Abstract

The plant Ensete ventricosum is used in agriculture in Africa. It is a source of fibres, which can be used in the interaction with polymers. This study deals with a material utilization of these fibres with a length of 1 to 2 mm, 2 to 3 mm, and 3 to 5 mm, together with reactoplastics resin ChS Epoxy 1200/324, following requirements of developing countries. Some areas of the African continent suffer from a lack of wood, and material based on epoxy and fibres can substitute for many wood products. The aim of this experiment was to describe basic mechanical properties (tensile strength σm, strain at the break εb, modulus of the elasticity Et, and impact strength an) of the composite material reinforced with fibres of the false banana plant, Ensete ventricosum. The plant, which originated in Ethiopia, is exploitable in developing countries. Geometrical aspects and morphology of the used fibres was characterized by scanning electron microscopy (SEM). The addition of fibres increased the modulus of elasticity and the impact strength, whereas the tensile strength and the strain at break were decreased.

Download PDF

Full Article

Strength Characteristics of Untreated Short-fibre Composites from the Plant Ensete ventricosum

Miroslav Müller,a,* Petr Valášek,a and Alessandro Ruggiero b

The plant Ensete ventricosum is used in agriculture in Africa. It is a source of fibres, which can be used in the interaction with polymers. This study deals with a material utilization of these fibres with a length of 1 to 2 mm, 2 to 3 mm, and 3 to 5 mm, together with reactoplastics resin ChS Epoxy 1200/324, following requirements of developing countries. Some areas of the African continent suffer from a lack of wood, and material based on epoxy and fibres can substitute for many wood products. The aim of this experiment was to describe basic mechanical properties (tensile strength σm, strain at the break εb, modulus of the elasticity Et, and impact strength an) of the composite material reinforced with fibres of the false banana plant, Ensete ventricosum. The plant, which originated in Ethiopia, is exploitable in developing countries. Geometrical aspects and morphology of the used fibres was characterized by scanning electron microscopy (SEM). The addition of fibres increased the modulus of elasticity and the impact strength, whereas the tensile strength and the strain at break were decreased.

Keywords: Permanently sustainable sources; Local resources; False banana plant; Reactoplastics

Contact information: a: Czech University of Life Sciences Prague, Faculty of Engineering, Department of Material Science and Manufacturing Technology, Kamýcká 129, 165 21, Prague 6, Czech Republic; b: University of Salerno, Department of Industrial Engineering, Salerno, Italy;

* Corresponding author:muller@tf.czu.cz

INTRODUCTION

The exploitation of permanently sustainable sources is key in terms of global society. Cheap and available materials are suitable to use in material engineering in developing countries, including those in Sub-Saharan Africa. An ideal example is the material exploitation of secondary agricultural products, such as fibres of the false banana plant (De Assis et al. 2015; Zaman and Beg 2016).

The design of new materials based on natural renewable resources is essential for both environmental and economic analyses (Alves et al. 2010). Presently, there is great attention to the application of natural fibres as a substitute for synthetic fibres (Mizera et al. 2016).

These fibres from renewable energy sources are environmentally friendly, biodegradable, and recyclable, and obviously, the use of natural fibres reduces problems of waste disposal and reduces environmental pollution (Kalia et al. 2013; Valášek and Müller 2015; Mizera et al. 2016).

In the past few decades, research and engineering interest has shifted from traditional monolithic materials to fibre-reinforced polymer-based materials, due to their unique advantages of a high strength to a weight ratio, a non-corrosive property, and high fracture toughness. These composite materials consist of a low strength polymeric matrix and high strength fibres, such as carbon, glass, and aramid; they have dominated the aerospace, leisure, automotive, construction, and sporting industries. Unfortunately, these fibres have serious drawbacks, such as being non-renewable and non-recyclable; having high energy consumption in the manufacturing process; presenting health risks when inhaled; and being non-biodegradable (Cheung et al. 2009).

Natural fibres can be used as reinforcements in composite materials (Poole et al. 2009; Mizera et al. 2016). They can be suitable substitutes for synthetic fibres because they have relatively high strength, stiffness, and low density (Wambua et al. 2003; Faruk et al. 2012; Mizera et al. 2016). Natural fibres such as jute, kenaf, hemp, sisal, flax, bagasse, etc., are successfully used as the filler in plastic composites (Lu et al. 2003; Kakou et al. 2014; Zhao et al. 2014; Abdul Nasir et al. 2015; Doumbia et al. 2015). Their advantages are their low price, low density, abundance, renewability, biodegradability, and environmental friendliness (Nechwatal et al. 2003; Sharifah and Martin 2004; Cheung et al. 2009; Mominul Haque et al. 2009; Ku et al. 2011).

The main disadvantages of natural fillers utilized in polymeric composites are their low wettability and non-homogeneity (Herrera-Franco and Valadez-Gonzalez 2005). The fibres are mostly hydrophilic natural fibres, and they have low tensile strength (Sharifah and Martin 2004; Alkbir et al. 2016; Mizera et al. 2016). These problems can be alleviated by suitable compatibilisers and coupling agents (Prasad et al. 2016).

One suitable plant with great potential for the production of natural fibres is ensete (Ensete ventricosum), also known as a false banana (Tsehaye and Kebebew 2006; Mizera et al. 2016). Ensete ventricosum does not produce edible fruits and it is not categorized as usual banana plants (genera Musa). Traditionally, Ensete ventricosum fibres have been harvested from leaves of this plant for the production of ropes, etc. Composite material reinforced with the Ensete ventricosum fibres could be used for the production of parts for the automotive industry.

Natural fibres gained from the plant Ensete ventricosum have many advantages similar to most natural fibres, e.g., price, low density, age-resistance, and low abrasiveness during processing (Chandramohan and Bharanichandar 2014; Pupure et al. 2016). Their disadvantages are related to the biological essence of the material, e.g., decreased resistance to degradation environments, sensitivity to water and moisture effects, and sensitivity to higher temperatures or biological corrosion. Composites with natural fibres hold increasingly important positions in modern material engineering (Messiry 2013; Chandramohanand Bharanichandar 2014).

According to De Assis et al. (2015), banana fibres have many advantages for industrial applications, e.g., they have properties like waterproof, UV protection (because of lignin content), and moisture absorption; they are anti-oxidant and biodegradable, etc.

An optimization of the matrix reinforcing with the filler depends on an interfacial interaction. A transfer of a stress from the matrix to the reinforcement occurs by adhesion, i.e., Coulomb’s friction in the interface of the matrix and fibres (Ruggiero et al. 2015; Valášek et al. 2015; Ruggiero et al. 2016). There is a logical requirement for the highest strength and creating corresponding mutual interaction. The modern concept of the fibre composites uses fibre surface treatments for an optimization of this boundary; however, it increases the technological demands of the fibre preparation and of the composite itself. Processes for fibre surface optimization and composite preparation (e.g., vacuum) are not often secured in developing countries.

However, surface treatments of banana fibres can optimize the interaction with the polymeric materials, which create the matrices. Zaman and Beg (2016) described the modification of banana fibres with methylacrylate (MA) mixed with methanol (MeOH) along with 2% benzyl peroxide under a thermal curing method at different temperatures (50 to 90 °C). This treatment increased the tensile strength. The surface treatment of fibres (alkali and acrylic acid) increases (Prasad et al. 2016), along with the water-resistance of the composite, except for increasing mechanical properties.

The technologically demanding treatments of fibres described above are not available in developing countries, which is why this study aimed to define basic mechanical characteristics of the composite with non-treated fibre surfaces and commonly used reactoplastics. This alternative of the fibre utilization is financially undemanding, and the preparation is possible without special equipment. In addition to evaluating composite strength characteristics, scanning electron microscopy (SEM) was used to evaluate the interaction of fibres with the reactoplastics matrix.

The aim of this experiment was to describe the mechanical behavior of the composite material reinforced with the fibres of the plant false banana Ensete ventricosum, including the tensile strength σm, strain at the break εb, modulus of the elasticity Et, and impact strength an. Geometrical aspects of the fibres were characterized by optical analysis.

This paper aims to define basic mechanical characteristics of the composite exploitable in the developing countries without demands for modern machines and equipment. The nature of the epoxy resin enables good wetting of fibres also without their surface treatment; however, the main reason of the absence of surface treatments is a minimization of technological demands and costs.

EXPERIMENTAL

Materials and Methods

Fibres of the plant Ensete ventricosum (the false banana) were used in the experiment. This plant grows in many developing countries. The experiment used fibres from the plants grown in plantations in Ethiopia (Fig. 1).

Fig. 1. Stem of plant Ensete ventricosum with visible fibres, as harvested in Ethiopia

This plant is used to prepare traditional dishes in Ethiopia (Tsehaye and Kebebew 2006; Yirmaga 2013). A secondary product from this plant is natural fibres. The material exploitation of these fibres is demanding owing to their economic evaluation. The fibre density was 0.71 ± 0.45 g·cm-3 (Mizera et al. 2016). Fibres had been dried at 105 °C for 20 h before they were applied as a filler into the resins.

The resin ChS Epoxy 1200/324 (hardener P 11 – Diethylentriamin; DCH-Sincolor, a.s., Pilsen, Czech Republic) used in the experiment is a structural two-component reactoplastics epoxy resin, which shows effective adhesion to a huge number of materials.

The fibres were added into the matrix ChS Epoxy 1200/324 in the ratio of 0.5, 1.0, 1.5, 2.0, 2.5, and 3.0 wt.%. Weight ratios were chosen with respect to a practical application when the filler was mixed mainly on the basis of weight ratios. The aforementioned weights correspond to 0.8, 1.6, 2.4, 3.1, 3.9, and 4.6 vol.%. The reinforcing fibres were prepared by cutting on a cutting machine from the firm Moraknife with the lengths 1 to 2 mm, 2 to 3 mm, and 3 to 5 mm with a random arrangement of the fibres in the matrix. Appropriate lengths of fibres (a mean and a standard deviation) falling into presented intervals were measured by means of an electron microscope.

The CSN EN ISO 527-1 (1997) standard was used for the evaluation of tensile characteristics. The tensile strength σm, strain at break εb, and modulus of elasticity Et were tested. The test specimens for tensile testing CSN EN ISO 527-1 (1997) were prepared according to standard CSN EN ISO 3167 (2015).

The impact strength an was measured using the equipment Dynstat (Louis Schopper, Leipzig, Germany) for testing of plastics. The test specimen preparation and impact tests were performed according to the standard CSN 64 0611 (1968).

The specified matrix-filler (fibres) phases ratio was mixed to make the composite, which was used for the preparation of test specimens according to the specified standards. The moulds for casting were made from Lukopren N material (Lučební závody, a.s., Kolín, Czech Republic) using models. The form and the size of moulds met the corresponding standards. The test samples of matrix and composite materials were maintained at 22 ± 2 °C for 48 h.

The tensile properties were evaluated using a LABTest 5.50ST universal tensile strength testing machine (Labortech, s.r.o., Opava, Czech Republic) with an AST type KAF 50 kN sensing unit and Test & Motion software (DOLI Elektronik GmbH, Munich, Germany). The speed of the deformation corresponded to 2 mm·min-1.

The optical analysis of fracture surfaces and the adhesive bond cut was examined with SEM using a MIRA 3 TESCAN microscope (Tescan Orsay Holding, Brno, Czech Republic). The fracture surfaces were dusted with gold.

The effect of the fibre dispersion on the composite failure was studied with SEM images. The effect of the particle size of fibres, the wettability, and the porosity on the interfacial crack was investigated also with SEM. The shape and the dimension were evaluated using the Gwiddion program (Software Foundation, Inc., Boston, USA). The results of measuring were statistically analysed. Statistical hypotheses were also tested at measured sets of data by STATISTICA software (StatSoft Inc., Tulsa, USA). A validity of the zero hypothesis (H0) showed that there was no statistically significant difference (p > 0.05) among tested sets of data. In contrast, the hypothesis H1 denied the zero hypothesis and showed that there was a statistically significant difference among tested sets of data or a dependence among variables (p < 0.05).

RESULTS AND DISCUSSION

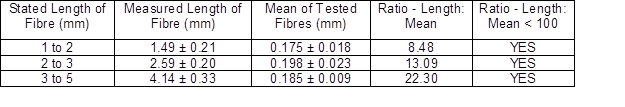

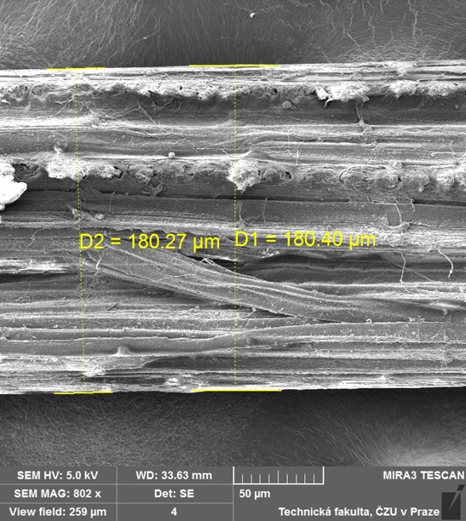

The length and the thickness of the fibres were evaluated by microscopy, as shown in Table 1 and Fig. 2. The fibre morphology was an essential factor influencing subsequent interfacial interaction with the matrix. It was obvious from the ratio results of the length and the mean of tested fibres that they were short-fibre composite systems, i.e., the ratio between the length and the mean of fibres was smaller than 100. Tested composite systems belonged to the group with discontinuous reinforcement. The ratio between the length and the mean of the filler was presented in Table 1. With this ratio, the anisotropic filler had an effect similar to the particle filler (Debnath et al. 2004).

Table 1. Basic Characteristics of Tested Fibres

Fig. 2. Measurement of fibre width

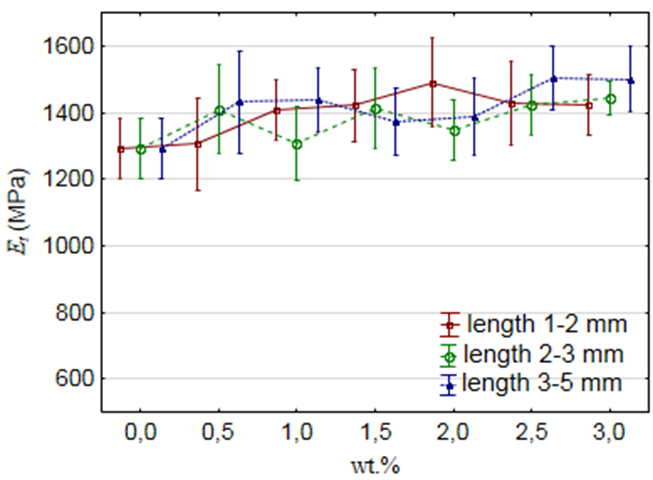

The modulus of elasticity of unfilled resin was 1292.09 ± 92.93 MPa (Fig. 3). The inclusion of any fibre length increased these values; however, it did not cause a statistically significant increase, as shown by ANOVA in Fig. 3 (p > 0.10). Thus, the hypothesis H0 was confirmed, i.e., there was no difference in the modulus of elasticity Et at the significance level of 0.05 among single length of the fibres from Ensete ventricosum.

The variation coefficient increased with the inclusion of short fibres (up to 16.2%). This increase was observed for all set tensile characteristics of the filled material. The dispersion of measured data showed possible imperfect wetting of the fibres with the matrix, and it also could have been caused by a presence of air bubbles. The highest measured modulus of elasticity was 1503.73 ± 126.87 MPa, measured in the resin filled with the fibres with the length 3 to 5 mm and 2.5 wt.%.

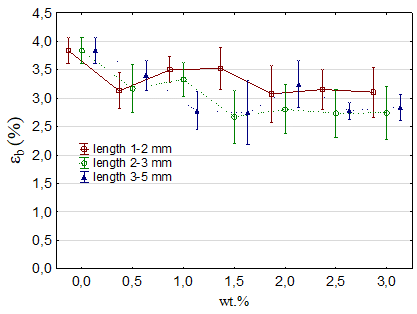

The strain at break εb was decreased with the inclusion of the fibres of Ensete ventricosum. This decrease was statistically verifiable compared with the unfiled resin (Fig. 4, p = 0.00).The hypothesis H0 was not certified, i.e., there was a difference in the strain at break in the significance level of 0.05 among single concentrations of the fibres of Ensete ventricosum. The strain at break of the unfilled resin corresponded to 3.86 ± 0.16%. Figure 4 shows a quick decline in the strain at break at low concentrations of short fibres in the matrix and then a consequent settling of this decline. The smallest value 2.65 ± 0.52% was measured at 2.5 wt.% fibres with the length 2 to 3 mm.

Fig. 3. Modulus of elasticity Et of composites with various lengths of fibres

Fig. 4. Strain at break εb of composites with various lengths of fibres

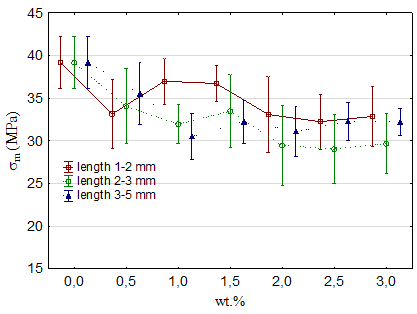

The tensile strength σm of composites filled with short fibres of the false banana was decreased compared with the unfilled resin (39.06 ± 3.21 MPa). The hypothesis H0 was not certified, i.e., there was a difference in the tensile strength in the significance level of 0.05 among single concentrations of the fibres from Ensete ventricosum. The inclusion of the fibres of 2 to 3 mm decreased the tensile strength to 28.90 ± 4.71 MPa (Fig. 5). Standard deviations – scattering of measured data – reflect a fact that this is material with low demands on a technological preparation determined for developing areas. This fact influenced mutual interactions of phases.

Longer fibres gave smaller strain at break and tensile strength. This is caused due to an agglomeration among the longer fibres. These agglomerates were not fully wetted by the polymer resin. Bad wetting caused weak areas within the composite. This bad wetting showed itself by a gap of 0.12 ± 0.04 µm between the fibre and the resin.

Fig. 5. Tensile strength σm of composites with various lengths of fibres

Fig. 6. Impact strength an of composites with various lengths of fibres

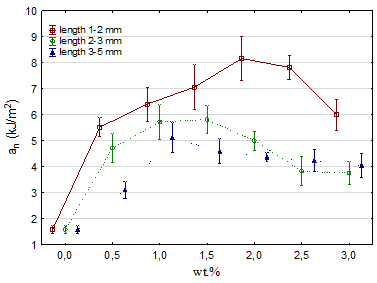

Figure 6 shows the impact strength an values. Ensete ventricosum fibres had a positive effect on the filler. The reactoplastics matrix based on the two-component epoxy adhesive was relatively brittle, with an impact strength of 1.57 ± 0.14 kJ·m-2.

The addition of Ensete ventricosum fibres increased the impact strength, which was higher than that of the pure epoxy. The fibres increased the impact strength an by 420%. The optimum concentration (i.e., 1 to 2 g of the filler) was determined from the results. The maximum values of the impact strength were found at these concentrations. The best results were gained with the fibres of 1 to 2 mm in length. The hypothesis H0 was not certified, i.e., there was a difference in the impact strength in the significance level of 0.05 among single concentrations of the fibres from Ensete ventricosum.

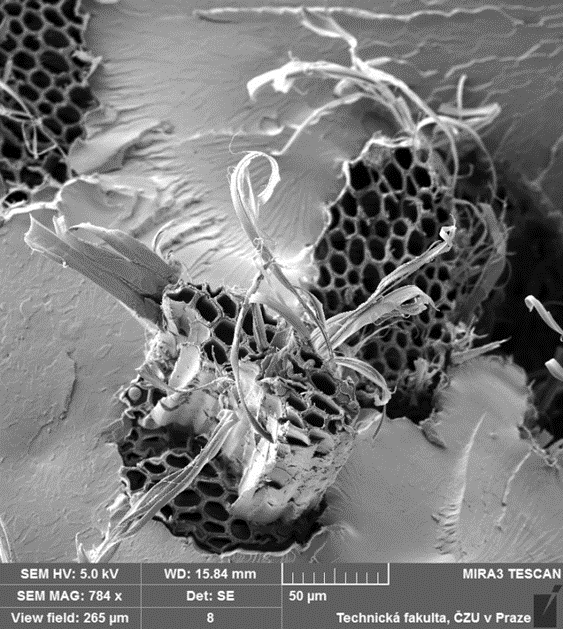

Electron microscopy was used to evaluate the interfacial interaction between untreated fibres of Ensete ventricosum and the epoxy resin. The fractured sample showed randomly oriented banana Ensete ventricosum fibres in the composite (Fig. 7). The transfer of the loading mechanism in the short-fibre composite via the fibre ends was visible. The ends of the fibres were greatly deformed after the destruction. The transfer of the stress was mediated near the end of the fibres. This mechanism has been observed in the short-fibre composite systems.

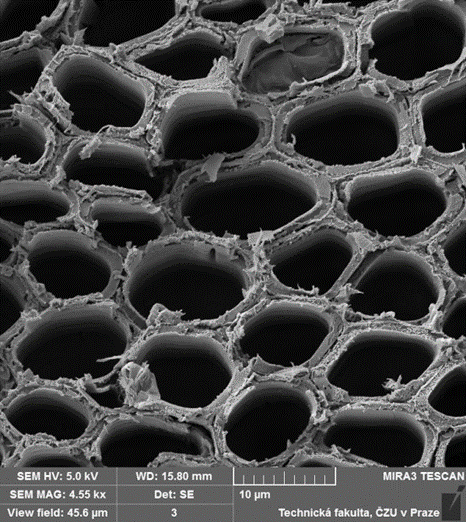

The research on the fibres drenched in the epoxy matrix did not prove its ingress into the hollow section of tested fibres (Fig. 8). Single hollow sections had a mean diameter of 10.14 ± 1.77 μm.

Fig. 7. Interaction of matrix and fibres. Micrograph of banana fibre composite (Ensete ventricosum) with untreated fibres (secondary electrons)

Fig. 8. SEM: hollow section of Ensete ventricosum fibre (secondary electrons)

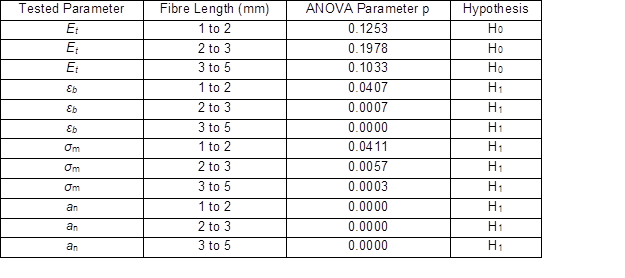

Table 2 shows the statistical comparison (ANOVA, α = 0.05) of the influence of increasing filler concentration on the mechanical properties of the composite material.

Table 2. Statistical Comparison of Influence of Filler Content on Mechanical Properties of Composite Material

It is desirable to integrate renewable resources into material engineering. The performed experiment described the interaction of the short surface-untreated fibres of the plant Ensete ventricosum. The composite were prepared based on the local renewable resources, which were readily availability at low price. Hidayat et al. (2014) used secondary products from the agricultural plants in their study. They described the use of biological-based secondary raw materials (cakes from the plant Jatropha curcas L.) to form boards, which had properties very similar to similar products made of particleboard.

Described materials – composites – can serve as the alternative to traditional products based on wood. Natural fibres could be combined with various waste materials (Saxena et al. 2010). These materials can be widely applied e.g., as transoms, floor tiles, etc. However, untreated fibres have irremovable disadvantages, including lower interaction with the matrix, a high tendency to get wet, and biological degradation. Nevertheless, the results described in this experiment could apply to other natural fibres cultivated in developing countries.

Electron micrographs of the interface between the fibres and matrix revealed that the surface of the fibres was not wet entirely optimally, which led to decreased strength.

The hollow section did not decrease the mechanical properties, as has been demonstrated by others, e.g., at the flight chicken feather (Cheung et al. 2009). This conclusion about the hollow section was verified for the composite systems filled with the reinforcing phases in the form of hollow fibres at the impact strength and the modulus of elasticity. Silva et al. (2008) showed that the hollow structure inside sisal fibre ultimately weakened the strength of its composites as the net cross-sectional area decreased, and thus, the stress taken by the fibre was then increased.

Short-fibre composites were used in all of the above applications, where it could not be exactly determined in advance the effects of the stress or the stress was approximately the same in all directions (Mueller et al. 2007). Further, the short-fibre composites have been applied in cases where there were requirements for easy processability and good mechanical properties (De and White 1996; Mallick 2000).

The addition of fillers to epoxy adhesive does not produce a definite improvement or deterioration in the impact strength (Dadfar and Ghadami 2013; Kejval and Müller 2013; Müller 2015). Rahman et al. (2014) stated that the tensile strength was decreased, whereas the modulus of elasticity and the Charpy impact strength were increased with increasing content of jute fibres.

The fibres play an important role in the impact strength; they resist crack propagation and act as a load transfer medium. The improvement in the impact strength of the composites is due to increased fibre content (Amuthakkannan et al. 2013). The impact strength is increased also by adding of the natural fibres from kenaf, coir, sisal, hemp, and jute into the epoxy matrix of the composite material (Wambua et al. 2003). This quality was also confirmed with the fibres of the false banana Ensete Ventricosum (Fig. 6).

The adhesive bonding technology was limited by the dynamic loading, namely in the area of bonding, i.e., using reactoplastics-based adhesives (two-component epoxy resins) (Debnath et al. 2004; Adamvalli and Parameswaran 2008; Hayashida et al. 2015). The reason was low resistance of the two-component epoxy system to the dynamic loading. The conclusions of the research proved the increase of the impact strength of the composite system which decreased the brittleness.

The conclusions of various authors were certified that adding the filler into the reactoplastics epoxy-based matrix affected the mechanical properties of the resulting composite (Kim and Khamis 2001; Galusek et al. 2007; Müller and Valášek 2012; Valášek and Müller 2012). These results agreed with the conclusions of Ge et al. (2004), who mentioned the use of biocomposites (bamboo with PVC) in the area of materials for the surface treatment of materials used at wood constructions. In terms of mechanical properties, the considered material could be a wood substitute in some applications.

CONCLUSIONS

- Isotropic composites can be advantageous in situations where it is not possible to determine the direction of prevailing loading in advance. Composites reinforced with casually oriented short fibres fulfill this requirement.

- The strength characteristics described in the experiment were influenced by the inclusion of the fibres of the plant Ensete ventricosum of different lengths 1 to 2 mm, 2 to 3 mm, and 3 to 5 mm and of the concentration until 3 wt. % in the epoxy resin.

- The strength values were decreased by 26% (i.e., of 10.2 MPa).

- The modulus of elasticity was increased by 5% (i.e., of 207.4 MPa).

- The strain at break was decreased by 31.9% (i.e., of 1.2%).

- The impact strength was increased by 420% compared to the matrix.

ACKNOWLEDGMENTS

This paper was supported by Grant IGA TF CZU: 2016:31140/1312/3109. Authors would like to thank Vladimíra Krmelová for providing fibers.

REFERENCES CITED

Abdul Nasir, A. A., Azmi, A. I., and Khalil, A. N. M. (2015). “Measurement and optimisation of residual tensile strength and delamination damage of drilled flax fibre reinforced composites,” Measurement 75, 298-307. DOI: 10.1016/j.measurement.2015.07.046

Adamvalli, M., and Parameswaran, V. (2008). “Dynamic strength of adhesive single lap joints at high temperature,” International Journal of Adhesion & Adhesives 28, 321-327. DOI: 10.1016/j.ijadhadh.2007.10.005

Alkbir, M. F. M., Sapuan, S. M., Nuraini, A. A., and Ishak, M. R. (2016). “Fibre properties and crashworthiness parameters of natural fibre reinforced composite structure: A literature review,” Composite Structures 148, 59-73. DOI: 10.1016/j.compstruct.2016.01.098

Alves, C., Ferrao, P. M. C., Silva, A. J., Reis, L. G., Freitas, M., and Rodrigues, L. B. (2010). “Ecodesign of automotive components making use of natural jute fiber composites,” Journal of Cleaner Production 18, 313-327. DOI: 10.1016/j.jclepro.2009.10.022

Amuthakkannan, P., Manikandan, V., Winowlin Jappes, J. T., and Uthayakumar, M. (2013). “Effect of fibre length and fibre content on mechanical properties of short basalt fibre reinforced polymer matrix composites,” Materials Physics and Mechanics 16, 107-117.

Chandramohan, D., and Bharanichandar, J. (2014). “Natural fiber reinforced polymer composites for automobile accessories,” American Journal of Environmental Sciences 9(6), 494-504. DOI: 10.3844/ajessp.2013.494.504

Cheung, H.-Y., Ho, M.-P., Lau, K.-T., Cardona, F., and Hui, D. (2009). “Natural fibre-reinforced composites for bioengineering and environmental engineering applications,” Composites: Part B 40, 655-663. DOI: 10.1016/j.compositesb.2009.04.014

CSN EN ISO 3167 (2015). “Plastics – multipurpose test specimens,” Czech Standards Institute, Prague, Czech Republic.

CSN EN ISO 527-1 (1997). “Plastics – Determination of tensile properties – Part 1: General principles,” Czech Standards Institute, Prague, Czech Republic.

CSN 64 0611 (1968). “Plastics testing. Determination of the impact resistance of rigid plastics by means of Dynstat apparatus,” Czech Standards Institute, Prague, Czech Republic.

Dadfar, M. R., and Ghadami, F. (2013). “Effect of rubber modification on fracture toughness properties of glass reinforced hot cured epoxy,” Materials and Design 47, 16-20. DOI: 10.1016/j.matdes.2012.12.035

De, S. K., and White, J. R. (1996). Short Fibre-Polymer Composites, Woodhead Publishing, Cambridge, UK.

De Assis, F. S., Netto, P. A., Margem, F. M., Loiola, R. L., and Monteiro, S. N. (2015). “Flexural mechanical characterization of epoxy composites reinforced with continuous banana fibers,” in: Characterization of Minerals, Metals, and Materials 2015 – TMS 2015 144th Annual Meeting and Exhibition, Orlando, FL, USA, pp. 153-158.

Debnath, S., Ranade, R., Wunder, S. L., McCool, J., Boberick, K. and Baran, G. (2004). “Interface effects on mechanical properties of particle-reinforced composites,” Dental Materials 20, 677-686. DOI: 10.1016/j.dental.2003.12.001

Doumbia, A. S., Castro, M., Jouannet, D., Kervoëlen, A., Falher, T., Cauret, L., and Bourmaud, A. (2015). “Flax/polypropylene composites for lightened structures: Multiscale analysis of process and fibre parameters,” Materials and Design 87, 331-341. DOI: 10.1016/j.matdes.2015.07.139

Faruk, O., Bledzki, A. K., Fink, H. P., and Sain M. (2012). “Biocomposites reinforced with natural fibers: 2000–2010,” Progress in Polymer Science 37, 1552-1596. DOI: 10.1016/j.progpolymsci.2012.04.003

Galusek, D., Sedláček, J., and Riedler, R. (2007). “Al2O3-SiC composites prepared by warm pressing and sintering of an organosilicon polymer-coated alumina powder,” Journal of the European Ceramic Society 27(6), 2385-2392. DOI: 10.1016/j.jeurceramsoc.2006.09.007

Ge, X. C., Li, X. H., and Meng, Y. Z. (2004). “Tensile properties, morphology, and thermal behavior of PVC composites containing pine flour and bamboo flour,” Journal of Applied Polymer Science 93(4), 1804-1811. DOI: 10.1002/app.20644

Hayashida, S., Sugaya, T., Kuramoto, S., Sato, Ch., Mihara, A., and Onumac, T. (2015). “Impact strength of joints bonded with high-strength pressure-sensitive adhesive,” International Journal of Adhesion and Adhesives 56, 61-72. DOI: 10.1016/j.ijadhadh.2014.09.005

Herrera-Franco, P. J., and Valadez-Gonzalez, A. (2005). “A study of the mechanical properties of short natural-fiber reinforced composites,” Composites: Part B 36, 597-608. DOI: 10.1016/j.compositesb.2005.04.001

Hidayat, H., Prijanto, U., Van Dam, J. E. G., Heeres, H. J. and Keijsers, E. R. P. (2014). “Preparation and properties of binderless boards from Jatropha curcas L. seed cake,” Industrial Crops and Products 52, 245-254. DOI: 10.1016/j.indcrop.2013.10.024

Kakou, C. A., Arrakhiz, F. Z., Trokourey, A., Bouhfid, R., Qaiss, A., and Rodrigue, D. (2014). “Influence of coupling agent content on the properties of high density polyethylene composites reinforced with oil palm fibers,” Materials and Design 63, 641-649. DOI: 10.1016/j.matdes.2014.06.044

Kalia, S., Thakur, K., Celli, A., Kiechel, M. A., and Schauer, C. L. (2013). “Surface modification of plant fibers using environment friendly methods for their application in polymer composites, textile industry and antimicrobial activities,” Journal of Environmental Chemical Engineering 1, 97-112. DOI: 10.1016/j.jece.2013.04.009

Kim, H. S., and Khamis, M. A. (2001). “Fracture and impact behaviours of hollow micro-sphere/epoxy resin composites,” Composites Part A: Applied Science and Manufacturing 32(9), 1311-1317. DOI: 10.1016/S1359-835X(01)00098-7

Kejval, J., and Müller, M. (2013). “Mechanical properties of multi-component polymer composite with particles of Al2O3/SiC,” Scientia Agriculturae Bohemica 4, 237-242. DOI: 10.7160/sab.2013.440407

Ku, H., Wang, H., Pattarachaiyakoop, N., and Trada, M. (2011). “A review on the tensile properties of natural fiber reinforced polymer composites,” Composites: Part B 42, 856-873. DOI: 10.1016/j.compositesb.2011.01.010

Lu, X., Zhang, M. Q., Rong, M. Z., Shi, G., and Yang, G. C. (2003). “Melt processable composites of sisal,” Composites Science and Technology 63,177-186. DOI: 10.1016/S0266-3538(02)00204-X

Mallick, P. K. (2000) “Particulate and short fiber reinforced polymer composites,” Comprehensive Composite Materials 2, 291-331.

Messiry, M. E. (2013). “Theoretical analysis of natural fiber volume fraction of reinforced composites,” Alexandria Engineering Journal 52(3), 301-306. DOI: 10.1016/j.aej.2013.01.006

Mizera, Č., Hrabě, P., Müller, M., and Herák, D. (2016). “Creep behaviour of the polymer composite with false banana fibres (Ensete ventricosum),” Manufacturing Technology 16(1), 188-192.

Mominul Haque, M., Hasan, M., Saiful Islam, M., and Ershad Ali, M. (2009). “Physical– mechanical properties of chemically treated palm and coir fiber reinforced polypropylene,” Bioresource Technology 100, 4903-4906. DOI: 10.1016/j.biortech.2009.04.072

Mueller, D. H., Doersch, C., and Gebauer, I. (2007). “Advantages of airlaid natural fiber composites for the automotive industry,” Nonwovens World 16(3), 69-75.

Müller, M. (2015). “Hybrid composite materials on basis of reactoplastic matrix reinforced with textile fibres from process of tyres recyclation,” Agronomy Research 13(3), 700-708.

Müller, M., and Valášek, P. (2012). “Abrasive wear effect on polyethylene, polyamide 6 and polymer particle composites,” Manufacturing Technology 12, 55-59.

Nechwatal, A., Mieck, K. P., and Reußmann, T. (2003). “Developments in the characterization of natural fibre properties and in the use of natural fibres for composites,” Composites Science and Technology 63, 1273-1279.DOI: 10.1016/S0266-3538(03)00098-8

Poole, A. J., Church, J. S., and Huson, M. G. (2009). “Environmentally sustainable fibers from regenerated protein,” Biomacromolecules 10, 1-8. DOI: 10.1021/bm8010648

Prasad, N., Agarwal, V. K., and Sinha, S. (2016). “Banana fiber reinforced low-density polyethylene composites: Effect of chemical treatment and compatibilizer addition,” Iranian Polymer Journal (English Edition), 25(3), 229-241. DOI: 10.1007/s13726-016-0416-

Pupure, L., Varna, J., and Joffe, R. (2016). “Natural fiber composite: Challenges simulating inelastic response in strain-controlled tensile tests,” Journal of Composite Materials 50(5), 575-587. DOI: 10.1177/0021998315579435

Rahman, G. M. S., Mamun, M. A. A., and Khan, M. A. (2014). “Effect of γ (Gamma)-radiation on the physico-mechanical properties of grafted jute fabric reinforced polypropylene (PP) composites,” Fibers and Polymers 15(2), 340-346. DOI: 10.1007/s12221-014-0340-7

Ruggiero, A., D’Amato, R., Gómez, E., and Merola, M. (2016). “Experimental comparison on tribological pairs UHMWPE/TIAL6V4 alloy, UHMWPE/AISI316L austenitic stainless and UHMWPE/Al2O3 ceramic, under dry and lubricated conditions,” Tribology International 96, 349-360. DOI: 10.1016/j.triboint.2015.12.041.

Ruggiero, A., Merola, M., Carlone, P., and Archodoulaki, V. M. (2015). “Tribo-mechanical characterization of reinforced epoxy resin under dry and lubricated contact conditions,” Composite Part B: Engineering. 79, 595-603. DOI: 10.1016/ j.compositesb.2015.05.015.

Saxena, M., Mehrotra, P., and Asokan, P. (2010). “Innovative building materials developed from natural fibres and industrial waste,” Land Contamination and Reclamation 18(4), 355-362. DOI: 10.2462/09670513.1016

Silva, F. A., Chawla, N., and Filho, R. D. T. (2008). “Tensile behavior of high performance natural (sisal) fibers,” Composites Science and Technology 68, 3438-3443. DOI: 10.1016/j.compscitech.2008.10.001

Sharifah, H. A., and Martin, P. A. (2004). “The effect of alkalization and fiber alignment on the mechanical and thermal properties of kenaf and hemp bast fiber composites: Part 1 – polyester resin matrix,” Composites Science and Technology 64, 1219-1230. DOI:10.1016/j.compscitech.2003.10.001

Tsehaye, Y., and Kebebew, F. (2006). “Diversity and cultural use of Enset (Enset ventricosum (Welw.)Cheesman) in Bonga in situ Conservation Site, Ethiopia,” Ethnobotany Research and Applications 4, 147-157.

Valášek, P., and Müller, M. (2015). “Abrasive wear in three-phase waste-based polymeric particle composites,” Technicki Vjestnik 22(2), 257-262. DOI: 10.17559/TV-20130905190904

Valášek, P., Müller, M., and Hloch, S. (2015). “Recycling of corundum particles – Two-body abrasive wear of polymeric composites based on waste,” Technicki Vjestnik 22(3), 567-572. DOI: 10.17559/TV-20131111140048

Valášek, P., and Müller, M. (2012). “Impact strength of polymer particle composites with filler on the basis of corundum waste,” in: Engineering for Rural Development 24.05.2012, Jelgava, Latvia, pp. 304-308.

Wambua, P., Ivens, J., and Verpoest I. (2003). “Natural fibres: Can they replace glass in fibre reinforced plastics?,” Composites Science and Technology 63, 1259-1264. DOI: 10.1016/S0266-3538(03)00096-4

Yirmaga, M. T. (2013). “Improving the Indigenous processing of kocho, an Ethiopian traditional fermented food,” Journal of Nutrition and Food Science 3, 1-6.

Zaman, H. U., and Beg, M. D. H. (2016). “Banana fiber strands-reinforced polymer matrix composites,” Composite Interfaces 30, 1-15. DOI: 10.1080/09276440.2016.1137178

Zhao, X., Li, R. K.Y., and Bai, S.-L. (2014). “Mechanical properties of sisal fiber reinforced high density polyethylene composites: Effect of fiber content, interfacial compatibilization, and manufacturing process,” Composites: Part A 65, 169-174. DOI: 10.1016/j.compositesa.2014.06.017

Article submitted: July 29, 2016; Peer review completed: October 2, 2016; Revised version received; October 10, 2016; Accepted: November 5, 2016; Published: November 14, 2016.

DOI: 10.15376/biores.12.1.255-269