Abstract

This study investigated the possibility of furniture factory waste sawdust (FFWS) utilization in polypropylene (PP) composites and producing furniture support leg prototypes. Test samples were manufactured using a single screw extruder and injection molding machine utilizing 10, 15, 20, 25, 30, and 35% by weight of FFWS and 0% or 3% maleated polypropylene (MAPP). Selected mechanical and physical properties of manufactured samples were determined. The presence of FFWS and MAPP significantly improved mechanical properties compared to neat PP. The higher FFWS amount increased the flexural strength, flexural modulus, tensile modulus, impact resistance, and density. Tensile strength and elongation at break decreased with filler amount, but the addition of MAPP caused a dramatic increase in tensile strength. In addition, flexural strength, flexural modulus, tensile strength, elasticity modulus, and density values of the composites containing MAPP had higher values than the ones without MAPP. However, impact resistance and elongation at break values were slightly decreased with the addition of MAPP. Optimization results showed that formulation mixtures containing 20% filler and 3% MAPP fit best for prototype furniture legs manufacturing.

Download PDF

Full Article

Using Furniture Factory Waste Sawdust in Wood-plastic Composite Production and Prototype Sample Production

İbrahim Kılıç,a Büşra Avcı,b İlkay Atar,b Nesrin Korkmaz,c Güngör Yılmaz,d Fatih Mengeloğlu b

This study investigated the possibility of furniture factory waste sawdust (FFWS) utilization in polypropylene (PP) composites and producing furniture support leg prototypes. Test samples were manufactured using a single screw extruder and injection molding machine utilizing 10, 15, 20, 25, 30, and 35% by weight of FFWS and 0% or 3% maleated polypropylene (MAPP). Selected mechanical and physical properties of manufactured samples were determined. The presence of FFWS and MAPP significantly improved mechanical properties compared to neat PP. The higher FFWS amount increased the flexural strength, flexural modulus, tensile modulus, impact resistance, and density. Tensile strength and elongation at break decreased with filler amount, but the addition of MAPP caused a dramatic increase in tensile strength. In addition, flexural strength, flexural modulus, tensile strength, elasticity modulus, and density values of the composites containing MAPP had higher values than the ones without MAPP. However, impact resistance and elongation at break values were slightly decreased with the addition of MAPP. Optimization results showed that formulation mixtures containing 20% filler and 3% MAPP fit best for prototype furniture legs manufacturing.

DOI: 10.15376/biores.18.4.7212-7229

Keywords: Furniture factory waste sawdust; Polypropylene; Natural fiber-based composites; Mechanical properties

Contact information: a: Department of Material and Energy, Hemp Research Institute, Yozgat Bozok University, Yozgat, Turkey; b: Department of Forest Industry Engineering, Faculty of Forestry, Kahramanmaras Sutcu Imam University, Kahramanmaras, Turkey; c: Department of Basic Sciences and Health, Hemp Research Institute, Yozgat Bozok University, Yozgat, Turkey; d: Department of Field Crops, Faculty of Agriculture, Yozgat Bozok University, Yozgat, Turkey;

* Corresponding author: ibrahim.kilic@bozok.edu.tr

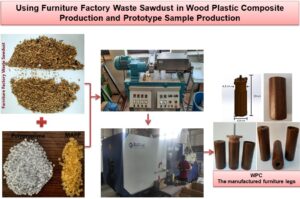

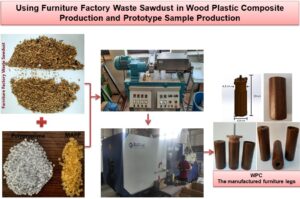

GRAPHICAL ABSTRACT

INTRODUCTION

Wood plastic composites (WPCs) consist of cellulosic fibers from wood in combination with polymers. WPCs can be made of plastic of any kind. However, today WPCs are commonly (if not practically all) based on polyethylene (PE), polypropylene (PP), or polyvinyl chloride (PVC) (Klyosov 2007; Behravesh et al. 2010). The expression “cellulosic fibers” refers to lignocellulosic materials such as flour from various wood species, flour from timber particles, agricultural waste, bleached cellulose, and natural fibers (Klyosov 2007; Mengeloğlu and Çavuş 2020).

In recent years, with the widespread use of wood-plastic composites (WPCs), many lignocellulosic-based products have become raw materials for composite material production (Mantia and Morreale 2011). They can be from primary raw material sources or valorization of lignocellulosic wastes in the agricultural and forest products sector (Bos 2004; Özmen et al. 2014; Mengeloğlu et al. 2015).

Some properties of lignocellulosic materials, such as ease of processing, low density, low cost, and renewability, make them preferable (Karakuş et al. 2011; Mengeloğlu et al. 2015; Wu et al. 2020). In addition, the evaluation of lignocellulosic materials in composite production has increased in recent years in response to the increasing demand for the development of biodegradable, sustainable, and recyclable materials (Karakuş et al. 2011; Shahzad 2011; Youssef et al. 2019). Lignocellulosic-added plastic composites or WPCs are composite materials with different application areas and are called “eco-composite” or “environmental composite” (Mantia and Morreale 2011).

In previous studies, hardwood and softwood flour, non-wood natural fibers like wheat straw, rice straw, hemp fiber, jute fiber, kenaf fiber, bamboo fiber, and industrial lignocellulosic wastes have been used as lignocellulosic fillers in the production of WPCs (Mohanty et al. 2001; Bos 2004; Fotouh et al. 2014; Mengeloğlu et al. 2015; Berzin et al. 2020). The waste generated in the furniture industry can be another lignocellulosic raw material for WPC manufacturing instead of being disposed of or incinerated. Recycling or reusing the waste material instead of disposing is a more sustainable method. The furniture industry in Turkey is a developing sector day by day, with increasing production capacities and resulting in lignocellulosic waste. For this reason, the potential of using lignocellulosic waste as raw materials in wood-plastic composites draws attention.

WPC manufacturing utilizes different production methods. The homogenization of component mixtures has a vital role in these methods. Mixers can be heated or unheated. In a heat-using mixer, the mixture begins to soften or melt at a fixed temperature, depending on the type of polymer used. Subsequently, the mixture is poured out, cooled, dried, and pelletized. Unheated mixers provide only cold mixing of thermoplastic and lignocellulosic material. The softening and melt mixing is achieved during the following stage, namely extrusion. This mixture was pelletized and dried. For final product manufacturing, extrusion, press, or injection molding methods are employed for product or sample production (Bledzki and Faruk 2005; Mengeloğlu 2006; Mengeloğlu and Karakuş 2012).

WPC products, including profiles, coatings, decking, roof tiles, and window sills, are commonly produced by extrusion processes (Wechsler and Hızıroğlu 2007). Even though the manufacturers have preferred the injection molding method for many plastic-based products manufacturing, their application in WPCs manufacturing is limited. Because the fluency of the WPC granule matrix decreases during processing in a molten state, it is also challenging to produce a product with complex-shaped elements by injection method, making it difficult to evaluate the product shape and diversity offered by this injection method in WPC production. The limited number of product development studies, the fact that the usage areas of the products that can be produced are not determined, or the suitability of the products produced by this method is not known enough delaying the progress in this field.

In order to reveal this potential, it is necessary to increase the studies and productions in this field. It is clear that there is still great potential for injection-molded WPC product manufacturing. It is thought that this study will contribute to the potential of product development, attracting plastic product manufacturers and encouraging product manufacturing in the industry by making progress in the issues mentioned above.

In WPC production, the ratio of lignocellulosic filler should be kept low in the injection method compared to the extrusion method. In the literature studies reviewed, it has been observed that the proportions of lignocellulosic fillers generally vary between 10% and 40% by weight (Yan et al. 2013; Sullins et al. 2017; Langhorst et al. 2018; Maziero et al. 2019; Çavuş 2020; Çavuş and Mengeloğlu 2020; Mengeloğlu and Çavuş 2020; Manaia and Manaia 2021; Vallejos et al. 2023). Increasing the filler ratios decreases the melt flow index of the plastic. Therefore, highly filled plastics make it difficult to fill the molds and negatively affect the smooth surface formation (Kaymakçı et al. 2012). Considering these disadvantages, since the project is aimed at producing an exemplary prototype product in a factory process, the lignocellulosic filler ratio is limited to a maximum of 35%.

Poor bonding in the interaction of filler and polymer matrix is one of the main disadvantages encountered due to poor wetting between hydrophobic organic polymer matrix and hydrophilic fibers. For this, coupling agents are used to improve compatibility and adhesion between the polar lignocellulosic fiber and the non-polar polymer matrix. Thus, the performance properties of the composites are increased by providing better interfacial adhesion. Maleic anhydride-grafted polypropylene (MAPP) is one of the commonly used compatibilizers as a coupling agent (Çetin et al. 2000; Shahzad 2011; Langhorst et al. 2018; Çavuş and Mengeloğlu 2020; Çavuş 2020; Han et al. 2021). It has been observed that the mixing ratios of coupling agents are used in the range of 2 to 10%, and optimum properties are often achieved in the range of 3 to 5% (Çetin et al. 2000; Panthapulakkal and Sain 2007; Langhorst et al. 2018; Maziero et al. 2019; Díaz et al. 2020; Başboğa et al. 2022; Vallejos et al. 2023). Considering these findings, in the present study, MAPP was used at 0% and 3% by weight.

In this study, the potential of using lignocellulosic waste, which is approximately 400 thousand tons per year in a furniture factory, in the production of PP-based composites was evaluated. This furniture factory uses particleboard in approximately 90% of its productions. Although many lignocellulosic raw materials can be used in WPC production, the convertible lignocellulosic wastes generated in a furniture factory into a product manufactured in the same factory manufacturing process make this study original. At the same time, the fact that the production results and lignocellulosic wastes can be evaluated also has attracted the attention of the furniture factory, making this study original. In addition, the evaluation of lignocellulosic wastes and the production of more environmentally friendly products have also attracted attention. WPC production was carried out in two stages. In the first stage, the selected mechanical and physical properties of the test samples produced in different combinations in the laboratory were determined. In the second stage, the furniture support legs were produced in the furniture factory based on the optimization results.

EXPERIMENTAL

Materials

Polypropylene (PP) (MH 418; density 0.905 g/cm3, MFI 4.7 g/10 min, melting point 163 °C, Petkim Petrochemical Co., Turkey) and furniture factory waste sawdust (FFWS) were used as a thermoplastic matrix and a lignocellulosic filler, respectively. The Modalife furniture factory in Kırıkkale, Turkey, donated the lignocellulosic wastes FFWS, consisting of approximately 90% particleboard (raw and decor paper-covered), 4% poplar plywood, 3% medium-density fiberboard (MDF), and others. The preferred coupling agent was maleic anhydride grafted polypropylene (MAPP) (Licocene® PP MA 7452 by Clariant, Berlin, Germany, melting point 155 to 161 °C, density 0.92 to 0.94 g/cm3).

Methods

The FFWS was turned into flour using a Wiley Mill (Altundal, Kahramanmaraş, Turkey). Flour passed through a 60-mesh screen and remained on an 80-mesh screen for manufacturing. The FFWS flours were oven-dried to reduce the moisture to under 1% for 24 h at 103 ± 2 °C before manufacturing.

Table 1 presents the experimental design for composite manufacturing. Depending on the formulation, selected PP, FPWS flour, and MAPP were dry-mixed in a high-speed mixer to produce a homogeneous blend and compounded in a single screw extruder at 50 rpm speed, at temperatures from feed zone to die of 180, 185, 190, 195, and 200 °C. The extrudates were cooled in a water pool (23 °C ± 2 °C) and then granulated into pellets and dried below 1% in an oven at 103 ± 2 °C for 24 h. It is vital to reduce pellets’ moisture content before injection molding (HAIDAHDX–88, Ningbo, China). Selected injection molding conditions were as follows: injection temperature 170, 180, 185, 190, and 190 °C (from feed zone to die), injection speed 85 mm/s, injection pressure 9 to 10 MPa, and cooling time 40 s. The optimum formulation was selected according to laboratory-scale experiments and utilized for furniture support legs production in a Haitian Brand, MA 4700 injection molding machine in Modalife (Kırıkkale, Turkey) furniture factory. The injection molding conditions for furniture support legs were as follows: injection temperature of 170, 180, 185, 190, and 190 °C (from feed zone to die), injection speed of 85 mm/s, injection pressure of 9 to 10 MPa, and cooling time of 40 s.

Table 1. Experimental Design for Composites Manufacturing

Before testing, sample conditioning was performed in a climate cabinet at 23 ± 2°C and 65± 2% relative humidity. Five specimens for each group were tested. The density of the sample was determined by a water displacement technique according to the ASTM D792 (2007) standard. Tensile properties, according to ASTM D638 (2001), and flexural properties, according to ASTM D790 (2003), were determined using Zwick 10 KN (Zwick/Roell, Ulm, Germany) instrument. In addition, notched-impact strength (IS) was determined according to ASTM D256 (2000) using a Zwick HIT5, 5P instrument. The notches on samples were added using a Polytest notching cutter by RayRan™ (London, UK). The dimensions (length x width x thickness) of the test specimens for density, flexural properties, tensile properties, and impact strength were 20 mm x 20 mm x 4mm, 165 mm x 13 mm x 4mm, 165 mm x 13 mm (narrow section) x 4 mm (Dog Bone shape), 65 mm x 13 mm x 4 mm, respectively. Design-Expert®, version 13 software (Stat-Ease, Inc., Minneapolis, USA), was used for statistical analysis.

RESULTS AND DISCUSSION

The effect of filler proportional amounts and MAPP use on PP composites density and selected mechanical properties were studied in test samples produced in the laboratory.

Table 2. Properties of Test Specimens

Five specimens for each group were tested, *: Average values, **: standard deviation

The optimal result gathered from these tests was utilized in the prototype furniture legs manufacturing. The properties of density, tensile strength (TS), tensile modulus (TM), elongation at break (EatB), flexural strength (FS), flexural modulus (FM), and impact strength (IS) were evaluated. The values of the test samples are presented in Table 2.

The density values obtained from the test specimens ranged from 0.890 to 0.975 g/cm3. P0-0 had the lowest mean density values, while P35-3 had the highest mean density values. The interaction graph of the density is presented in Fig. 1. The red line shows the groups without MAPP, and the green line shows the groups with 3% MAPP. Statistical analysis showed that filler loading level (P < 0.0001) and MAPP (P = 0.0007) had a significant effect on density. Overall, samples with low amounts of lignocellulosic filler had lower average density values, while samples with high amounts of lignocellulosic filler had higher average density values. It is believed that the incorporation of lignocellulosic matrix (approximately 1.5 g/cm3), which has a higher cell wall density compared to the polymer matrix, increases the density values of the final compounds (Matuana et al. 1998; Mengeloğlu and Karakuş 2008; Islam et al. 2013; Mengeloğlu et al. 2015; Mengeloğlu and Çavuş 2019; Çavuş and Mengeloğlu 2020; Çavuş 2020). The high-pressure processes such as injection molding encountered during plastic processing can cause the lignocellulosic hollow fibers to collapse or fill them with low molecular weight plastics. Consequently, adding lignocellulosic fibers to commercial plastics such as polypropylene increases the density values (Clemons and Caufield 2005).

Fig. 1. Interaction graph of FFWS and MAPP loading on composites density values

The TS, TM, and EatB interaction graphs are presented in Fig. 2, Fig. 3, and Fig 4, respectively. The red line shows the groups without MAPP, and the green line shows those with 3% MAPP. The TS of test specimens ranged from 22.48 to 31.30 MPa. The lowest and the highest TS values were observed in P35-0 and P35-3 coded specimens, respectively. Statistical analysis showed that filler loading level and MAPP significantly affected TS (P < 0.0001). The TS values decreased with the increase of the FFWS filler addition into the polymer matrix, but an increase was observed in the TS values with the addition of MAPP. Similar results have been reported in previous studies (Yang et al. 2004; Yang et al. 2007; Bledzki and Faruk 2013; Maziero et al. 2019; Çavuş 2020; Çavuş and Mengeloğlu 2020; Başboğa et al. 2022).

It is thought that there is a weak bond between the PP matrix and FFWS fibers, and the bond in the polymer matrix decreases with the increase of the FFWS incorporation level, thus reducing the TS values. It has been reported that the weak interfacial bond between the polymer matrix and the filler causes a decrease in strength and an increase in brittleness as tensile stress is applied (Yang et al. 2004; Maziero et al. 2019). The compatibilizers were used to improve the adhesion between the polar lignocellulosic fiber and the non-polar polymer matrix, providing better interfacial adhesion (Çetin et al. 2000; Kim et al. 2007; Klyosov 2007; Yuan et al. 2008; Narayana and Rao 2021; Han et al. 2021; Wu et al. 2021; Çavuş 2020). Efficient stress transfer is known to occur when MAPP is attached to the hydroxyl groups of a lignocellulosic fiber and the MAPP contains a sufficiently long chain length to mix with the PP matrix (Langhorst et al. 2018; Maziero et al. 2019). As a result, the addition of MAPP significantly increased the TS values of the composites.

Fig. 2. Interaction graph of FFWS and MAPP loading on composites tensile strength

The TM values of the test samples ranged from 650 to 1150 MPa. The lowest and highest TM values were observed in P0-3 and P35-3 coded samples, respectively. Statistical analysis showed that both FFWS loading level and MAPP significantly affected TM values (P < 0.0001). The TM values increased with increasing FFWS addition to the polymer matrix. It is common knowledge that adding lignocellulosic fillers to thermoplastics often increases modulus values. Similar results were reported in other studies (Zaini et al. 1996; Stark and Berger 1997; Yuan et al. 2008; Çavdar et al. 2011; Çavuş ve Mengeloğlu 2020; Başboğa et al. 2022). TM values increased independently of MAPP since lignocellulosic fibers gave a higher modulus than the polymer matrix. When the polymer matrix is mixed with lignocellulosic fillers, it is expected that the TM will have a value between polymer and fillers (Mengeloğlu and Karakuş 2012; Çavuş and Mengeloğlu 2020). In addition, the addition of MAPP increased the TM due to the increased bond between the polymer matrix and the filler.

Fig. 3. Interaction graph of FFWS and MAPP loading on composites tensile modulus

For the elongation at break (EatB) values, the testing machine measured elongation up to 400%. Statistical analysis was not conducted because samples without FFWS filler added (P0-0, P0-3) were not broken within this elongation limit. These groups were not shown in the interaction graph of elongation at break. Samples had EatB values in the range of 3.85 to 10.07%. Statistical analysis showed that the FFWS loading level and MAPP significantly affected EatB (P < 0.0001). Regardless of having MAPP, the EatB values decreased significantly with increasing FFWS addition. This is a common observation in almost all thermoplastic composites with lignocellulosic fillers (Çavuş and Mengeloğlu 2020; Başboğa et al. 2022). With an increase of the lignocellulosic fillers ratio in WPCs, the brittleness of the composite increases. Thus, composites lose their elasticity and turn into a more rigid structures. As a result, the elongation at break (EatB) values decrease (Zaini et al. 1996; Tanasa et al. 2014). MAPP-added groups resulted in lower elongation values than without MAPP groups. The decrease in elongation at break values in composites depends on the hardness and brittleness of the material. A higher modulus is expected to yield lower elongation at break values. As a result, the higher modulus of the MAPP groups was consistent with the lower elongation at break values.

Fig. 4. Interaction graphs of FFWS and MAPP loading on composites elongations at break

The FS and FM are essential mechanical properties that affect WPCs’ performance and application areas. The FS and FM interaction graphs are presented in Figs. 5 and 6, respectively.

Fig. 5. Interaction graph of FFWS and MAPP loading on composites flexural strength

The red line shows the groups without MAPP, and the green line shows those with 3% MAPP. The FS values of the test samples ranged from 40.2 to 57.5 MPa. Statistical analysis showed that FFWS loading level and MAPP significantly affected FS values (P < 0.0001). The FS values slightly increased with adding FFWS filler to the polymer matrix. However, significant increases in FS values were observed with increasing FFWS filler amount in MAPP-added composites. It has been reported that efficient stress transfer from the PP matrix to the lignocellulosic fibers occurs when there is significant binding of MAPP on the hydroxyl groups of the cellulose portions of a lignocellulosic fiber in WPCs (Langhorst et al. 2018). Others have reported similar results (Kim et al. 2007; Mengeloğlu and Karakuş 2008; Bledzki and Faruk 2013; Kada et al. 2016; Çavuş and Mengeloğlu 2020).

The FM values of the produced samples ranged from 1190 to 2770 MPa. Statistical analysis showed that FFWS loading level and MAPP significantly affected FM values (P < 0.0001). The FM values increased with increasing FFWS filler loading to the polymer matrix. The addition of MAPP to formulations resulted in higher FM values. Lignocellulosic fillers have higher flexural modulus values than thermoplastic polymers. As a result, composite materials obtain a higher flexural modulus than neat polymers, which can be explained by the rule of mixtures (Mengeloğlu and Çavuş 2020).

Fig. 6. Interaction graph of FFWS and MAPP loading on composites flexural modulus

The IS values of the composite samples ranged from 2.59 to 3.89 kJ/m2. The lowest and highest IS values were observed in P0-0 and P35-0 coded samples, respectively. The notched IS interaction graph is presented in Fig. 7. The red line shows the groups without MAPP, and the green line shows the groups with 3% MAPP. Statistical analysis showed that both the FFWS filler loading level (P < 0.0001) and MAPP (P = 0.0240) had a significant effect on IS values. Impact strength is a measure of the ability of the material to resist breakage under stress applied at high speed and is directly related to the material’s toughness (Panthapulakkal and Sain 2007). The IS values increased with FFWS filler loading to the polymer matrix. It has been reported that this may be attributed to the ability of lignocellulosic fillers to absorb and dissipate energy from the thermoplastic matrix (Burgada et al. 2021). Yuan et al. (2008) reported that when lignocellulosic fillers are added to the polymer matrix, more energy is required to break the fillers during breakage. Panthapulakkal and Sain (2007) reported that the fillers play an essential role in the impact resistance of WPCs as they interact with the crack formation and act as stress-transferring. Increases in impact resistance values with the use of lignocellulosic filler have also been reported in other studies (Yuan et al. 2008; Lu and Oza 2013; Burgada et al. 2021; Vallejos et al. 2023). However, lower IS values were obtained in composites with MAPP compared to composites without MAPP. Other studies have also reported that compatibilizers reduce IS values in composites (Mengeloğlu and Karakuş 2008; Langhorst et al. 2018).

Fig. 7. Interaction graph of FFWS and MAPP loading on composites notched impact strength

In this study, a group was selected from the groups whose tests were carried out, and support legs that can be used in furniture products such as sofas, bed bases, etc., were produced. The desirability function was used for group selection. The desirability function is one of the approaches used for optimization. This approach can be preferred for process conditions and targeted product properties (Zolfaghari et al. 2013). Furniture support legs were manufactured by injection molding in the furniture factory process. The furniture factory manufactures this product from 100% plastic, and the mold design was designed according to neat plastics. As a result of this information, the optimal filler and MAPP ratio were preferred in group selection. For this purpose, the results obtained from the test samples were determined according to the criteria in Table 3.

Table 3. Expected Objectives of the Criteria for Optimization

The filler material and MAPP ratio of the group selected according to desirability among the groups and the test results are shown in Fig. 8. The red and blue colored signs in Fig. 8 show the location of the characteristics of the selected group among the groups. According to the desirability results, the group coded P20-3 (20% FFWS filler and 3% MAPP) was used in the production of furniture support legs. The images of the furniture support legs produced are shown in Fig. 9.

Fig. 8. Desirability values among composite samples for furniture support leg production

Fig. 9. The manufactured furniture support legs

The potential to utilize lignocellulosic waste generated in a furniture factory in the same process has attracted considerable attention. This is especially an issue for furniture factories that produce at high capacities may experience significant problems in the disposal of lignocellulosic waste or their removal from the factory. Considering the evaluation of waste and more environmentally friendly approaches, it is essential to evaluate the lignocellulosic waste generated in the furniture factory in producing WPCs. The production of such composites by injection molding and determining their use in furniture will contribute to the furniture industry’s raw material and product diversity.

CONCLUSIONS

This study produced wood-plastic composites (WPCs), in which either 0, 5, 10, 15, 20, 25, 30, or 35% of furniture factory waste sawdust (FFWS) was loaded as filler to the polypropylene matrix, respectively. The composites were produced with 0% and 3% maleic anhydride polypropylene (MAPP) coupling agents. Desirability was determined through the mechanical and physical values obtained from the composite samples, and it was produced as a support leg used in group (P20-3) furniture products containing 20% FFWS and 3% MAPP. Furniture factory waste sawdust (FFWS)-filled composites and manufacturing of prototype furniture legs were successfully produced, and the following conclusions can be drawn:

1. The WPCs produced with waste sawdust resulting from production in furniture factories provided excellent properties comparable to those produced with neat PP.

2. The MAPP utilization significantly improved the properties of WPCs.

3. Flexural strength, tensile modulus, flexural modulus, impact resistance, and density values of FFWS-filled composite samples produced without MAPP were higher than samples produced with neat PP. Additionally, the tensile strength values of the composites produced with MAPP were higher than those produced with neat PP. Elongation at break (EatB) values decreased with FFWS loading, independent of MAPP.

4. Furniture support legs were successfully manufactured from mixtures of 20% FFWS, 3% MAPP, and 77% PP in fabrication scale injection molding.

ACKNOWLEDGMENTS

This study was supported by The Scientific and Technological Research Council of Türkiye (Project Number 122O317).

We thank “Modalife Plastic Furniture Construction Industry and Trade Limited Company” for using the injection machine and mold to manufacture prototype products and providing furniture factory waste sawdust.

REFERENCES CITED

ASTM D256 (2000). “Standard test methods for 814 determining the Izod Pendulum impact resistance of plastics,” ASTM International, West Conshohocken, PA, USA.

ASTM D638 (2001). “Standard test methods for tensile properties of plastics,” ASTM International, West Conshohocken, PA, USA.

ASTM D790 (2003). “Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials,” ASTM International, West Conshohocken, PA, USA.

ASTM D792 (2007). “Standard test methods for density and specific gravity (relative density) of plastics by displacement,” ASTM International, West Conshohocken, PA, USA.

Başboğa, H. İ., Kılıç, İ., Atar, İ., and Mengeloğlu, F. (2022). “The usage of wood of dahoma (Piptadeniastrum africanum), a tropic tree, in the production of wood plastic composite,” Turkish Journal of Forestry Research 9(Special Issue), 271-280. DOI: 10.17568/ogmoad.1091247

Behravesh, A. H., Shakouri, E., Zolfaghari, A., and Golzar, M. (2010). “Theoretical and experimental study on die pressure prediction in extrusion of wood-plastic composite,” Journal of Composite Materials 44(11), 1293-1304. DOI: 10.1177/0021998309352703

Berzin, F., Lemkhanter, L., Marcuello, C., Chabbert, B., Béghin, V. A., Molinari, M., Castellani, R., and Vergnes, B. (2020). “Influence of the polarity of the matrix on the breakage mechanisms of lignocellulosic fibers during twin-screw extrusion,” Polymer Composite 41, 1106-1117. DOI: 10.1002/pc.25442

Bos, H. L. (2004). “The potential of flax fibres as reinforcement for composite materials,” Technische Universiteit Eindhoven, DOI: 10.6100/IR575360.

Burgada, F., Fages, E., Carrillo, L. Q., Lascano, D., Martinez, J. I., Arrieta, M. P., and Fenollar, O. (2021). “Upgrading recycled polypropylene from textile wastes in wood plastic composites with short hemp fiber,” Polymers 13, article 1248. DOI: 10.3390/polym13081248

Bledzki, A., and Faruk, O. (2003). “Wood fibre reinforced polypropylene composites: Effect of fibre geometry and coupling agent on physico-mechanical properties,” Applied Composite Materials 10, 365-379. DOI: 10.1023/A:1025741100628

Clemons, C. M., and Caufield, D. F. (2005). “Wood flour,” in: Functional Fillers for Plastics, Wiley-VCH, Weinheim, ISBN 3-527-31054-1, pp. 249-270.

Çavdar, A. D., Kalaycıoğlu, H., and Mengeloğlu, F. (2011). “Tea mill waste fibers filled thermoplastic composites: The effects of plastic type and fiber loading,” Journal of Reinforced Plastics and Composites 30(10) 833-844. DOI: 10.1177/0731684411408752

Çavuş, V. (2020). “Selected properties of mahogany wood flour filled polypropylene composites: The effect of maleic anhydride-grafted polypropylene (MAPP),” BioResources 15(2), 2227-2236. DOI: 10.15376/biores.15.2.2227-2236

Çavuş, V., and Mengeloğlu, F. (2020). “Effect of wood particle size on selected properties of neat and recycled wood polypropylene composites,” BioResources 15(2), 3427-3442. DOI: 10.15376/biores.15.2.3427-3442

Çetin, N. S., Alma, M. H., and Baştürk, M. A. (2000). “Chemical agents and methods providing compatibility between ligno-cellulosic fibers and synthetic polymer to obtain new composites,” KSÜ Journal of Science and Engineering 3(2), pp.58-68.

Díaz, D. H., Ribera, R. V., Julián, F., Tarrés, Q., Espinach, F. X., and Aguilar, M. D., (2020). “Topography of the interfacial shear strength and the mean intrinsic tensile strength of hemp fibers as a reinforcement of polypropylene,” Materials 13(4), article 1012. DOI: 10.3390/ma13041012

Fotouh, A., Wolodko, J. D., and Lipsett, M. G. (2014). “Fatigue of natural fiber thermoplastic composites,” Composites Part B: Engineering 62, 175-182. DOI: 10.1016/j.compositesb.2014.02.023

Han, H. C., Gong, X. L., Zhou, M., Li, C., and Yang, H. B. (2021). “A study about silane modification and interfacial ultraviolet aging of hemp fiber reinforced polypropylene composites,” Polymer Composites 42, 2544-2555. DOI: 10.1002/pc.26000

Islam, M. R., Mohammad, D. H. B., and Gupta, A. (2013). “Characterization of laccase-treated kenaf fibre reinforced recycled polypropylene composites,” BioResources 8(3), 3753-3770. DOI: 10.15376/biores.8.3.3753-3770

Kada, D., Migneault, S., Tabak, G., and Koubaa, A. (2016). “Physical and mechanical properties of polypropylene wood-carbon fiber hybrid composites,” BioResources 11(1), 1393-1406. DOI: 10.15376/biores.11.1.1393-1406

Karakuş, K., Şeker, B., Kılıç, İ., Ciobanu, R. C., and Mengeloğlu, F. (2011). “The utilize of lignocellulosic based wastes in the manucfacture of thermoplastic composite,” in: National Mediterranean Forest and Environment Symposium, Kahramanmaraş, Turkey, pp. 645-650.

Kaymakçı, A., Ayrılmış, N., and Akbulut, T. (2012). “Determination of mechanical behaviour of wood polymer composites manufactured using waste aluminium polyethylene (Tetra Pak) and brass handle,” Journal of History Culture and Art Research 1(4). DOI: 10.7596/taksad.v1i4

Kim, H.-S., Le, B.-H., Choi, S.-W., Kim, S., and Kim, H.-J. (2007). “The effect of types of maleic anhydride-grafted polypropylene (MAPP) on the interfacial adhesion properties of bio-flour-filled polypropylene composites,” Composites Part A: Applied Science and Manufacturing 38, 1473-1482. DOI: 10.1016/j.compositesa.2007.01.004

Klyosov, A. A. (2007). Wood-plastic Composites, John Wiley & Sons, Inc., Hoboken, NJ, USA.

Langhorst, A. E., Burkholder, J., Long, J., Thomas, R., Kiziltas, A., and Mielewski, D. (2018). “Blue-agave fiber-reinforced polypropylene composites for automotive applications,” BioResources 13(1), 820-835. DOI: 10.15376/biores.13.1.820-835

Lu, N., and Oza, S. (2013). “A comparative study of the mechanical properties of hemp fiber with virgin and recycled high density polyethylene matrix,” Composites Part B: Engineering 45, 1651-1656. DOI: 10.1016/j.compositesb.2012.09.076

Manaia, J. P., and Manaia, A. (2021). “Interface modification, water absorption behaviour and mechanical properties of injection moulded short hemp fiber‐reinforced thermoplastic composites,” Polymers 13, article 1638. DOI:10.3390/polym13101638

Mantia, F. P. L., and Morreale, M. (2011). “Green composites: A brief review,” Composites Part A: Applied Science and Manufacturing 42, 579-588. DOI: 10.1016/j.compositesa.2011.01.017

Matuana, L. M., Park, C. P., and Balatinecz, J. J. (1998). “Cell morphology and property relationships of microcellular foamed PVC/wood-fiber composites,” Polymer Engineering Science 38(1), 1862-1872. DOI: 10.1002/pen.10356

Maziero, R., Soares, K., Filho, A. I., Franco, A. R., and Rubio, J. C. C. (2019). “Maleated polypropylene as coupling agent for polypropylene composites reinforced with Eucalyptus and Pinus particles,” BioResources 14(2), 4774-4791. DOI: 10.15376/biores.14.2.4774-4791

Mengeloglu, F. (2006). “Wood/thermoplastic composites,” in: Proceeding of I. Polymer Composite Symposium and Exhibition, Chamber of Chemical Engineers, İzmir, Turkey, pp. 471- 480.

Mengeloglu, F., and Karakuş, K. (2008). “Thermal degradation, mechanical properties and morphology of wheat straw flour filled recycled thermoplastic composites,” Sensors 8, 500-519.

Mengeloğlu, F., and Karakus, K. (2008). “Some properties of eucalyptus wood flour filled recycled high density polyethylene polymer-composites,” Turkish Journal of Agriculture & Forestry 32, 537-546.

Mengeloglu, F., and Karakuş, K. (2012). “Mechanical properties of injection-molded foamed wheat straw filled HDPE biocomposites: The effects of filler loading and coupling agent contents,” BioResources 7(3), 3293-3305. DOI: 10.15376/biores.7.3.3293-3305

Mengeloğlu, F., Başboğa, H. İ., and Aslan, T. (2015). “Selected properties of furniture plant wasted filled thermoplastic composites,” PROLIGNO 11(4), 199-206.

Mengeloğlu, F., and Çavuş, V. (2020). “Preparation of thermoplastic polyurethane-based biocomposites through injection molding: Effect of the filler type and content,” BioResources 15(3), 5749-5763. DOI: 10.15376/biores.15.2.2227-2236

Mohanty, A. K., Misra, M., and Drzal, L. T. (2001). “Surface modifications of natural fibers and performance of the resulting biocomposites: An overview,” Composite Interfaces 8(5), 313-343. DOI: 10.1163/156855401753255422

Narayana, V. L., and Rao, L. B. (2021). “A brief review on the effect of alkali treatment on mechanical properties of various natural life reinforced polymer composites,” Materials Today: Proceedings 44(Part 1), 1988-1994. DOI: 10.1016/j.matpr.2020.12.117

Özmen, N., Çetin, N. S., Narlıoğlu, N., Çavuş, V., and Altuntaş, E. (2014). “Utilisation of MDF waste for wood plastic composites production,” University of Süleyman Demirel Faculty of Forestry Journal 15, 65-71. DOI: 10.18182/tjf.64025

Panthapulakkal, S., and Sain, M. (2007). “Injection-molded short hemp fiber/glass fiber reinforced polypropylene hybrid composites-mechanical, water absorption and thermal properties,” Journal of Applied Polymer Science 103, 2432-2441. DOI: 10.1002/app.25486

Shahzad, A. (2011). “Hemp fiber and its composites,” Journal of Composite Materials 46(8) 973-986. DOI: 10.1177/0021998311413623

Stark, N., and Berger, M. J. (1997). “Effect of species and particle size on properties of wood-flour-filled polypropylene composites,” in: Symposium of Functional Fillers for Thermoplastics and Thermosets, San Diego, CA, USA, pp. 1-20.

Sullins, T., Pillay, S., Komus, A., and Ning, H. (2017). “Hemp fiber reinforced polypropylene composites: The effects of material treatments,” Composites Part B 114, 15-22. DOI: 10.1016/j.compositesb.2017.02.001

Vallejos, M. E., Vilaseca, F., Méndez, J. A., Espinach, F. X., Aguado, R. J., Aguilar, M. D., and Mutjé, P. (2023). “Response of polypropylene composites reinforced with natural fibers: Impact strength and water-uptake behaviors,” Polymers 15, 900. DOI: 10.3390/polym15040900

Wu, H., Xu, D., Zhou, Y., Gao, C., Guo, J., He, W., He, Y., and Qin, S. (2020). “Tung oil anhydride modified hemp fiber/polypropylene composites: The improved toughness, thermal stability and rheological property,” Fibers and Polymers 21(9), 2084-2091. DOI: 10.1007/s12221-020-1157-1

Wu, H., Xu, D., Zhou, Y., Guo, J., He, W., He, Y., Yi, Y., and Qin, S. (2021). “The improved mechanical and thermal properties of hemp lifs reinforced polypropylene composites with dodecyl bromide modification,” Fibers and Polymers 22, 2869-2877. DOI: 10.1007/s12221-021-0127-6

Youssef, A. M., Hasanin, M. S., El-Aziz, M. A., and Darwesh, O. M. (2019). “Green, economic, and partially biodegradable wood plastic composites via enzymatic surface modification of lignocellulosic fibers,” Heliyon 5(3), 2-19. DOI: 10.1016/j.heliyon.2019.e01332

Yan, Z., Zhang, J., Zhang, H., and Wang, H. (2013). “Improvement of mechanical properties of noil hemp fiber reinforced polypropylene composites by resin modification and fiber treatment,” Advances in Materials Science and Engineering article ID 941617, 7 pages. DOI: 10.1155/2013/941617

Yang, H.-S., Kim, H.-J., Son, J., Park, H. J., Lee, B. J., and Hwang, T. S. (2004). “Rice-husk flour filled polypropylene composites; mechanical and morphological study,” Composite Structures 63, 305-312. DOI: 10.1016/S0263-8223(03)00179-X

Yang, H. S., Kim, H. J., Park, H. J., Lee, B. J., and Hwang, T. S. (2007). “Effect of compatibilizing agents on rice-husk flour reinforced polypropylene composites,” Composite Structures 77, 45-55. DOI: 10.1016/j.compstruct.2005.06.005

Yuan, Q., Wu, D., Gotama, J., and Bateman, S. (2008). “Wood fiber reinforced polyethylene and polypropylene composites with high modulus and impact strength,” Journal of Thermoplastic Composite Materials 21(3), 195-208. DOI: 10.1177/0892705708089472

Zaini, M. J., Fuad, M. Y. A., Ismail, Z., Mansor, M. S., and Mustafah, J. (1996). “The effect of filler content and size on the mechanical properties of polypropylene/oil palm wood flour composites,” Polymer International 40, 51-55. DOI: 10.1002/(SICI)1097-0126(199605)

Zolfaghari, A., Behravesh, A. H., and Adli, A. (2013). “Continuous glass fiber reinforced wood plastic composite in extrusion process: Mechanical properties,” Materials and Design 51, 701-708. DOI: 10.1016/j.matdes.2013.04.082

Wechsler, A., and Hiziroglu, S. (2007). “Some of the properties of wood–plastic composites,” Building and Environment 42(7), 2637-2644. DOI: 10.1016/j.buildenv.2006.06.018

Article submitted: May 17, 2023; Peer review completed: July 28, 2023; Revised version received: August 23, 2023; Accepted: August 24, 2023; Published: August 29, 2023.

DOI: 10.15376/biores.18.4.7212-7229