Abstract

Elephant dung (ED) particleboard (PB) still has subpar physical and mechanical qualities. In earlier research, adding wood shavings and bamboo layers to ED-derived PB successfully enhanced its physical and mechanical qualities. However, the resistance to termites and decay of this PB is still unknown. Therefore, this study examines the resistances to termites and decay of the PBs from ED fiber-modified with wood shavings and bamboo layering. ED and wood shavings were distributed throughout the PB in ratios of 100/0, 90/10, 80/20, 70/30, 60/40, and 50/50 (w/w %). Meanwhile, tali bamboo (Gigantochloa apus), talang bamboo (Schizostachyum brachycladum), kuning bamboo (Bambusa vulgaris), belangke bamboo (Gigantochloa pruriens), and betung bamboo (Dendrocalamus asper) were the materials used in this study. These findings demonstrated that adding wood shavings could improve PB’s resistance to termite and decay attacks. However, in this investigation, the layering of bamboo diminishes the PB’s resistance to termite and decay attack. A 50/50 ratio between ED and wood shavings achieved slightly higher termite mortality and lower weight loss than others. Meanwhile, kuning bamboo had lower termite mortality and higher weight loss than others.

Download PDF

Full Article

Termite and Decay Resistances of Sumatran Elephant Dung-based Particleboard Modified with Wood Shavings and Bamboo Layering

Rudi Hartono,a,* Jajang Sutiawan,a,c Dede Hermawan,b Santiyo Wibowo,c and Deni Zulfiana c

Elephant dung (ED) particleboard (PB) still has subpar physical and mechanical qualities. In earlier research, adding wood shavings and bamboo layers to ED-derived PB successfully enhanced its physical and mechanical qualities. However, the resistance to termites and decay of this PB is still unknown. Therefore, this study examines the resistances to termites and decay of the PBs from ED fiber-modified with wood shavings and bamboo layering. ED and wood shavings were distributed throughout the PB in ratios of 100/0, 90/10, 80/20, 70/30, 60/40, and 50/50 (w/w %). Meanwhile, tali bamboo (Gigantochloa apus), talang bamboo (Schizostachyum brachycladum), kuning bamboo (Bambusa vulgaris), belangke bamboo (Gigantochloa pruriens), and betung bamboo (Dendrocalamus asper) were the materials used in this study. These findings demonstrated that adding wood shavings could improve PB’s resistance to termite and decay attacks. However, in this investigation, the layering of bamboo diminishes the PB’s resistance to termite and decay attack. A 50/50 ratio between ED and wood shavings achieved slightly higher termite mortality and lower weight loss than others. Meanwhile, kuning bamboo had lower termite mortality and higher weight loss than others.

DOI: 10.15376/biores.18.3.5073-5084

Keywords: Bamboo; Elephant dung; Particleboard; Termites resistance; Decay resistance; Wood shaving

Contact information: a: Forest Products Department, Faculty of Forestry, Universitas Sumatera Utara, Medan, 20155, Indonesia; b: Forest Products Department, Faculty of Forestry and Environment, IPB University, Dramaga, 16680, Indonesia; c: Research Center for Biomass and Bioproducts, National Research and Innovation Agency, Cibinong, 16911, Indonesia;

*Corresponding author: rudihartono@usu.ac.id

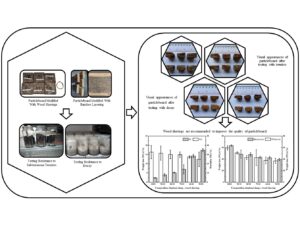

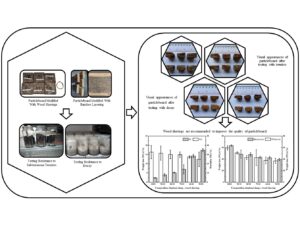

GRAPHICAL ABSTRACT

INTRODUCTION

The dung of the Sumatran elephant (Elephas maximus sumatranus) is one of the many natural fibers that has not been well utilized. The fibers in the elephant dung (ED) can be utilized as a particleboard (PB) raw material because of its high fiber content. Like other ruminants, the Sumatran elephants absorb 40% of what they consume and produce up to 100 to 130 kg of dung daily (Masunga et al. 2006; Albani et al. 2018). The Sumatran elephant has long been utilized as a source of biogas. ED was developed into an unusual paper by Farah et al. (2014) and it has also been successfully used as a raw material for PB in earlier research (Jati et al. 2014; Widyorini et al. 2018). Using an adhesive containing 10% citric acid, Jati et al. (2014) effectively produced an ED-based PB with a density of 0.8 g/cm3. The elastic and rupture moduli of the obtained PB complied with JIS A 5908 (2003) requirements. However, the JIS A 5908 (2003) standard was not met by the PB’s dimensional stability and internal bond strength. To solve this issue, Widyorini et al. (2018) adjusted the pressing temperature and citric acid concentration. According to their findings, increasing pressing temperature and citric acid content greatly improved the dimensional stability of PB made from ED fiber. In the cited study, a pressing temperature of 200 °C and a citric acid content of 20% was determined to be ideal.

Through using wood shavings, Hartono et al. (2022a) were able to enhance the physical and mechanical characteristics of ED-derived PB. The findings of the study suggest that the mechanical and physical characteristics of ED-PB are enhanced by the addition of wood shavings. Wood shavings had a considerable impact on the characteristics of the ED-PB in addition to moisture content and water absorption. Except for thickness swelling, the JIS A 5908 (2003) standard was best satisfied using ED and wood shavings in a 50/50 ratio used in the study.

Additionally, Hartono et al. (2022b) demonstrated that layering bamboo can enhance the mechanical and physical characteristics of ED-PB. The physical characteristics of ED-PB with bamboo layerings include a density of 0.62 to 0.69 g/cm3, moisture content of 7.87% to 10.35%, water absorption of 38.27% to 68.58%, and thickness swelling of 10.87% to 30.00%. It also complies with JIS A 5908 (2003) minimum norms (Hartono et al. 2022b). ED-PB with bamboo layering satisfies JIS A 5908 (2003) standards for internal bond strength, rupture modulus, and modulus of elasticity with values of 1952 to 7282 MPa, 20.44 to 68.27 MPa, and 0.16 to 0.38 MPa. The best PB in this investigation had layers of belangke bamboo. However, it is unknown how well this PB resists termites and decay. Testing for termites and decay is one of the most important tests to see the quality of PB resistance before application (Hashim et al. 2009; Tascioglu and Tsunoda 2010a, 2010b; Tascioglu et al. 2014; Mohareb et al. 2017; Terzi et al. 2009, 2017; Sutiawan et al. 2022). Therefore, this study examines the resistance to termites and decay of PBs from ED fiber modified with wood shavings and bamboo layering.

EXPERIMENTAL

Materials

Elephant dung (ED) (Elephas maximus sumatranus) was collected at the Aek Nauli Conservation Camp in Simalungun Regency, while wood shavings Mahogany (Swietenia mahagoni) waste was collected in the Wood Working Industry Medan. Tali bamboo (Gigantochloa apus), talang bamboo (Schizostachyum brachycladum), kuning bamboo (Bambusa vulgaris), belangke bamboo (Gigantochloa pruriens), and betung bamboo (Dendrocalamus asper) were the layering materials used in this study. The adhesive utilized contained 7% isocyanate and 98% solid content.

Elephant dung (ED) was first cleaned using water to remove the fiber before being used to make particleboard. Following air drying of the ED, the fibers and wood shavings were oven-dried for 24 h at 103 °C to achieve an equilibrium moisture content of 8%. After that, the fibers and wood shavings were sieved to the size passed through and retained of 4 to 20 mesh. A 20-cm-long piece of bamboo, 1.0 cm wide, and 1.0–mm-thick piece, was carved out of the material.

Particleboard (PB) Manufacturing

Following Hartono et al. (2022a,b), PB was created from elephant dung (ED) in two stages with a target density of 0.8 g/cm3:

Stage 1: ED and wood shavings were distributed throughout the PB in ratios of 100/0, 90/10, 80/20, 70/30, 60/40, and 50/50 (w/w %). The two types of particles were mixed in a bucket and sprayed with isocyanate with an adhesive content of 7% and a solids content of 98% using a compressor machine. The mixture was then added into a mold with dimensions of 20 × 20 cm2. With a compressed pressure of roughly 30 kg/cm2, the prepared board was then placed into a hot press. The temperature used was 160 °C for approximately 5 min.

Stage 2: The PB used in this study included three layers: the face, the back, and the core. The face and back layers were made of bamboos, and the core was constructed of ED. Using a spray gun, an even mixture of ED and isocyanate was combined, and adhesive was applied to one side of the bamboo layer. The sample was placed into a mold that was 20 cm (long) and 20 cm (wide) in size after being layered with an ED and bamboo layer, including the face, core, and back. Additionally, the samples were pressed with a hot press at 160 °C for 10 min at a pressure of 30 kg/cm2. This study involved 14 days of conditioning at room temperature (20 to 25 °C). The PB used in this investigation was produced in stages, as shown in Table 1. In addition, the sample PB from each stage is shown in Fig. 1.

Table 1. Conditions Used for the Manufacture of Particleboard

Stage 1

Stage 2

Fig. 1. Sample particleboard from each stage

Physical Properties’ Determination

The physical properties measured were the density and moisture content, according to JIS A 5908-2003.

Testing Resistance to Subterranean Termites

Particleboard (PB) resistance for termite testing was carried out according to the standard SNI 7207 2014 (Fig. 2). Small wood blocks (25 × 25 × 5 mm) of pine (Pinus merkusii) were used as a control. Parameters calculated after testing for termites with SNI standards consist of weight percent loss and mortality. For 48 h, the sample was kept in an oven at 60 °C. It was then weighed to get the mass of the PB before testing (W1). The sample was placed in a glass bottle with 200 g of sterilized sand and 50 mL of water. The test sample was placed in an angled position at the bottom of the glass bottle (60 mm in diameter and 100 mm in height). About 200 subterranean termites (Coptotermes curvignathus Holmgren) collected from a laboratory termite colony at Center for Standardization of Sustainable Forest Management Instruments, Ministry of Environment and Forestry, Indonesia, all in good condition and activity, were inserted into each test bottle. PB, sand, and termite samples were placed in test bottles, which were then kept in the dark for four weeks at 25 to 30 °C and 80% to 90% relative humidity. Three replicates were tested for each board type. The containers were weighed weekly, and if the moisture content of the sand decreased by 2% or more, water was added to achieve the moisture content standard. Following the termite inspection, the test samples were cleaned and placed in an oven at 60 °C for 48 h. After the oven process was complete, the samples from the test results were weighed to obtain the mass after the test (W2). Based on SNI 7207 (2014) standard, the categorization of wood resistance to subterranean termites was evaluated. The following equation was used to determine how much weight loss and mortality were worth,

(1)

(2)

where W1 is the mass before testing (g), W2 is the mass after testing (g), D is the number of dead worker termites (per piece), and n is the number of worker termites in the test (200).

Fig. 2. Test unit of subterranean termite attack on the sample

Testing for Resistance to Decay (Trametes versicolor and Fomitopsis palustris)

Particleboard (PB) testing against wood rot decay (T. versicolor and F. palustris) was carried out using the standard JIS K 1571 (2004) (Fig. 3). A 100-mL aliquot of liquid medium containing 1.5% malt extract, 0.3% peptone, and 4% glucose was inoculated with stock culture of either T. versicolor or F. palustris. The incubation of inoculated liquid medium was conducted using a shaker (120 rpm) at 26 °C for 10 days. A 250-g medium of sea sand in a glass jar was permeated with 80 to 85 mL of nutrient solution containing 4% glucose, 0.3% peptone, and 1.5% malt extract for T. versicolor. Half as much of each component was used for F. palustris. About 3–4 mL of these liquid fungal stock cultures were used in inoculating the jars. When the mycelium had fully covered the medium in the glass jars, the specimens were placed on top of the growing mycelium.

Small wood blocks (20 × 20 × 5 mm) of pine (Pinus merkusii) were used as a control. The parameter determined after evaluating the decay using the JIS standard is the weight loss percentage after 48 h spent with the sample in an oven at 60 °C. The PB was weighed to determine its mass before being tested (W1). Furthermore, the test sample was fed to a medium overgrown with rotting decay in a test bottle and tightly closed to avoid contamination of other decaying materials. The test sample was cleaned after 12 weeks and then oven-dried for 48 h at 60 °C until the mass remained constant (W2). Three replicates were tested for each board type. The following equation is used to determine the value of weight loss,

(3)

where W1 is the mass before testing (g) and W2 is the mass after testing (g).

Fig. 3. Test unit of decay attack on the sample

Statistical analysis with a non-factorial completely randomized design (CRD) was performed in this study. Stage 1 analyzed the effect of comparing ED particles and wood shavings particles at proportions of 100/0, 90/10, 80/20, 70/30, 60/40, and 50/50 against the termites’ attack and decay. Meanwhile, stage 2 analyzed the effect of the bamboo layering treatment, namely without layering (untreated), belangke bamboo layering, tali bamboo layering, betung bamboo layering, kuning bamboo layering, and talang bamboo layering on termites and their decay attack.

RESULTS AND DISCUSSION

Effect of Wood Shavings

The termite mortality in the particleboard (PB) was 4.67% to 34.67% (Table 2). Data analysis showed that increasing the mortality through addition of wood shavings was statistically significant. The higher termite mortality found in the 50/50 ratio than in the other mixing ratios suggests that the 50/50 ratio was more resistant to termite assault. The PB used in the 50/50 ratio may have had a higher density than the other PB, according to these observations. It is suggested that the termites did not favor PB with a 50/50 mix because it was more difficult to digest. The highest PB density was observed at a 50/50 ratio (0.68 g/cm3), and the lowest was found at a 100/0 ratio (0.63 g/cm3) (Table 3). Because the ED substance has a low density, these occurrences are caused by differences in the densities of the raw materials. ED has an estimated bulk density of 0.11 g/cm3, according to Widyorini et al. (2018). ED-PB gains density after being mixed with Mahogany wood shavings, which have a density of 0.60 to 0.08 g/cm3. Mahogany density was estimated to be 0.58 to 0.63 by Gilbero et al. (2019). In addition, the higher moisture content contributed to the PB’s resistance against termite attacks. The highest moisture content of PB is found at a ratio of 100/0 (9.78%) (Table 3). Hadi et al. (2021) observed that the reduced moisture level increased resistance to termite activity.

Table 2. Mortality and Weight Loss of Termite and Decay Resistance Test at Various Compositions of Wood Shavings

The same letters in a column are not significantly different (p≤0.05)

Table 3. Density and Moisture Content of particleboard at Various Compositions of Wood Shavings

Values in parentheses are standard deviations

The weight loss against termites determined the resistance class of the PB, as shown in Table 2. In addition, weight loss against decay is shown in Table 2. The weight losses against termites of the PB were 12.4% to 16.3%. The weight percent losses against the decay of the PB was 36.9% to 63.5%. The data analysis showed that the weight loss of decay of PB was greatly impacted by the addition of wood shavings. However, it did not significantly affect the PB weight loss by termites. The weight loss by termite and decay of the 50/50 ratio of the PB showed a trend significantly different from others. This phenomenon is affected by the density, moisture content, as well as in mortality of PB. In addition, the use of isocyanate adhesives increases the resistance of PB to termites and decay (Papadopoulos 2006). Isocyanate resins work exceptionally well and are ideal for enhancing the mechanical and physical qualities of wood products (Papadopoulos 2006). The presence of active hydroxyl groups from the bonded material ensures that the isocyanate can generate covalent bonds (Papadopoulos 2006). Isocyanates can block hydroxyl groups from cellulose and hemicellulose and have a strong reactivity to hydroxyl groups, according to earlier investigations (Zhao et al. 2011). Additionally, the wood-isocyanate bonding process lowers the moisture content and strengthens the wood’s resistance to decay (Williams and Hale 1999, 2003). The 50/50 PB was still classified as poorly (class IV) termite resistant by the SNI standard 7207 (2014). Figures 4 and 5 illustrate the visual appearances of PB after testing termites and decay.

Fig. 4. Visual appearances of particleboard after testing with termites at various compositions of wood shavings: (a) 100/0, (b) 90/10, (c) 80/20, (d) 70/30, (e) 60/40, and (f) 50/50

Fig. 5. Visual appearances of particleboard after testing brown-rot decay at various compositions of wood shavings: (a) 100/0, (b) 90/10, (c) 80/20, (d) 70/30, (e) 60/40, and (f) 50/50

Effect of Bamboo Layering

The particleboard (PB) termite mortality in this study ranged from 4.3% to 6.3% (Table 4). Control wood (pine) had the same mortality (5.00%) as PB in this study. This phenomenon indicates that the termites used were healthy. The weight loss by termites after exposure for four weeks can be seen in Table 4. In this investigation, the weight loss of PB ranged from 11.0% to 16.4%. Kusumah et al. (2017) reported mortality of PB bonded using citric acid, phenol-formaldehyde, and isocyanates adhesives ranges from 37.9% to 46.4%. The weight loss of PB bonded with urea-formaldehyde ranges from 12.4% to 30.0%, according to Iswanto et al. (2017). The weight loss of PB bonded with citric acid, phenol-formaldehyde, and isocyanates ranges from 3.92% to 5.91%, according to Kusumah et al. (2017). Data study showed that termite weight loss and PB mortality were not significantly impacted by bamboo layering.

Table 4. Mortality and Weight Loss of Termite and Decay Resistance Test Using Various Bamboo Layerings

The same letters in a column are not significantly different (p≤0.05).

Table 5. Density and Moisture Content of particleboard at Various Bamboo Layerings

Values in parentheses are standard deviations

Table 4 displays the weight loss of PB following a 12-week exposure to the decaying by T. versicolor and F. palustris. The control sample’s weight loss was 37.9% to 54.8% after 12 weeks of exposure. Meanwhile, PB in various layerings of bamboo had higher weight loss (41.5% to 60.9%). The layering of ED-PBs with bamboo reduces mortality and increases the weight loss of PBs against termites and decay. According to the results from statistical analysis, the PB’s weight loss against decay was greatly impacted by the layering of bamboo. Duncan’s test further showed that the highest weight loss against decay was found in kuning bamboo-layered PBs. This phenomenon is because the kuning bamboo has a lower density and mechanical properties than other bamboo samples. According to Hartono et al. (2022c), the betung bamboo has the maximum density, measuring 0.83 g/cm3. At 0.60 g/cm3, kuning bamboo has the lowest density. In addition, kuning bamboo has the highest moisture content compared to the others. According to a prior study, dasar bamboo has the lowest average moisture content, at 62.31%, and kuning bamboo has the greatest average moisture content, at 223.4%. According to Hadi et al. (2021), the reduced moisture content increased resistance to termite activity. In contrast to the results of adding wood shavings, layering of bamboo decreases termite resistance. According to Iswanto et al. (2017), strand bamboo is the least resistant to subterranean termite attacks. Additionally, bamboo with a high starch content has a lesser termite resistance than wood (De Melo et al. 2015; Maulana et al. 2022). Figures 6 and 7 illustrate the visual appearances of PB after testing termites and fungal decay.

Fig. 6. Visual appearances of particleboard after testing with termites using various bamboo layerings: (a) tali, (b) talang, (c) kuning, (d) belangke, (e) betung, and (f) untreated

Fig. 7. Visual appearances of particleboard after testing brown-rot decay at various bamboo layerings: (a) tali, (b) talang, (c) kuning, (d) belangke, (e) betung, and (f) untreated

Comparison of Wood Shavings and Bamboo Layering

The mechanical and physical characteristics of ED-PB were enhanced by the addition of wood shavings and bamboo layering. The physical and mechanical properties fulfilled the JIS A 5908-2003 standard. The addition of wood shavings could increase the resistance of PB against termite and decay attacks. However, the layering of bamboo decreased the resistance of PB against termite and decay attacks. These phenomena were attributed to the fact that bamboo has a higher starch component than wood. Bamboo with a high starch content has a lesser termite resistance than wood (De Melo et al. 2015; Maulana et al. 2022). Therefore, wood shavings are a recommendation of the best method in improving the quality of ED-PB compared to bamboo layering.

CONCLUSIONS

- The addition of wood shavings slightly increased the resistance of particleboard against termite and decay attacks.

- However, including bamboo layering reduces the resistance of the particleboard to termite and decay attacks.

- The 50/50 ratio between elephant dung and wood shavings achieved slightly higher termite mortality and lower weight loss than other samples, indicating that the 50/50 ratio was more resistant to termite and decay attacks.

- Meanwhile, kuning bamboo in this study indicated lower termite mortality and higher weight loss than others, revealing that this bamboo type was not as resistant to termite and decay attacks compared to other varieties.

- Therefore, wood shavings are recommended to improve the quality of particleboard from elephant dung, as compared to bamboo layering.

ACKNOWLEDGMENTS

The authors are grateful for the financial support of the TALENTA Universitas Sumatera Utara Scheme Penelitian Kolaborasi Perguruan Tinggi, Grant No. 339/UN5.2.3.1/PPM/KP-TALENTA/2022.

REFERENCES CITED

Albani, F., Pikoli, M. R., and Sugoro, I. (2018). “Type of feed affects biogas production from elephant dung; a study case of sumateran elephant (Elephas maximus sumatranus temminck; 1847) in ragunan wildlife park; South Jakarta,” Journal of Natural Resources and Environmental Management 8(2), 264-270. DOI: 10.29244/jpsl.8.2.264-270

Farah, N., Amna, M., Naila, Y., and Ishtiaq, R. (2014). “Processing of elephant dung and its utilization as a raw material for making exotic paper,” Research Journal of Chemical Sciences 4(8), 94-103.

Gilbero, D. M., Abasolo, W. P., Matsuo-Ueda, M., and Yamamoto, H. (2019). “Surface growth stress and wood properties of 8-year-old planted Big-leaf mahogany (Swietenia macrophylla King) from different landrace provenances and trial sites in the Philippines,” Journal of Wood Science 65(1), article 35. DOI: 10.1186/s10086-019-1814-4

Hadi, Y. S., Mulyosari, D., Herliyana, E. N., Pari, G., Arsyad, W. O. M., Abdillah, I. B., and Gérardin, P. (2021). “Furfurylation of wood from fast-growing tropical species to enhance their resistance to subterranean termite,” European Journal of Wood and Wood Products 79(4), 1007-1015. DOI: 10.1007/s00107-021-01676-4

Hartono, R., Dalimunthe, A. M., Iswanto, A. H., Herawati, E., Sutiawan, J., and de Azevedo, A. R. G. (2022a). “Mechanical and physical properties of particleboard made from the sumatran elephant (Elephas maximus sumatranus) dung and wood shaving,” Polymers 14(11), article 2237. DOI: 10.3390/polym14112237

Hartono, R., Iswanto, A. H., Herawati, E., Suramana, R. E., Sutiawan, J., Amin, Y., and Sumardi, I. (2022b). “The improvement of sumatran elephant (Elephas maximussumatranus) dung particleboard characteristics using bamboo layering,” Polymers 14(16), article 3330. DOI: 10.3390/polym14163330

Hartono, R., Iswanto, A. H., Priadi, T., Herawati, E., Farizky, F., Sutiawan, J., and Sumardi, I. (2022c). “Physical, chemical, and mechanical properties of six bamboo from Sumatera Island Indonesia and its potential applications for composite materials,” Polymers 14(22), article 4868. DOI: 10.3390/polym14224868

Hashim, R., Boon, J. G., Sulaiman, O., Kawamura, F., and Lee, C. Y. (2009). “Evaluation of the decay resistance properties of Cerbera odollam extracts and their influence on properties of particleboard,” International Biodeterioration and Biodegradation 63(8), 1013-1017. DOI: 10.1016/j.ibiod.2009.07.002

Iswanto, A. H., Aritonang, W., Azhar, I., Supriyanto, and Fatriasari, W. (2017). “The physical, mechanical and durability properties of sorghum bagasse particleboard by layering surface treatment,” Journal of the Indian Academy of Wood Science 14(1), 1-8. DOI: 10.1007/s13196-016-0181-7

Jati, A. S., Widyorini, R., and Prayitno, T. A. (2014). “Educational materials for the utilization of particleboard dung from elephant dung,” Taman Safari Indonesia II: Prigen Pasuruan, Indonesia.

JIS K 1571 (2004). “Test methods for determining the effectiveness of wood preservatives and their performance requirements,” Japanese Standards Association, Tokyo, Japan.

Kusumah, S. S., Umemura, K., Guswenrivo, I., Yoshimura, T., and Kanayama, K. (2017). “Utilization of sweet sorghum bagasse and citric acid for manufacturing of particleboard II: Influences of pressing temperature and time on particleboard properties,” Journal of Wood Science 63(2), 161-172. DOI: 10.1007/s10086-016-1605-0

Masunga, G. S., Andresen, Ø., Taylor, J. E., and Dhillion, S. S. (2006). “Elephant dung decomposition and coprophilous fungi in two habitats of semi-arid Botswana,” Mycological Research 110, 1214-1226. DOI: 10.1016/j.mycres.2006.07.004

Maulana, M. I., Jeon, W. S., Purusatama, B. D., Kim, J. H., Prasetia, D., Yang, G. U., Savero, A. M., Nawawi, D. S., Nikmatin, S., Sari, R. K., Febrianto, F., Lee, S. H., and Kim, N. H. (2022). “Anatomical characteristics for identification and quality indices of four promising commercial bamboo species in Java, Indonesia,” BioResources 17(1), 1442-1453. DOI: 10.15376/biores.17.1.1442-1453

Melo, R. R., Stangerlin, D. M., Santana, R. R. C., and Pedrosa, T. D. (2015). “Decay and termite resistance of particleboard manufactured from wood, bamboo and rice husk,” Maderas: Ciencia y Tecnologia 17(1), 55-62. DOI: 10.4067/S0718-221X2015005000006

Mohareb, A. S. O., Hassanin, A. H., Candelier, K., Thévenon, M. F., and Candan, Z. (2017). “Developing biocomposites panels from food packaging and textiles wastes: Physical and biological performance,” Journal of Polymers and the Environment 25(2), 126-135. DOI: 10.1007/s10924-016-0791-6

Papadopoulos, A. N. (2006). “Property comparisons and bonding efficiency of UF and PMDI bonded particleboards as affected by key process variables,” BioResources 1(2), 201-208. DOI: 10.15376/biores.1.2.201-208

SNI 01-7207 (2014). “Wood and wood product resistance test to wood-destroying organism,” The National Standardization Agency, Jakarta, Indonesia.

Sutiawan, J., Hadi, Y. S., Nawawi, D. S., Abdillah, I. B., Zulfiana, D., Lubis, M. A. R., Nugroho, S., Astuti, D., Zhao, Z., Handayani, M., et al. (2022). “The properties of particleboard composites made from three sorghum (Sorghum bicolor) accessions using maleic acid adhesive,” Chemosphere 290, article ID 133163. DOI: 10.1016/j.chemosphere.2021.133163

Tascioglu, C., and Tsunoda, K. (2010a). “Biological performance of copper azole-treated wood and wood-based composites,” Holzforschung 64(3), 399-406. DOI: 10.1515/HF.2010.039

Tascioglu, C., and Tsunoda, K. (2010b). “Laboratory evaluation of wood-based composites treated with alkaline copper quat against fungal and termite attacks,” International Biodeterioration and Biodegradation 64(8), 683-687. DOI: 10.1016/j.ibiod.2010.05.010

Tascioglu, C., Umemura, K., Yoshimura, T., and Tsunoda, K. (2014). “Biological performance of zinc borate-incorporated particleboard: Effects of leaching on efficacy,” Composites Part B: Engineering 57, 31-34. DOI: 10.1016/j.compositesb.2013.09.037

Terzi, E., Kartal, S. N., Gerardin, P., Ibanez, C. M., and Yoshimura, T. (2017). “Biological performance of particleboard incorporated with boron minerals,” Journal of Forestry Research 28(1), 195–203. DOI: 10.1007/s11676-016-0288-0

Terzi, E., Köse, C., Büyüksari, Ü., Avci, E., Ayrilmiş, N., and Kartal, S. N. (2009). “Evaluation of possible decay and termite resistance of particleboard containing waste tire rubber,” International Biodeterioration and Biodegradation 63(6), 806-809. DOI: 10.1016/j.ibiod.2009.01.010

Widyorini, R., Dewi, G. K., Nugroho, W. D., Prayitno, T. A., Jati, A. S., and Tejolaksono, M. N. (2018). “Properties of citric acid-bonded composite board from elephant dung fibers,” Journal of the Korean Wood Science and Technology 46(2), 132-142. DOI: 10.5658/WOOD.2018.46.2.132

Williams, F. C., and Hale, M. D. (1999). “Resistance of wood chemically modified with isocyanates Part I. Brown rot, white rot and acid chlorite delignification,” Holzforschung 53(3), 230-236. DOI: 10.1515/hf.1999.039

Williams, F. C., and Hale, M. D. (2003). “The resistance of wood chemically modified with isocyanates: The role of moisture content in decay suppression,” International Biodeterioration and Biodegradation 52(4), 215-221. DOI: 10.1016/S0964-8305(03)00070-2

Zhao, L. F., Liu, Y., Xu, Z. D., Zhang, Y. Z., Zhao, F., and Zhang, S. B. (2011). “State of research and trends in development of wood adhesives,” Forestry Studies in China 13(4), 321-326. DOI: 10.1007/s11632-013-0401-9

Article submitted: February 8, 2023; Peer review completed: March 4, 2023; Revised version received: March 29, 2023; Accepted: April 22, 2023; Published: June 2, 2023.

DOI: 10.15376/biores.18.3.5073-5084