Holzforschung 66, 757-764. DOI: 10.1515/hf-2011-0174

Mukudai, J., and Yata, S. (1988). “Verification of Mukudai’s mechano-sorptive model,” Wood Science and Technology 22(1), 43-58. DOI: 10.1007/BF00353227

Norimoto, M., Gril, J., and Rowell, R. M. (1992). “Rheological properties of chemically modified wood: Relationship between dimensional and creep stability,” Wood and Fiber Science24(1), 25-35.

Ozyhar, T., Hering, S., and Niemz, P. (2013). “Viscoelastic characterization of wood: Time dependence of the orthotropic compliance in tension and compression,” Journal of Rheology 57(2), 699-717. DOI: 10.1122/1.4790170

Palka, L. C. (1993). “An overview of bending creep and creep-rupture of waferboard panels: The Forintek experience,” in: Proceedings of the Structural Board Association Duration of Load Workshop, Toronto, Canada.

Pérez-Pena, N., Segovia, F., Salinas, C., and Ananías, R. (2016). “Perpendicular mechano-sorptive strains during moisture desorption from Eucalyptus nitens specimens,” BioResources 11(4), 8277-8284. DOI: 10.15376/biores.11.4.8277-8284

Price, E. W. (1985). “Creep behavior of flakeboards made with a mixture of southern species,” Wood and Fiber Science 17(1), 58-74.

Ranta-Maunus, A. (1975). “The viscoelasticity of wood at varying moisture content,” Wood Science Technology 9(3), 189-205. DOI: 10.1007/BF00364637

Schaffer, E. L. (1972). “Modeling the creep of wood in changing moisture content,” Wood and Fiber Science 3(4), 232-235.

Senft, J. F., and Suddarth, S. K. (1971). “An analysis of creep-inducing stress in sitka spruce,” Wood and Fiber Science 2(4), 321-327.

Shen, Y., and Gupta, R. (1997). “Evaluation of creep behavior of structural lumber in a natural environment,” Forest Products Journal 47(1), 89-96.

Smith, W. R., and Wu, Q. L. (2005). “Durability improvement for structural wood composites: Current state of the art,” Forest Products Journal 55(2), 8-17.

Szabo, T., and Ifju, G. (1970). “Influence of stress on creep and moisture distribution in wooden beams under sorption conditions,” Journal of Wood Science 2(3), 159-167.

Tang, R. C., Lee, J. N., and Hse, C. Y. (1996). “Effect of adhesive and press types on creep behavior of flakeboards under open-shed environment,” in: 3rd Pacific Rim Bio-based Composites Symposium, Kyoto, Japan. pp. 124-132.

Tang, R. C., Pu, J. H., and Price, E. W. (1997). “Effect of temperature on the creep of commercial oriented strand boards under cyclic relative humidity,” Forest Products Journal 47(7-8), 1-8.

Van der Put, T. A. C. M. (1989). “Theoretical explanation of the mechano-sorptive effect in wood,” Wood and Fiber Science 21(3), 219-230.

Wu, Q., Lee, J.N., Cai, Z., and Zhou D. (2009). “Creep behavior of borate-treated strand board: effect of zinc borate retention, wood species, and load level,” Maderas Cienciay Tecnologia Journal. 11(1), 19-32.

Wu, Q. (1999). “Application of nelson’s sorption isotherm to wood composites and overlays,” Wood and Fiber Science 31(2), 187-191.

Wu, Q., and Milota, M. R. (1995) “Rheological behavior of Douglas-fir perpendicular to the grain at elevated temperatures,” Wood and Fiber Science 27(3), 285-295.

Xu, X., Lee, S., Wu, Y., and Wu, Q. (2013). “Borate-treated strand board from southern wood species: Resistance against decay and mold fungi,” BioResources 8(1), 104-114. DOI: 10.15376/biores.8.1.104-114

Yeh, M. C. (1990). Time-dependent Structural Behavior of Wood Composite Panels, Ph.D. Dissertation, Auburn University, Auburn, AL.

Article submitted: March 31, 2017; Peer review completed: June 19, 2017; Revised version received and accepted: June 22, 2017; Published: June 28, 2017.

DOI: 10.15376/biores.12.3.5812-5825