Abstract

The shorter natural durability and low energy density of eucalyptus wood hampers its use in generating energy. Torrefaction or pre-carbonization, which is treatment in low oxygen with temperatures between 200 °C and 300 °C, accumulates carbon and lignin, decreases the hygroscopicity, increases the energy efficiency, and reduces the attractiveness of wood to xylophagous organisms, such as termites. The objective of this study was to evaluate the resistance of fresh and torrefied Eucalyptus urophylla (20 min at temperatures of 180 °C, 220 °C, and 260 °C) to dry wood termites (Cryptotermes brevis), following IPT standards. The torrefaction process increased the resistance to dry wood termite attack after 45 d of exposure, with mass losses five times greater in the in natura wood compared with the wood torrefied at 260 °C. The larger visual damage to the in natura chips confirmed its lower resistance to dry wood termites. Torrefaction at 260 °C increased the resistance to dry wood termites and was more efficient with a lower mass loss and wear, and caused a greater mortality of dry wood termites.

Download PDF

Full Article

Resistance of in natura and Torrefied Eucalyptus Wood to Cryptotermes brevis (Isoptera)

Vinícius Resende de Castro,a Matheus Perdigão de Castro Freitas,a Antônio José Vinha Zanuncio,a,b José Cola Zanuncio,a,c Paula Gabriella Surdi de Castro,a Angélica de Cássia Oliveira Carneiro,a and Benedito Rocha Vital a

The shorter natural durability and low energy density of eucalyptus wood hampers its use in generating energy. Torrefaction or pre-carbonization, which is treatment in low oxygen with temperatures between 200 °C and 300 °C, accumulates carbon and lignin, decreases the hygroscopicity, increases the energy efficiency, and reduces the attractiveness of wood to xylophagous organisms, such as termites. The objective of this study was to evaluate the resistance of fresh and torrefied Eucalyptus urophylla (20 min at temperatures of 180 °C, 220 °C, and 260 °C) to dry wood termites (Cryptotermes brevis), following IPT standards. The torrefaction process increased the resistance to dry wood termite attack after 45 d of exposure, with mass losses five times greater in the in natura wood compared with the wood torrefied at 260 °C. The larger visual damage to the in natura chips confirmed its lower resistance to dry wood termites. Torrefaction at 260 °C increased the resistance to dry wood termites and was more efficient with a lower mass loss and wear, and caused a greater mortality of dry wood termites.

Keywords: Biomass; Heat treatment; Termites

Contact information: a: Departamento de Engenharia Florestal, Universidade Federal de Viçosa, Viçosa, Minas Gerais, 36570-900 Brasil; b:Present address: Instituto de ciências agrárias, Universidade Federal de Uberlândia, Monte Carmelo, Minas Gerais, 38500-000 Brasil; c: Departamento de Entomologia/BIOAGRO, Universidade Federal de Viçosa, Viçosa, Minas Gerais, 36570-900 Brasil;

* Corresponding author: vinicius.castro@ufv.br

INTRODUCTION

Termites are one of the most successful insect groups and they feed on dead plant material and cellulose, usually in the form of wood, litter, soil, and animal manure (Guerreiro et al. 2014; Cruz et al. 2015). The dry wood termite Cryptotermes brevis (Isoptera, Kalotermitidae) damages lignocellulosic objects, such as books, furniture, firewood, and wood structures with a moisture content lower than 30%. This insect does not need contact with soil and may compromise the physical and mechanical properties of Eucalyptus sp. wood (Peralta et al. 2004; Arango et al. 2006; Knapic et al. 2018).

Cryptotermes brevis is the most common wood termite species and one of the most researched because it is easily disseminated with small, almost imperceptible colonies that can be transported in furniture and wood pieces (Gonçalves and Oliveira 2006; Maistrello 2018). Dry wood termites prefer woods with sapwood, which is more nutritious. Heartwood normally has a greater natural resistance because of its extractives (Da Silva et al. 2007).

Wood that is used for power generation is chipped, usually in the field or at a factory. However, due to the large water content in the freshly cut wood, it is necessary to subject this material to a drying period of 90 days or until it reaches the equilibrium moisture content (EMC). Termites can colonized the wood during this time, which modifies its properties and reduces its energy potential.

Undesirable wood characteristics that may limit its potential for energy production, as well as termite damage, are of concern to the forestry industries in the energy field. Torrefaction increases the carbon and lignin relative proportions in the wood, which reduces the damage by termites (Da Silva et al. 2018; He et al. 2018; Wang et al. 2018). This process consists in subjecting the wood to high temperatures in an oxygen-poor atmosphere to avoid its combustion and to minimize environmental impacts (Van der Stelt et al. 2011). This treatment alters the chemical composition of the material, increasing the lignin contents and energy density, while reducing the hygroscopicity and attractiveness of the material to xylophagous organisms (Shang et al. 2014; Wang et al. 2018).

The objective of this study was to evaluate the resistance of Eucalyptus urophylla chips, in natura and after torrefaction, to biological deterioration by the dry wood termite C. brevis.

EXPERIMENTAL

Materials

The wood chips used were from seven-years-old Eucalyptus urophylla trees from experimental plantings in Viçosa, Minas Gerais state, Brazil (20º 45′ 14″ S and 42º 52′ 55″ W).

The material in natura, and torrefied were exposed to the dry wood termite C. brevis according to the method IPT 1157 (1980), with some adaptations.

Methods

Material torrefaction

The wood chips were sieved and those that passed through a 31.5-mm sieve and were retained on a 16-mm sieve were used in the experiment. The selected chips were oven-dried at 103 °C ± 2 °C to a 0% dry basis moisture content and then torrefied for 20 min at the temperatures of 180 °C, 220 °C, and 260 °C.

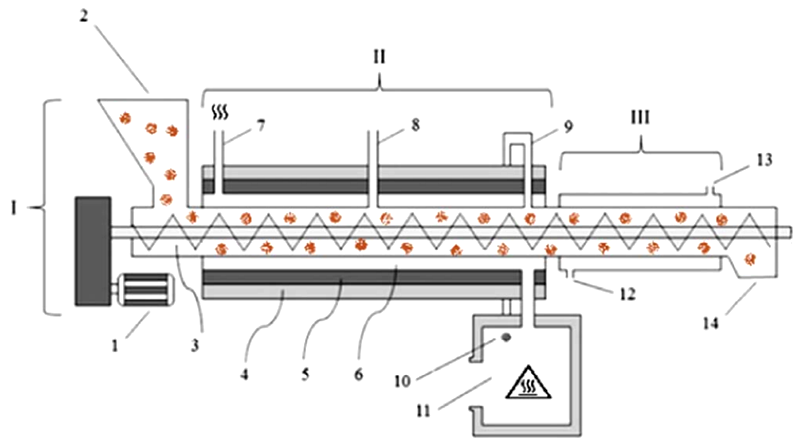

Torrefaction was conducted with an endless screw reactor developed in the Panels and Wood Energy Laboratory (LAPEM/UFV, Viçosa, Brazil) (Da Silva et al. 2018). The prototype of this equipment was a semi-continuous screw reactor that reuses volatile gases in the heating system (Fig. 1). The primary structure of this reactor has three systems essential to most reactors that facilitate the dry torrefaction: (I) transport; (II) heating; and (III) cooling. The first system moves the biomass for the homogenization process, which can be classified as continuous, intermittent, or mixed. The second system produces and transfers heat to the biomass under controlled conditions for direct or indirect heating. The third system releases the torrefied biomass within the safe temperature limits.

Fig. 1. Lateral view of the layout of the prototype screw reactor developed by a Brazilian university (Universidade Federal de Viçosa) for thermal treatment of lignocellulosic biomass: I- transport system; II- heating system; III- cooling system; 1- motor; 2- input biomass; 3- worm-screw; 4- insulating layer; 5- refractory layer; 6- heating gas flow; 7- heating gas output; 8- first chimney; 9- second chimney; 10- connection chimney with the burner; 11- connecting burner; 12- water supply; 13- water exit; and 14- torrefied biomass exit

Gravimetric yield, chemical characterization, and hygroscopic equilibrium moisture content

The gravimetric yield of torrefaction process was calculated by the ratio between the mass of torrefied material produced and the wood dry mass used.

The hygroscopic equilibrium moisture content of the material, calculated on a dry weight basis, was determined using chip samples that had been placed in a climatic chamber at 20 °C and 65% relative humidity until a constant mass was reached. The chip samples were ground and sieved in a 40-mesh to 60-mesh screen to determine the structural chemical composition according to TAPPI standards. The wood was prepared for chemical testing according to TAPPI T264 cm-97 (1996). The extractives, lignin, and cellulose and hemicellulose contents were determined according to TAPPI T204 om-88 (1988), TAPPI T222 om-98 (1996), and TAPPI T223 om-84 (1996), respectively. The ash content was determined according to ABNT NBR 8112 (1986).

Termite testing

Young, healthy unwinged C. brevis termites were collected manually from colonized school chairs.

Eucalyptus chips, torrefied and in natura, were oven-dried at 103 °C ± 2 °C to a constant weight, weighed, and placed in a climatic chamber for two weeks at 25 °C ± 2 °C and 65% ± 5% relative humidity for acclimatization.

Petri dishes contained 39 workers and one C. brevis soldier with 5 g of dry wood chips. There were six replicates for each treatment condition, according to IPT 1157 (1980).

Holes were drilled in the lids of the Petri dishes to allow gas exchange with the environment. The experiment was maintained in a laboratory (25 °C ± 2 °C and 65% ± 5% relative humidity). The wood mass loss and termite mortality were determined after 45 days and the damage was rated from 0 to 4 by four examiners. The termite damage was based on the average rating of each examiner and corresponded to none (0), superficial damage (1), moderate damage (2), accentuated damage (3), and deep damage (4), following IPT 1157 (1980).

The food preference assay was evaluated in the six Petri dishes with 39 workers and one C. brevis soldier each. Two wood chips were placed per Petri dish, which totaled eight wood chips exposed simultaneously to termites, according to IPT 1157 (1980).

Statistical analysis

The equilibrium moisture content (EMC), chemical composition, and biological assay were analyzed using a completely randomized design for the four treatments (in natura and three torrefaction temperatures) with six replicates. The averages were grouped using the means test (p ≤ 0.05). Statistical analyses were performed with Statistica 8.0 software (StatSoft Inc., Tulsa, OK, USA).

RESULTS AND DISCUSSION

The hygroscopic equilibrium moisture content of the torrefied and in natura chips ranged from 5.1% to 12.5% (Table 1). It decreased as the torrefaction temperature increased and the lowest value was found with the treatment at 260 °C. Torrefaction at 220 °C and 260 °C decreased the hygroscopic equilibrium moisture content by 56.0% and 59.3%, respectively, compared with the control (in natura). The wood hygroscopicity reduction was caused by the degradation of cellulose and hemicellulose, which required temperatures lower than that for lignin degradation (Waters et al. 2017). Consequently, the water adsorption capacity (Skaar 1972; Engelund et al. 2013) and hygroscopic equilibrium moisture content were lower (Li et al. 2016). This reduction was desirable for energy purposes because a smaller amount of energy is spent to evaporate water from the chips (Swithenbank et al. 2011; Whittaker and Shield 2017). The wood chemical components degradation resulted in loss of the material, reducing the gravimetric yield, with the lowest value in the material torrefied at 260 °C, with 71.7%.

Table 1. Hygroscopic Equilibrium Humidity and Chemical Composition of the in natura and Torrefied Eucalyptus urophylla Chips

Averages followed by the same letter, per line, do not differ significantly (p > 0.05)

Holocellulose (sum of the cellulose and hemicellulose contents) was the main chemical component in the wood degraded by the heat treatment, with a decrease from 69.2% in the control to 45.6% in the chips treated at 260 °C. Hemicellulose is less thermally stable and degrades between 220 °C and 315 °C, while cellulose degrades at higher temperatures, usually from 300 °C to 360 °C, and thus requires more energy for depolymerization and to break its monomers (Pereira et al. 2013). Therefore, the reduction in the holocellulose content was mainly because of hemicellulose degradation above 220 °C (Yang et al. 2007).

The total lignin content in the chips torrefied at 260 °C increased by 76.9% compared with the in natura chips. Lignin degradation begins at 160 °C, but traces of this structure can still be found after treatment at 900 °C (Yang et al. 2007). Lignin is the most thermally stable chemical compound in the cell wall and is therefore desired for energy purposes because it increases the calorific value of the material and the gravimetric yield from torrefaction and carbonization (Candelier et al. 2013; Pereira et al. 2013).

The total extractives content increased with the torrefaction temperature up to 220 °C. Hemicellulose degradation generates compounds that remain in the biomass as molecules with fragile connections with the fibers, which are removed by alcohol/toluene and increase its extractives content after treatments at up to 220 °C (Brito et al. 2008; Colin et al. 2017). These hemicellulose degradation compounds and the polar extractives, which degraded between 130 °C and 250 °C (Mészáros et al. 2007), are volatilized at higher temperatures. This explained the decrease in the extractives content at 260 °C. An increase in the extractives content after treatments at up to 220 °C has been reported for grasses (Wei et al. 2017) and coniferous woods (Colin et al. 2017).

The ash content increased with the torrefaction temperature, and was 20.7% higher in the material torrefied at 260 °C than in the in natura chips. This may have been because of the organic mass losses of the biomass caused by hemicellulose degradation, which reduced the volatile material percentage. The ash content is characteristic of the initial biomass and varies between species and clones (Couto et al. 2017; Souza et al. 2017). It is necessary to reduce the biomass ash content because this material reduces the energy production and increases equipment corrosion after combustion (Pereira et al. 2013; Zachar et al. 2018).

Deterioration by the dry wood termites and the mass losses were reduced for the torrefied material, where the mass losses were 59.8% lower in the wood torrefied at 180 °C compared with that in the in natura chips (Table 2). High temperatures chemically modified the wood, degraded and changed the wood carbohydrates, which is a food source for termites, and generated extractives with fungicide and insecticide properties (Silva et al. 2004; da Silva et al. 2007; Brocco et al. 2017). This reduced the material hygroscopicity (Thybring 2017) and increased the material acidity, which hindered termite development (Paes et al. 2007; Pereira et al. 2016).

The mass losses from the damage caused by C. brevis in the wood chips were lower than 1.7%. This may seem low, but the evaluation lasted 45 d with only 40 termites per plot. Dry wood termite colonies have 300 individuals on average, which would cause greater mass losses (Guerreiro et al. 2014).

Table 2. Average Mass Losses, Mortality, and Wear Grade of the in Natura and Torrefied Eucalyptus Wood Chips

Averages followed by the same letter, per line, did not differ significantly (p > 0.05)

Torrefaction of the material generated and accumulated extractives sufficient to minimize damage by the dry wood termites because certain substances, such as lignin and extractives, make wood more resistant to deterioration by xylophagous organisms (Knapic et al. 2018). Lignin and phenolic extracts produced during the torrefaction process can reduce the insect food availability, thus reducing the attack intensity and mass loss, even without causing termite death. Phenolic extracts have chelating agents that are capable of forming complexes with metals and protecting the wood and, when more concentrated, act as natural preservatives (fungicides and insecticides) (Brocoo et al. 2017).

The termite mortality rate in the torrefied eucalyptus chips increased by an average of 65.2%, which was higher than that reported in the literature for seven forest species (58.6%) (Gonçalves and Oliveira 2006) and heat-treated E. grandis wood (32.3%) (Pessoa et al. 2006). The increase in the insect mortality rate for the torrefied chips was because of the high increase in the lignin content during this process, presence of phenolic organic compounds from thermal degradation by torrefaction, and reduction in the holocellulose, as it was reported for E. grandis wood (Pessoa et al. 2006).

Wood damage was recorded for all of the treatments, which indicated that torrefaction did not fully protect the wood. The attack degree and mass loss decreased as the torrefaction treatment temperature increased. These results were similar to those obtained with E. grandis wood that was torrefied at 200 °C with near moderate wear, and was emphasized in the in natura wood (Pessoa et al. 2006).

Chemical components generated during torrefaction of the E. urophylla wood chips may have contributed to the lower mass loss, higher mortality, and lower wear degree by the termites. The higher mortality could have resulted from direct action on the termites or from the imbalance caused to their symbionts, because chemical substances like terpenoids, terpenes, quinones, polyphenols, and other extractives have been widely studied as repellents and/or are toxic to termites or their symbionts (Tisseverasinghe and Jayatilleke 1973; Bultman and Parrish 1979; Scheffrahn 1991; Cornelius et al. 1995). The quantity of microorganisms in the termite intestines may have become insufficient to digest cellulose, which influenced the eating habits of these insects and led to their death (Lepage 1986).

The weight losses caused by the dry wood termites were four times higher in the in natura chips compared with the chips treated at 180 °C (Table 3), which confirmed the dry wood termite preference for the in natura wood. This may have been associated with the lignin concentration in the torrefied material, and indicated an increased wood resistance to xylophagous termite attack.

Table 3. Mass Losses, Mortality, and Wear Score of the in natura and Torrefied Eucalyptus Wood Chips Subjected to Dry Wood Termites in the Food Preference Test

Means followed by the same letter, per line, do not differ significantly (p > 0.05)

The in natura wood chip wear was higher than for the thermally treated chips, with moderate damage in the in natura chips, superficial damage in the chips treated at 180 °C, and no damage in the chips treated at 220 °C and 260 °C. The lower feed preference for the chips torrefied at 220 °C and 260 °C was explained by the change in the water adsorption capacity. The chips became less hygroscopic as the temperature increased (Knapic et al. 2018). The number of water molecules between and inside of the polysaccharide molecules (cellulose and hemicelluloses) and the hydrogen bonds formed between the polysaccharide hydroxyls of the wood and water decreased (Wahl et al. 2004). The lower hygroscopicity made it difficult for the termites to recognize the food substrate (Weiland and Guyonnet 2003). Changes in the chemical composition of the wood may include the production of new free molecules that can act as insecticides and fungicides, as well as cause changes in the lignin cross-linking. The present results confirmed that the wood durability increased as the heat treatment temperature increased (Maistrello 2018).

The increase of the torrefaction temperature decreased the gravimetric yield as determined during the experiment. At the same time, the temperature increase also increased resistance against termites. Therefore, these two variables can contributed to reduced damage by these insects and fungi (Chaouch et al. 2010).

CONCLUSIONS

1. Torrefaction degraded unstable chemical components at high temperatures. Therefore, the content of lignin, extractives, and ash increased and the holocellulose content decreased.

2. Torrefied material had lower water adsorption capacity, resulting in lower equilibrium moisture content (EMC).

3. Torrefaction increased the wood chip resistance to the dry wood termites, with a greater efficiency and weight losses higher in the in natura chips compared with the chips treated torrefied; and the dry wood termites fed preferentially in the in natura wood.

ACKNOWLEDGEMENTS

The authors would like to thank the Brazilian agencies “Conselho Nacional de Desenvolvimento Cientifico e Tecnológico (CNPq), Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES/PELD), Fundação de Amparo à Pesquisa do Estado de Minas Gerais (FAPEMIG) and Programa Cooperativo sobre Proteção Florestal (PROTEF) do Instituto de Pesquisas e Estudos Florestais (IPEF)” for the scholarships and financial support.

REFERENCES CITED

ABNT NBR 8112 (1986). “Carvão vegetal – Análise imediata [Charcoal – Immediate analysis],” Associação Brasileira de Normas Técnicas, Rio de Janeiro, Brazil.

Arango, R. A., Green III, F., Hintz, K., Lebow, P. K., and Miller, R. B. (2006). “Natural durability of tropical and native woods against termite damage by Reticulitermes flavipes (Kollar),” Int. Biodeter. Biodegr. 57(3), 146-150. DOI: 10.1016/j.ibiod.2006. 01.007

Brito, J. O., Silva, F. G., Leão, M. M., and Almeida, G. (2008). “Chemical composition changes in eucalyptus and pinus woods submitted to heat treatment,” Bioresource Technol. 99(18), 8545-8548. DOI: 10.1016/j.biortech.2008.03.069

Brocco, V. F., Paes, J. B., da Costa, L. G., Brazolin, S., and Arantes, M. D. C. (2017). “Potential of teak heartwood extracts as a natural wood preservative,” J. Clean. Prod. 142(Part 4), 2093-2099. DOI: 10.1016/j.jclepro.2016.11.074

Bultman, J. D., and Parrish, K. K. (1979). “Evaluation of some wood extractives and related compounds as anti-borer, anti-fungal, and anti-termitic agents,” International Biodeterior. 15, 19-27.

Candelier, K., Dumarçay, S., Pétrissans, A., Desharnais, L., Gérardin, P., and Pétrissans, M. (2013). “Comparison of chemical composition and decay durability of heat treated wood cured under different inert atmospheres: Nitrogen or vacuum,” Polym. Degrad. Stabil. 98(2), 677-681. DOI: 10.1016/j.polymdegradstab.2012.10.022

Chaouch, M., Pétrissans, M., Pétrissans, A., and Gérardin P. (2010). “Use of wood elemental composition to predict heat treatment intensity and decay resistance of different softwood and hardwood species,” Polym. Degrad Stabil. 95(12), 2255-2259. DOI: 10.1016/j.polymdegradstab.2010.09.010

Colin, B., Dirion, J.-L., Arlabosse, P., and Salvador, S. (2017). “Quantification of the torrefaction effects on the grindability and the hygroscopicity of wood chips,” Fuel 97, 232-239. DOI: 10.1016/j.fuel.2017.02.028

Couto, A. M., Teodoro, P. E., and Trugilho, P. F. (2017). “Path analysis of the energy density of wood in eucalyptus clones,” Genet. Mol. Res. 16(1). DOI: 10.4238/gmr 16019536

Cornelius, M. L., Grace, J. K., Ford, P. W., and Davidson, B. S. (1995). “Toxicity and repellency of semi chemicals extracted from a Dolichoderine ant (Hymenoptera, Formicidae) to the formosan subterranean termites (Isoptera, Rhinotermitidae),” Environ. Entomol. 24, 1263-1269.

Cruz, H., Jones, D., and Nunes, L. (2015). “Wood,” in: Materials for Construction and Civil Engineering, M. C. Gonçalves and F. Margarido (eds.), Springer International Publishing Switzerland, Basel, Switzerland, pp. 557-583.

Da Silva, C. A., Monteiro, M. B. B., Brazolin, S., Lopez, G. A. C., Richter, A., and Braga, M. R. (2007). “Biodeterioration of brazilwood Caesalpinia echinata Lam. (Leguminosae-Caesalpinioideae) by rot fungi and termites,” Int. Biodeter. Biodegr. 60(4), 285-292. DOI: 10.1016/j.ibiod.2007.05.003

Da Silva, C. M. S., Carneiro, A. d. C. O., Vital, B. R., Figueiró, C. G., Fialho, L. d. F., de Magalhães, M. A., Carvalho, A. G., and Cândido, W. L. (2018). “Biomass torrefaction for energy purposes – Definitions and an overview of challenges and opportunities in Brazil,” Renew. Sust. Energ. Rev. 82(Part 3), 2426-2432. DOI: 10.1016/j.rser.2017.08.095

Engelund, E. T., Thygesen, L. G., Svensson, S., and Hill, C. A. S. (2013). “A critical discussion of the physics of wood–water interactions,” Wood Sci. Technol. 47(1), 141-161. DOI: 10.1007/s00226-012-0514-7

Gonçalves, F. G., and Oliveira, J. T. d. S. (2006). “Resistência ao ataque de cupim-de-madeira seca (Cryptotermes brevis) em seis espécies florestais [Resistance to the attack of dry-wood termites (Cryptotermes brevis) of six wood species],” Cerne 12(1), 80-83.

Guerreiro, O., Cardoso, P., Ferreira, J. M., Ferreira, M. T., and Borges, P. A. V. (2014). “Potential distribution and cost estimation of the damage caused by Cryptotermes brevis (Isoptera: Kalotermitidae) in the Azores,” J. Econ. Entomol. 107(4), 1554-1562. DOI: 10.1603/EC13501

He, C., Tang, C., Li, C., Yuan, J., Tran, K.-Q., Bach, Q.-V., Qiu, R., and Yang, Y. (2018). “Wet torrefaction of biomass for high quality solid fuel production: A review,” Renew. Sust. Energ. Rev. 91, 259-271. DOI: 10.1016/j.rser.2018.03.097

IPT 1157 (1980). “Métodos de ensaios e análise em preservação de madeira: Ensaio acelerado de laboratório da resistência natural ou de madeira preservada ao ataque de térmitas do gênero Cryptotermes (Fam. Kalotermitidae) [Methods of testing and analysis in wood preservation: Accelerated laboratory test of natural ressitance or wood preserved to the attack of termites of the genus Cryptotermes (Fam. Kalotermitidae)],” Instituto de Pesquisas Tecnológicas, São Paulo, Brazil.

Knapic, S., Santos, J., Santos, J., and Pereira, H. (2018). “Natural durability assessment of thermo-modified young wood of eucalyptus,” Maderas-Cienc. Tecnol. 20(3), 489-498. DOI: 10.4067/S0718-221X2018005031801

Lepage, E. S. (1986). “Química da Madeira [Chemistry of Madeira],” in: Manual de Preservação de Madeira [Manual of Wood Preservation], IPT, São Paulo, Brazil, pp. 1-707.

Li, M. F., Chen, L. X., Li, X., Chen, C. Z., Lai, Y. C., Xiao, X., and Wu, Y. Y. (2016). “Evaluation of the structure and fuel properties of lignocelluloses through carbon dioxide torrefaction,” Energ. Convers. Manage. 119, 463-472. DOI: 10.1016/ j.enconman.2016.04

Maistrello, L. (2018). “Termites and standard norms in wood protection: A proposal targeting drywood termites,” in: Termites and Sustainable Management: Volume 2 – Economic Loses and Management, M. A. Khan and W. Ahmad (eds.), Springer International Publishing AG, Cham, Switzerland, pp. 261-287.

Mészáros, E., Jakab, E., and Várhegyi, G. (2007). “TG/MS, Py-GC/MS and THM-GC/MS study of the composition and thermal behavior of extractive components of Robinia pseudoacacia,” J. Anal. Appl. Pyrol. 79(1-2), 61-70. DOI: 10.1016/j.jaap. 2006.12.007

Paes, J. B., de Melo, R. R., and de Lima, C. R. (2007). “Resistência natural de sete madeiras a fungos e cupins xilófagos em condições de laboratório [Natural resistance of seven woods to xylophogous fungi and termites under laboratory condition],” Cerne 13(2), 160-169.

Peralta, R. C. G., Menezes, E. B., Carvalho, A. G., and Aguiar-Menezes, E. d. L. (2004). “Wood consumption rates of forest species by subterranean termites (Isoptera) under field conditions,” Rev. Árvore 28, 283-289.

Pereira, B. L. C., Carneiro, A. d. C. O., Carvalho, A. M. M. L., Colodette, J. L., Oliveira, A. C., and Fontes, M. P. F. (2013). “Influence of chemical composition of Eucalyptus wood on gravimetric yield and charcoal properties,” BioResources 8(3), 4574-4592. DOI: 10.15376/biores.8.3.4574-4592

Pereira, M. P. d. C. F., Costa, E. V. S., Pereira, B. L. C., Carvalho, A. M. M. L., Carneiro, A. d. C. O., and Costa, A. (2016). “Torrefação de cavacos de eucalipto para fins energéticos [Torrefaction of eucalyptus chips for energy purposes],” Pesquisa Florestal Brasileira 36(87), 269-275. DOI: 10.4336/2016.pfb.36.87.1093

Pessoa, A. M. d. C., Filho, E. B., and Brito, J. O. (2006). “Avaliação da madeira termorretificada de Eucalyptus grandis, submetida ao ataque de cupim de madeira seca, Cryptotermes brevis [Evaluation of the Eucalyptus grandis thermorectificated wood submitted to the drywood termite attack, Cryptotermes brevis],” Sci. For. 72, 11-16.

Scheffrahn, R. H. (1991). “Allelochemical resistance of wood to termites,” Sociobiology 19(1), 257-281.

Shang, L., Ahrenfeldt, J., Holm, J. K., Bach, L. S., Stelte, W., and Henriksen, U. B. (2014). “Kinetic model for torrefaction of wood chips in a pilot-scale continuous reactor,” J. Anal. Appl. Pyrol. 108, 109-116. DOI: 10.1016/j.jaap.2014.05.010

Silva, J. d. C., Lopes, A. G. C., and Oliveira, J. T. d. S. (2004). “Influência da idade na resistência natural da madeira de Eucalyptus grandis W. Hill ex. Maiden ao ataque de cupim de madeira seca (Cryptotermes brevis) [Influence of age on the natural resistance of Eucalyptus grandis wood W. Hill ex. Maiden to the attack of dry wood termite (Cryptotermes brevis)],” Rev. Árvore 28(4), 583-587. DOI: 10.1590/S0100-67622004000400012

Skaar, C. J. (1972). Water in Wood, Syracuse University Press, Syracuse, NY, 1-252.

Souza, F. M. L., Sansígolo, C. A., Pupo, C. H., and Sereghetti, G. C. (2017). “Wood and pulping properties of Eucalyptus urophylla and its hybrid grown by silvopastoral and conventional forest production models,” Cell. Chem. Technol. 51(3-4), 347-353.

Swithenbank, J., Chen, Q., Zhang, X., Sharifi, V., and Pourkashanian, M. (2011). “Wood would burn,” Biomass Bioenerg. 35(3), 999-1007. DOI: 10.1016/j.biombioe.2010.12.026

TAPPI T204 om-88 (1988). “Solvent extractives of wood and pulp,” TAPPI Press, Atlanta, GA.

TAPPI T222 om-88 (1996). “Acid insoluble lignin wood and pulp,” TAPPI Press, Atlanta, GA.

TAPPI T223 om-88 (1996). “Pentosans in wood and pulp,” TAPPI Press, Atlanta, GA.

TAPPI T264 om-88 (1996). “Preparation of wood goes chemical analysis,” TAPPI Press, Atlanta, GA.

Thybring, E. E. (2017). “Water relations in untreated and modified wood under brown-rot and white-rot decay,” Int. Biodeter. Biodegr. 118, 134-142. DOI: 10.1016/j.ibiod.2017.01.034

Tisseverasinghe, A. E. K., and Jayatilleke, M. P. A. (1973). “Preliminary study of the feeding preferences of the dry wood termites,” Sri Lanka Forestry 1, 13-18.

Van der Stelt, M. J. C., Gerhauser, H., Kiel, J. H. A., and Ptasinski, K. J. (2011). “Biomass upgrading by torrefaction for the production of biofuels: A review,” Biomass Bioenerg. 35(9), 3748-3762. DOI: 10.1016/j.biombioe.2011.06.023

Yang, H., Yan, R., Chen, H., Lee, D. H., and Zheng, C. (2007). “Characteristics of hemicellulose, cellulose and lignin pyrolysis,” Fuel 86(12-13), 1781-1788. DOI: 10.1016/j.fuel.2006.12.013

Wahl, P., Simonaho, S.-P., Pakarinen, T., and Silvennoinen, R. (2004). “Effect of heat-treatment on scattering of laser light from wood grains,” Holz Roh. Werkst. 62(5), 343-345. DOI: 10.1007/s00107-004-0511-0

Wang, L., Barta-Rajnai, E., Skreiberg, Ø., Khalil, R., Czégény, Z., Jakab, E., Barta, Z., and Grønli, M. (2018). “Effect of torrefaction on physiochemical characteristics and grindability of stem wood, stump and bark,” Appl. Energ. 227, 137-148. DOI: 10.1016/j.apenergy.2017.07.024

Waters, C. L., Janupala, R. R., Mallinson, R. G., and Lobban, L. L. (2017). “Staged thermal fractionation for segregation of lignin and cellulose pyrolysis products: An experimental study of residence time and temperature effects,” J. Anal. Appl. Pyrol. 126, 380-389. DOI: 10.1016/j.jaap.2017.05.008

Wei, Y., Wang, M., Zhang, P., Chen, Y., Gao, J., and Fan, Y. (2017). “The role of phenolic extractives in color changes of locust wood (Robinia pseudoacacia) during heat treatment,” BioResources 12(4), 7041-7055. DOI: 10.15376/biores.12.4.7041-4055

Weiland, J. J., and Guyonnet, R. (2003). “Study of chemical modifications and fungi degradation of thermally modified wood using DRIFT spectroscopy,” Holz Roh. Werkst. 61(3), 216-220. DOI: 10.1007/s00107-003-0364-y

Whittaker, C., and Shield, I. (2017). “Factors affecting wood, energy grass and straw pellet durability – A review,” Renew. Sust. Energ. Rev. 71, 1-11. DOI: 10.1016/j.rser.2016.12.119

Zachar, M., Lieskovský, M., Majlingová, A., and Mitterová, I. (2018). “Comparison of thermal properties of the fast-growing tree species and energy crop species to be used as a renewable and energy-efficient resource,” J. Therm. Anal. Calorim. 134(1), 543-548. DOI: 10.1007/s10973-018-7194-y

Article submitted: November 8, 2018; Peer review completed: January 1, 2019; Revised version received and accepted: January 27, 2019; Published: February 7, 2019.

DOI: 10.15376/biores.14.2.2480-2490