Abstract

The mechanical characteristics of cellulose fibres in biocomposites (epoxy resin/Musa textilis) were investigated relative to the microstructure of these fibres as determined by porosimetry and electron microscopy in terms of their utilization in composite systems. The influence of the chemical treatment via alkali (NaOH) on the change in surface properties and the interfacial interaction of fibres with an epoxy resin was investigated as well as mechanical characteristics of abaca/epoxy composites. The porosity of abaca fibres reached 57% on average, and the averaged tensile strength value was 641 MPa and a Young modulus of 26 MPa. Evaluated composite systems were prepared through a vacuum infusion in which various orientations of long ordered fibres in these composites were evaluated along with the influence of a 6% NaOH chemical treatment on the resultant mechanical properties. The alkali treatment increased the tensile strength of the observed composite systems by up to 16 MPa. The chemical treatment of the abaca fibres led to an increase in the interfacial interaction, which was evaluated with electron microscopy.

Download PDF

Full Article

Musa textilis Cellulose Fibres in Biocomposites – An Investigation of Mechanical Properties and Microstructure

Petr Valášek,a,* Roberto D’Amato,b Miroslav Müller,a and Alessandro Ruggiero c

The mechanical characteristics of cellulose fibres in biocomposites (epoxy resin/Musa textilis) were investigated relative to the microstructure of these fibres as determined by porosimetry and electron microscopy in terms of their utilization in composite systems. The influence of the chemical treatment via alkali (NaOH) on the change in surface properties and the interfacial interaction of fibres with an epoxy resin was investigated as well as mechanical characteristics of abaca/epoxy composites. The porosity of abaca fibres reached 57% on average, and the averaged tensile strength value was 641 MPa and a Young modulus of 26 MPa. Evaluated composite systems were prepared through a vacuum infusion in which various orientations of long ordered fibres in these composites were evaluated along with the influence of a 6% NaOH chemical treatment on the resultant mechanical properties. The alkali treatment increased the tensile strength of the observed composite systems by up to 16 MPa. The chemical treatment of the abaca fibres led to an increase in the interfacial interaction, which was evaluated with electron microscopy.

Keywords: Porosimetry; Synergic effect; Tensile strength; Vacuum infusion; Water jet

Contact information: a: Czech University of Life Sciences Prague, Faculty of Engineering, Department of Material Science and Manufacturing Technology, Prague, Czech Republic; b: Universidad Politecnica de Madrid, Departamento de Ingeniería Mecánica, Química y Diseño Industrial- ETSIDI (ES), Madrid, Spain; c: University of Salerno, Department of Industrial Engineering, Salerno, Italy;

* Corresponding author: valasekp@tf.czu.cz

INTRODUCTION

The utilization of renewable natural resources, i.e. cellulose fibres, in an area of composite systems is an environmentally friendly trend. This substitution of synthetic fibres with cellulose-based fibres offers the production of economically acceptable materials that are environmentally friendly and have satisfactory mechanical characteristics. The Musa textilis plant, from which cellulose fibres denoted as abaca are gained, grows primarily in the Philippines. These fibres, containing more than 70% of cellulose, are used in an area of textile industry, but they are suitable also for the production of composite systems by virtue of their mechanical characteristics (Jawaid and Abdul Khalil 2011; Yan et al. 2016).

Composite materials combine properties of partial components (Madyan et al. 2016; Feo et al. 2017). They belong among prospective systems that determine the direction of future materials, such as aerogel and other composites and materials, which are created from phases based on natural materials (Das et al. 2016; Ruggiero et al. 2016b). Currently, many countries emphasize a social-economic expectation in relation to searching for new materials that will have similar mechanical properties as conventionally used systems (Valášek and Müller 2015). New alternatives are needed in the area of composite material reinforcements when natural fibres have been abundantly used in recent years (Ruggiero et al. 2015; Mittal et al. 2016; Elsabbagh et al. 2017; Valášek et al. 2017a). Obtaining fibres from renewable resources saves fossil raw materials and is desirable from an environmental process point of view. The main application area of fibre composites is the automotive industry; according to the European Union regulation, EP Directive 2000/53/EC, the overall recycling rate of vehicles must be 85% and the overall recoverability must be 95%. Automotive manufacturers are currently focusing on their environmental impact from start to finish, from obtaining the raw materials to the manufacturing process, and lastly to disposal. Natural fibres fulfill the assumptions in this industry (Holbery and Houston 2006; Kumar and Das 2017).

The advantages of natural fibres, such as good mechanical properties, low cost, low density, low thermal conductibility, and recyclability, make them a good potential replacement for synthetic fibres in composite materials (Ruggiero et al. 2015; Valášek et al. 2017b). The natural character of natural fibres is one of their basic disadvantages when it is difficult to determine the exact properties of creating composite systems. This is because fibre properties depend on the place where they grow, actual climatic conditions, and other unchangeable factors (temperature, humidity, rainfall, etc.). However, the unambiguous advantages of using natural fillers exceed the disadvantages. Natural fibres are characterized by the fact that they are created by mostly hollow single structures (Müller et al. 2016; Otto et al. 2017; Valášek et al. 2017a). A seemingly circular cross-section of fibres is created from the pores. The porosimetry can be used for the identification of these pores. Mercury intrusion porosimetry is an adsorption technique that uses mercury as the adsorbate. By applying pressure, mercury is forced into the pores of the solid. The mercury volume value (Table 4) that has entered allows one to calculate the area, distribution by pore sizes, and percentage of porosity of the material.

The surface treatment of fibres before their application is an important aspect according to many authors (Xue and Tabil 2007; Le Troedec et al. 2008; Punyamurthya et al. 2017). Chemical treatments are very widespread surface treatments. They can be treatments in alkali, distilled water, or viabenzenediazonium chloride.

Abaca fibres are natural vegetable fibres obtained from banana plants that are a laeding product grown in the area of the Philippines. Their annual production corresponds to 0.10 million tons (Jawaid and Abdul Khalil 2011; Yan et al. 2016). The price ranges from approximately 1.8 €/kg to 2.5 €/kg (Jawaid and Abdul Khalil 2011; Yan et al. 2016). Currently, the growth of this plant is expanding into the area of Sumatra and Borneo regions of Southeast Asia. The fibres consist of ca. 77% of cellulose, 20% of hemicellulose, and 9% of lignin. They can be up to 9 m in length (Jawaid and Abdul Khalil2011; Yan et al. 2016). A leaching of soluble fractions, e.g., hemicellulose, occurs by means of the alkalis (Le Troedec et al. 2008; Iucolano et al. 2015).

These fibres have excellent resistance to salt water, and they have good strength (Bledzki et al. 2009). Many authors state that abaca fibres create a very weak interfacial interface with matrices, and thus it is suitable to chemically treat the fibres (Le Troedec et al. 2008; Van Vuure et al. 2015).

Abaca fibres demonstrate enormous potential as reinforcing agents in composite materials. Bledzki et al. (2007) state that composites with abaca fibres have worse tensile properties compared with jute composites but abaca fibres increased the impact strength more. Additionally, Haque et al. (2010) reported a higher tensile strength of composite materials filled with coconut fibres compared with abaca-fibre systems. A significant increase in the tensile strength was observed in composite systems with short and long abaca fibres, e.g., 10% of the fibres in matrix. (Vasquez and Diaz 2017).

Abaca can also be used in composite systems in the building industry, in which Iucolano et al. (2015) used 2 wt% (abaca fibres in matrix) to the optimization of the toughness, a flexural strength at good workability.

This experiment aims to describe the mechanical properties of fibres from the banana plant Musa textilis and to define the composite systems made by the vacuum infusion. Electron microscopy was used for the evaluation of the fibre morphology and to observe the influence of the fibre surface treatment by the NaOH water solution on the change of surface structures. In addition, the mutual interfacial interaction and the influence of the fibre chemical treatment on this interaction were evaluated by electron microscopy. The experimental program focuses on long-fibre composite systems.

EXPERIMENTAL

Materials

Reinforcing phase– Abaca fibres

Abaca fibres were obtained from the plant M. textilis that is grown all over the Philippines. For chemical treatment of the fibres, the fibres were treated with a 6% NaOH water solution for 10 h at 24 °C ± 2 °C. The concentration of NaOH solution was chosen on a base of cellulose fibre studies (Nam et al. 2011; Imran and Adelbert 2015). The alkalis are used for the optimization of the surface morphology. The surface properties are important for the interfacial interactions of all materials (Krolczyk et al. 2016; Ruggiero et al. 2016a). All fibres were dried at 105 °C before their application into the resin.

Continuous phase- Matrix

The matrix used was created by the epoxy resin suitable for the vacuum infusion, i.e., the resin with extremely low viscosity with good mechanical properties. This resin was hardened with a cycloaliphatic polyamine-based hardener (specifications are shown in Table 1.).

Table 1. Specifications of Used Epoxy Resin and Hardener

Preparation of composite systems

Boards with dimensions of 200 × 300 mm and a height of 4 mm were made by vacuum infusion (30 vol%). A vacuum pump was used for the experiment with a capacity of 55 l·min-1 and an absolute pressure of 100 mbar abs. The fibres were applied on the glass treated with a liquid separator. These fibres were pressed through a press with 5 tons loading before vacuum infusion was applied. A separating layer and a layer for spreading the epoxy resin were placed on the fibres. Everything was covered with a vacuum foil that was hermetically closed with a vacuum tape. The height of the prepared board with the long fibres was 4 mm. This height was divided into two 2-mm layers. The fibres in these layers were oriented identically (i.e., For 0°/0°, the fibres were oriented in the direction of the loading force during mechanical tests; for 90°/90°, the same preparation was applied but the direction of the fibres during the mechanical tests was perpendicular to the direction of the loading force; for 45°/45°, the orientation of the fibres was 45° shifted to the direction of the loading force; and 0°/90°, where the first layer was perpendicular to the other layer). The test specimens were cut from these boards with a water jet (AW-CT 0806 Awac, Prague, Czech Republic) according to relevant standard ČSN EN ISO 527-1 (2012) (as shown in Fig. 1). Particles of a synthetic garnet (MESH 80, a mass flow of the abrasium was ca. 90 g·min-1) were used for the water jet cutting. Cutting parameters were chosen such as to avoid delamination and a rise of cracks caused by the cut. Thus, the speed of the cut was 100 mm·min-1. The diameter of the nozzle was 0.8 mm. The working pressure was 380 MPa. However, the study did not focus on the evaluation of a suitability of AWJ method for fibre composites with cellulose fibres. The distance of the nozzle from the cutting sample corresponded to 3 mm. A surface roughness on the upper side of the cutted sample corresponded to Ra = 9.16 ± 2.16 µm, Rz = 49.66 ± 11.23 µm (0°/0°); and to Ra = 15.00 ± 0.84 µm, Rz = 76.30 ± 3.83 µm (90°/90°) on average at a height of 4 mm. Six test samples from one board were always cut.

Fig. 1. Preparation process of test specimens: a) vacuum infusion, b) board cut by AWJC technology, and c) all test specimens

The heterogeneity of the test specimens was not disturbed by using the water jet, as is visible in Fig. 2. The water jet cut the specimens according to the standard CSN EN ISO 3167 (2015) by their dimensions, and they were used for the determination of basic strength characteristics of the composite system.

Fig. 2. Surface of composite system exposed to effect of abrasive water jet

Methods

Testing of fibre (abaca) mechanical characteristics – Strength characteristics

A mechanical simulation was conducted using the Hounsfield H10KT machine (Hounsfield Test Equipment, Redhill, UK), and the results were stored and displayed by a software package known as Datahawk by Metrotec (Techlab systems, S.L., Lezo, Spain).

The machine was the vertical test bench type with a test capacity of 10,000 N (Fig. 3). The maximum diameter of the tested samples was 405 mm; with a maximum traverse of the crossbar, excluding the grippers, of 1100 mm. The test machine consisted of a crosshead in which the load cell and grippers were mounted, as shown in Fig. 3. The acceptance limit of the test was that the break of each fibre was to take place at the center of the separation length. This condition occurred for 90% of the samples. The number of test fibres corresponded to 15. Jaws were fitted with rubber inserts which prevent a slippage of fibres. Fibres were always placed perpendicular to the jaws at keeping a constant fibre length.

Fig. 3. Testing of tensile characteristics of abaca fibres

Testing of fibre (Abaca) mechanical characteristics– Porosimetry

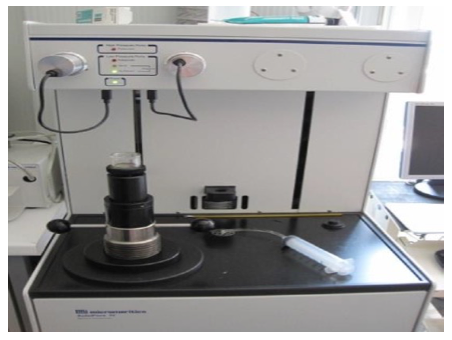

The mercury intrusion-extrusion equipment used for the test was a Micromeritics AutoPore IV 9510 (Micromeritics, Norcross, GA, USA) (as shown in Fig. 4). Its resolution in terms of pore size was from 7 nm to 360 μm.

Fig. 4. Mercury intrusion-extrusion equipment

The porosimetry test began with the standardization of the size and shape of the sample, so that its outer surface was uniform and constant. Given the influence of the contact angle on the results, care must be taken to clean the sample by washing it with distilled water if it is considered convenient, as shown in Table 2. The sample was oven-dried at 80 °C for 24 h, and the dry weight of the sample was determined.

Table 2. Hg Parameters

The second step was the filling and low-pressure porosimetry. Initially the sample was evacuated to remove air and residual moisture or other liquids from the pore system (parameters shown in Table 3). A complete evacuation was important to avoid possible air pockets and contamination issues. The sample cell was filled with mercury as the entire system was still under reduced pressure. Slowly increasing the overall pressure then allows mercury to penetrate the largest pores in the sample or any void spaces between sample pieces. The first data point was taken at a pressure of 3000 Pa to 4000 Pa (0.5 psia). The last data point was taken at a pressure of 7000 Pa (1.02 psia). At the end of this low-pressure part of the analysis, the weight of the penetrometer filled with mercury and the sample was determined, which allows for calculation of the bulk density of the sample (using corresponding blank-runs as a reference). The intruded mercury volume was measured continuously through changes in the capacitance between the column of mercury in the dilatometer stem (capillary tube of known diameter connected to the sample cell) and a coaxial metal sheet surrounding the stem.

Table 3. Porosimetry Parameters for Low-pressure Test

The last step was the high-pressure porosimetry. The sample-cell was transferred to the high-pressure system and it was surrounded by hydraulic fluid, and pressures of up to 414 MPa (60,000 psia) were applied in an isostatic way using the Micromeritics AutoPore IV 9510 (Micromeritics, Norcross, GA 30093-l877, USA), as shown in the attached specifications.

Testing of composite systems

Tensile characteristics were tested by a universal testing machine testing machine LabTest 5.50ST (Labortech s.r.o., Opava, Czech Republic) enabling a maximum load of 5 t. The tests were performed in accordance with the standard CSN EN 527 (2012), and the testing speed corresponded to 6 mm·min-1.

The hardness of the composite systems was experimentally determined in the accordance with the standard CSN EN ISO 2039-1 (2003). A ball of a diameter of 5 mm was used as an indentor, with a loading force of 961 N. The hardness was evaluated in accordance with the standard according to impression depth.

Image analysis

The image analysis of the fibres, fracture surfaces, and interfacial interaction was performed with a Tescan Mira 3 GXM electron microscope (Tescan Brno, s.r.o., Brno, Czech Republic).

The experimentally measured data were evaluated by means of an analysis of variance (ANOVA) and T-test in which a parameter p > 0.05 implies a statistically insignificant difference among the means of the compared sets of data using the software program Statistica (StatSoft, Palo Alto, CA, USA).

RESULTS AND DISCUSSION

Physical and Mechanical Properties of Abaca Fibres

Electron microscopy established that the cross-section of the fibres was not entirely a circle but that the fibre contained pores, or so-called lumens. The structure of the abaca fibre and the detailed description of the microstructure are displayed in Fig. 5.

Porosimetry was used for the description of the microstructure. Table 4 shows the results of the mercury porosimetry of the abaca fibre. The volume of the pore was 1.01 mL/mg, which corresponded to a maximum mercury pressure of 59900 (psia), as shown in Fig. 6. The pore diameter value was approximately 3.6 nm for mercury pressure values of 59900 (psia), and 213.9 (µm) for a low-pressure of 1.02 (psia). The average pore diameter of the cylinder-shaped pores was 99.8 nm.

Fig. 5. Microstructure of the abaca fibre: a) under 3.74 kx magnification and b) under 13.7 kx magnification

Table 4. Results of Porosimetry

From the analysis of the hysteresis curve (Fig. 6), it was possible to investigate the pore shape of the abaca fibre by comparison of the results present in previous literature. The intrusion and extrusion curve at the highest test pressure have the same pattern of the hysteresis curves of the needles pore shape and spherical pore shape (Liabastre and Orr 1978; Zgrablich et al. 1991).

The fibre cross-sectional area is a very important parameter that appears to govern mechanical properties such as tensile strength, Young modulus, and its elongation. For this reason, the geometry of the cross-sectional area was investigated to evaluate the shapes. It was found that the shape of the cross-section of these fibres was approximately circular (Table 5).

The tensile characteristics of the abaca fibres are visible in Table 5. Mekel et al. (2016) observed that the average strength of the abaca fibres was 541 MPa and the mean of the abaca fibres was 0.151 mm. The measured results were in accordance with the measurements of Yan et al. (2016) and Jawaid and Abdul Khalil (2011), who stated the strength to be between 400 MPa and 900 MPa, an elastic modulus between 6.2 GPa and 20.0 GPa, and the elongation at break as 1.0% to 10.0%. The NaOH treatment of the abaca fibres can also lead to the increase in tensile strength and Young’s modulus compared to the untreated fibre (Cai et al. 2015). From this point of view, the authors recommend shorter treating times, at ca. 2 h and with solutions of approximately 5% NaOH (Cai et al. 2015).

Fig. 6. a) Cumulative intrusion vs. pressure and b) log differential Intrusion vs. pore size

Table 5. Mechanical Properties of the Abaca Fibres

Electron microscopy was used for the evaluation of the fibre morphology. Figure 7a, shows the structure of the fibre detail, and Fig. 7b, shows the fibre surface before the chemical treatment with NaOH solution. The alkali treatment of the natural fibres is a common treatment that leads to the increase of the fibre surface due to disruption of hydrogen bonds in a network structure. The chemical treatment of the fibres clearly led to the change of the fibre surface, as shown in Fig. 7.

Fig. 7. a) Structure of fibres before treatment and b) surface of fibres after treatment

This was in accordance with the conclusions of many authors who manipulated the amount of surface layers and increased the roughness of the fibres due to the alkali treatment of the natural vegetable fibres. The right treatment of natural fibres increases the roughness of fibres according to Sood et al. (2015). The process of the surface treatment via NaOH solution led to the removal of hemicellulose and lignin. Extended exposure to alkali then leads to dividing single bunches of the fibres, and higher concentrations of 10% to 15% of NaOH lead to a breakdown of the lumen of the abaca fibres due to swelling (Cai et al. 2015).

The treatment with NaOH solution led to an increase of a texture of the fibre surface due to removing the cellulose including artificial and natural impurities from the fibre surface. Also a layout of units in the cellulose macromolecule is influenced due to the alkali environment, which influences the resultant mechanical properties of the fibre (Valadez-Gonzales et al. 1999).

Mechanical Properties of Abaca/Epoxy Composites

The inclusion of the abaca fibres led to a decrease of the system hardness. The value of the unfilled resin corresponded to 132 ± 21 HB (hardness by 961 N), and the values of the composite system are presented in Fig. 8. Based on the measurements, it was shown that the fibre orientation at the same concentration of the filler in the matrix did not influence the resultant hardness. Neither the fibre orientation nor the chemical treatment demonstrably influenced the resultant hardness of the composite systems (p > 0.05).

Fig. 8. Hardness of composites with abaca fibres with different orientations

The strength values of the composite systems with different orientations of fibres and different surface treatments are presented in Fig. 9 (0°/0° represents a 4-mm layer in the direction of tensile stress, 90°/90° represents a 4-mm layer perpendicular to the direction of tensile stress, and 0°/90° represents fibres in two layers, both 2 mm with different orientations). The unfilled resin reached the tensile strength values of 44.5 MPa ± 3.3 MPa. In terms of the tensile strength, the optimum arrangement of the fibres was in the lengthwise direction to the direction of the loading force. In this case, the increase in strength occurred compared to the unfilled resin of 80.7 MPa (and the variation coefficient did not exceed 11%). For the composite orientated in two perpendicular layers (0°/90°), an increase in strength of up to 47.0 MPa occurred. At the orientation of the fibres perpendicular to the direction of the loading a decrease in strength of up to 41.3 MPa on average (90°/90°) and 26.5 MPa on average (45°/45°) occurred compared with the unfilled resin. A significant dispersion of the values occurred–the variation coefficient 28%. Vasquez and Diaz et al. (2017) demonstrated the increase in the strength of the composites with the alkali-treated abaca fibres of 6.9 MPa, namely by means of increasing the interfacial interaction, which was obvious under scanning electron microscopy (SEM) analysis.

Fig. 9. Tensile characteristics of composites with abaca fibres with different orientations: a) tensile strength and b) elongation

The average tensile strength value for the composites with NaOH-treated fibres was 15.6 MPa (0°/0°) and 11.5 MPa (0°/90°), higher than the strength of systems without treatment. This increase can be attributed to increasing strength characteristics of NaOH-treated fibres in accordance with conclusions of a study of Cai et al. (2015). When statistically comparing the tensile strength of composite systems with the untreated and treated fibres, the influence of this treatment on the resultant strength was not proved (p > 0.05) in the significance level of 0.95, as shown in Table 6. A typical failure of the test specimens after the static tensile test is presented in Fig. 10. The failure occurred with a partial pulling out of the fibres in the direction of the affecting force. Provided that the direction of the loading force cannot be estimated in advance, the use of the composite system with different orientation of the layers (0°/90°) seems to be suitable.

Table 6. Statistical Comparison of Tensile Strength Between Composites with Fibres Treated by NaOH and Composites with Untreated Fibres (T-test)

Fig. 10. Different types of failures of specimens

The increase of the fibre roughness leads to an improved interaction with polymeric materials (Dalmay et al. 2010). This increased interaction was possible to observe by SEM analysis on the interfacial interaction of test specimens, as shown in Fig. 11. However, the increase of the interfacial interaction did not significantly reduce the propensity of the composites to a failure by a transversal mechanism.

Fig. 11. a) Interfacial interaction before fibre surface treating and b) detail of interfacial interaction after fibre treatment by NaOH

This finding was evident in the results of the tensile strength of the composites (45°/45°) and (90°/90°), when it did not come to the significant increase of the strength characteristics in the comparison of treated and untreated fibres (Fig. 9). The failure of these composites was similar as in a study of Zuccarello et al. (2017a). A single-fibre pull-out test can be used for a definition of the interfacial interaction itself which e.g. Zuccarello et al. (2017b) use for biocomposites.

CONCLUSIONS

This study evaluated the possibilities of abaca fibre utilization in composite systems. The tensile strength of observed long-fibre composite systems increased due to the chemical treatment of the fibres. The fibres described in this experimental program are another alternative to commonly used fibres such as coir or sisal. The most important conclusions are as follows:

- Analysis by scanning electron microscopy (SEM) demonstrated the influence of the alkali treatment by the NaOH solution on the surface structure of the fibres through removal of the surface layers and the increase in roughness.

- The SEM analysis showed the optimization of the interaction of the abaca fibres and the epoxy resin due to the alkali treatment.

- The composite systems with treated fibres showed higher tensile strength values on average, but because of the variation coefficients of the measurements, this increase was evaluated as statistically non-demonstrable, with the significance level of 0.95

- The increase of the tensile strength of composites (0°/0°) with treated fibres of 15.6 MPa was caused by the optimization of mechanical properties of the fibre due to the alkali treatment.

- The interfacial interaction between NaOH treated fibres and the epoxy resin was not so significant in order to lead to the increase of the strength characteristics of composites (45°/45°) and (90°/90°) – i.e. the reduction of the composite propensity to the failure by transversal mechanisms – dividing matrices from fibres.

- Mechanical properties of composites (0°/90°) are given by the combination of the effect caused by increasing the strength characteristics of treated fibres and the failure by transversal mechanisms.

- The hardness of the composite systems was decreased by the fibre inclusion.

ACKNOWLEDGMENTS

This paper was made with the assistance of the grant IGA TF CZU 2017:31140/1312/3113. The research was conducted thanks to the cooperation between the Department of Material Science and Manufacturing Technology of the Czech University of Life Sciences Prague (CULS), Faculty of Engineering, Applied Mechanics Lab of the Department of Industrial Engineering of the University of Salerno (IT), and the University Politecnica de Madrid, Spain.

REFERENCES CITED

Bledzki, A. K., Jaszkiewicz, A., and Scherzer, D. (2009). “Mechanical properties of PLA composites with man-made cellulose and abaca fibres,” Composites Part A: Applied Science and Manufacturing40(4), 404-412. DOI: 10.1016/j.compositesa.2009.01.002

Bledzki, A. K., Mamun, A. A., and Faruk, O. (2007). “Abaca fibre reinforced PP composites and comparison with jute and flax fibre PP composites,” eXPRESS Polymer Letters 1(11), 755-762. DOI: 10.3144/expresspolymlett.2007.104

Cai, M., Takagi, H., Nakagaito, A. N., Katoh, M., Ueki, T., Waterhouse, G., and Li, Y. (2015). “Influence of alkali treatment on internal microstructure and tensile properties of abaca fibers,” Industrial Crops and Products 65(1), 27-35. DOI: 10.1016/j.indcrop.2014.11.048

ČSN EN ISO 527-1 (2012). “Plastics – Determination of tensile properties – Part 1: General principes,” Czech Office for Standards, Metrology and Testing, Prague, Czech Republic.

ČSN EN ISO 2039-1 (2003). “Plastics – Determination of hardness – Part 1: Ball indentation method,” Czech Office for Standards, Metrology and Testing, Prague, Czech Republic.

ČSN EN ISO 3167 (2015). Plastics – Multipurpose test specimens,” Czech Office for Standards, Metrology and Testing, Prague, Czech Republic.

Dalmay, P., Smith, A., Chotard, T., Sahay-Turner, P., Gloaguen, V., and Krausz, P. (2010). “Properties of cellulosic fibre reinforced plaster: Influence of hemp or flax fibres on the properties of set gypsum,” Journal of Materials Science 45, 793-803. DOI: 10.1007/s10853-009-4002-x

Das, O., Bhattacharyya, D., Hui, D., and Lau, K. T. (2016). “Mechanical and flammability characterisations of biochar/polypropylene biocomposites,” Composites Part B: Engineering 106, 120-128. DOI: 10.1016/j.compositesb.2016.09.020

Elsabbagh, A., Steuernagel, L., and Ring, J. (2017). “Natural Fibre/PA6 composites with flame retardance properties: Extrusion and characterization,” Composites Part B: Engineering 108(1), 325-333. DOI: 10.1016/j.compositesb.2016.10.012

European Parliament (EP) Directive 2000/53/EC (2000). “End-of life vehicles,” European Union, Brussels, Belgium.

Feo, L., Latour, M., Penna, R., and Rizzano, G. (2017). “Pilot study on the experimental behavior of GFRP-steel slip-critical connections,” Composites Part B: Engineering 115, 209-222. DOI: 10.1016/j.compositesb.2016.10.007

Haque, M., Rahman, R., Islam, N., Huque, M., and Hasan, M. (2010). “Mechanical properties of polypropylene composites reinforced with chemically treated coir and abaca fiber,” Journal of Reinforced Plastics and Composites 29(15), 2253-2261. DOI: 10.1177/0731684409343324.

Holbery, J., and Houston, D. (2006). “Natural-fiber-reinforced polymer composites in automotive applications,” The Journal of The Minerals, Metals & Materials Society 58(11), 80-86. DOI: 10.1007/s11837-006-0234-2

Imran, S. M., and Adelbert, T. (2015). “Effect of alkali treatments of physical and mechanical properties of coir fiber,” Chemical and Materials Engineering 3(2), 23-28. DOI: DOI: 10.13189/cme.2015.030202

Iucolano, F., Caputo, D., Leboffe, F., and Liguori, B. (2015). “Mechanical behavior of plaster reinforced with abaca fibers,” Construction and Building Materials 99, 184-191. DOI: 10.1016/j.conbuildmat.2015.09.020

Jawaid, M., and Abdul Khalil, H. P. S. (2011). “Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review,” Carbohydrate Polymers 86(1), 1-18. DOI: 10.1016/j.carbpol.2011.04.043

Krolczyk, G. M., Krolczyk, J. B., Maruda, R. W., Legutko, S., and Tomaszewski, M. (2016). “Metrological changes in surface morphology of high-strength steels in manufacturing,” Measurement88, 176-185. DOI: 10.1016/j.measurement.2016.03.055

Le Troedec, M., Seda, D., Peyratout, C., Bonnet, J. P., Smith, A., Guinebretiere, R., Gloaguen, V., and Krausz, P. (2008). “Influence of various chemical treatments on the composition and structure of hemp fibres,” Composites Part A: Applied Science and Manufacturing 39(3), 514-522. DOI: 10.1016/j.compositesa.2007.12.001

Liabastre, A. A., and Orr, C. (1978). “An evaluation of pore structure by mercury penetration,” Journal of Colloid and Interface Science 64(1), 1-18. DOI: 10.1016/0021-9797(78)90329-6

Madyan, O. A., Fan, M., Feo, L., and Hui, D. (2016). “Physical properties of clay aerogel composites: An overview,” Composites Part B: Engineering 102, 29-37. DOI: 10.1016/j.compositesb.2016.06.057

Mekel, A. N., Soenoko, R., Suprapto, W., and Purnowidodo, A. (2016). “Tensile strength of abaca strands from Sangihe Talaud islands,” ARPN Journal of Engineering and Applied Sciences 11(15), 1819-6608.

Mittal, V., Saini, R., and Sinha, S. (2016). “Natural fiber-mediated epoxy composites – A review,” Composites Part B: Engineering 99(15), 425-435. DOI: 10.1016/j.compositesb.2016.06.051

Müller, M., Valášek, P., and Ruggiero, A. (2016). “Strength characteristics of untreated short-fibre composites from the plant Ensete ventricosum,” BioResources 12(1), 255-269. DOI: 10.15376/biores.12.1.255-269

Nam, T. H., Ogihara, S., Tung, T. H., and Kobayashi, S. (2011). “ Effect of alkali treatment on interfacial and mechanical properties of coir fiber reinforced poly(butylene succinate) biodegradable composites,” Composites Part B: Engineering 42(6), 1648-1656. DOI: 10.1016/j.compositesb.2011.04.001

Kumar, N., and Das, D. (2017). “Fibrous biocomposites from nettle (Girardinia diversifolia) and poly (lactic acid) fibers for automotive dashboard panel application,” Composites Part B: Engineering130(1), 54-63. DOI: 10.1016/j.compositesb.2017.07.059

Otto, G. P., Moisés, M. P., Carvhalo, G., Rinadli, A. W., Garcia, J. C., Radovanovic, E., and Fávaro, S. L. (2017). “Mechanical properties of a polyurethane hybrid composite with natural lignocellulosic fibers,” Composites Part B: Engineering 110(1), 459-465. DOI: 10.1016/j.compositesb.2016.11.035

Punyamurthya, R., Sampathkumara, D., Ranganagowdac, R. P. G., Bennehallic, B., and Srinivasad, C. V. (2017). “Mechanical properties of abaca fiber reinforced polypropylene composites: Effect of chemical treatment by benzenediazonium chloride,” Journal of King Saud University – Engineering Sciences 29(3), 289-294. DOI: 10.1016/j.jksues.2015.10.004

Ruggiero, A., D’Amato, R., Gómez, E., and Merola, M. (2016a). “Experimental comparison on tribological pairs UHMWPE/TIAL6V4 alloy, UHMWPE/AISI316L austenitic stainless and UHMWPE/AL2O3 ceramic, under dry and lubricated conditions,” Tribology International 96, 349-360. DOI: 10.1016/j.triboint.2015.12.041

Ruggiero, A., Valášek, P., and Müller, M. (2016b). “Exploitation of waste date seeds of Phoenix dactylifera in form of polymeric particle biocomposite: Investigation on adhesion, cohesion and wear,” Composites Part B: Engineering 104(1), 9-16. DOI: 10.1016/j.compositesb.2016.08.014

Ruggiero, A., Merola, M., Carlone, P., and Archodoulaki, V. M. (2015). “Tribo-mechanical characterization of reinforced epoxy resin under dry and lubricated contact conditions,” Composites Part B: Engineering 79, 595-603. DOI: 10.1016/j.compositesb.2015.05.015

Sood, M., Dharmpal, D., and Guptac, V. K. (2015). “Effect of fiber chemical treatment on mechanical properties of sisal fiber/recycled HDPE composite,” Materials Today: Proceedings 2(4-5), 3149-3155. DOI: 10.1016/j.matpr.2015.07.103

Valadez-Gonzalez, A., Cervantes-Uc, J. M., Olayo, R., and Herrera-Franco, P. J. (1999). “Effect of fiber surface treatment on the fiber–matrix bond strength of natural fiber reinforced composites,” Composites Part B: Engineering 30(3), 309-320. DOI: 10.1016/S1359-8368(98)00054-7

Valášek, P., Müller, M., and Šleger, V. (2017a). “Influence of plasma treatment on mechanical properties of cellulose-based fibres and their interfacial interaction in composite systems,” BioResources 12(3), 5449-5461. DOI: 10.15376/biores.12.3.5449-5461

Valášek, P., Ruggiero, A., and Müller, M. (2017b). “Experimental description of strength and tribological characteristic of EFB oil palm fibres/epoxy composites with technologically undemanding preparation,” Composites Part B: Engineering 122, 79-88. DOI: 10.1016/j.compositesb.2017.04.014

Valášek, P., and Müller, M. (2015). “Abrasive wear in three-phase waste-based polymeric particle composites,” Technicki Vjestnik 22(2) 257-262. DOI: 10.17559/TV-20130905190904

Van Vuure, A. W., Baets, J., Wouters, K., and Hendrickx, K. (2015). “Compressive properties of natural fibre composites,” Materials Letters 149, 138-140. DOI: 10.1016/j.matlet.2015.01.158

Vasquez, J. Z., and Diaz, L. J. L. (2017). “Unidirectional abaca fiber reinforced thermoplastic starch composite,” Materials Science Forum 894, 56-61. DOI: 10.4028/www.scientific.net/MSF.894.56

Xue, L., and Tabil, L. G. (2007). “Chemical treatments of natural fiber for use in natural fiber reinforced composites: A review,” Journal of Polymers and the Environment 15(1), 25-33. DOI: 10.1007/s10924-006-0042-3

Yan, L., Kasal, B., and Huang, L. (2016). “A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering,” Composites Part B: Engineering 92, 94-132. DOI: 10.1016/j.compositesb.2016.02.002

Zgrablich, G., Mendioroz, S., Daza, L., Pajares, J., Mayagoitia, V., Rojas, F., and Conner, W. C. (1991). “Effect of porous structure on the determination of pore size distribution by mercury porosimetry and nitrogen sorption,” Langmuir 7(4), 779-758. DOI: 10.1021/la00052a029

Zuccarello, B., and Scaffaro, R. (2017a). “Experimental analysis and micromechanical models of high performance renewable agave reinforced biocomposites, “ Composites Part B: Engineering 119, 141-152. DOI: 10.1016/j.compositesb.2017.03.056

Zuccarello, B., and Zingales, M. (2017b). “Toward high performance renewable agave reinforced biocomposites: Optimization of fiber performance and fiber-matrix adhesion analysis, “ Composites Part B: Engineering 122, 109-120. DOI: 10.1016/j.compositesb.2017.04.011

Article submitted: November 9, 2017; Peer review completed: January 28, 2018; Revised version received and accepted: March 1, 2018; Published: March 13, 2018.

DOI: 10.15376/biores.13.2.3177-3194