Abstract

The use of chemithermomechanical (CTMP) pulp from rapeseed residues as raw material for the manufacturing of linerboard and fluting medium grades was investigated. For this purpose, different alternatives for improving mechanical and optical properties of rapeseed CTMP were studied, and the addition of nanofibrillated cellulose (NFC) was proposed to decrease the intensity of the beating process and enhance the final mechanical properties. Handsheets from each pulp were produced, and their properties compared to those of linerboard from recycled paper. Compared to kraft linerboard from recycled paper, rapeseed CTMP required less beating to reach an optimal breaking length. This reduction in beating can be combined with the addition of NFC to improve the mechanical properties of paper. Therefore, rapeseed CTMP from crop residues is a technically affordable alternative for the production of fluting and linerboard grades.

Download PDF

Full Article

Suitability of Rapeseed Chemithermomechanical Pulp as Raw Material in Papermaking

Israel González,ª Manuel Alcalá,b* Gerard Arbat,c Fabiola Vilaseca,ª and Pere Mutjè ª

The use of chemithermomechanical (CTMP) pulp from rapeseed residues as raw material for the manufacturing of linerboard and fluting medium grades was investigated. For this purpose, different alternatives for improving mechanical and optical properties of rapeseed CTMP were studied, and the addition of nanofibrillated cellulose (NFC) was proposed to decrease the intensity of the beating process and enhance the final mechanical properties. Handsheets from each pulp were produced, and their properties compared to those of linerboard from recycled paper. Compared to kraft linerboard from recycled paper, rapeseed CTMP required less beating to reach an optimal breaking length. This reduction in beating can be combined with the addition of NFC to improve the mechanical properties of paper. Therefore, rapeseed CTMP from crop residues is a technically affordable alternative for the production of fluting and linerboard grades.

Keywords: Rapeseed; Chemithermomechanical pulp; Fluting and liner paper; PFI-beating; Nanofibrillated cellulose

Contact information: a: Group LEPAMAP, Department of Chemical Engineering, University of Girona, c/M. Aurèlia Capmany, nº 61, Girona 17071, Spain; b: Group PRODIS, Department of Organization, Business Management and Product Design, University of Girona, EPS Campus Montilivi, 17071, Girona, Spain; c: Dept. of Agricultural Engineering and Food Technology, University of Girona, (Spain). *Corresponding author: manuel.alcala@udg.edu; University of Girona, EPS Campus Montilivi, 17071 Girona, Spain.

INTRODUCTION

Rapeseed (Brassica napus) is the main crop devoted to the production of source material for biodiesel fuel manufacture in Europe. European regulations in this field are promoting the use of this kind of fuel oil (Official Journal of the European Communities, 2001, 2003, 2009); minimum consumption levels have been set to reach 10% of the total in 2020. Under the influence of this legislation, the production of rapeseed grain in the European Union has doubled during the last 10 years. After the collection of rapeseed grains (where biofuel is obtained), leaves and stalks are considered a residue and left by farmers to be composted. However, rapeseed stalks can be processed to obtain lignocellulosic fibers, and used in the manufacture of paper products such as cardboard or linerboard.

Various pulping processes can be applied to obtain either mechanical pulp (MP), thermomechanical pulp (TMP), chemimechanical pulp (CMP), semichemical pulp (SCP), or chemical pulp (CP) from these residues. In particular, chemithermo-mechanical pulp (CTMP) can be obtained from processes with yields ranging from 65% to 90%. High-yield CTMP procedures make it possible to minimize the production of side-products. In 2010, Hosseinpour et al. showed that CTMP pulps from rapeseed stalks presented good physico-mechanical properties. The use of rapeseed residues can reduce the dependence on wood fibers for the production of paper. Moreover, fibers from rapeseed wastes can be used as secondary fibers, bringing better mechanical properties than recycled paper, which is presently the main source of fibers other than virgin wood pulp fibers. It should be noted that many countries do not have a domestic supply of virgin pulp fiber to manufacture paper and paperboard grades.

In areas of emerging markets, such as India, China, and the Middle East, the forecasted growth in demand for paper is 4.1% per year until 2020. Therefore, together with the cost-effectiveness and abundance of these crop residues, it is reasonable to consider its use in the pulp and paper production (Hammett et al. 2001; Fatehi et al. 2009; Hosseipour 2010; Kasmani et al. 2012).

Considering the strength properties of rapeseed CTMP (Enayati et al. 2009; Hosseinpour et al. 2010), fluting medium and linerboard might be produced from them. Nevertheless, a beating process is probably required to improve the final performance of paperboard. Mechanical beating is the most common method used in the papermaking industry for enhancing properties of pulps; this process improves the flexibility and the bonding ability of fibers (Molin et al. 2004). It is also expected that the beating process will reduce the drainage rate and runnability during papermaking (Li et al. 2011). Drainability is a critical parameter since water elimination is an energy-demanding process that limits the efficiency of a paper machine (Norell et al.1999). The addition of nanofibrillated cellulose (NFC) as a reinforcing additive in papermaking can be seen as an alternative to the mechanical beating. This approach has been recently explored with promising results (Ahola et al. 2008; Eriksen et al. 2008; Mörseburg and Chinga-Carrasco 2009; Taipale et al. 2010; Sehaqui et al. 2011; González et al. 2012).

It is expected that the use of NFC as a paper additive will reduce the need for intensive mechanical beating, together with an increase in the final paper strength. However, the addition of NFC might also diminish the drainage capacity of pulps. The main objective of the study was to assess the suitability of rapeseed CTMP fibers as raw material in the production of linerboard and fluting medium. Different alternatives for improving mechanical and optical properties of rapeseed CTMP were investigated, and the use of NFC was proposed to decrease the intensity of beating process. The properties of the resulting pulps were compared to those of linerboard made from recycled kraft fibers.

EXPERIMENTAL

Materials

Rapeseed residues were obtained from Fundació Mas Badia (La Tallada d’Emporda, Girona, Spain). Hardwood Eucalyptus kraft pulp for the production of NFC was supplied by La Montañesa (Grupo Torraspapel, Zaragoza, Spain), and softwood pine TMP was provided by Zubialde S.A. (Aizarnazabal Guipuzcoa, Spain). Kraft liner pulp was fabricated from recycled paper, kindly supplied by Saica S.A. (Zaragoza, Spain).

For the oxidation process in the production of NFC, 2,2,6,6-tetramethyl-piperidine-1-oxyl radical (TEMPO), sodium bromide (NaBr), sodium hypochlorite solution (NaOCl), and sodium chlorite (NaClO2) were acquired from Sigma-Aldrich and used without any further purification. Sodium hydroxide (NaOH) and anthraquinone (C14H8O2) used in the pulping process were also provided by Sigma-Aldrich. Cationic starch and colloidal silica were provided by Torraspapel S. A. (Sarrià de Ter, Girona, Spain) and used as retention agents during the preparation of paper handsheets.

Methods

Production of rapeseed CTMP pulp

Rapeseed residues were cooked in a rotary digester. Rapeseed residues were introduced in the digester, previously heated up to 80ºC. Then, 15 wt% of sodium hydroxide and 0.1 wt% of anthraquinone, with respect to dry matter, were added. The liquor to wood ratio was 6:1 and the temperature profile for the cooking process was 140ºC during 40 min. The resulting pulp was rapidly washed with tap water. A 50% consistency pulp was then passed two times through a Sprout-Waldron refiner (model 105-A) with a plate clearance manually adjusted until fiber diameter was constant. The resulting CTMP pulp was kept in plastic bags and stored at 4ºC.

Production of recycled kraft liner pulp

Recycled paper was disintegrated with water in a pulper equipped with a helicoidal rotor. The process was carried out at 50ºC and 1 wt% of NaOH under constant stirring (1000 rpm) for 15 min. After this, the pulp was washed with water to remove the residual NaOH and stored at 4ºC.

Production of NFC

NFC was fabricated by way of TEMPO-mediated oxidation methodology at neutral pH, as reported by Besbes et al. (2011). Five grams of hardwood Eucalyptus kraft pulp were suspended in 0.05 M sodium phosphate buffer solution (500 mL, pH 7) that contained TEMPO (25 mg) and NaBr (250 mg). The suspension was stirred to ensure good dispersion of all reagents. Sodium chlorite solution (1.13 g, 10 mM) and sodium hypochlorite solution (1.13 g, 10 mM) were added to the suspension. Next, the mixture was stirred at 500 rpm and 60ºC for 2 h. Oxidation was terminated by adding 100 mL of ethanol.

The oxidized fibers were filtered and washed two times. Finally, the fiber suspension was cooled to room temperature before proceeding to the mechanical treatment. The fibrillation process was carried out by passing a 1 to 2 wt% fiber suspension through a high-pressure homogenizer (NS1001L PANDA 2K-GEA). The equipment operated at 600 bar pressure and at 60 to 70ºC. The process was repeated 10 to 20 times until a transparent gel-like product was obtained. Based on previous studies (Besbes et al. 2011), the NFC diameter is between 30 to 40 nm.

Paper handsheets for mechanical characterization

Prior to its use, pulps for this study were first disintegrated in distilled water at 180,000 revolutions. The resulting suspension was then filtered in order to eliminate excess water. Next, fiber slurry at 10 wt% was prepared and beaten in a PFI mill (NPFI 02, Metrotec S.A.) at 250, 500, 1000, and 1500 revolutions. The beaten slurry was then stored at 4ºC. For the preparation of handsheets, the desired amount of beaten pulp was dispersed in water and stirred; while stirring, colloidal silica and cationic starch were added as retention agents in the amounts of 0.8 and 0.5 wt%, respectively. Stirring was continued for 30 min at 500 rpm in order to ensure good dispersion of all substances. In the case of NFC-reinforced pulps, NFC was added to the slurry during the disintegration step. The amount of added NFC was calculated to obtain paper handsheets with 3, 6, and 9 wt% of NFC for unbeaten pulps and 1.5 and 3 wt% for the mildly beaten ones. Handsheets were fabricated in a Rapid-Köthen sheet former (ISP mod. 786FH) according to ISO standard 5269-2 and conditioned at 25ºC and 50% humidity during 48 h before mechanical testing. Handsheets of 75 gr/m2 grammage were prepared.

Chemical characterization

The contents of cellulose, lignin, pentosans, and ash of the rapeseed residues were determined. Cellulose content was measured according to Wise et al. (1946). The result indicates the total amount of holocellulose. Lignin, pentosans, and ash were determined following TAPPI standard methods T222 om-88, T223 cm-84, and T211 om-93, respectively.

Physical and Morphological Characterization

Schopper-Riegler freeness

The rate of drainage of pulps was determined with a Schopper-Riegler tester (mod. 95587 PTI) following ISO standard 5267/1.

Water retention value

Water retention value (WRV) was determined by vacuum-filtering 100 mL of the pulp slurry. Four equal portions were obtained from these 100 mL batches and each portion was centrifuged at 4000 rpm for 15 min in order to eliminate non-bound water. After centrifuging, the four portions were dried at 105±1ºC for 12 h in previously weighed containers. The average WRV was then calculated from the difference between the centrifuged weights and the dried weights of the four portions.

Fiber morphology

Fines content and fiber morphology were determined using a MorFI Compact analyzer (TechPap) controlled with a computer workstation. The equipment utilizes 1000 mL of 1 wt% aqueous fiber suspension by analyzing pictures taken from the suspension with a CCD video camera. About 10,000 fibers were analyzed in each test by the software MorFi v.8.2.

Mechanical characterization

Tensile tests were conducted to determine tensile index and breaking length; tests were performed with a Hounsfield 42 universal testing machine equipped with a 2.5 kN load cell. Testing conditions were set according to ISO standard 1924-1 and 1924-2. Internal cohesion (Scott bond) was determined with a Scott bond testing machine (IDM mod. IBT 10A) following TAPPI test method T569. Burst index assays were performed with a burst tester (IDM mod. EM-50), and the test conditions were set according to ISO standard 2758. Tear index was determined with a Elmendorf tear instrument (mod. F53.98401 Frank PTI), and the assay conditions were set according to ISO standard 1974.

In all cases, at least seven or more tests were performed from each sample, and only those values within 95% of statistical confidence coefficient were averaged.

RESULTS AND DISCUSSION

Comparison between rapeseed CTMP and pine TMP

In order to evaluate rapeseed as a raw material for the papermaking industry, it was important to compare its properties with wood cellulose fibers typically used in the production of paper. In Table 1, chemical composition of rapeseed residues is presented and compared with softwood and hardwood fibers according to García Hortal (2007) and Rowell (2008).

Table 1. Comparison in Chemical Composition between Rapeseed Residues and Softwood and Hardwood Fibers

From Table 1, one can notice that the chemical composition of rapeseed residue is similar to that of hardwood. The comparison showed that cellulose content is slightly higher in rapeseed than in softwood and hardwood, whereas lignin content is lower in rapeseed. This is an important feature since rapeseed raw material contains both a fairly high level of cellulose and a lesser amount of lignin, which is interesting for the production of bleached pulps. Rapeseed residues might be suitable for beating processes, as pentosans content is comparable to that of hardwood. On the other hand, the ash percentage is higher in rapeseed than in the other sources. In general, the chemical composition of rapeseed is similar to that of hardwood fibers, but with somewhat higher cellulose content. Therefore, high yield chemithermomechanical pulping procedures will not modify the chemical composition of rapeseed, as only extractives, ash, and a relatively small amount of pentosans will be removed.

The characteristics of high-yield rapeseed CTMP (chemithermomechanical pulp) can now be compared with pine TMP (thermomechanical pulp), which is a typical papermaking pulp with similar process yield. In Table 2, morphological characteristics of rapeseed CTMP and pine TMP are presented. Mechanical pulp from rapeseed was not considered for this study due to its poor paper properties observed in previous unpublished experiments.

Table 2. Yield and Morphological Properties of Rapeseed CTMP and Pine TMP

*Weighted in length

Abbreviations: Schopper-Riegler (ºSR), fiber’s length (lF), fiber’s diameter (dF), length of fines (lf), aspect ratio (lF/dF)

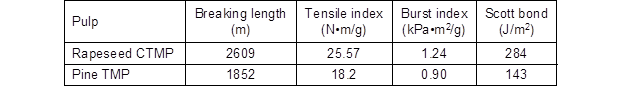

The drainability, expressed as Schopper-Riegler degrees, was inferior for pine TMP compared to rapeseed CTMP. Fibers from rapeseed CTMP were shorter and narrower than those of pine TMP. Fibers from pine TMP presented diameter values of around 25 μm, which is smaller than the 30 to 35 μm reported in the literature for softwood TMP; these diameters are found in slurries from SGW (stone groundwood) and TMP from wood (Rowell 2008; Yuan et al. 2009). In these bibliographic studies, fines were defined as particles with fiber length below 200 m. For the present study, fines are defined as any particle with lengths equal or below 75 μm or 200 mesh. The aspect ratio of fibers (lF/dF) has a close relationship with the intrinsic strength of fibers and the mechanical properties of paper (Dasgupta 1994). The aspect ratios of rapeseed CTMP and pine TMP were very similar. Regarding mechanical properties (Table 3), handsheets from rapeseed CTMP presented better strength than pine TMP. Breaking length and tensile index were 48% higher, whereas burst index and Scott bond presented higher values by 37.7 and 98.6%, respectively.

Table 3. Mechanical Properties of Rapeseed CTMP and Pine TMP

Effect of beating on rapeseed CTMP compared to kraft liner pulpThe information presented up to now demonstrated that rapeseed CTMP has comparable mechanical properties to typical wood mechanical pulp used nowadays. In addition, it is important to remark that the incorporation of mechanical pulps into the papermaking process is always problematic due to the high presence of fines, compared to chemical and semichemical pulps. The elevated percentage of fines is responsible for the poor drainage capacity of mechanical pulps. For this reason, only a mild beating of such pulps is suggested; industrial beating (i.e. refining) promotes fiber swelling and consequent hydration, increases external fibrillation, and increases the percentages of fines. This slows the drainage of these pulps during sheet formation and slows the runnability of the paper machine. In the following sections, different alternatives for improving mechanical properties of the rapeseed CTMP are investi-gated in the context of their possible use for fluting medium or linerboard grades.

At an industrial scale, recycled kraft liner pulp is often manufactured from mixtures of waste paper and varying percentages of virgin mechanical pulps. The proportions depend on the desired quality of paper. According to Hurter (2002), the breaking length for linerboard manufactured from non-wood pulps is around 4000 m, and around 5000 m for fluting medium/linerboard manufactured from 100% waste-paper. In Table 4, the mechanical properties of beaten kraft liner pulp from recycled paper are presented.

Table 4. Mechanical Properties of Beaten Kraft Liner/Fluting Pulp Produced from Recycled Paper

* Mean weighted in length

Abbreviations: revolutions (rev.), Schopper-Riegler (ºSR), water retention value (WRV), fiber length (lfw), breaking length (B.L.), burst index (B.I.), Scott bond (S.B.), tear index (T.I.), Gurley porosity (G.P.)

Drainage capacity (ºSR) gradually diminished as a consequence of beating, a phenomenon well known by papermakers that is strongly dependent upon the refining level. Water retention value increased moderately. Beating also reduced fiber length, as expected, whereas the percentage in length of fines slightly increased. The improvement in mechanical properties after beating was significant. Breaking length increased up to 46% for kraft liner pulp beaten at 1500 PFI-revolutions. At an industrial level, this value can reach 5746 m (factor 1.3) due to fiber orientation in the paper machine and up to 6435 m (factor 1.12) when fibers are covered with starch (in the size press). The other mechanical strength parameters increased with beating intensity except for the tear index. Beaten pulps formed less porous handsheets than unbeaten ones due the extensive fibrillation, according to the increase in Gurley porosity.

Table 5. Mechanical Properties of Beaten Rapeseed CTMP

* Mean weighted in length

Abbreviations: revolutions (rev.), Schopper-Riegler (ºSR), fiber length (lfw), breaking length (B.L.), burst index (B.I.), Scott bond (S.B.), tear index (T.I.), Gurley porosity (G.P.)

Mechanical properties of beaten rapeseed CTMP (Table 5) showed a similar trend with beating as observed with kraft liner pulp. However, it is worth noticing that the drainage rate was lower for rapeseed CTMP than for kraft liner pulp, even in unbeaten pulps. This low drainability became more evident as further beating was applied to the rapeseed CTMP compared to kraft liner pulp, as can be seen in Fig. 1.

Fig. 1. Evolution of drainage capacity (ºSR) in kraft liner pulp and rapeseed CTMP after beating

Fibers in rapeseed CTMP were shorter compared to kraft liner pulp, and the percentage in length of fines was significantly lower; this parameter remained almost constant with beating. Moreover, rapeseed CTMP beaten at 1000 and 1500 PFI-revolutions presented better mechanical properties than kraft liner pulps at the same beating degree. This trend is better observed in Fig. 2 where breaking length of rapeseed CTMP (beaten at 1000 PFI-revolutions) was 4478 m, whereas that of kraft liner pulp was 3887 m under the same beating intensity. The same behavior was observed at 1500 PFI-revolutions. Though burst index in rapeseed CTMP was slightly lower than kraft liner pulp, Scott bond was significantly higher. Burst index increased gradually with the degree of beating in contrast to kraft liner pulp, where the burst index was reduced with increasing beating degree. Rapeseed CTMP handsheets were remarkably less porous than those from kraft liner pulp; this characteristic was accentuated by increased beating.

Fig. 2. Breaking length evolution of kraft liner and rapeseed CTMP pulps after beating

It can be observed that beaten rapeseed CTMP met the strength requirements for fluting/liner paperboard products. Moreover, these requirements were achieved with less beating intensity than when kraft liner pulp was used. However, the increase in mechanical properties was also accompanied by poorer drainage capacity due to shorter fibers and fines. The use of NFC as a strength-enhancer additive was analyzed as an alternative to beating.

Reinforcement of rapeseed CTMP with NFC

Several recent studies have demonstrated the suitability of applying NFC to pulp slurries as a way to improve strength, reduce porosity, and improve opacity of paper (González et al.2012). In Table 6 the evolution of drainability and mechanical properties of NFC-reinforced handsheets is presented.

Table 6. Mechanical Properties of Rapeseed CTMP Reinforced with NFC

Abbreviations: Schopper-Riegler (ºSR), breaking length (B.L.), burst index (B.I.), Scott bond (S.B.), tear index (T.I.), Gurley porosity (G.P.)

The addition of NFC clearly improved the paper strength. The high specific surface area of NFC helped to increase the bonding capacity of fibers; in fact, the enhancement on the mechanical properties was proportional to the amount of added NFC. A breaking length of 4000 m was achieved in pulps with 6 to 9 wt% of NFC. The maximum value was found in pulps with 9 wt%, though it is possible that better results could be obtained by adding more reinforcement. Burst and tensile index values were also higher with the NFC-reinforced pulps than the beaten ones, though the Scott bond improvement was not significant. The porosity also diminished. The table also shows that the incorporation of NFC produced a loss in drainage capacity. This phenomenon has been observed by several authors (Taipale et al. 2010; González et al. 2012). According to these results, in order to get 4000 m of breaking length, the drainage rate was raised up to 80 ºSR. The reduction in drainability is a consequence of the high specific surface area in NFC, which facilitates water retention in fibers by hydrogen bonding (Taipale et al. 2010). The strong decrease in drainage capacity after the addition of NFC is an important drawback when considering this methodology at an industrial scale.

Mildly beaten rapeseed CTMP reinforced with NFC

A third approach was followed by combining the two methodologies previously described. This approach employed a mild beating treatment of the CTMP, with the addition of a small amount of NFC to the slurry. For the present study, two set of samples were prepared and pulps beaten at 500 and 250 PFI-revolutions were reinforced with 1.5 and 3 wt% of NFC, respectively. The mechanical properties of these samples are presented in Table 7 and compared with the properties of non-NFC reinforced beaten pulps.

Table 7. Mechanical Properties of Mildly Beaten Rapeseed CTMP Reinforced with NFC

Abbreviations: Schopper-Riegler (ºSR), breaking length (B.L.), burst index (B.I.), Scott bond (S.B.), tear index (T.I.), Gurley porosity (G.P.)

The results indicated that, by beating rapeseed CTMP at 500 PFI-revolutions and adding 1.5 wt% of NFC, it was possible to achieve values of breaking length close to 4000 m. The same was found for samples beaten at 250 PFI-revolutions and reinforced with 3 wt% of NFC. An important characteristic of this approach is that, although there is a loss in drainage rate, it is lower than with the single application of NFC (Table 6). The best results for burst index and Scott bond were found in pulps beaten at 500 and reinforced with 1.5 wt% of NFC, though tear index was slightly higher for pulps beaten at 250 and reinforced with 3 wt% of NFC.

The main advantage of this methodology is that the mild beating diminishes the damage on the rapeseed CTMP fiber, and this would reduce its deterioration during further recycling processes, thus allowing a longer lifetime of the paper made therefrom.

CONCLUSIONS

- Chemithermomechanical pulp (CTMP) from rapeseed residues was produced. The pulp was subjected to three different methodologies to improve its mechanical properties, i) beating in a PFI mill, ii) the addition of NFC, and iii) a combination of mild beating and NFC addition. Handsheets for mechanical testing were fabricated from the resulting pulps.

- Beating increased the mechanical properties of rapeseed CTMP in a linear relationship to beating intensity. Porosity was significantly reduced. The best results were observed in pulps beaten at 1500 PFI-revolutions. The improvement of mechanical properties was accompanied by a reduction of pulp’s drainage capacity.

- NFC-reinforced pulps also exhibited a significant enhancement in mechanical properties as well as a reduction in porosity; the best mechanical properties were observed with pulps reinforced with 9 wt% of NFC, though drainage capacity was strongly reduced by the presence of NFC, and this reduction was more pronounced than with beaten CTMP.

- Mildly beaten pulps (500 and 250 PFI-revolutions) reinforced with small amounts of NFC (1.5 and 3 wt%) produced pulps with good mechanical properties and breaking length very close to 4000 meters. These pulps also showed moderate increases in drainage capacity and porosity.

- The results presented indicated that rapeseed CTMP is a suitable raw material for producing kraft linerboard in place of fibers from recycled paper. Compared to kraft liner from recycled paper, rapeseed CTMP required less beating in order to obtain optimal breaking length. This reduction in beating can be combined with the addition of NFC to obtain paperboard with better mechanical properties.

ACKNOWLEDGMENTS

The authors wish to thank the Ministerio de Ciencia e Innovación for the financial support (CTQ2010-21660-C03-03 and CTM2011-28506-C02-01) of this study.

REFERENCES CITED

Ahola, S., Österberg, M., and Laine, J. (2008). “Cellulose nanofibrils-adsorption with poly(amideamine) epichlorohydrin studied by QCM-D and application as a paper strength additive,” Cellulose 15(2), 303-314.

Besbes, I., Rei Vilar, M., and Boufi, S. (2011). “Nanofibrillated cellulose from alfa, eucalyptus and pine fibers: Preparation, characteristics and reinforcing potential,” Carbohydrate Polymers 86(3), 1198-1206.

Dasgupta, S. (1994). “Mechanism of paper tensile-strength development due to pulp beating,” Tappi J. 77(6), 158-166.

Enayati, A. A., Hamzeh, Y., Mirshokraie, S. A., and Molaii, M. (2009). “Papermaking potential of canola stalks,” BioResources 4(1), 245-256.

Eriksen, O., Syverud, K., and Gregarsen, O. (2008). “The use of microfibrillated cellulose produced from kraft pulp as strength enhancer in TMP paper,” Nordic Pulps Paper Res. J. 23(3), 299-304.

Fatehi, P., Tutus, A., and Xiao, H., (2009). “Cationic PVA as a dry strength additive for rice straw pulp,” Bioresour. Technol. 100(2), 749-758.

García Hortal, J. A. (2007). Fibras Papeleras, Ediciones UPC, Barcelona.

González, I., Boufi, S., Pèlach, M. A., Alcalà, M., Vilaseca, F., and Mutjé, P. (2012). “Nanofibrillated cellulose as paper additive in eucalyptus pulps,” BioResources 7(4), 5167-5180.

Hammett, A. L., Youngs, R. L., Sun, X., and Chandra, M. (2001). “Non-wood fiber as an alternative to wood fiber in China’s pulp and paper industry,” Holzforschung 55(2), 219-224.

Hosseinpour, R., Fatehi, P., Latibari, A. J., Ni, Y., and Javad Sepiddehdam, S. (2010). “Canola straw chemimechanical pulping for pulp and paper production,” Bioresource Technology, 101(11), 4193-4197.

Hurter Consult Incorporated (2002). “100% non-wood fiber content papers – Part 1: corrugated medium physical properties,” http://www.hurterconsult.com/nonwood_paper_1.htm

Kasmani, J. E., Samariha, A., Ravanbakhsh, F., and Shorkaei, J. S. (2012). “Characterization and evaluation of rapeseed as a raw material for paper production,” Research on Crops 13(2), 514-516.

Li, B., Li, H., Zha, Q., Bandekar, R., Alsaggaf, A., and Ni, Y. (2011). “Review: Effects of wood quality and refining process on TMP pulp and paper quality,” BioResources 6(3), 3569-3584.

Molin, U., and Daniel, G. (2004). “Effects of refining on the fiber structure of Kraft pulp as revealed by FE-SEM and TEM: Influence of alkaline degradation,” Holzforschung 53(3), 226-232.

Mörseburg, K., and Chinga-Carrasco, G. (2009). “Assessing the combined benefits of clay and nanofibrillated cellulose in layered TMP-based sheets,” Cellulose 16(5), 795-806.

Norell, M., Johansson, K., and Persson, M. (1999). “Retention and drainage,” In: Papermaking Science and Technology, Book 4: Papermaking Chemistry, L. Neimo (ed.), Fapet Oy, Helsinki, Finland 43-81.

Official Journal of the European Communities, 2001. Directive 2001/77/EC of the European Parliament and of the Council of 27 September 2001on the promotion of electricity produced from renewable energy sources in the internal electricity market. L. 283, 33–40 pp. European Commission, The Publications Office of the European Union, Luxembourg.

Official Journal of the European Communities, 2003. Directive 2003/30/EC of the European Parliament and of the Council of 8 May 2003 on the promotion of the use of biofuels or other renewable fuels for transport. L. 123, 42–46 pp. European Commission, The Publications Office of the European Union, Luxembourg.

Official Journal of the European Communities, 2009. Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the promotion of the use of energy from renewable sources and amending and subsequently repealing Directives 2001/77/EC and 2003/30/EC. L. 140, 16–62 pp. European Commission, The Publications Office of the European Union, Luxembourg.

Rowell, R. M. (2008). “Natural fibers: types and properties,” In: Pickering, K. L. (ed.), Properties and Performance of Natural-fiber Composites, Woodhead Publishing Limited, Cambridge, U.K. (2008).

Sehaqui, H., Allais, M., Zhou, Q., and Berglund, L. (2011). “Wood cellulose biocomposites with fibrous structures at micro- and nanoscale,” Composites Science and Technology 71(3), 382-387.

Taipale, T., Österberg, M., Nykänen, A., Ruokolainen, J., and Laine, J. (2010). “Effect of microfibrillated cellulose and fines on the drainage of kraft pulp suspensions and paper strength,” Cellulose 17(5), 1005-1020.

Yuan, Z., Heitner, C., Miles, K., Omholt, I., McGarry, P., and Browne, T. (2009). “Evaluation of various mechanical pulping processes for mature and juvenile loblolly pine in lightweight coated paper,” Tappi J. 8(3), 32-40.

Wise, L. E., Marphy, M., and D’Adieco, A. (1946). “Chlorite holocellulose, its fractionation and bearing on summative wood analysis and on studies on the hemicelluloses,” Paper Trade J. 122(2), 35-43.

Article submitted: December 13, 2012; Peer review completed: February 2, 2013; Revised version received: February 6, 2013, Accepted: February 7, 2013; Published: February 12, 2013.