Abstract

The isolation of cellulosic fibers and their applications in composite materials have drawn considerable interest due to their outstanding thermal and mechanical properties combined with light-weight character, biodegradability, and renewability. Bamboo is a fast-growing plant, and its properties include sustainability and excellent tensile strength. In this study, bamboo fibers from the culms and shoots of Dendrocalamus asper were treated with 5 wt% sodium hydroxide and subjected to ultra-sonication for 5 hours to obtain bamboo cellulose. Infra-red spectra showed that lignin and hemicelluloses were removed after treatment. With the removal of amorphous cellulosic regions, both cellulosic fibers exhibited higher decomposition temperatures than the raw fibers. Thermogravimetric analysis confirmed that both types of bamboo cellulose had a peak decomposition temperature at 408 °C. Cellulose isolated from the bamboo shoots exhibited similar chemical and thermal properties, indicating its huge potential as an alternative to mature bamboo culms.

Download PDF

Full Article

Thermal Properties of Bamboo Cellulose Isolated from Bamboo Culms and Shoots

Arif Naim, Cindy Soo Yun Tan, and Fui Kiew Liew *

The isolation of cellulosic fibers and their applications in composite materials have drawn considerable interest due to their outstanding thermal and mechanical properties combined with light-weight character, biodegradability, and renewability. Bamboo is a fast-growing plant, and its properties include sustainability and excellent tensile strength. In this study, bamboo fibers from the culms and shoots of Dendrocalamus asper were treated with 5 wt% sodium hydroxide and subjected to ultra-sonication for 5 hours to obtain bamboo cellulose. Infra-red spectra showed that lignin and hemicelluloses were removed after treatment. With the removal of amorphous cellulosic regions, both cellulosic fibers exhibited higher decomposition temperatures than the raw fibers. Thermogravimetric analysis confirmed that both types of bamboo cellulose had a peak decomposition temperature at 408 °C. Cellulose isolated from the bamboo shoots exhibited similar chemical and thermal properties, indicating its huge potential as an alternative to mature bamboo culms.

DOI: 10.15376/biores.17.3.4806-4815

Keywords: Thermal properties; Activation energy; Fibers; Culms; Shoots

Contact information: Faculty of Applied Sciences, Universiti Teknologi MARA,Cawangan Sarawak, 94300 Kota Samarahan, Sarawak, Malaysia; *Corresponding author: liewsan2004@gmail.com

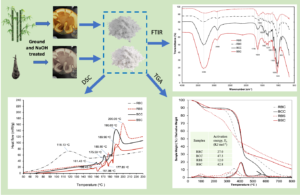

GRAPHICAL ABSTRACT

INTRODUCTION

Natural cellulosic fibers have attracted attention due to their unique properties such as biodegradability, flexibility, high mechanical strength, and stiffness (Thakur et al. 2020; Jin et al. 2021; Noori et al. 2021). Bamboo is a fast-growing renewable resource (3 to 5 years for it to mature), readily available, with excellent material properties similar to that of wood and can be processed by existing technologies (Muhammad et al. 2019; Liew et al. 2020). Bamboo shoots are the young, edible parts of bamboo plants; they emerge from the ground with a height of 20 to 30 cm with a tapered end.

Bamboo fiber typically consists of cellulose (73.8%), hemicellulose (12.5%), lignin (10.1%), pectin (0.4%), and aqueous extracts (3.2%) (Chaowana 2013). The high cellulosic content and fast growth rate of bamboo plants are advantageous for the broad utilization of bamboo in household products, textiles, building and construction materials, food industry, and composite manufacturing (Banik and Sastry 2018; Wijaya et al. 2019; Noori et al. 2021; Yang et al. 2021). However, bamboo fiber suffers from several drawbacks, including low thermal stability, polar and hydrophilic natures, and poor compatibility with polymer matrixes, leading to weakened interfacial bonding with other surfaces, thus hindering their applications in bamboo-based composites.

Natural fibers can be modified chemically to improve the surface properties and interfacial bonding of composite materials; these methods including acetylation, silane treatment, alkaline hydrolysis, and coupling reactions (Qian and Sheng 2017; Buson et al. 2018; Hassan et al. 2020; Cruz-Riaño et al. 2021). Alkaline treatment, or mercerization, is a popular approach to modify natural fibers. With the removal of lignin and hemicellulose from the cellulose, the alkaline-treated fibers exhibit enhanced surface roughness, hydrophobicity, and affinity for the polymeric matrix (Rebelo et al. 2019). The bundles of fiber are broken down into smaller fibers in the mercerization, rupturing the ester bonds form crosslinks involving xylan and lignin, which eventually reduce the porosity of lignocellulose (Giacon et al. 2021). As a result, bulk mechanical properties of alkaline-treated cellulosic fibers, mainly mechanical strength and stiffness, are improved.

In the present work, cellulose fibers were obtained from the culms and shoots of Dendrocalamus asper bamboo using NaOH hydrolysis and mechanical treatments, including ultra-sonication and homogenization. The chemical and thermal properties of the bamboo cellulosic fibers isolated from both matured culms and young shoots via the mechanical treatment and alkaline hydrolysis were analyzed and compared to see whether the bamboo shoot fibers could be an alternate source of bamboo fibers, which are currently isolated from mature bamboo culms.

EXPERIMENTAL

Materials

Bamboo culms (3 years old) and shoots (30 cm length) of Dendrocalamus asper were obtained from the Forest Research Institute Sarawak, Malaysia. Analytical grade sodium hydroxide and sulphuric acid (Sigma Aldrich, St. Louis, MO, USA) were used.

Preparation of Bamboo Fibers

The length of the bamboo culm trims, excluding the bamboo internode, was 1 m. They were cut into chips using a planner machine (HC410G, Elektra-Beckum, Niederschmiedeberg, Germany), which were then ground into powder. The bamboo shoot was cut into 10 mm length and ground into powder. This was done by using a heavy-duty food grinding machine (YS-150, JINFUDA, Henan, China). Both ground raw bamboo culm (RBC) and shoots (RBS) were dried in an oven at 70 °C for 72 h. The oven-dried samples were sieved, passed through a 100-µm mesh sieve and kept in sealed vacuum bags for further uses. The moisture content of raw bamboo culm was 60 to 65%, and the raw bamboo shoot was 70 to 80%. After being ground and oven-dried, moisture contents were 8 to 10 % for both. All bamboo was freshly harvested, clean, and processed.

Isolation of Cellulose from Bamboo Fibers

Ground bamboo culms and shoots were treated with NaOH as described previously (Liew et al. 2017). Ground bamboo (10 g) was weighed and immersed in a flask of NaOH (5 wt.%) solution for 8 h. The mixture was heated for 2 h at 80 °C under continuous stirring and then was left to cool down to room temperature with stirring at 150 rpm overnight. After that, the mixture was filtered and added with H2SO4 (1%) stirred for another 2 h. Finally, the treated mixture was rinsed with distilled water until pH 7. The treated product was obtained through vacuum filtration.

The alkaline pre-treated product (0.2% w/w solid content) was soaked in distilled water. The solution (120 mL) was then placed in an ultrasonic generator (Elma T310, 35 kHz) for 4 h at an output power of 70 W to produce a suspension. The sonicated suspension was centrifuged to separate the large bundles from the cellulose fibrils; slender cellulose fibrils were obtained from the supernatant fraction. The ultrasonic treatment was further carried out in an ice/water bath throughout the entire ultrasonication for 1 h.

Fourier Transform Infrared Spectroscopy (FTIR)

The FTIR spectra were obtained using an ATR-FTIR spectrometer (Spectrum 100, Perkin Elmer, Waltham, MA). The transmittance range of the scan was from 4000 to 650 cm-1.

Thermogravimetric Analysis (TGA)

Thermogravimetric measurements were performed using a Perkin Elmer system (Pyris 1 TGA). All measurements were obtained under a nitrogen flow of 20 mL·min-1 between 30 and 800 °C.

The activation energy (Ea) was calculated from TGA graphs using the Broido equation as given below,

(1)

where y is the fraction of undecomposed non-volatilized material, T is the absolute temperature (K), and R is the gas constant (8.314 J mol-1 K-1). The values of y have been taken from the TGA data. The values of were plotted on the Y axis, while the temperatures as 1/T (K-1) were plotted on the X axis. The activation energy of the composite was calculated from the slope of the trend line.

Differential Scanning Calorimetry (DSC)

The calorimetric tests were conducted using a differential scanning calorimeter (DSC 8000, Perkin Elmer). The temperature programmes were run from 50 to 230 °C at the heating rate of 20 °C·min-1 under a 20 mL·min-1 nitrogen atmosphere using 5 mg to 10 mg of sample.

RESULTS AND DISCUSSION

Fourier Transform Infrared Spectroscopy

The FTIR spectra of alkaline treated bamboo fibers isolated from its culms and shoots were compared to observe changes in their functional groups (Fig. 1). The absorption band at 3346 cm-1 represents the stretching vibration of OH, and the band at 2900 cm-1 is attributed to the asymmetric stretching vibration of -CH2 and -CH in cellulose, hemicellulose, and lignin (Xie et al. 2016). The prominent peaks at 893 and 1165 cm-1 were observed only in the raw bamboo culms (RBC), and not in raw bamboo shoots (RBS), due to the presence of lignin, which contributes to higher cellulosic crystallinity in the bamboo culms. As the bamboo matures, the cellulose in the bamboo cell walls gradually develops increasing lignin content, thus its cellulose crystallinity changes from the base to the top of the bamboo as evidenced by the stronger C=C band (1508 cm-1) of lignin aromatic ring in the culms than that of the young bamboo shoots (Toba et al. 2015).

Reduced intensity of a band as well as appearance or disappearance of any peaks in the FTIR spectra indicates the chemical changes in the cellulosic samples after a chemical modification. The absence and/or decreased peak intensity of the characteristic absorbance peaks of lignin (1596, 1508 and 1450 cm-1) and hemicellulose band at 1735 cm-1 in all alkaline treated bamboo samples clearly indicate the successful removal of lignin and hemicellulose from the treated bamboo fibers. The presence of significant bands at 1033 and 1055 cm-1 representing the C-O-C pyranose ring stretching vibration indicates the higher content of cellulose in the mercerized fibers, which agrees with the findings by Mohamed et al. (2015) and Javier-Astete et al. (2021). The peaks between 1240 and 1260 cm-1 were assigned to C-O stretch and O-H in plane of the polysaccharide. Generally, sharper and more intense peaks were observed in the bamboo shoots cellulose (BSC) (Fig. 1) compared with those of the bamboo culms cellulose (BCC), which shows that the crystallinity of the bamboo shoot was higher than bamboo culm after the alkaline treatment.

The band at 1638 cm-1 was attributed to the H-O-H stretching vibration of absorbed water and hydroxyl groups in the fibers (Elmas and Yilgor 2020). More specifically, the hydrophilic cellulose strongly interacts with water on molecular level (Galiwango et al. 2019). The more intense peaks at 3346 cm-1 (-OH) and 2900 cm-1 (-CH2, -CH) indicate the presence of more -OH groups in the treated cellulose fibers than in the raw samples. The broader OH peak in BSC and BCC was likely due to the hydrogen bonding among multiple -OH groups on the cellulose backbones formed from the cleavage of phenolic ether links between cellulose and lignin moieties during the alkaline treatment (Zannen et al. 2016). Although hemicellulose and part of the lignin (matrix components) were removed from the bamboo fibers during the chemical treatment, the original molecular structure of cellulose remained intact.

Fig. 1. FTIR spectra of raw bamboo shoots (RBS), raw bamboo culms (RBC), bamboo culm cellulose (BCC) and bamboo shoot cellulose (BSC)

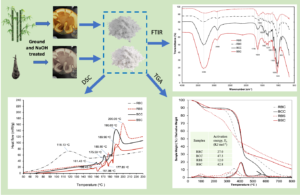

Thermogravimetric Analysis

Figure 2 shows the TGA and derivative thermogravimetric (DTG) output of RBS, RBC, BCC, and BSC. An initial weight loss in all bamboo samples at the low temperature range (75 to 100 °C) corresponds to moisture evaporation from the fibers. The weight loss was observed between 4.5 to 7.7% of the total weight, with BSC showing the lowest weight loss at 4.5%. Both raw and treated samples exhibited 2 to 3 stages of decomposition. Following the evaporation stage, a high rate of weight loss occurred between 150 to 425 °C on account of active pyrolysis of hemicellulose, lignin, and pectin in the samples. The thermal decomposition of biomass components mainly occurs between 180 to 380 °C for hemicellulose, 320 to 400 °C for cellulose, and above 400 °C for lignin (Zhou et al. 2017).

Both raw samples (RBS and RBC) exhibited lower degradation temperatures compared with the treated samples that had undergone partial removal of hemicellulose (Liew et al. 2015). Hemicellulose is a heterogeneous branched polymer of low molecular weight with a degree of polymerization between 80 and 425, which can degrade readily at low temperatures (Wang et al. 2019).

Fig. 2. TGA and DTG curves of RBC, BCC, RBS, and BSC

It is worth noting that RBS showed four stages of peak decompositions at 188, 307, 346, and 497 °C (Fig. 2, DTG curve), representing the decomposition of initial hemicellulose (188 °C), hemicellulose and the cleavage of glycosidic linkages of cellulose (307 °C), followed by cellulose (346 °C) and lignin (497 °C). In contrast, only one peak of decomposition at 409 °C was observed in BSC, which is mainly attributed to decomposition of cellulose (Huang et al. 2020). With the higher content of heat-resistant cellulose obtained by mercerization, the initial decomposition temperature of cellulose in BSC was substantially increased by approximately 60 °C (Table 1). Similar phenomenon was reported by Alothman et al. 2021.

RBC only exhibited two peaks of decomposition at 359 and 561 °C, which can be attributed to the decomposition of cellulose and lignin, respectively. Two peaks of decomposition for cellulose and lignin were reported for BCC at 408 and 560 °C, respectively. Most cellulose I is converted to cellulose II after the NaOH treatment, which is often associated with the higher peak decomposition temperature. Lignin was not completely removed in the mercerization and could be observed in BCC (Fig. 2, shown with an arrow) implying the presence of lignin in the treated bamboo culms, but not in treated bamboo shoots (BSC). Interestingly, BCC and BSC showed similar decomposition extents of cellulose (19 to 19.5%, Fig. 2, DTG graph), implying that cellulose derived from the bamboo culms and shoots are of comparable thermal properties regardless of its growth stages. It is worth noting that the average yield of cellulose obtained from the oven-dried bamboo shoot was 32.5%, comparable to the average yield of cellulose obtained from oven-dried culms (34%). Moreover, cellulose isolation of the young bamboo shoots is relatively simpler compared to the processing of bamboo culms. The bamboo shoots could also be harvested at 2 to 4 weeks, which is 39x shorter harvesting period compared to bamboo culms which typically take 3 years to mature.

Table 1. Comparison of Activation Energies of the Raw Bamboo Shoots (RBS), Raw Bamboo Culms (RBC), Bamboo Culms Cellulose (BCC) and Bamboo Shoots Cellulose (BSC)

a Temperature corresponding to the beginning of decomposition; b Temperature corresponding to maximum rate of mass loss; c Temperature corresponding to the end of decomposition; d Mass at temperature corresponding to the beginning of decomposition; e Mass at temperature corresponding to the maximum rate of mass loss; f Mass at temperature corresponding to the end of decomposition

All untreated raw bamboo fibers revealed low activation energies compared with bamboo cellulose fibers (Table 1). Among those samples, RBS showed the lowest activation energy (12.0 kJ mol-1), followed by RBC (27.0 kJ mol-1). The low activation energy values indicate lower thermal stability of the raw fibers. After alkaline hydrolysis, both BSC and BCC reported higher activation energies between 42 to 47 kJ mol-1, which were 1.5 to 3.5 times higher than those of raw bamboo fibers, indicating higher thermal stability among the treated bamboo cellulose. From these preliminary findings, the comparable thermal properties between BSC and BCC suggested that the young bamboo shoots are a potential alternative of bamboo cellulose, which can be available at the early stage of bamboo growth (2 to 4 weeks).

Differential Scanning Calorimetry

DSC analysis was carried out to further investigate the thermal energy released or absorbed by the bamboo fibers, in exothermic and endothermic reactions. While the exothermic reactions provide insights of the crystallization, oxidation, combustion, decomposition, and chemical reactions of the sample, the endothermic reactions represent the melting, phase transitions, evaporation, dehydration, and pyrolysis (Kabir et al. 2012).

The DSC curves of BCC and BSC fibers show three significant peaks (Fig. 3). Two minor exothermic peaks were observed at the region from 160 to 180 °C, owing to the degradation of hemicellulose in treated samples (Zhang et al. 2015). Two exothermic peaks at 161.9 and 177.8 °C were observed for BSC fibers. Broader exothermic peaks were observed for BCC at the same temperature range. The sharp endothermic peaks observed for the BSC and BCC at 190.0 and 190.5 °C, respectively, support that the alkaline treatment had successfully removed the amorphous polysaccharide, leaving behind crystalline and more heat-resistant cellulose macromolecules (Karthik and Murugan 2013). From the comparison of the DSC curves, those peaks in BCC were broader than those of BSC, which agree with the higher cellulose content in the matured bamboo fibers, thus, the higher thermal stability of BCC compared to the younger fibers from the bamboo shoots (BSC). This finding is also supported by the higher activation energy for BCC than that of BSC (Table 1).

Fig. 3. DSC curves of fibers derived from bamboo culms and shoots before and after NaOH and mechanical treatments

CONCLUSIONS

- Bamboo cellulose was isolated from bamboo culms and shoots of Dendrocalamus asper using a combination of NaOH hydrolysis and ultra-sonication.

- The alkaline hydrolysis successfully removed the non-cellulosic polysaccharides in the bamboo fibers. The alkali-treated bamboo fibers exhibited more intense infrared (IR) peaks of the crystalline cellulose at 1033 cm-1. The intense IR peaks in bamboo shoot cellulose (BSC) imply higher crystallinity than that of bamboo culm cellulose (BCC).

- With the increase of cellulose II content, the initial decomposition temperatures of cellulose in the BSC and BCC were increased by approximately 60 °C, demonstrating higher thermal stability and activation energies for treated bamboo fibers.

- Based on the differential scanning calorimeter (DSC) results, broader peaks seen in BCC implied higher cellulose content compared to the BSC.

- Based on the comparison of the chemical and thermal properties of both types of bamboo cellulose, BSC is deemed highly suitable as an alternate and quick source of bamboo cellulose to substitute BCC in composite manufacturing.

ACKNOWLEDGMENTS

The authors are grateful for the laboratory support of the UiTM Sarawak.

REFERENCES CITED

Alothman, O. Y., Kian, L. K., Saba, N., Jawaid, M., and Khiari, R. (2021). “Cellulose nanocrystal extracted from date palm fiber: Morphological, structural and thermal properties,” Industrial Crops and Products 159, 113075. DOI:10.1016/J.INDCROP.2020.113075.

Banik, N., and Sastry, G. (2018). “An experimental assiduity on the dominance of process parameters on mechanical properties for making a fire retardant bamboo fiber composite with the help of Taguchi experimental design,” Materials Today: Proceedings 5(2), 5701-5708. DOI: 10.1016/j.matpr.2017.12.164

Buson, R. F., Melo, L. F., Oliveira, M. N., Rangel, G. A., and Deus, E. P. (2018). “Physical and mechanical characterization of surface treated bamboo fibers,” Science and Technology of Materials 30(2), 67-73. DOI: 10.1016/J.STMAT.2018.03.002

Chaowana, P. (2013). “Bamboo: An alternative raw material for wood and wood-based composites,” Journal of Materials Science Research 2(2), 90-102. DOI: 10.5539/jmsr.v2n2p90

Cruz‐Riaño, L. J., Quintero‐Giraldo, L. J., García‐Guzmán, J. A., Alcaraz‐Zapata, A., González‐Castrillón, E. S., and Osorio‐Saraz., J. A. (2021). “Synthesis of polymeric composites reinforced with short bamboo fibers supported by experiment design,” Polymer Composites 42(1), 474-483. DOI: 10.1002/pc.25840

Elmas, G. M., and Yilgor, N. (2020). “Chemical and thermal characterizations of Pinus sylvestris and Pinus pinaster,” BioResources 15(2), 3604-3620. DOI: 10.15376/biores.15.2.3604-3620

Galiwango, E., Abdel Rahman, N. S., Al-Marzouqi, A. H., Abu-Omar, M. M., and Khaleel, A. A. (2019). “Isolation and characterization of cellulose and α-cellulose from date palm biomass waste,” Heliyon 5(12), 1-8. DOI: 10.1016/j.heliyon.2019.e02937

Giacon, V. M., Rebelo, V. S., Santos, G. M., Sanches, E. A., Fiorelli, J., Santos Costella, Â. M., Melo, G. M., and Brito, L. M. (2021). “Influence of mercerization on the physical and mechanical properties of polymeric composites reinforced with Ama-zonian fiber,” Fibers and Polymers 22(7), 1-7. DOI: 10.1007/s12221-021-0460-9

Hassan, M. Z., Roslan, S. A., Sapuan, S. M., Rasid, Z. A., Mohd Nor, A. F., Md Daud, R. Dolah, M. Y., and Mohamed Yusoff, M. Z. (2020). “Mercerization optimization of bamboo (Bambusa vulgaris) fiber-reinforced epoxy composite structures using a Box-Behnken design,” Polymers 12(6), 1-19. DOI: 10.3390/POLYM12061367

Huang, H., Liu, J., Liu, H., Evrendilek, F., and Buyukada, M. (2020). “Pyrolysis of water hyacinth biomass parts: Bioenergy, gas emissions, and by-products using TG-FTIR and Py-GC/MS analyses,” Energy Conversion and Management 207(0), 112552. DOI: 10.1016/j.enconman.2020.112552

Javier-Astete, R., Jimenez-Davalos, J., and Zolla, G. (2021). “Determination of hemicellulose, cellulose, holocellulose and lignin content using FTIR in Calycophyllum spruceanum (Benth.) K. Schum. and Guazuma crinita Lam. Plos one 16(10), e0256559. DOI: 10.1590/0104-1428.01717

Jin, Z., Li, J., Wang, Q., Su, W., Duan, X., and Tang, Z. (2021). “Characterization of multifunctional panels from jute fibers for interior wall covering,” Industrial Crops and Products 167, 113530. DOI: 10.1016/j.indcrop.2021.113530

Kabir, M. M., Wang, H., Lau, K.T., and Cardona, F. (2012). “Chemical treatments on plant-based natural fiber reinforced polymer composites: An overview,” Composites Part B: Engineering 43(7), 2883-2892. DOI: 10.1016/J.COMPOSITESB.2012.04.053

Karthik, T., and Murugan, R. (2013). “Characterization and analysis of ligno-cellulosic seed fiber from Pergularia daemia plant for textile applications,” Fibers and Polymers 14(3), 465-472. DOI: 10.1007/s12221-013-0465-0

Liew, F. K., S. Hamdan, M. R. Rahman, M. Rusop, J. C. H. Lai, Hossen, M. F., and Rahman, M. M. (2015). “Synthesis and characterization of cellulose from green bamboo by chemical treatment with mechanical process,” Journal of Chemistry 1-6. DOI: 10.1155/2015/212158

Liew, F. K., Hamdan, S., Rahman, M. R., and Rusop, M. (2017). “Thermomechanical properties of jute/bamboo cellulose composite and its hybrid composites: The effects of treatment and fiber loading,” Advances in Materials Science and Engineering 1-10. DOI: 10.1155/2017/8630749

Liew, F. K., Hamdan, S., Rahman, M. R., Rusop, M., and Khan, A. (2020). “Thermo-mechanical properties of jute/bamboo/polyethylene hybrid composites: The combined effects of silane coupling agent and copolymer,” Polymer Composites 41(11), 4830-4841. DOI: 10.1002/pc.25755

Mohamed, M. A., Salleh, W. N. W., Jaafar, J., Asri, S. E. A. M., and Ismail, A. F. (2015). “Physicochemical properties of “green” nanocrystalline cellulose isolated from recycled newspaper,” RSC Advances 5(38), 29842-29849. DOI: 10.1039/C4RA17020B

Muhammad, A., Rahman, M. R., Hamdan, S., and Sanaullah, K. (2019). “Recent developments in bamboo fiber-based composites: A review,” Polymer Bulletin 76, 2655-2682. DOI: 0.1007/s00289-018-2493-9

Noori, A., Lu, Y., Saffari, P., Liu, J., and Ke, J. (2021). “The effect of mercerization on thermal and mechanical properties of bamboo fibers as a biocomposite material: A review,” Construction and Building Materials 279(5), pages. DOI: 10.1016/j.conbuildmat.2021.122519

Qian, S., and Sheng, K. (2017). “PLA toughened by bamboo cellulose nanowhiskers: Role of silane compatibilization on the PLA bionanocomposite properties,” Composites Science and Technology 148, 59-69. DOI: 10.1016/J.COMPSCITECH.2017.05.020

Rebelo, V., Silva, Y., Ferreira, S., Filho, R. T., and Giacon, V. (2019). “Effects of mercerization in the chemical and morphological properties of amazon piassava,” Polimeros 29(1), 1-6. DOI: 10.1590/0104-1428.01717

Thakur, M., Sharma, A., Ahlawat, V., Bhattacharya, M., and Goswami, S. (2020). “Process optimization for the production of cellulose nanocrystals from rice straw derived α-cellulose,” Materials Science for Energy Technologies 3(3), 328-334. DOI: 10.1016/j.mset.2019.12.005

Toba, K., Nakai, T., Shirai, T., and Yamamoto, H. (2015). “Changes in the cellulose crystallinity of moso bamboo cell walls during the growth process by X-ray diffract-tion techniques,” J. Wood Science 61, 517-524. DOI: 10.1007/s10086-015-1490-y

Wang, K. L., Wang, B., Hu, R., Zhao, X., Li, H., Zhou, G., Song, L. and Wu, A. M. (2019). “Characterization of hemicelluloses in Phyllostachys edulis (moso bamboo) culm during xylogenesis,” Carbohydrate Polymers 221, 127-136. DOI: 10.1016/J.CARBPOL.2019.05.088

Wijaya, C. J., Ismadji, S., Aparamarta, H. W., and Gunawan, S. (2019). “Optimization of cellulose nanocrystals from bamboo shoots using response surface methodology,” Heliyon 5(11), 1-7. DOI: 10.1016/j.heliyon.2019.e02807

Xie, J., Hse, C. Y., Hoop, C.H., Hu, T., Qi, J., and Shupe, T. F. (2016). “Isolation and characterization of cellulose nanofibers from bamboo using microwave liquefaction combined with chemical treatment and ultrasonication,” Carbohydrate Polymers 151, 725-734. DOI: 10.1016/j.carbpol.2016.06.011

Yang, J., Wu, L., Yang, H., and Pan, H. (2021). “Using the major components (cellulose, hemicellulose, and lignin) of Phyllostachys praecox bamboo shoot as dietary fiber,” Frontiers in Bioengineering and Biotechnology 1-8. DOI: 10.3389/fbioe.2021.669136

Zannen, S., Ghali, L., Halimi, M.T., and Hassen, M. (2016). “Effect of combined chemical treatment on physical, mechanical and chemical properties of Posidonia fiber,” Advances in Materials Physics and Chemistry 06(11), 275-290. DOI: 10.4236/ampc.2016.611027

Zhang, X., Wang, F., and Keer, L. M. (2015). “Influence of surface modification on the microstructure and thermo-mechanical properties of bamboo fibers,” Materials 8(10), 6597-6608. DOI: 10.3390/ma8105327

Zhou, X., Li, W., Mabon, R., and Broadbelt, L. J. (2017). “A critical review on hemicellulose pyrolysis,” Energy Technology 5(1), 52-79. DOI: 10.1002 / ente.201600327

Article submitted: March 5, 2022; Peer review completed: May 9, 2022; Revised version received: June 3, 2022; Accepted: June 5, 2022; Published: June 30, 2022.

DOI: 10.15376/biores.17.3.4806-4815