Abstract

Bamboo culms or bamboo plywood possessing a native green surface color are highly valuable for use in interior decoration. However, the green surface color of bamboo can easily become discolored in ambient environments without any protection. In order to maintain the green surface color of Neosinocalamus affinis bamboo, this study used copper sulfate (CuSO4), phosphoric acid (H3PO4), and acetic acid (CH3COOH) solutions as protectors. The changes in surface color and characteristics of the bamboo samples before and after the treatment were evaluated. The results showed that the N. affinis bamboo samples treated with 2% CuSO4 solution at 80 °C for 3 h exhibited an attractive green color, with a* and b* values of -7.61 and 5.13, respectively. The indoor durability test result indicated that bamboo samples treated with CuSO4, CuSO4/H3PO4, and CuSO4/CH3COOH solutions all had excellent color durability. After the treatment, the relative copper content on the bamboo surface slightly increased, while the magnesium content decreased. The chlorophyll structure was changed, and reactions between chlorophyll and copper ions may have occurred. The silicon was almost completely removed, and the surface structure of the treated bamboo changed, resulting in good permeability for the treatment.

Download PDF

Full Article

The Effect of Chemical Treatment on Green Color Preservation and Surface Characteristics of Neosinocalamus affinis Bamboo

Lin Chen,#,a Lu He,#,a Jiulong Xie,*,a Zhongpeng Qiu,a Jinqiu Qi,a Yongze Jiang,a Hui Xiao,a Yuzhu Chen,a Cornelis F. de Hoop,b and Chung-Yun Hse c

Bamboo culms or bamboo plywood possessing a native green surface color are highly valuable for use in interior decoration. However, the green surface color of bamboo can easily become discolored in ambient environments without any protection. In order to maintain the green surface color of Neosinocalamus affinis bamboo, this study used copper sulfate (CuSO4), phosphoric acid (H3PO4), and acetic acid (CH3COOH) solutions as protectors. The changes in surface color and characteristics of the bamboo samples before and after the treatment were evaluated. The results showed that the N. affinis bamboo samples treated with 2% CuSO4 solution at 80 °C for 3 h exhibited an attractive green color, with a* and b* values of -7.61 and 5.13, respectively. The indoor durability test result indicated that bamboo samples treated with CuSO4, CuSO4/H3PO4, and CuSO4/CH3COOH solutions all had excellent color durability. After the treatment, the relative copper content on the bamboo surface slightly increased, while the magnesium content decreased. The chlorophyll structure was changed, and reactions between chlorophyll and copper ions may have occurred. The silicon was almost completely removed, and the surface structure of the treated bamboo changed, resulting in good permeability for the treatment.

Keywords: Neosinocalamus affinis; Green color preservation; Chemical treatment; Surface characteristics

Contact information: a: College of Forestry, Sichuan Agricultural University, Chengdu, Sichuan 611130, PRC; b: School of Renewable Natural Resources, Louisiana State University Agricultural Center, Baton Rouge, Louisiana 70803, USA; c: Southern Research Station, USDA Forest Service, Pineville, Louisiana 71360, USA; # Authors contributed equally to this manuscript;

* Corresponding author: Jiulong Xie, jxie6@sicau.edu.cn

INTRODUCTION

There are approximately 1,250 species of bamboo that are mainly found in Asian countries such as China. These bamboo species provide an annual output of 6 to 7 million tons (Liu et al. 2018a). As a green and renewable material, bamboo has attracted increasing attention due to its low cost and excellent performance (Sukmawan et al. 2016; Hao et al. 2018). Bamboo has been widely used in building materials and floor processing, composites, bioenergy, and other fields (Felisberto et al. 2018; Liu et al. 2018b). Neosinocalamus affinis, a cluster bamboo with a culm height of 8 m to 12 m, mainly grows in the Chinese provinces of Sichuan, Guizhou, Yunnan, Guangxi, Hunan, west Hubei, and south Shaanxi, where it is widely used in the daily lives of local residents. From an industry perspective, N. affinis bamboo is an important raw material for pulping, construction, furniture manufacturing, and other bamboo fiber-based materials (Wang et al. 2009; Sun et al. 2011). For example, the bamboo plywood made from N. affinis has excellent physical and mechanical properties (Qi et al. 2014). The bamboo fiber bundle reinforced composites prepared by N. affinis exhibited lower water absorption, higher structural stability, and higher mechanical properties (Xie et al. 2016). The scrimbers bamboo prepared by N. affinis is not only used in indoor building materials, but also in the fields of wind turbine blade, building structure material, container floor, and cement mold (Yu and Yu 2013).

Freshly harvested N. affinis bamboo culms have been employed as materials for indoor and outdoor utilization in the Sichuan province of China, because of its abundance and excellent properties. However, due to the influences of heat, light, and moisture, the surface color of N. affinis bamboo gradually changes from green or dark green to gray or yellow without any treatment, resulting in the reduction in decoration ability and values (Wang and Ren 2008; Zhang et al. 2013a). Green paints have been applied to bamboo in order to restore the original color of fresh bamboo. However, existing epidermis and silicon on the bamboo surface has provided poor paint adhesion, resulting in uneven painting and cracks. The treatment of bamboo with wood preservatives such as chromated copper arsenate (CCA) and ammoniacal copper arsenate (ACA) could preserve the green color of bamboo for a certain period (Chang and Wu 2000; Chang and Yeh 2001). For example, the green color of Dendrocalamus latiflorus bamboo can be preserved after treatment with copper salt aqueous solution (Wu et al. 2002b). The use of quaternary ammonium copper and copper oxazole preservatives can also protect the green color of bamboo (Chung et al. 2005). Copper salt preservation treatment combined with chromium-based oxide and H3PO4 was found to better protect the green color of bamboo (Chang and Yeh 2001; Chang et al. 2002). However, since chromium and arsenic are toxic and are not environmentally friendly, their use has been gradually restricted (Yoshida et al. 2004; Deng and Chen 2014; Chen et al. 2018). Moreover, an alcohol-based solution was also explored to protect the bamboo color (Wu et al. 2004). Although this process was found to be efficient and environmentally friendly, its high processing cost and safety concerns limit its industrial application.

Although some bamboo species have been treated with chemicals for green color protection purposes, the properties of bamboo species differ from one another, so an efficient green color preservation process for N. affinis bamboo is still needed. Since arsenate is toxic, a treatment method avoiding using arsenate is preferable. Therefore, this study examined the color parameters and surface characteristics of the treated N. affinis bamboo using copper sulfate (CuSO4) solution. This study investigated whether CuSO4 solution with proper pretreatment was a good option for the green color preservation of N. affinis bamboo for interior decoration use.

EXPERIMENTAL

Materials

Three-year-old N. affinis bamboo samples with dimensions of 50 mm long × 40 mm wide × thickness were collected from Chengdu, China. The samples were stored in the dark at 4 °C before use. All chemicals were commercially purchased and used as received.

Treatment Process

The bamboo samples were first treated in a 1% potassium hydroxide solution maintained at 80 °C for 30 min in a water bath. The treated samples were thoroughly washed with distilled water until the solution reached a neutral pH. The alkali-treated samples were then treated with CuSO4 solutions having different concentrations. The conditions for each treatment are listed in Table 1. The treated samples were oven-dried at 60 °C for 12 h.

Table 1. List of Conditions for Each Chemical Treatment on N. affinis bamboo

Color Measurement

The color measurement was carried out immediately after the sample had been oven-dried. The color measurement was carried out by using a high-quality computer colorimeter (NR69CP; Shenzhen Threenh Technology Co., Ltd., Shenzhen, China) with a D65 light source and a measuring aperture of 3 mm. For each sample, 25 points were measured, and the mean values was taken. According to the TAPPI T524 om-79 (1979), in the CIELAB color system, L* is the value on the white/black axis, a* is the value on the red /green axis, and b* is the value on the blue/yellow axis. The a* value best represents the difference in green and red, where a smaller a* value indicates a greener sample color.

Color Durability Test

Outdoor durability test

The treated samples were placed on a board for the outdoor durability test. To ensure that the samples could receive the maximum light energy, the board was placed on an inclined plane at an angle of 30° according to the local latitude (Fig. 1). The samples were maintained without any cover for 42 d (September 11, 2018 to October 23, 2018). The average precipitation, the pH value of the precipitation, and the average temperature during the test period were 102.6 mm, 7.43, and 18 °C, respectively.

Fig. 1. Solar orbit and sample placement

Indoor durability test

For the indoor durability test, the samples were placed in an indoor environment with an average temperature of 23 °C and an average humidity of 80%. The test period was 42 d as well.

SEM Images

Scanning electron microscopy (SEM) energy-dispersive X-ray (EDX) (SU-3300; Hitachi High-Technologies Co., Ltd., Nake, Japan) analysis was used to observe the surface structure and detect the inorganic elements of the N. affinis bamboo surface samples before and after the treatment. The green bamboo on the surface was peeled off, and samples that were 5 mm × 5 mm × 1 mm in size were prepared. The samples were oven dried at 103 °C until a constant weight was reached. After drying, a conductive carbon double-sided adhesive tape was used to bind the sample on a metal support. Gold was sputtered and coated with a thickness of 3 nm to 6 nm on the sample surface prior to the test.

Chlorophyll Analysis

For the chlorophyll structure analysis, a referenced method was used (Chang et al. 1998). Samples were scraped from the green surface of the bamboo, and a 2 g sample was weighed and mixed with 95% ethanol. Silica and calcium carbonate were added for grinding. When the mixture reached a white viscous state, the mixture was filtered and 15 mL of 95% alcohol was added to the filtrate. The absorbance of the liquid was measured using an ultraviolet (UV) spectrophotometer (UV-4802; UNICO, Dayton, NJ, USA).

RESULTS AND DISCUSSION

Chromaticity Changes

Figure 2 shows the effect of the CuSO4 concentration on the CIE L*a*b* values of the samples.

Fig. 2. Effect of CuSO4 concentration on the color parameters of bamboo samples treated at 60 °C for 3 h

The results showed that the a* values of the samples treated with different concentrations were all smaller than -6.0, and the a* values slightly decreased as CuSO4 concentration increased. The influence of CuSO4 concentration on the b* values of the samples was not obvious. The b* values of the samples treated with 2% CuSO4 solution were near 0.69, which means that the treatment had no obvious yellow tendency. The b* values of the samples treated with 1% and 4% concentrations of CuSO4 were below 0. By comparing the a* values of the samples, the treatment with 2% CuSO4 was more suitable.

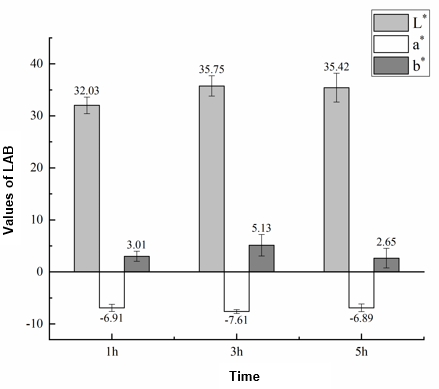

Figure 3 shows the effect of the treatment time on the CIE L*a*b* values of the samples. The a* values for the samples treated for 1 h, 3 h, and 5 h were -6.91, -7.61, and -6.89, respectively. The a* values of the samples treated for 3 h were the lowest. By prolonging the treatment time, the a* values first increased and then decreased, while the b* values first decreased and then increased. The b* values for the samples treated for 3 h was 5.13, which was higher than those treated for 1 h and 5 h. The above results showed that the samples with 3 h treatment can obtain a relative low a* values and a high b* values.

Fig. 3. Effect of treatment time on the color parameters of bamboo samples treated with 2% CuSO4 at 60 °C

Figure 4 shows the CIE L*a*b* values of the samples with respect to the treatment temperatures. By increasing the treatment temperature, the a* values of the samples first increased and then decreased. When the treatment temperature was maintained at 80 °C, the sample had an a* value of -7.61 and a b* value of 5.13. These values were larger than the samples treated at 40 °C and 60 °C, which indicated that the samples treated at 80 °C were much greener and brighter. A higher temperature may also have a negative effect on the mechanical properties of bamboo for constructional utilizations, so a treatment temperature higher than 80 °C should be avoided in this process (Zhang et al. 2013b).

Fig. 4. Effect of temperature on the color parameters of bamboo samples treated with 2% CuSO4 for 3 h

Fig. 5. Effect of solution type on the color parameters of bamboo samples treated at 80 °C for 3 h

Figure 5 shows the a* values of the bamboo samples treated in different CuSO4 solutions at 80 °C for 3 h. The samples treated in the CuSO4/H3PO4 and CuSO4/CH3COOH solutions had less negative a* values than those treated in the CuSO4 solution. The a* values for the samples treated in the CuSO4/H3PO4 solution were less negative than those treated in CuSO4/CH3COOH solution. The changes in the concentration of the binary solutions had no obvious influence on the a* values.

Durability Test

Figure 6 shows the a* values of the bamboo samples before and after the indoor and outdoor exposure tests. After 42 d of indoor exposure, the increments in the a* values of the samples treated with CuSO4 aqueous solution, CuSO4/CH3COOH solution, and CuSO4/H3PO4 solution were 0.32, 1.42, and 0.14, respectively. While the change in the a* values for the indoor exposure samples was not obvious, the change in the a* values for the samples after 42 d of outdoor exposure was obvious. The increments in the a* values of the outdoor exposure treated with CuSO4 aqueous solution, CuSO4/CH3COOH solution, and CuSO4/H3PO4 solution were 6.37, 7.43, and 11.75, respectively. This result revealed that although lower a* values can be achieved in CuSO4/H3PO4 or CuSO4/CH3COOH solution, after the exposure test, all the samples had higher a* values than those treated with CuSO4 aqueous solution. This may be since acidity could slightly damage the original bamboo structure, resulting in a lower resistance ability to aging.

Fig. 6. Changes in a* values of the bamboo samples before and after the exposure test for 42 d

From the above results, it was concluded that the N. affinis samples treated in CuSO4 aqueous solution had higher a* values after the indoor exposure test. The samples treated with CuSO4aqueous and CuSO4/H3PO4 solution had minimal changes in their a* values, indicating that these samples had great potential in interior decoration utilization. However, after the outdoor exposure test, only the bamboo samples treated with CuSO4 aqueous solution had negative a* values, revealing that the N. affinis bamboo samples treated with CuSO4 aqueous solution could be used for a considerable period in an outdoor environment without any cover or protection. However, the greater a* values of the outdoor test sample than that of the indoor test sample may be because that chlorophyll is degraded and discolored by sunlight and rain (Cubas et al. 2008).

Chlorophyll Structure Analysis

Figure 7 shows the UV-visible absorption spectra of the chlorophyll solution extracted from the fresh bamboo and the samples treated with CuSO4 aqueous solution. There were two absorption peaks near 437 nm and 665 nm in the spectra of the ethanol extract from the fresh bamboo, which represent the typical structure of chlorophyll. No absorption peaks were observed in the range of 350 nm to 750 nm band in the spectrum of the air-dried bamboo (Sartory and Grobbelaar 1984), indicating that the chlorophyll in the air-dried bamboo samples was destroyed (Qudsieh et al. 2002). This result confirmed that the existing chlorophyll on the bamboo surface was an essential condition for exhibiting the green color of bamboo. There were also two absorption peaks in the ethanol extract of N. affinis bamboo samples treated with CuSO4 aqueous solution. Compared to the peak positions on the spectrum of the fresh bamboo, the peaks of the treated bamboo shifted to lower band ranges, indicating that the chemical structure of the chlorophyll was different between the fresh green bamboo samples and the treated bamboo samples (Wu et al. 2002a). Usually, chlorophyll color changes from green to yellowish brown by losing the magnesium ions under light oxidation, temperature changes, and enzymes (Cubas et al. 2008). A hypothesis could be made that the chlorophyll was first changed by losing the magnesium ions under the treatment temperature of 80 °C, then copper ions reacted with the chlorophyll forming the copper chlorophyll (Guzmán et al. 2002). Since the copper chlorophyll had better color stability to acid and light (Del Giovine and Fabietti 2005; Tumolo and Lanfer-Marquez 2012), the green color of the bamboo was retained.

Fig. 7. The UV-visible spectra of the chlorophyll extracted from the fresh, air-dried, and CuSO4 treated N. affinis bamboo samples

Surface Chemical Analysis

To further test possible reactions between the chlorophyll and the copper ions, the changes of elements on the green bamboo surface before and after the treatment was elucidated by EDX analysis. The results are shown in Fig. 8. The relative magnesium content slightly decreased from 0.12% to 0.10%, which showed the loss of magnesium ions during the drying process of bamboo. The copper content increased from 0.66% to 2.14%, revealing that the combination of copper and chlorophyll may occur during the treatment process. This result was consistent with the peaks shift in the UV-visible spectra of the chlorophyll. One interesting result was that the silicon element content dramatically decreased from 14.4% to 1.04% after the treatment. The removal of the silicon on the bamboo surface may provide good conditions for the treatment reactions with increasing the permeability (Yuan et al. 2016).

Fig. 8. Changes in the relative element content of bamboo epidermis before and after CuSO4 aqueous solution treatment

Fig. 9. The SEM images of (a) the original bamboo epidermis sample and (b) the treated sample

Surface Morphology Analysis

Figure 9 shows the SEM images of the N. affinis bamboo surface and the treated samples. The N. affinis had a rough surface with spherical substances. The spherical substances were not visible on the surface of the CuSO4 treated samples, providing a much looser structure. The structural changes during the treatment process provided favorable conditions for the permeability of the reagents and promoted the reactions.

CONCLUSIONS

- The Neosinocalamus affinis bamboo samples treated by the CuSO4 aqueous solution at 80 °C for 3 h were able to exhibit excellent green color, indicated by low a* values.

- The N. affinis samples treated in the CuSO4/H3PO4 and CuSO4/CH3COOH solutions had less negative a* values compared to those treated in the CuSO4 aqueous solution. The CuSO4/CH3COOH solution had the best efficiency on the green color preservation indicating by the less negative a* values.

- The durability test showed that the treated N. affinis samples exhibited almost the same color performance to the fresh bamboo after the indoor durability test, indicating that these samples had great potential in interior decoration utilization.

- The chlorophyll structure changed after the treatment, and a reaction may take place between the chlorophyll and the copper ions during the treatment. The removal of silicon provided favorable conditions for the reactions.

REFERENCES CITED

Chang, S.-T., Wang, S.-Y., and Wu, J.-H. (1998). “Rapid extraction of epidermis chlorophyll of moso bamboo (Phyllostachys pubescens) culm using ultrasonics,” J. Wood Sci. 44(1), 78-80. DOI: 10.1007/BF00521879

Chang, S.-T., Wu, J.-H., and Yeh, T.-F. (2002). “Effects of chromated-phosphate treatment process on the green color protection of ma bamboo (Dendrocalamus latiflorus),” J. Wood Sci.48(3), 227-231. DOI: 10.1007/BF00771372

Chang, S.-T., and Yeh, T.-F. (2001). “Protection and fastness of green color of moso bamboo (Phyllostachys pubescens Mazel) treated with chromium-based reagents,” J. Wood Sci. 47(3), 228-232. DOI: 10.1007/BF01171226

Chang, S.-T., and Wu, J.-H. (2000). “Green-color conservation of ma bamboo (Dendrocalamus latiflorus) treated with chromium-based reagents,” J. Wood Sci. 46(1), 40-44. DOI: 10.1007/BF00779551

Chen, H., Dou, J., and Xu, H. (2018). “The effect of low-molecular-weight organic-acids (LMWOAs) on treatment of chromium-contaminated soils by compost-phytoremediation: Kinetics of the chromium release and fractionation,” J. Environ. Sci. 70, 45-53. DOI: 10.1016/j.jes.2017.11.007

Cubas, C., Lobo, M. G., and González, M. (2008). “Optimization of the extraction of chlorophylls in green beans (Phaseolus vulgaris L.) by N,N-dimethylformamide using response surface methodology,” J. Food Compos. Anal. 21(2), 125-133. DOI: 10.1016/j.jfca.2007.07.007

Chung, M.-J., Wu, J.-H., and Chang, S.-T. (2005). “Green colour protection of makino bamboo (Phyllostachys makinoi) treated with ammoniacal copper quaternary and copper azole preservatives,” Polym. Degrad. Stabil. 90(1), 167-172. DOI: 10.1016/j.polymdegradstab.2005.03.005

Del Giovine, L., and Fabietti, F. (2005). “Copper chlorophyll in olive oils: Identification and determination by LIF capillary electrophoresis,” Food Control 16(3), 267-272. DOI: 10.1016/j.foodcont.2004.03.005

Deng, H., and Chen, G. (2014). “Health risk assessment for typical and abandoned chromium-contaminated sites,” Chinese Journal of Geochemistry 33(4), 382-386. DOI: 10.1007/s11631-014-0701-3

Felisberto, M. H. F., Beraldo, A., Costa, M. S., Boas, F. V., Franco, C. M. L., and Clerici, M. T. P. S. (2018). “Characterization of young bamboo culm starch from Dendrocalamus asper,” Food Res. Int. DOI: 10.1016/j.foodres.2018.03.074

Guzmán, G. R., Dorantes, A. L., Hernández, U. H., Hernández, S. H., Ortiz, A., and Mora, E. R. (2002). “Effect of zinc and copper chloride on the color of avocado puree heated with microwaves,” Innov. Food Sci. Emerg. 3(1), 47-53. DOI: 10.1016/S1466-8564(01)00053-4

Hao, H., Tam, L.-h., Lu, Y., and Lau, D. (2018). “An atomistic study on the mechanical behavior of bamboo cell wall constituents,” Compos. Part B-Eng. 151, 222-231. DOI: 10.1016/j.compositesb.2018.05.046

Liu, K., Wang, R., and Yu, M. (2018a). “An efficient, recoverable solid base catalyst of magnetic bamboo charcoal: Preparation, characterization, and performance in biodiesel production,” Renew. Energ. 127, 531-538. DOI: 10.1016/j.renene.2018.04.092

Liu, W., Hui, C., Wang, F., Wang, M., and Liu, G. (2018b). “Review of the resources and utilization of bamboo in China,” in: Bamboo – Current and Future Prospects, H. P. S. Abdul Khalil (ed.), IntechOpen, London, UK. pp. 174-198.

Qi, J. Q., Xie, J. L., Huang, X. Y., Yu, W. J., and Chen, S. M. (2014). “Influence of characteristic inhomogeneity of bamboo culm on mechanical properties of bamboo plywood: effect of culm height,” Journal of Wood Science 60(6), 396-402.

Qudsieh, H. Y. M., Yusof, S., Osman, A., and Rahman, R. A. (2002). “Effect of maturity on chlorophyll, tannin, color, and polyphenol oxidase (PPO) activity of sugarcane juice (Saccharum officinarum var. yellow cane),” J. Agr. Food Chem. 50(6), 1615-1618. DOI: 10.1021/jf010959l

Sartory, D. P., and Grobbelaar, J. U. (1984). “Extraction of chlorophyll a from freshwater phytoplankton for spectrophotometric analysis,” Hydrobiologia 114(3), 177-187. DOI: 10.1007/BF00031869

Sukmawan, R., Takagi, H., and Nakagaito, A. N. (2016). “Strength evaluation of cross-ply green composite laminates reinforced by bamboo fiber,” Hydrobiologia 84, 9-16. DOI: 10.1016/j.compositesb.2015.08.072

Sun, B. L., Chai, Y. B., Huang, A. M., and Liu, J. L. (2011). “Application of NIR spectroscopy to estimate of MFA and fiber length of Neosinocalamus affinis,” Spectrosc. Spect. Anal. 31(12), 3251-3255. DOI: 10.3964/j.issn.1000-0593(2011)12-3251-05

TAPPI T524 om-79 (1979). “Color of paper and paperboard,” TAPPI Press, Atlanta, GA.

Tumolo, T., and Lanfer-Marquez, U. M. (2012). “Copper chlorophyllin: A food colorant with bioactive properties?,” Food Res. Int. 46(2), 451-459. DOI: 10.1016/j.foodres.2011.10.031

Wang, X., and Ren, H. (2008). “Comparative study of the photo-discoloration of moso bamboo (Phyllostachys pubescens Mazel) and two wood species,” Appl. Surf. Sci. 254(21), 7029-7034. DOI: 10.1016/j.apsusc.2008.05.121

Wang, Y.-j., Huang, C.-d., Wang, X.-s., Hu, T., and Zhang, G.-q. (2009). “Carbon stock and spatial distribution characteristics of Neosinocalamus affinis forest ecosystem,” Journal of Fujian Forestry Science and Technology 2, 6-9, 87.

Wu, J.-H., Chung, M.-J., and Chang, S.-T. (2004). “Evaluation of the effectiveness of alcohol-borne reagents on the green colour protection of makino bamboo (Phyllostachys makinoi),” Polym. Degrad. Stabil. 83(3), 473-479. DOI: 10.1016/j.polymdegradstab.2003.08.014

Wu, J.-H., Wang, S.-Y., and Chang, S.-T. (2002a). “Extraction and determination of chlorophylls from moso bamboo (Phyllostachys pubescens) culm,” J. Bamboo and Rattan 1(2), 171-180. DOI: 10.1163/156915902760181630

Wu, J.-H., Wu, S.-Y., Hsieh, T.-Y., and Chang, S.-T. (2002b). “Effects of copper-phosphorous salt treatments on green colour protection and fastness of ma bamboo (Dendrocalamuslatiflorus),” Polym. Degrad. Stabil. 78(2), 379-384. DOI: 10.1016/S0141-3910(02)00190-8

Xie, J., Qi, J., Hu, T., Cornelis, F., Hse, C. Y., and Shupe, T. F. (2016). “Effect of fabricated density and bamboo species on physical–mechanical properties of bamboo fiber bundle reinforced composites,” Journal of Materials Science 51(16), 7480-7490.

Yoshida, T., Yamauchi, H., and Sun, G. F. (2004). “Chronic health effects in people exposed to arsenic via the drinking water: Dose-response relationships in review,” Toxicol. Appl. Pharm. 198(3), 243-252. DOI: 10.1016/j.taap.2003.10.022

Yuan, Z., Kapu, N. S., Beatson, R., Chang, X. F., and Martinez, D. M. (2016). “Effect of alkaline pre-extraction of hemicelluloses and silica on kraft pulping of bamboo (Neosinocalamus affinis Keng),” Ind. Crop. Prod. 91, 66-75. DOI: 10.1016/j.indcrop.2016.06.019

Yu, W. J., and Yu, Y. L. (2013). “Development and prospect of wood and bamboo scrimber industry in China,” China Wood Industry 27(1), 5-8.

Zhang, Y. M., Yu, Y. L., and Yu, W. J. (2013a). “Effect of thermal treatment on the physical and mechanical properties of Phyllostachys pubescens bamboo,” Eur. J. Wood Wood Prod. 71(1), 61-67. DOI: 10.1007/s00107-012-0643-6

Zhang, Y., Yu, W., and Yahui, Z. (2013b). “Effect of steam heating on the color and chemical properties of Neosinocalamus affinis bamboo,” J. Wood Chem. Technol. 33(4), 235-246. DOI: 10.1080/02773813.2013.779714

Article submitted: February 16, 2019; Peer review completed: May 9, 2019; Revised version received: May 17, 2019; Accepted: May 18, 2019; Published; May 21, 2019.

DOI: 10.15376/biores.14.3.5327-5338