Abstract

The flow characteristics of dilute aqueous suspensions of cellulose nanocrystals (CNC), nanofibrillated cellulose (NFC), and related products in dilute aqueous suspensions could be of great importance for many emerging applications. This review article considers publications dealing with the rheology of nanocellulose aqueous suspensions in the absence of matrix materials. In other words, the focus is on systems in which the cellulosic particles themselves – dependent on their morphology and the interactive forces between them – largely govern the observed rheological effects. Substantial progress in understanding rheological phenomena is evident in the large volume of recent publications dealing with such issues including the effects of flow history, stratification of solid and fluid layers during testing, entanglement of nanocellulose particles, and the variation of inter-particle forces by changing the pH or salt concentrations, among other factors. Better quantification of particle shape and particle-to-particle interactions may provide advances in future understanding. Despite the very complex morphology of highly fibrillated cellulosic nanomaterials, progress is being made in understanding their rheology, which supports their usage in applications such as coating, thickening, and 3D printing.

Download PDF

Full Article

Rheology of Nanocellulose-rich Aqueous Suspensions: A Review

Martin A. Hubbe,a Pegah Tayeb,a Michael Joyce,a Preeti Tyagi,a Margaret Kehoe,a,b Katarina Dimic-Misic,c and Lokendra Pal a

The flow characteristics of dilute aqueous suspensions of cellulose nanocrystals (CNC), nanofibrillated cellulose (NFC), and related products in dilute aqueous suspensions could be of great importance for many emerging applications. This review article considers publications dealing with the rheology of nanocellulose aqueous suspensions in the absence of matrix materials. In other words, the focus is on systems in which the cellulosic particles themselves – dependent on their morphology and the interactive forces between them – largely govern the observed rheological effects. Substantial progress in understanding rheological phenomena is evident in the large volume of recent publications dealing with such issues including the effects of flow history, stratification of solid and fluid layers during testing, entanglement of nanocellulose particles, and the variation of inter-particle forces by changing the pH or salt concentrations, among other factors. Better quantification of particle shape and particle-to-particle interactions may provide advances in future understanding. Despite the very complex morphology of highly fibrillated cellulosic nanomaterials, progress is being made in understanding their rheology, which supports their usage in applications such as coating, thickening, and 3D printing.

DOI: 10.15376/biores.12.4.Hubbe

Keywords: Nanocellulose hydrogels; Suspension viscosity; Nanofibrillated cellulose; Cellulose nanocrystals; Bacterial cellulose; Colloidal forces

Contact information: a: Department of Forest Biomaterials, North Carolina State University, Raleigh, NC 27695-8005; b: SNP Inc., 1301 South Briggs Ave., Durham NC 27703; c: School of Chemical Technology, Department of Forest Products Technology, Aalto University, 00076 Aalto, Helsinki, Finland;

* Corresponding author: hubbe@ncsu.edu

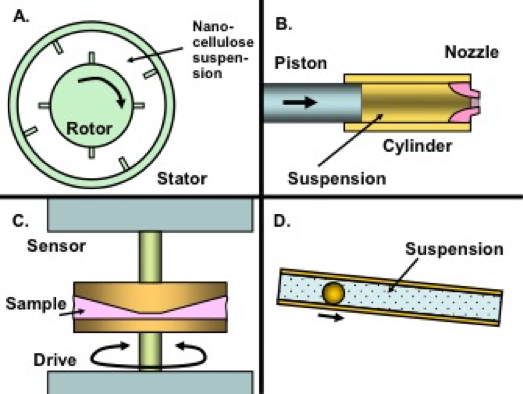

Contents

INTRODUCTION

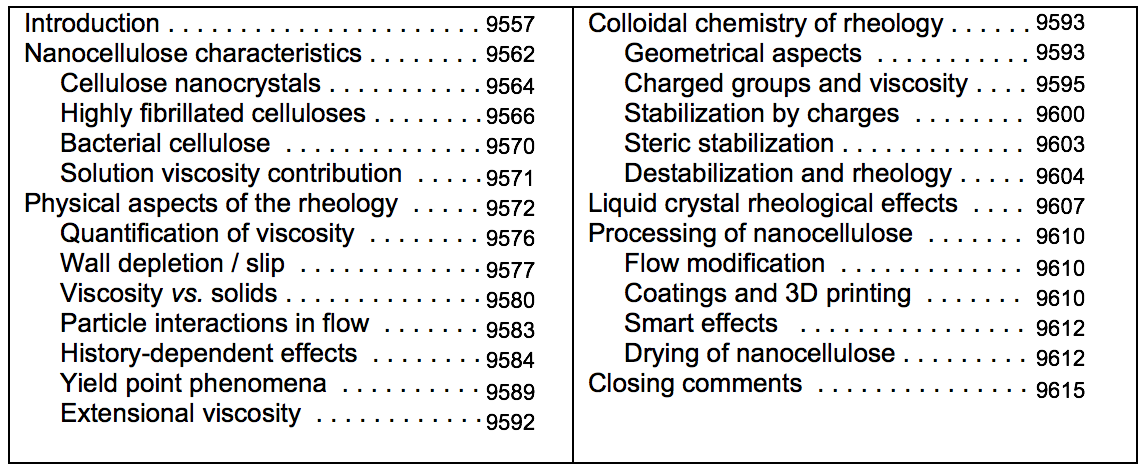

Aqueous suspensions in which the viscous aspects are dominated by extremely small cellulosic materials have attracted increasing interest. A rising pace of related publications provides motivation for the present review article. Emphasis in this article will be placed on systems in which the presence of nanocellulose – which generally includes cellulose nanocrystals (CNC), nanofibrillated cellulose (NFC), and processed bacterial cellulose (BC) – have significant effects on flow phenomena (Nechyporchuk et al. 2016). As shown in Fig. 1, a search of the literature showed an accelerating rate of published articles considering related aspects over the last 25 years.

Fig. 1. Annual citations for publications dealing with the rheology of aqueous suspensions of nanocellulose [Search terms: Rheology; Cellulose*; (Nano* or Microfibril* or Crystal* or Whisker*), and then items wrongly present in the list (about half of them) were removed one by one.]

In the course of searching the literature, it became evident that articles dealing with the effects of nanocellulose on viscoelastic properties of solutions or materials fall into different classes, though the boundaries between such classes are often indistinct. A key point of differentiation is whether or not the viscoelastic effects are dominated by the nanocellulose (as in the present article) or by a polymer matrix, which may be a solution, a molten phase, or solid-like. Aspects of the latter type of system have been considered by others (e.g. Zimmermann et al. 2004; Khan et al. 2010; Moon et al. 2011; Ching et al. 2016). General aspects of the viscosity of suspensions of particles in viscous media have been considered by Mewis and Wagner (2012). Thus, the effects of adding nanocellulose to non-aqueous mixtures, melts, or already highly viscous phases of polymer will only be briefly considered in the present work, mainly for the sake of pointing out some contrasting behaviors.

Factors that can affect the viscoelastic behavior of aqueous suspensions that contain nanocellulose will be the primary focus of this article. In general, rheology can be regarded as a relatively mature field of study, within which the properties of different compositions can be well understood and often predicted with confidence (Malkin 2017). However, the structures and detailed surface chemistry of nanocellulose specimens are often incompletely known or too complex to describe accurately by a model equation. Therefore, many questions remain regarding the application of rheological principles to these materials. Aspects that will be considered in this review include effects of nanocellulose morphology and interactive forces between the surfaces. It will be emphasized that the rheological attributes of suspensions tend to be governed by both equilibrium and non-equilibrium (history-dependent) effects. Thus, attention will be paid to studies in which the morphological and surface-chemical attributes of nanocellulose in suspension were systematically varied.

Consequences of the Rheology of Nanocellulose Suspensions

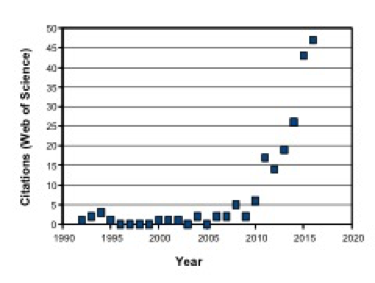

The rheological properties of nanocellulose aqueous suspensions can have important consequences during their preparation, processing, and combination with other materials. Rheological properties of suspensions, including the stability of those properties over time, can be of critical importance for various industrial unit operations, such as pumping, mixing, filtering, storage, application, and metering. As indicated in Fig. 2, for instance, the rheological properties are often profoundly affected by the hydrodynamic shear during flow and pumping, and such rheological changes can be expected to affect whatever manufacturing operations are envisioned. As noted recently by Lindström (2017), the pre-shearing of a nanocellulose suspension, leading to momentarily reduced viscosity, may be important for many potential applications.

Fig. 2. Schematic representation of delivery system from a supply tank of nanocellulose suspension to its point of use, emphasizing some phenomena to be discussed in this article that tend to change the rheological behavior as a function of shearing and time

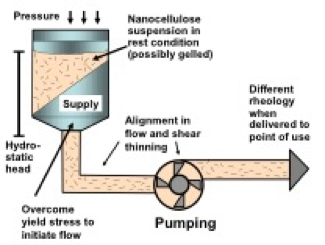

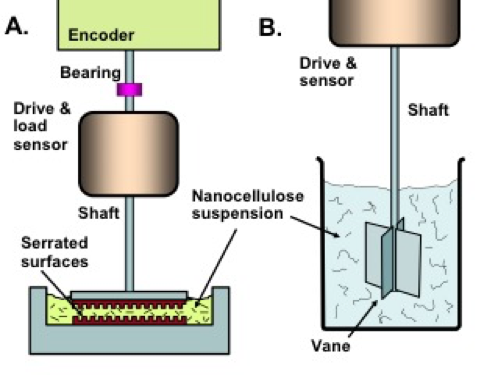

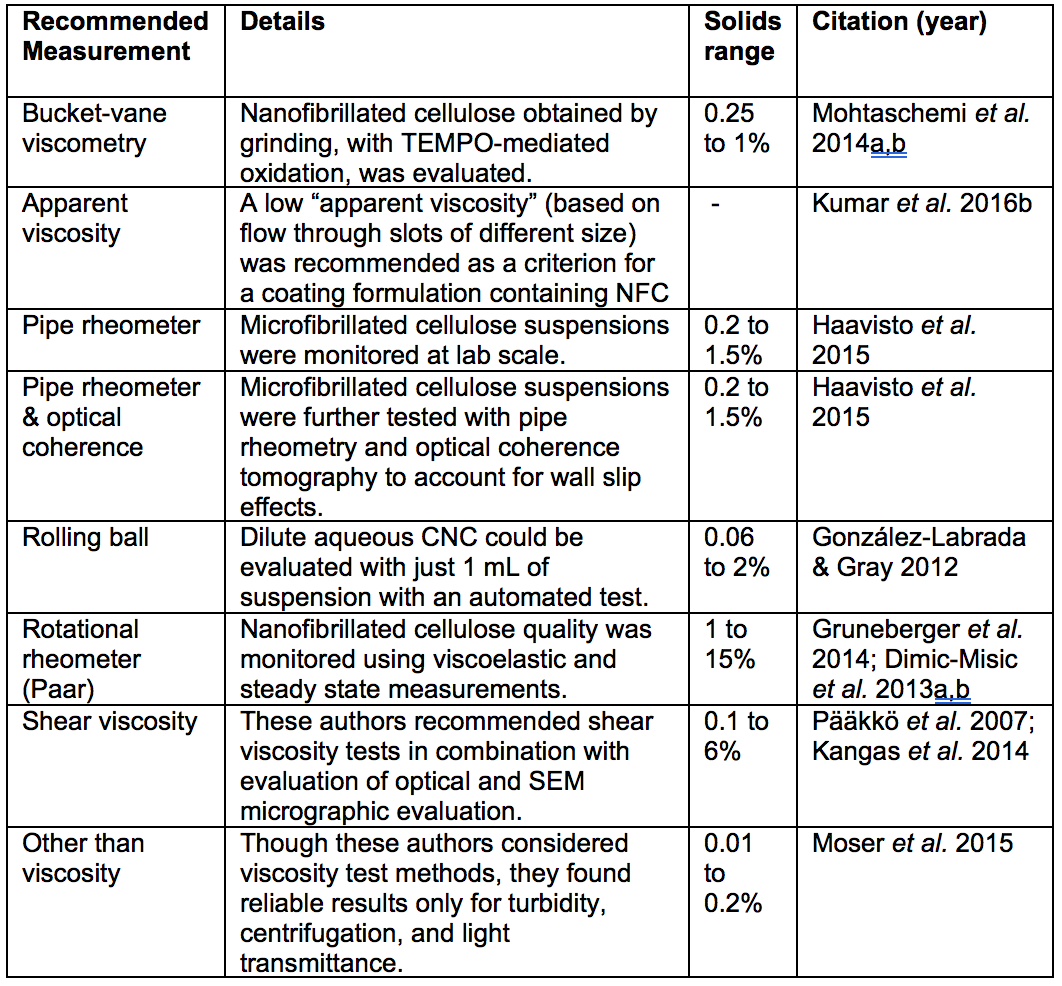

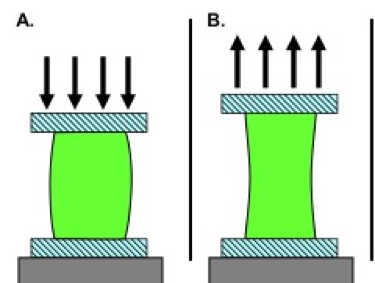

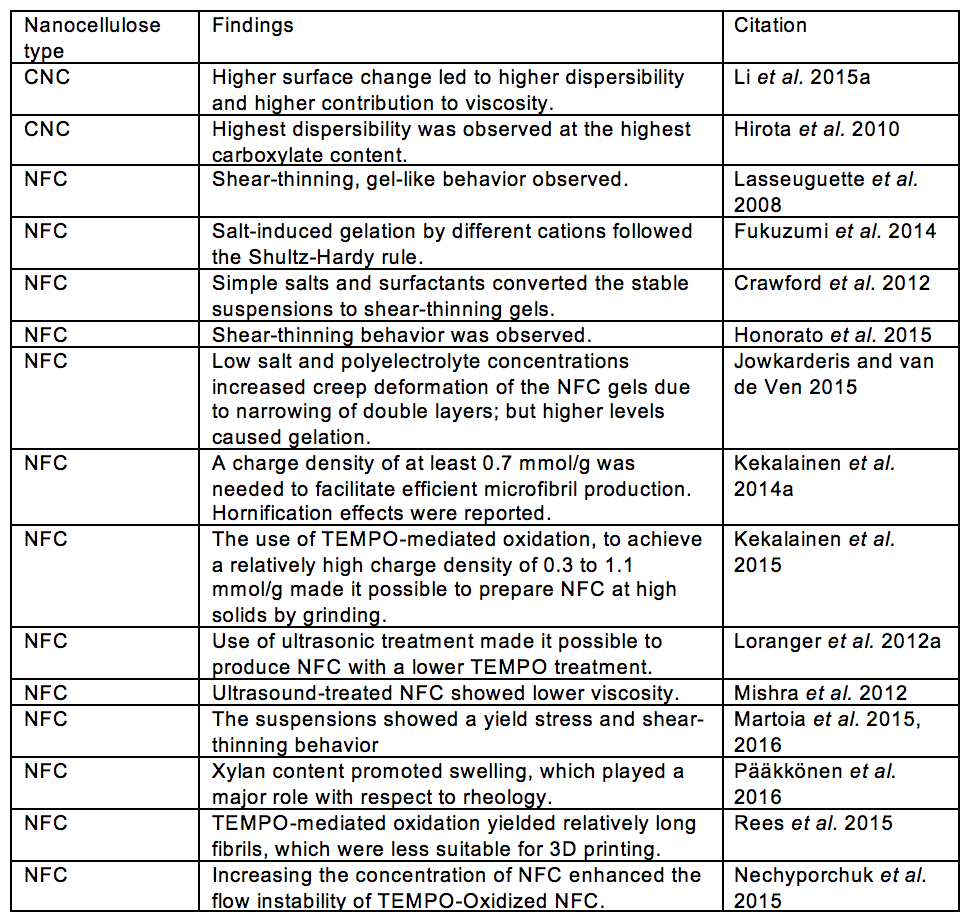

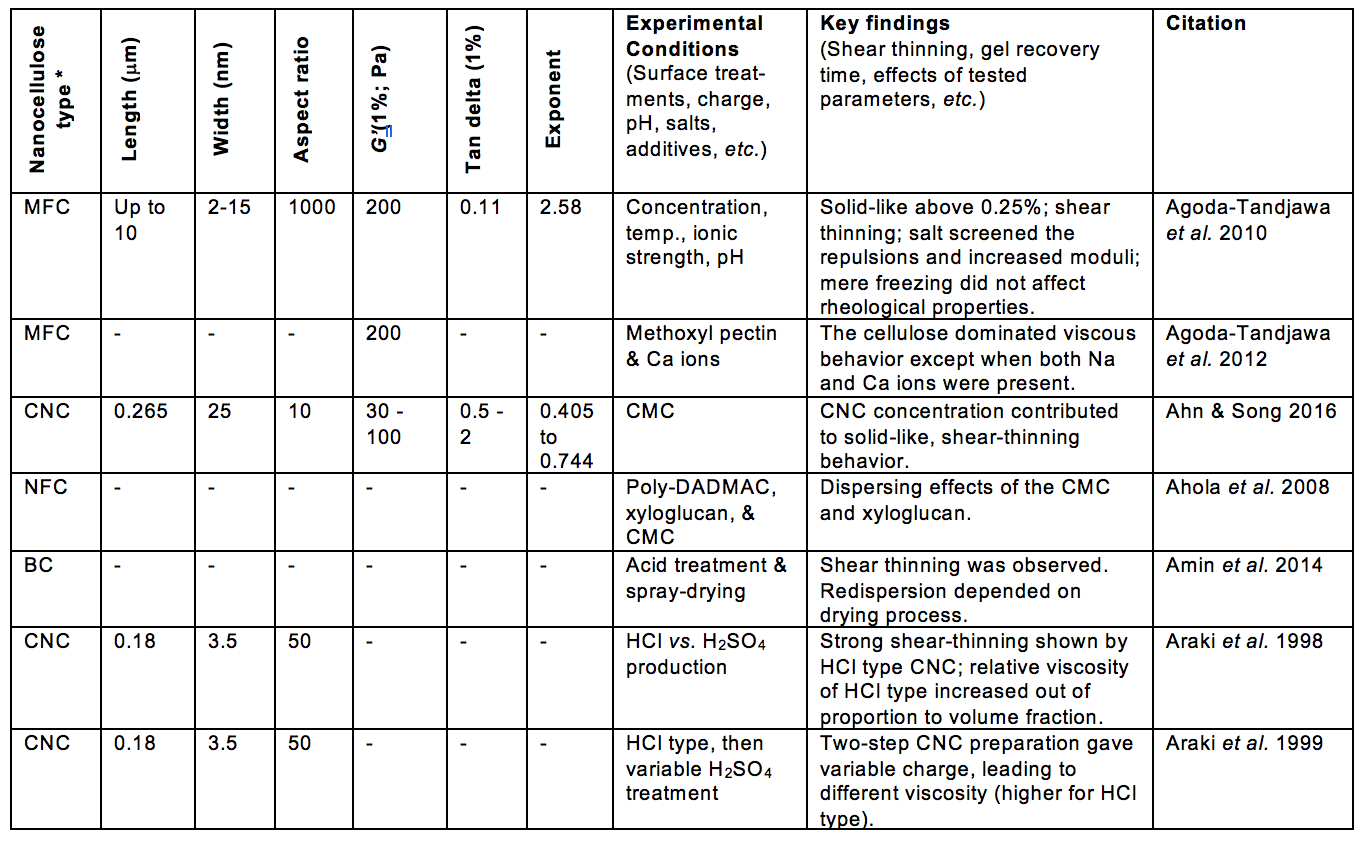

Stability with respect to temperature is important for ease of handling and to prevent process upsets when process interruptions occur. Stability of viscous behavior is also very important for maintaining good run conditions. Therefore, rheological measurements are frequently used to characterize nanocellulose characteristics, as well as for monitoring their behavior during their preparation and processing. The type of rheometer and accessories required for measuring rheological properties is dependent on various factors such as relevant shear rate, time scales, temperature, viscosity, sample size, etc. It has been documented that the use of serrated surfaces (in plate-plate rheometry) and a vane spindle (for bob in cup geometry) will decrease the wall-slip effects (Mohtaschemi et al. 2014a,b; Dimic-Misic et al. 2014; Nechyporchuc et al. 2015). Such issues are described in more detail later in this article. Table 1 lists publications in which various rheological measurements were recommended as a means of predicting likely outcomes of treatments for the preparation of nanocellulose suspensions. Figure 3 provides schematic views of some of the devices that have been employed in the reported analyses.

Fig. 3. Schematic views of some common ways to assess the viscosity of aqueous nanocellulose suspensions: A: Couette-type rheometer with baffles (related to “bucket and vane” devices) (Dimic-Misic et al. 2014); B: Extensional viscometer (Dimic-Misic et al. 2015a); C: Cone and plate rotational viscometer (Tanaka et al. 2014); D: Rolling ball viscometer (Tsvetkov et al. 2016)

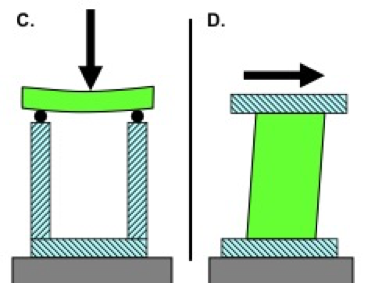

Figure 4 illustrates alternative systems that utilize either serrated plates or vanes to enable rheological measurements while avoiding wall depletion effects.

Fig. 4. Schematic views of (a) serrated plate system and (b) vane system for evaluation of suspension rheology while minimizing effects due to wall depletion

Table 1. Publications Suggesting Usage of Rheological Measurements as a Means of Characterizing Nanocellulose Attributes

Some of the criteria that have been considered when selecting a test device (as will be noted in later sections) include avoiding slip effects at the wall boundaries, providing a wide enough “gap” in the device to accommodate the suspended solids (including any network structures), and being able to carry out tests with small amounts of suspension.

Applications Involving Rheology

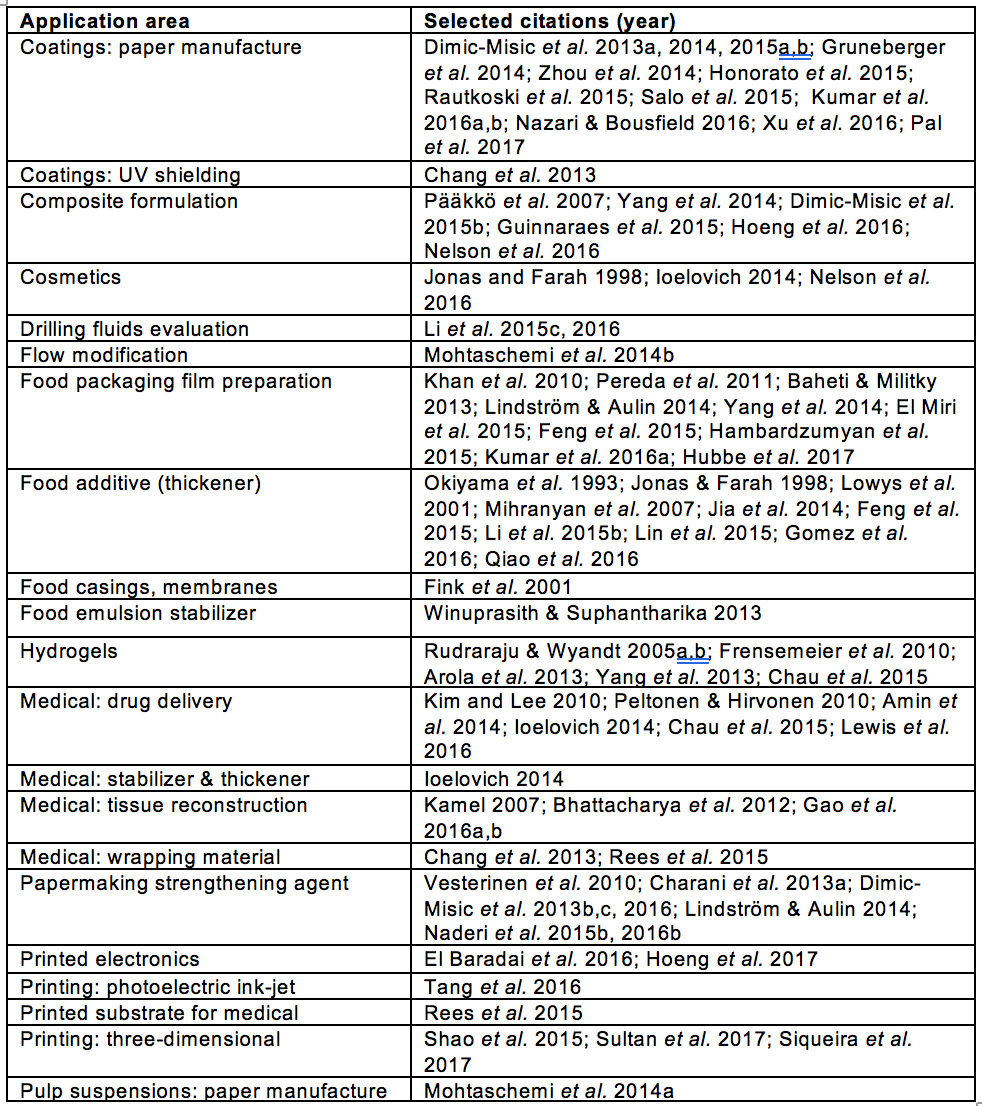

The rheological properties of nanocellulose suspensions can play a major role in different applications, such as thickening, coating, composites, and 3D printing. Table 2 lists various sources that discuss such potential or present uses of nanocellulose.

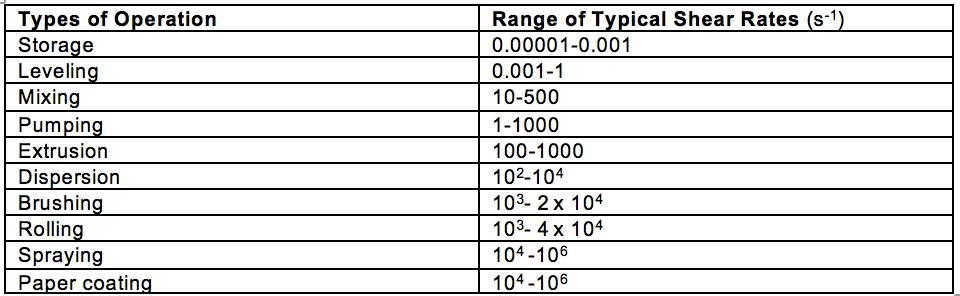

Regardless of the application, the rheological properties of any material is of high importance for the handling and use of a material during application and processing, which can occur over a broad range of shear rates. Table 3 shows generally accepted ranges of shear a material might experience during application and use.

Table 2. References Noting Various Applications in which the Rheology of Nanocellulose Aqueous Suspensions Are Important

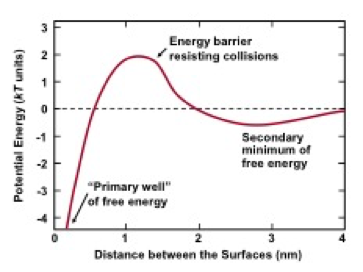

Some factors that can strongly influence the rheology of a suspension are the number of particles present and the volume fraction they occupy. A high solids fraction is often desired to reduce material transport and processing costs. Efforts to increase the solids level can benefit from an understanding of the effects of nanocellulose morphology and interactive forces between the nanocellulose surfaces. This is best accomplished by studying the flow characteristics of dilute aqueous suspensions. Other factors of importance are particle size, size distribution, shape, and interactions between particles. The interactions will be discussed in the section dealing with surface chemistry effects.

Table 3. Typical Ranges of Shear Rate for Common Industrial Operations (s-1)

General Effects of Flow

As background for later discussion of the rheological effects of nanocellulose in suspensions, selected general references can be recommended. Basic aspects of hydrodynamics, including a discussion of patterns of flow likely to be encountered in industrial applications, can be found in the book by Malkin (2017). The subject of extensional viscosity and related flow phenomena also have been elucidated, though to a limited extent (Petrie 2006). Time-dependent viscoelastic effects, including thixotropy, have been covered in well-known texts (Barnes 1997; Mewis and Wagner 2009, 2012; Puisto et al. 2012b). In addition, much is known about the rheology of suspensions of non-spherical particles (Chinesta and Ausias 2016). Aspects of the rheology and the viscosity of fluids containing nanoparticles also has been reviewed (Wierenga and Phillipse 1998; Mahbubul et al. 2012). Solomon and Spicer (2010) considered the rheological aspects of suspensions of rod-like particles, focusing on effects of aspect ratio and solids content for a wide range of natural and synthetic rod-like materials. They emphasized differences between gels (having a heterogeneous fractal-like structure) and glasses (having homogeneous network structure). Particular attention will be paid here to some non-reversible effects of stresses, strains, and time on the subsequent viscoelastic behavior of suspensions.

NANOCELLULOSE CHARACTERISTICS RELEVANT TO RHEOLOGY

Factors to Be Considered

Factors affecting the rheological properties of nanocellulose-containing aqueous suspensions can be regarded as falling into two useful categories. One of the most important is morphology, i.e. size and shape of fibrils. Another main point of differentiation is the surface-chemical composition of the solids, which can affect the surface charge. Both the morphology and surface composition can depend on the processes of treatments used to prepare the material. Therefore, a summary of nanocellulose preparation will be given in subsections that follow, with an emphasis on morphology and surface composition. For the sake of completeness, some key findings related to the influence of the viscosity of the suspending medium, in the case of nanocellulose suspensions, also will be reviewed.

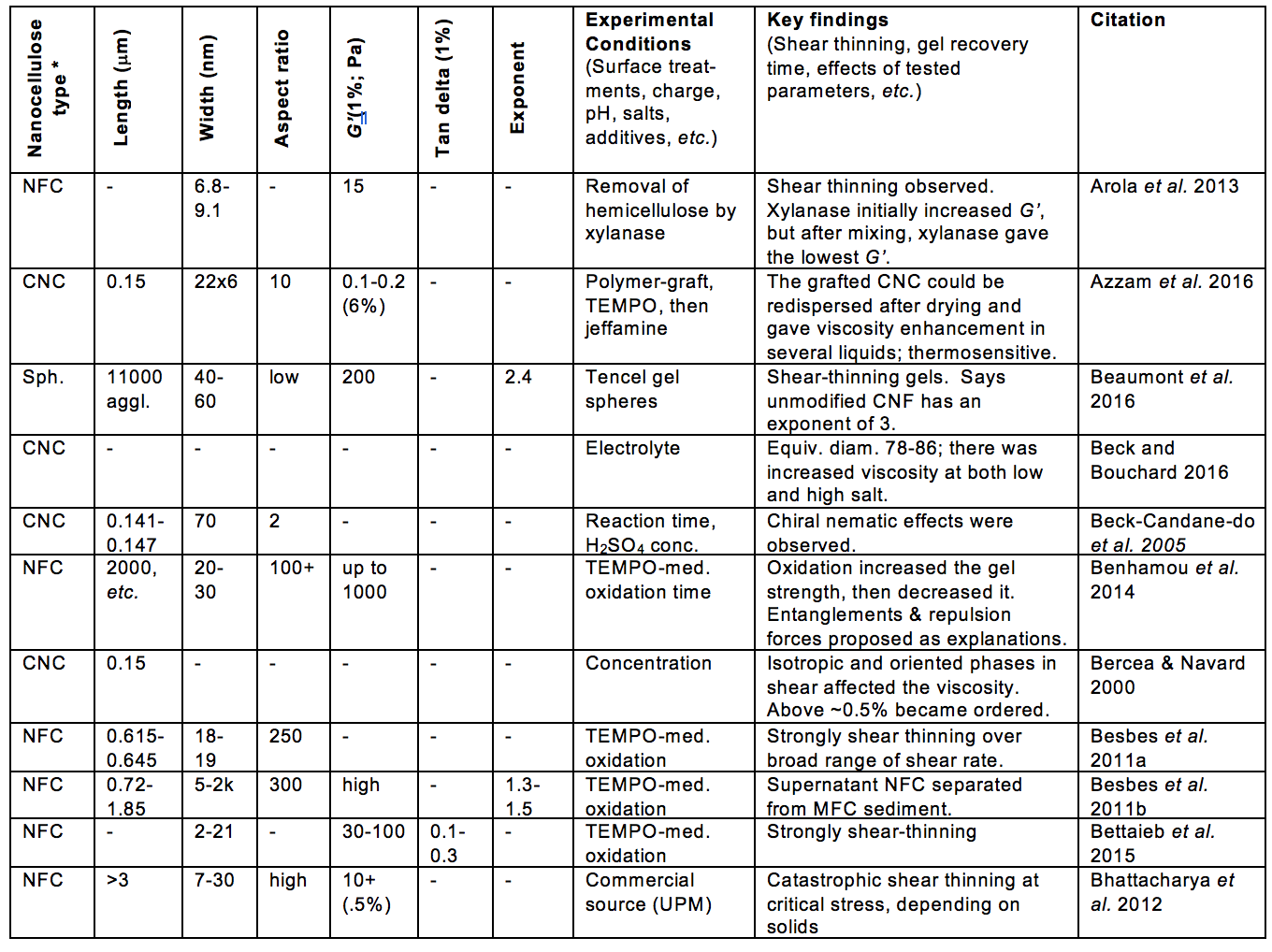

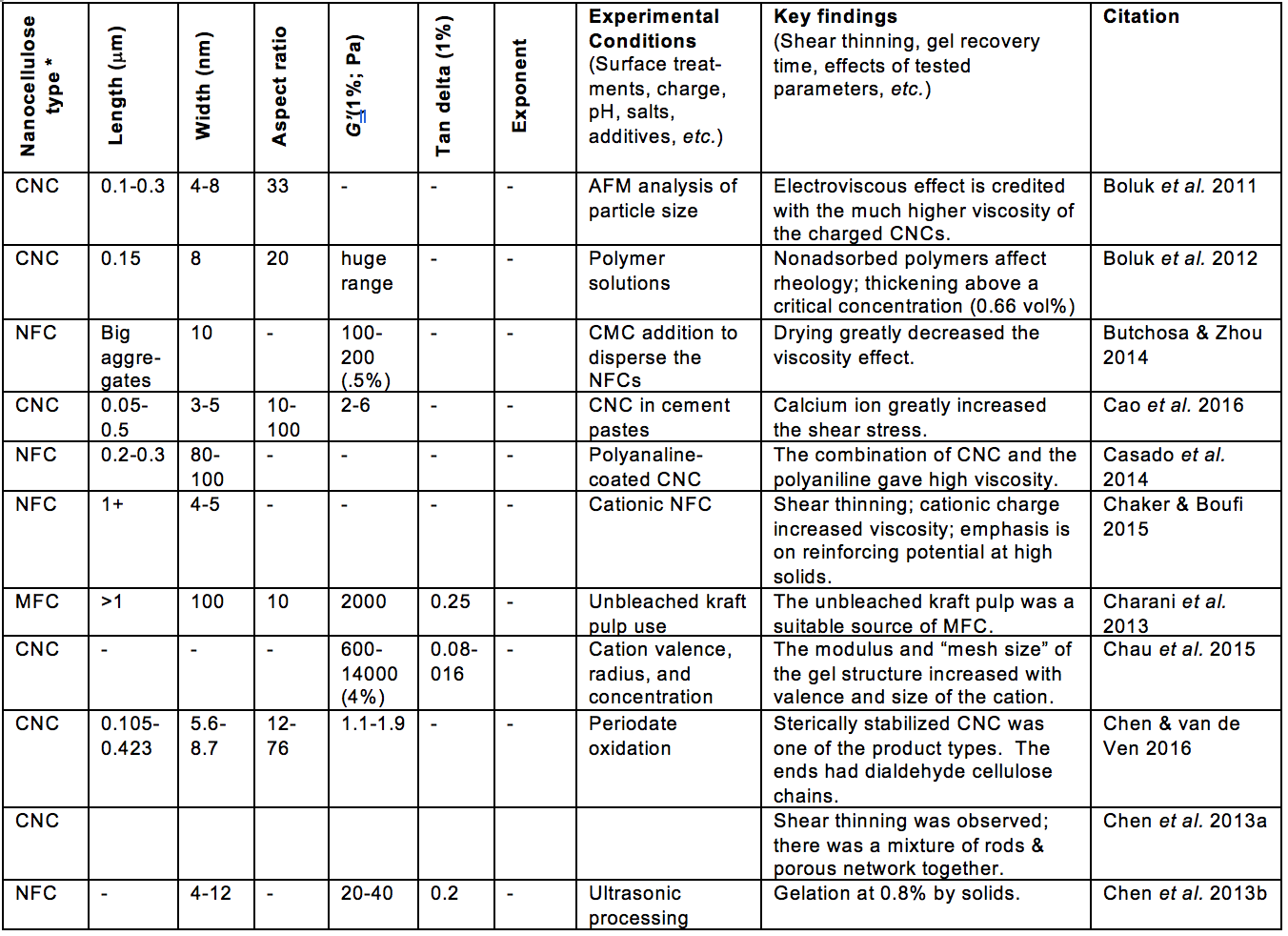

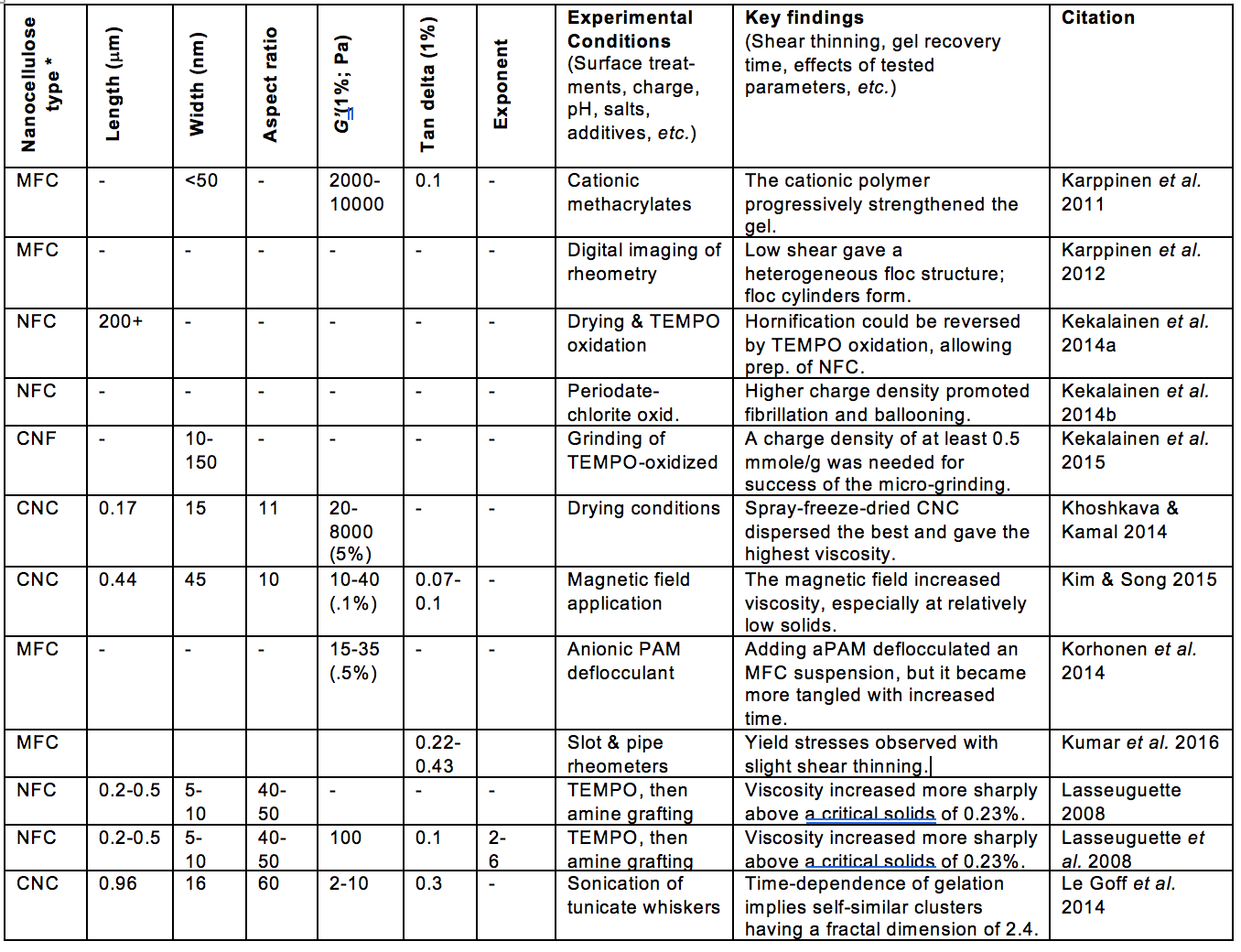

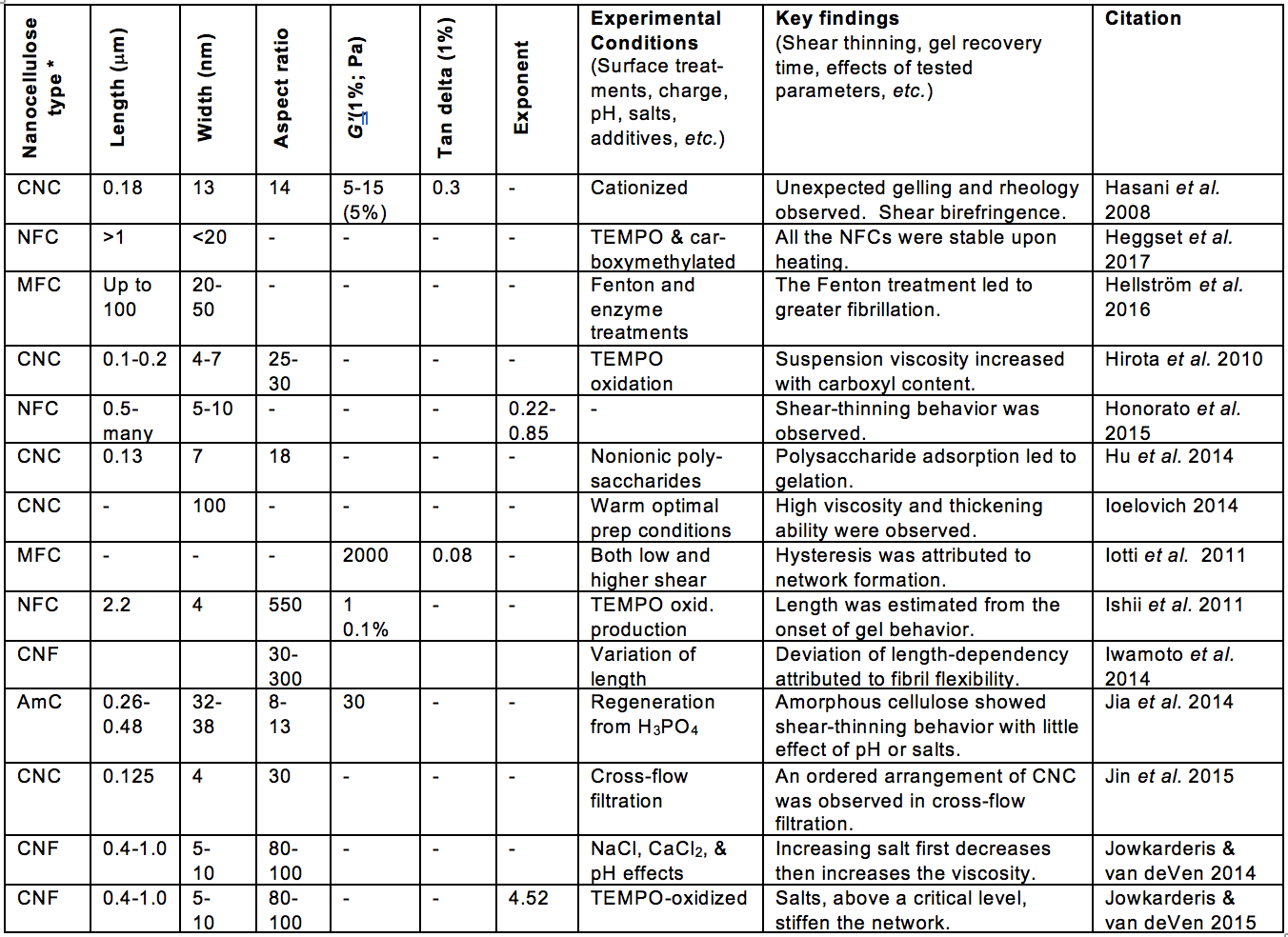

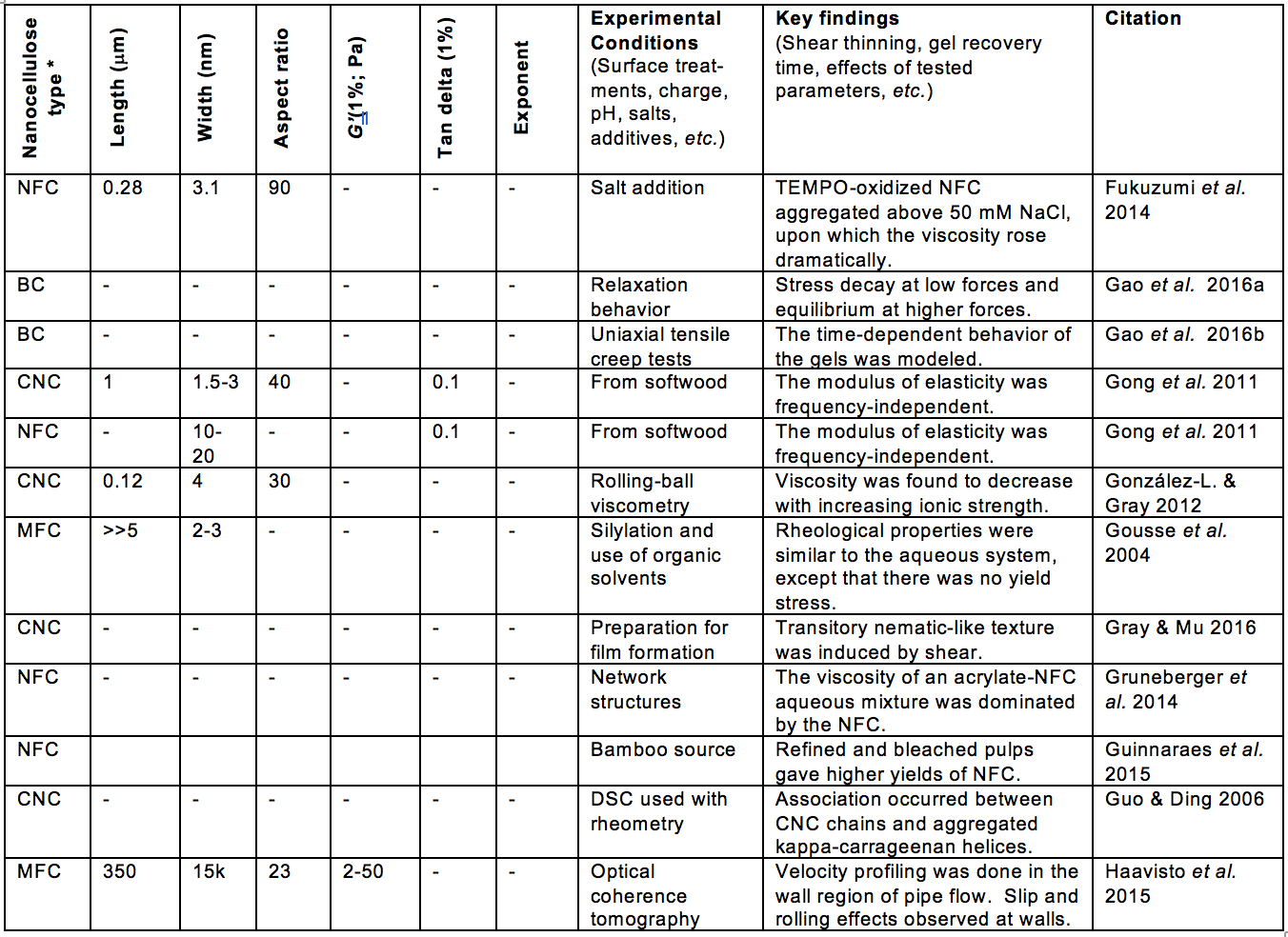

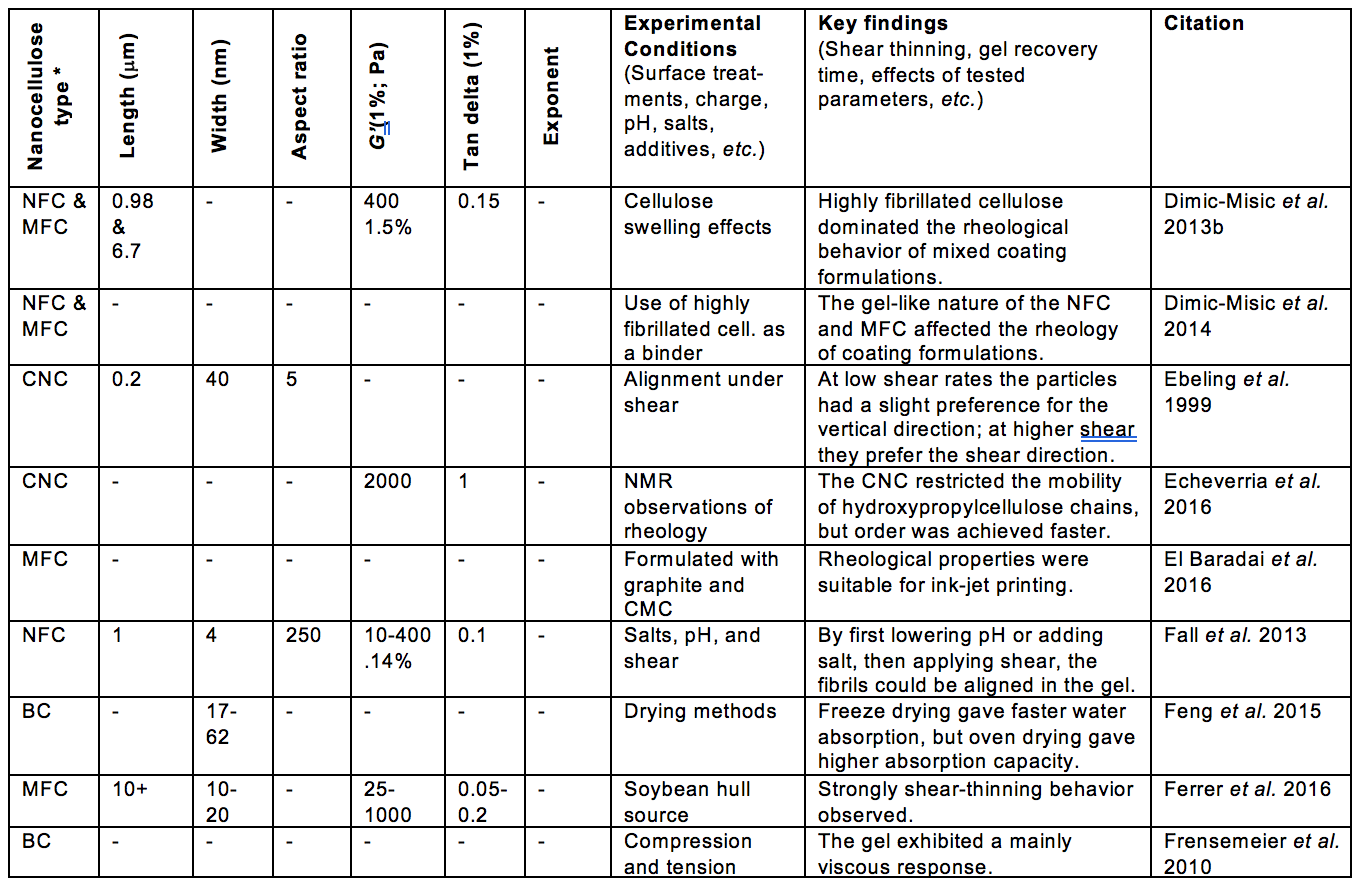

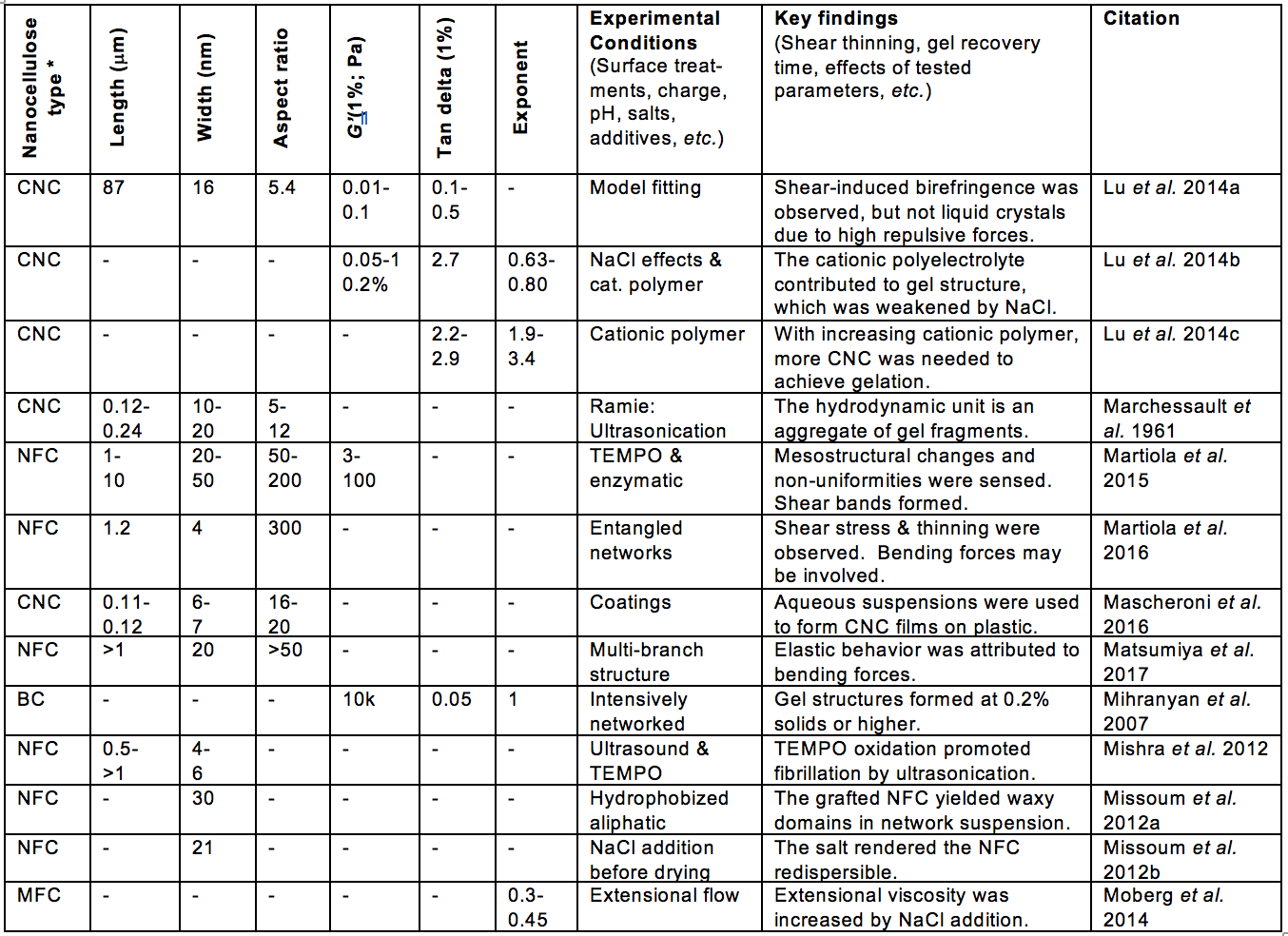

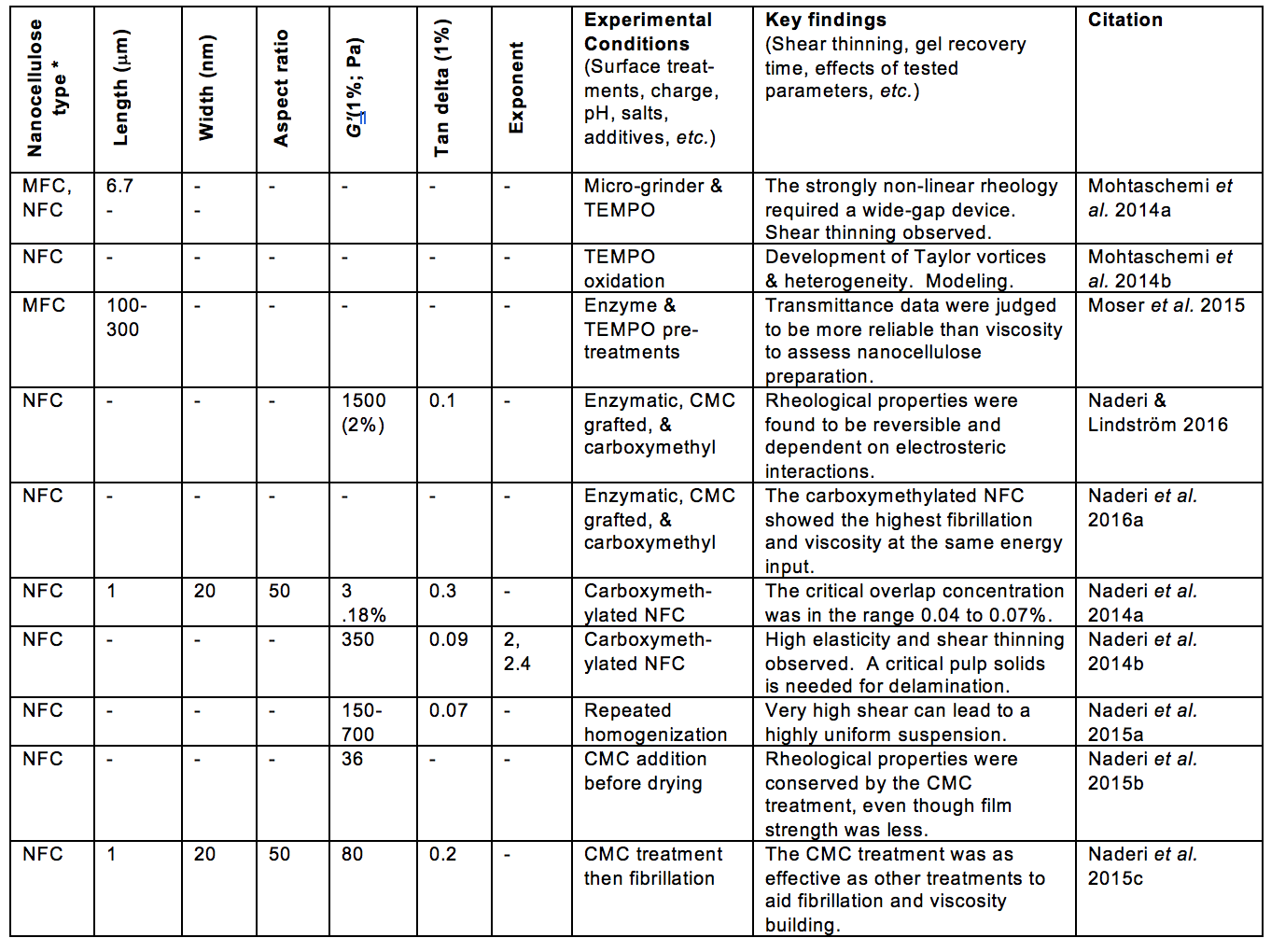

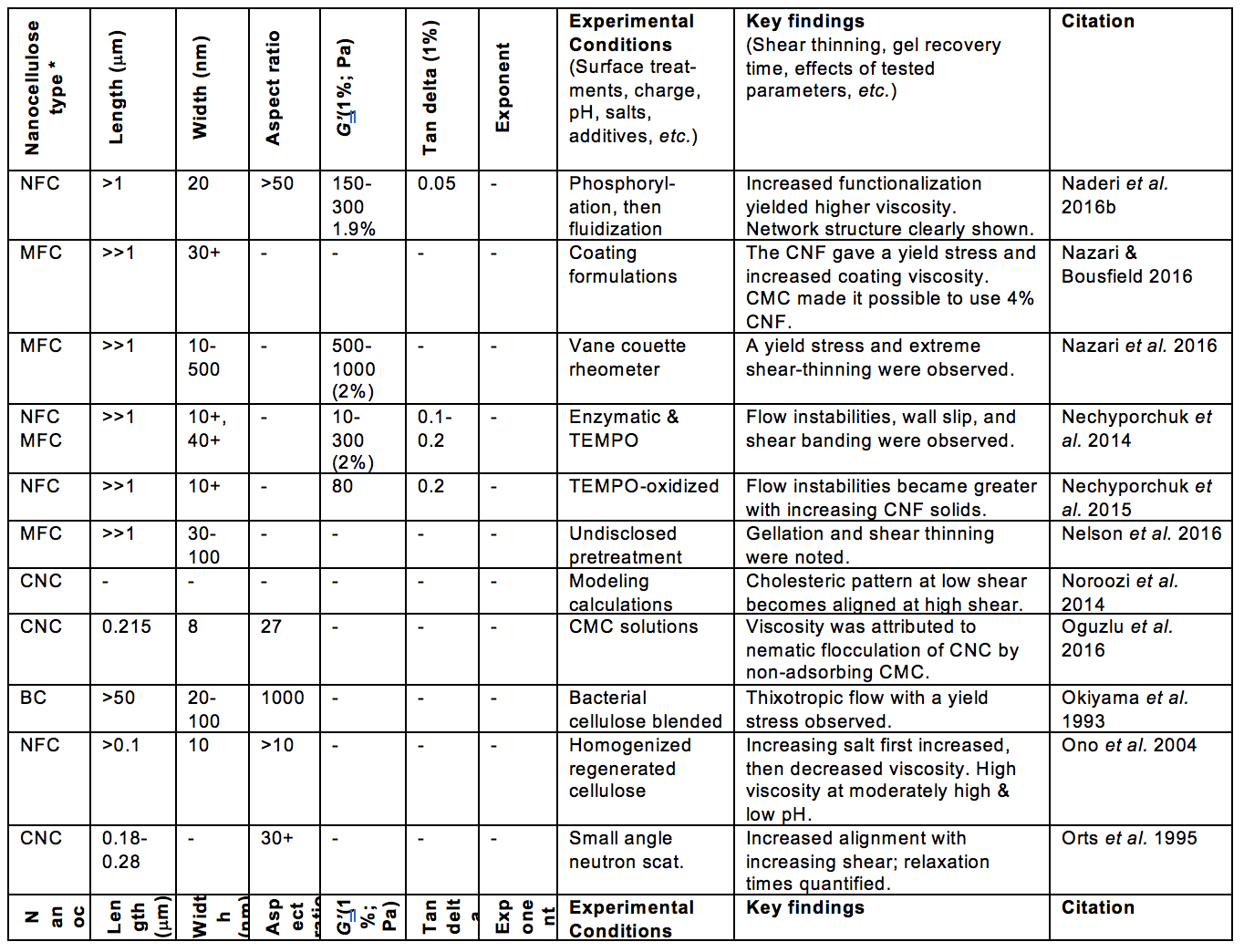

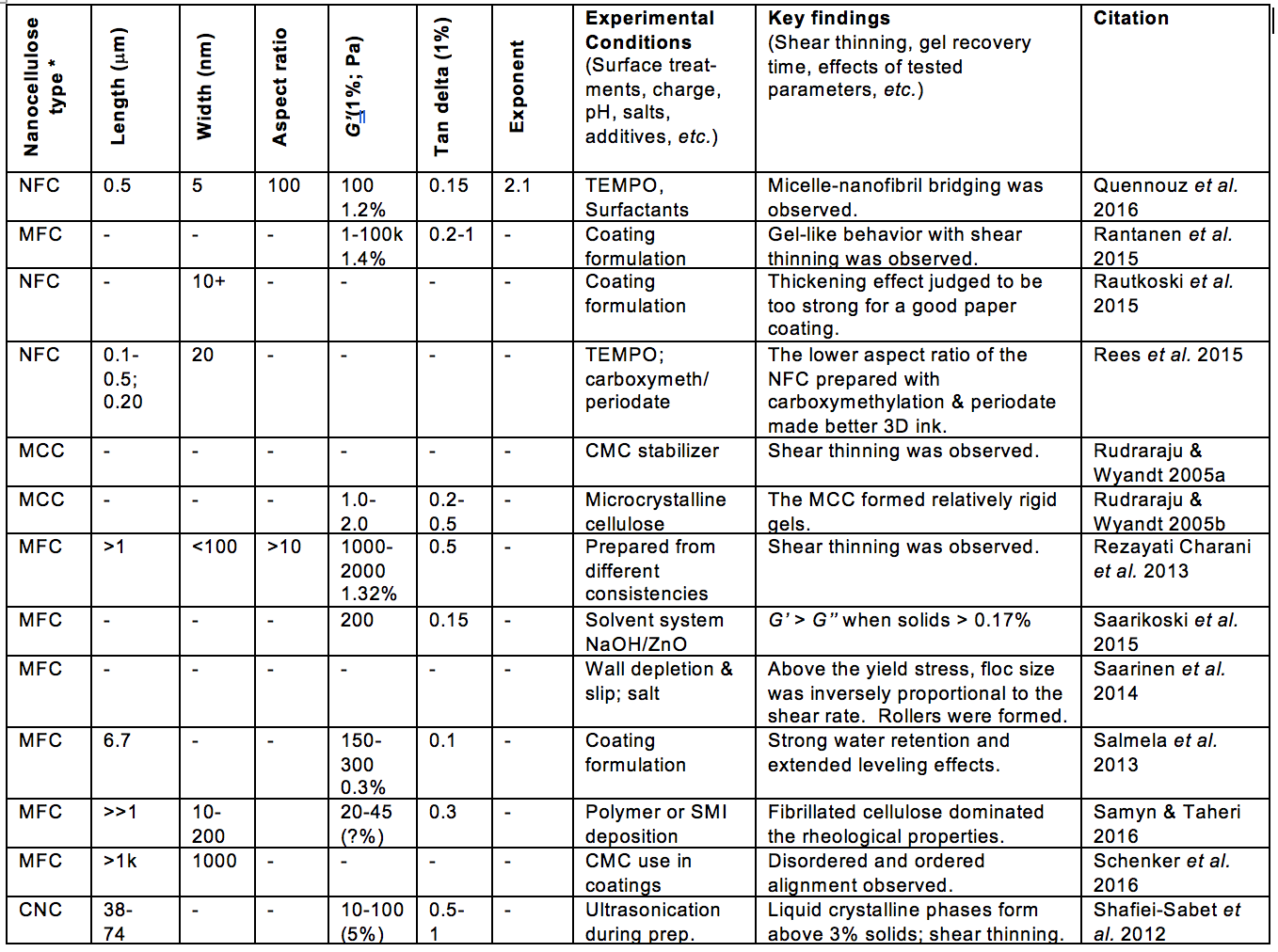

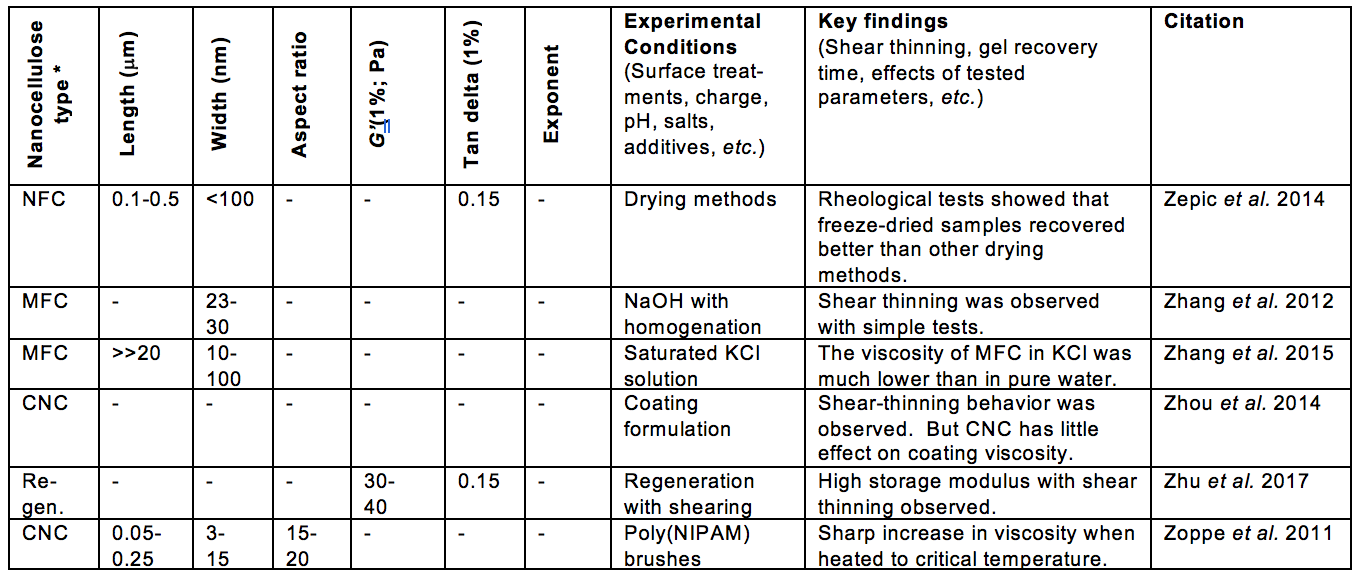

Some of the morphological aspects that have received much attention, relative to suspension rheology, can be encompassed by the terms fiber length, fiber diameter, fibrillation, and network structure. Table A (see Appendix) includes such information from the articles considered in this review. Likewise, aspects of surface chemistry of the nanocellulose can often be summarized by terms such as electrostatic or ionic charge, and hydrophilic or hydrophobic nature. In addition, the tendencies of cellulosic materials to swell in water can involve both morphology and surface chemistry.

The most important classes of nanocellulose, in terms of the volume of recent research publications, can be differentiated primarily by their processing, and secondarily by their biological origin. Research related to cellulose nanocrystals (CNCs) will be considered first, since CNCs tend to be the smallest and simplest of the nanocellulose entities, containing only crystalline domains of cellulose polymer. The main means of their isolation from the starting macroscopic cellulosic material is chemical digestion – most often with concentrated acid solution (Eichhorn 2011; Mariano et al. 2014). Alternatively, they can be prepared by oxidization, using ammonium persulfate (Leung et al. 2011) or the 2,2,6,6-tetramethylpiperidine-1-oxyl radical (TEMPO) (Hirota et al. 2010).

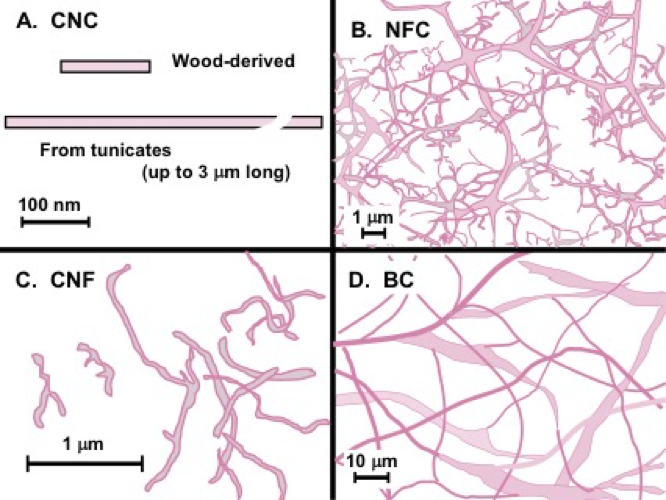

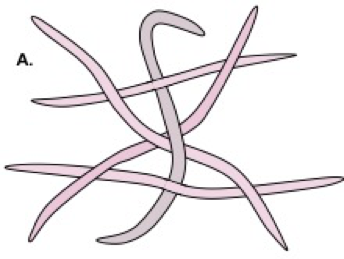

Fig. 5. Simplified diagrams to contrast the typical filament widths and shapes of nanocellulose materials that have been considered in various studies of rheological properties. Graphics were patterned after the following sources: A – multiple sources (cellulose nanocrystals); B: Crawford et al. 2012 (nanofibrillated cellulose); C: Iwamoto et al. 2014 (cellulose nanofibrils); D: Shi et al. 2012 (bacterial cellulose)

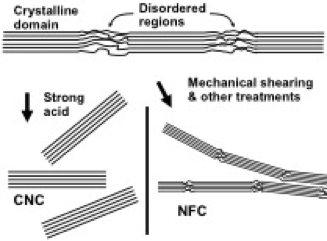

By contrast, mechanical processing, often accompanied by chemical or enzymatic pretreatment, plays a dominant role in the preparation of highly fibrillated cellulose materials (Siro and Plackett 2010; Lavoine et al. 2012; Sandquist 2013). In this article such materials will be referred to generally as either nanofibrillated cellulose (NFC) or microfibrillated cellulose (MFC) (Klemm et al. 2011). These labels can be regarded as synonyms, except that the term “nano” is used by many authors to emphasize a smaller size range. The term cellulose nanofibrils (CNF) (Nechyporchuk et al. 2016), which is also sometimes called “cellulose nanofibers,” will be used in this article in a narrow sense, referring to suspensions in which most of the fibrils mostly have been completely detached from each other, so there are no branched or network structures present. Exceptions include possible entanglements or agglomeration that is brought about by attractive forces.

Both CNCs and the fibrillated cellulose can be obtained from a wide variety of plant sources, including bacterial cellulose (BC). However, BC has a special status, since some varieties of BC are already in a similar “nano” size range as NFC even when they are first isolated (Moon et al. 2011). Figure 5 provides a simplified pictorial view of the main form of nanocellulose to be considered in this article.

Cellulose Nano-crystals (CNCs)

Preparation

As described in review articles, CNCs are most commonly prepared by digestion of cellulose in concentrated sulfuric acid (Araki et al. 1998; Gu et al. 2013; Mascheroni et al. 2016), hydrochloric acid (Gu et al. 2013), or other acids (Naderi et al. 2016b), sometimes with the addition of enzymes (Chen et al. 2012; Anderson et al. 2014). As illustrated in Fig. 6, the procedure can be understood based on an envisioned nanostructure of cellulose, in which crystalline regions are interposed by short non-crystalline or damaged regions (Nishiyama et al. 2003). Hirota et al. (2010) showed that CNC also can be prepared by relatively severe TEMPO-mediated oxidation of regenerated cellulose. Efforts are under way to produce CNC profitably at an industrial scale (Moser et al. 2015; Nelson et al. 2016). Some typical treatment conditions are 65% H2SO4 at 70 °C with stirring for 20 minutes (Araki et al. 1998). The main idea is to cleave and dissolve non-crystalline parts of the cellulose and any remaining hemicellulose, leaving behind just the nanocrystalline elements that are presumed to have been present in the starting material. Common plant sources for production of CNCs include delignified wood, cotton, bacterial cellulose, and even regenerated cellulose (Eichhorn 2011; Mariano et al. 2014).

Fig. 6. Schematic illustration of preparation of two contrasting types of nanocellulose, starting with native cellulosic material. Digestion of amorphous regions leads to cellulose nanocrystals (CNCs), whereas mechanical fibrillation (often with the assistance of chemical treatments) can yield nanofibrillated cellulose.

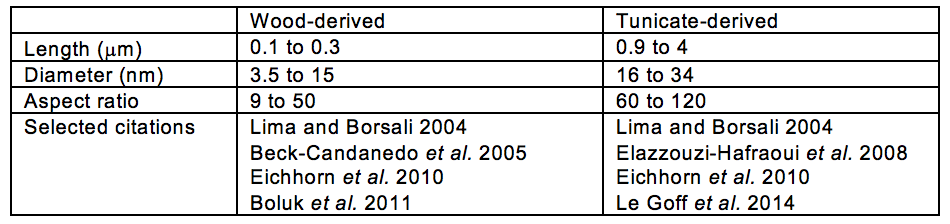

Typical dimensions

Table 4 lists typical dimensions of CNCs, based on the data collected in Table A (see Appendix). Though the dimensions shown can be regarded as typical, a wide range of dimensions is possible, given the many kinds of source materials and the many isolation strategies that have been employed. While the term “diameter” is shown in the table for this general description, it is worth noting that the cross-section of CNC in generally regarded as either rectangular (Eichhorn 2011) or hexagonal. In particular, an 18-chain hexagonal model has been proposed (Cosgrove 2014).

Table 4. Representative Characteristics of Cellulose Nanocrystal (CNC) Batches

Factors affecting crystal length

One can find different explanations in the literature to account for both the length and the thickness of CNCs. For instance, it has been proposed that the sizes of the crystals obtained after acid digestion are a close reflection of the dimensions of crystalline domains originally present in the cellulosic source material (Araki 2013). Regarding the length, it has been proposed that the native cellulose within lignified plants (e.g. including wood) have quite regular patterns of periodic defects or interruptions in their crystal structure (Araki 2013). Nishiyama et al. (2003) proposed that short polymer chain segments, maybe having approximately five anhydroglucose units, show deviations from the crystalline organization within an elementary fibril. Based on these findings it can be hypothesized that such defects would arise naturally during repeated flexing of a woody plant during its growth, exposure to wind, cycles of moisture change, or effects of thermal stresses (Takahashi et al. 2006; Lucander et al. 2009; Tomczak et al. 2012). As evidence to support the concept that mechanical stresses can cause damage at a molecular level, Joutsimo and Giacomozzi (2015) reported that mechanical stresses encountered by fibers during ordinary industrial processing of kraft fibers affects the fiber nanostructure and can affect the resulting paper properties significantly; fibers prepared to the same specifications under the mechanically gentler conditions of laboratory evaluation exhibited higher strength properties. Another likely explanation is that defects in the cellulose crystal structure are induced by the presence of other cell wall polysaccharides (Cosgrove 2014). Kontturi and Vuorinen (2009) found that CNC particles prepared from never-dried chemical pulps tended to be longer than those prepared from the corresponding dried pulps; it follows that the stresses imposed on the material during drying can induce periodic damage to the crystalline domains.

Some of the longest CNCs, with lengths ranging up to about 4000 nm, have been reported in the case of animal-derived cellulose, as obtained from the protective spines of tunicates (Lima and Borsali 2004; Elazzouzi-Hafraoui et al. 2008; Eichhorn et al. 2010). Unlike typical plant-derived CNCs, the “whiskers” obtained from tunicates generally show very wide distributions of length (Elazzouzi-Hafraoui et al. 2008). This can be tentatively attributed to the relatively infrequent and irregular occurrence of damaging levels of stress on the material during an ordinary life cycle of the animal.

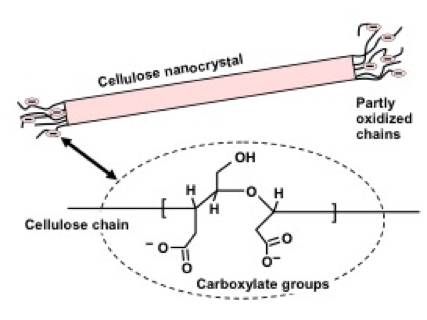

Hairy CNCs

While CNCs are ordinarily regarded as having a simple shape, as would be expected for a crystal, recent work by Lenfant et al. (2015) and van de Ven and Sheikhi (2016) presented CNCs having protruding macromolecular cellulose chains from the ends of the crystals. This is illustrated schematically in Fig. 7. Instead of using concentrated acid, the cited study employed a solution of meta-periodate, an oxidizing agent. Fibrils at the ends of the crystals were substantiated by transmission electron microscopy. Colloidal stability, which was enhanced at neutral to moderately high pH, was ascribed to the carboxylic acid groups provided by periodate oxidation of the protruding chains. Since protruding chains appear not to have been reported for CNCs produced by hydrolysis with acids or cellulases, it seems likely that these features can be expected only in the absence of cellulose-hydrolyzing agents.

Fig. 7. Schematic view of CNC prepared by periodate oxidation, in which oxidized cellulose chains extend from the ends of the crystals

Highly Fibrillated Cellulose Products

The application of very extensive mechanical shearing of cellulosic materials gives rise to a class of highly fibrillated materials, which generally contain both crystalline and amorphous cellulose. The names microfibrillated cellulose (MFC) and nanofibrillated cellulose (NFC) roughly correspond to different size ranges; however, the demarcation between MFC and NFC can be difficult to distinguish (Kangas et al. 2014). The term cellulose nanofibrils (CNF), which would literally mean that the fibrils are completely detached from each other, has become popular when referring to highly fibrillated cellulose preparations (Eichhorn et al. 2010); however, the term appears to be often misapplied to highly branched or network-like structures rather than suspensions of individual fibrils.

As a working definition, in the present article the term NFC can be taken to mean that the lengths have been substantially (e.g. at least 10 times) reduced compared to the fiber source and the widths or diameters of most of the cellulosic elements are no more than about 100 nm. Interestingly, the definition just stated (intended to define NFC) is substantially broader than the early definition for cellulose microfibrils given by Chanzy (1990), i.e. up to tens of mm in length and 2 to 20 nm in diameter. At the high end, various authors have used the term MFC to designate cellulosic fibers that were nearly their original size, but which had high levels of fibrillation (Haavisto et al. 2015; Moser et al. 2015; Zhang et al. 2015; Schenker et al. 2016; Shafiei-Sabet et al. 2016). Efforts to bring some order to the classification have been attempted (Kangas et al. 2014). The rheological aspects of this kind of cellulose have been recently reviewed (Iotti et al. 2011; Naderi and Lindström 2015; Nechyporchuk et al. (2016).

Faced with the difficulty of directly measuring the aspect ratio of NFC samples, with their branched and network-like attributes, Varanasi et al. (2013) based their estimates on the solids level in aqueous suspension corresponding to detection of gelation (see later discussion).

Fibrillation means

Details of the behavior of highly fibrillated cellulose products can be expected to depend on the type of mechanical action used for size reduction. Several different types of equipment are in current use to prepare highly fibrillated cellulose at various scales of production. In general terms, it appears that similar results can be achieved using contrasting equipment.

Conventional refining equipment, as used for many years in paper manufacture, can be employed, sometimes using modified refiner plates, to produce highly fibrillated celluloses (Kamel 2007; Chen et al. 2016a; Shafiei-Sabet et al. 2016). An advantage of such an approach is that industrial-scale equipment already exists and can be regarded as mature technology. On the other hand, there is no assurance that such equipment has an optimal format when the goal is not to prepare the fibers for ordinary papermaking, but to greatly reduce the dimensions of the cellulosic material.

High-pressure homogenizers have been used in several reported studies of the rheology of nanocellulose suspensions (Gouse et al. 2004, Kamel et al. 2007; Pääkkö et al. 2007; Besbes et al. 2011a,b; Hassan et al. 2011; Liu et al. 2011; Shogren et al. 2011; Li et al. 2012; Zhang et al. 2012; Osong et al. 2013; Winuprasith and Suphantharika 2013; Benhamou et al. 2014; Grueneberger et al. 2014; Kekalainen et al. 2014a; Lindström and Aulin 2014; Naderi et al. 2014a; Chaker and Boufi 2015; Lin et al. 2015; Naderi et al. 2015a,b; Beaumont et al. 2016; Chen et al. 2016b; Hellström et al. 2016; Hiasa et al. 2016; Pääkkönen et al. 2016). These devices work by forcing a suspension through a narrow space with abrupt changes in direction. Key variables are the operating pressure and the number of passes. Kekalainen et al. (2014a,b; 2015) achieved related effects using an inline homogenizer, where the suspension passed between a rotor and stator with a gap of less than 1 mm between alternating sets of teeth projecting into the high-shear zone.

Naderi et al. (2015c) considered a strategy to potentially reduce the energy and improve the outcomes of treatment in a homogenizer. Repeated passes were evaluated as a potential advantageous option in comparison to higher pressure processing with a single pass. Interestingly, these authors observed that films prepared from the highly fibrillated cellulose reached their ultimate strength when using only 40% of the energy required to fully reduce the material to NFC.

Microfluidizers, which involve the collision of opposing streams of suspensions, have also been used to prepare highly fibrillated nanocellulose (Charani et al. 2013a,b; Rezayati Charani et al. 2013; Naderi et al. 2015c, 2016b; Dimic-Misic et al. 2016; Samyn and Taheri 2016; Taheri and Samyn 2016). A possible advantage of this approach is reduced wear on the equipment.

Microgrinders are widely used to produce highly fibrillated cellulose, especially under laboratory conditions (Hassan et al. 2011; Mohtaschemi et al. 2014a; Bettaieb et al. 2015). The microgrinding procedure consists of passing a cellulose suspension between pairs of rough ceramic surfaces, usually prepared from high-hardness SiC mineral particles (Mohtaschemi et al. 2014a).

Chemical assistance to fibrillation

The amount of energy required to produce highly fibrillated cellulose products constitutes a major area of concern, especially for those considering the costs of scaling up processes for commercial production (Zimmermann et al. 2010; Lindström and Aulin 2014; Moser et al. 2015; Naderi et al. 2016a; Nelson et al. 2016). Various treatments with chemicals or enzymes are under investigation to reduce the energy required.

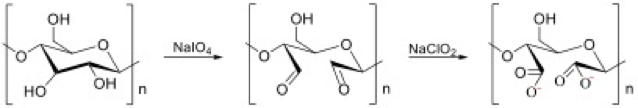

Treatment of cellulose with the relatively stable free-radical species 2,2,6,6-tetramethylpiperidine-1-oxyl radical (TEMPO) in the presence of an oxidizing agent has become a popular route to the production of NFC under reduced energy requirements (Lasseuguette 2008; Lasseuguette et al. 2008; Johnson et al. 2009; Hirota et al. 2010; Besbes et al. 2011a,b; Ishii et al. 2011; Loranger et al. 2012a,b; Mishra et al. 2012; Araki 2013; Benhamou et al. 2014; Fukuzumi et al. 2014; Kekalainen et al. 2014a, 2015; Lindström and Aulin 2014; Mohtaschemi et al. 2014a,b; Nechyporchuk et al. 2014, 2015; Bettaieb et al. 2015; Jowkarderis et al. 2015; Martoia et al. 2015, 2016; Rees et al. 2015; Pääkkönen et al. 2016; Xu et al. 2016). In addition to facilitating the fibrillation of the material, TEMPO-mediated oxidation also imparts a negative charge to the surfaces (at pH values near to or above the pKa value of the carboxylic acids) (Hirota et al. 2010; Isogai et al. 2011; Fukuzumi et al. 2014; Isogai 2015). Because the TEMPO system tends to exclusively oxidize the C6-hydroxyl groups of cellulose, it causes only a moderate reduction of molecular mass (Isogai et al. 2011). It has been estimated that TEMPO-mediated oxidation can enable a reduction of energy by a factor of between 24% and 54% when achieving an approximately equivalent level of fibrillation of the cellulose (Delgado-Aguilar et al. 2015).

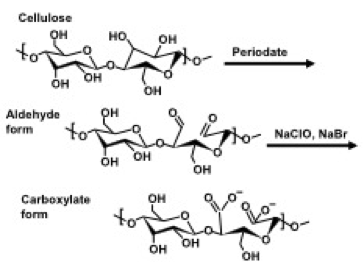

Fig. 8. Reaction sequence for conversion of cellulose to the corresponding aldehyde and carboxylate forms

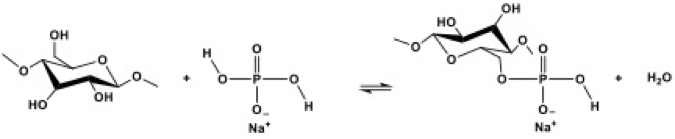

Other means of establishing carboxylic acid groups at cellulosic surfaces can be used. As indicated in Fig. 8, periodate oxidation, which favors conversion of the C2 and C3 hydroxyl groups to aldehydes and carboxylic acids, also has been evaluated for enabling the easier production of highly fibrillated celluloses (Kekalainen 2014b). Rees et al. (2015) evaluated a combined treatment with TEMPO and periodate. Naderi et al. (2014a,b, 2015a,c, 2016a) achieved energy reductions by carboxymethylation of the cellulose before application of high shear to prepare NFC. Again, the effect of increasing the carboxylic acid content at the cellulose surface was to reduce the energy needed to make NFC. Naderi et al. (2016b) achieved related effects with phosphorylation as a pretreatment before nanofibrillation. The fore-mentioned strategies, based on imparting a negative charge to cellulose, appear to facilitate easier fibrillation and help to electrostatically stabilize the suspensions (see later).

Another promising strategy for energy reduction consists of the partial degradation of the non-crystalline parts of the cellulose chains by optimized cellulase enzymatic treatment (Pääkkö et al. 2007; Hassan et al. 2011; Hellström et al. 2014, 2016; Martoia et al. 2015; Naderi et al. 2015b; Beaumont et al. 2016; Dimic-Misic et al. 2016; Naderi and Lindström 2016; Naderi et al. 2016a). Beaumont et al. (2016) were able to achieve in one pass of high-pressure homogenation of enzymatically hydrolyzed cellulose what needed up to about 20 passes in the absence of such treatment. Nechyporchuk et al. (2014) used a combination of cellulase and TEMPO mediated oxidation to promote the fibrillation of NFC.

Moderately hydrophobic modification of NFC was reported by Missoum et al. (2012a), who grafted long aliphatic chains onto the cellulose. Notably, despite an appreciable level of substitution, the modified NFC was still dispersible in water. The cited authors attributed this water-compatibility to a combination of self-association of hydrophobic groups and the persistence of uncovered, hydrophilic areas on the NFC surfaces.

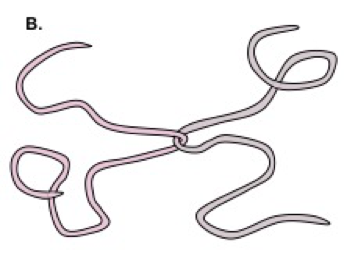

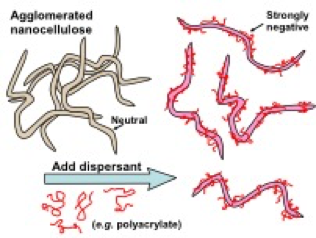

Network vs. separated structure of fibrillated celluloses

Micrographs of NFC products most often show highly complex structures that would be better described as networks rather than individual fibrils (Chen et al. 2016b; Martiola et al. 2016; Naderi et al. 2016b). For instance, Shogren et al. (2011) described corn cob tissue subjected to two passes of blender action as “networks of microfibrils and larger expanded fibrillar aggregates, while bundles of more separate microfibrils were observed after eight passes”. Chen et al. (2016b) report a “highly tangled fibril network”. Naderi et al. (2014a) use the term “severely entangled structure”. The high aspect ratio and charged nature of nanofibrillated cellulose gives rise to water-trapping properties. The NFC characteristics trigger a mechanism that constructs a gel and can lead to structure ensemble orientation. Strong electrostatic repellence of the highly charged nanoparticle surfaces and the “immobilization of the trapped interstitial water enable creation of elastic structured zones of fibrillated agglomerates within gel matrix” (Dimic-Misic et al. 2016).

Only in exceptional cases have individualized fibrils been reported as being derived from mechanical shearing – usually when accompanied by enzymatic treatment or intensive chemical oxidation (Pääkkö et al. 2007; Iwamoto et al. 2014; Jowkarderis and van deVen 2014; Kekalainen et al. 2015; Li et al. 2015a). Based on reported images, typical lengths of the aggregated structures are often in the range of 20 to 1000 mm. The widths are often in the range 20 to 500 nm. Thus, although the fibrils that compose typical NFC can be clearly in the “nano” range, the gross structure is typically a lot larger. The fact that such structures are firmly joined together by cellulosic elements needs to be kept in mind when considering efforts to predict rheological behavior based on measured or estimated dimensions.

Products that are relatively free of branch points and mechanically joined networks will be referred to in this article as cellulose nanofibrils (CNFs). It is notable that the combination of very high aspect ratio, the presence of both amorphous and crystalline cellulose, and the lack of branching or networking is shared by some forms of bacterial cellulose (native or processed), which will be considered next.

Bacterial Cellulose (BC)

Morphological aspects and other details about bacterial cellulose have been reviewed by Jonas and Farah (1998) and by Moon et al. (2011). Based on the number of publications, there has been strong interest in bacterial nanocellulose due its fibrils’ extremely high elastic moduli (78 GPa), high crystallinity, and absence of hemicellulose. These attributes enable a wide range of possible utilizations in films and aerogels. Bacterial cellulose nanofibrils (BC), such as the Acetobacter species (Iguchi et al. 2000; Lee and Bismarck 2012), have an advantage of being free from wax, lignin, hemicellulose, and pectin, which are all present in plant-based cellulosic materials (Pommet et al. 2008; Lee and Bismarck 2012). Surface modification of natural fibers with bacteria has been employed to deposit bacterial cellulose onto natural fibers to create hierarchical fiber reinforced nanocomposites (Pommet et al. 2008). When high aspect ratio bacterial cellulose is well disintegrated, its rheological behaviour can resemble that of liquid crystals (see later discussion). This suggests that BC fibrils in suspension, under certain shearing conditions, can become oriented, showing “order-disorder” alignment. Such properties of suspensions can be in turn utilized to make anisotropic films or aerogels. The crystallinity index (Cr. I) values of BC films were found to be around 78%) (Tsalagkas et al. 2015). However, it is difficult to define with precision the dimensions of single BC fibrils, as upon fluidization, a suspension may still contain fibrils that are mechanically bonded as part of larger fibril structures (Pääkkönen et al. 2016).

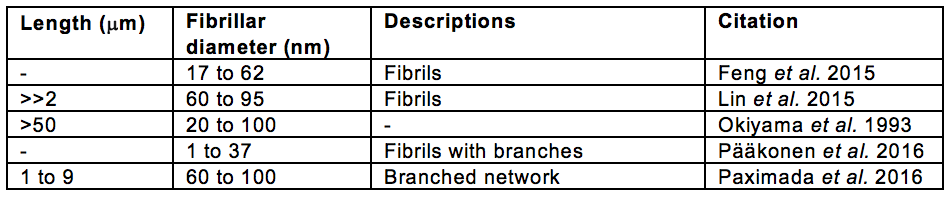

Table 5 lists relevant publications and their main findings with respect to fibrillar dimensions.

Table 5. Reported Bacterial Cellulose Dimensions and Descriptions

As a general rule, native bacterial cellulose consists of very high aspect-ratio fibrils. The length of bacterial cellulose fibrils is seldom reported, and published images often fail to show ends of fibrils (Feng et al. 2015; Pääkönen et al. 2016). Mechanical processing appears especially effective in separating the material laterally into thinner fibrils, while preserving a long length (Lin et al. 2015; Paximada et al. 2016). Thus, the format that one sees in micrographs is often a tangled loose coil or coils (Paximada et al. 2016). Okiyama et al. (1993) and Pääkönen et al. (2016) used the term “flocs” to describe BC suspensions. Authors have reported relatively high levels of water retention, i.e. swelling of bacterial cellulose, e.g. 2 to 4 g/g, relative to other highly fibrillated nanocellulose (Amin et al. 2014). These values are comparable to the water retention of xylan-free NFC suspensions (Pääkonen et al. 2016). The latter authors estimated an agglomerate diameter equal to 5 mm.

Contributions from the Viscosity of the Aqueous Medium

Though nanocellulose is assumed, in this article, to make the major contribution to rheological effects, the viscosity of the suspending medium cannot be ignored, so some points merit review. General background regarding viscous effects in particle-free aqueous systems can be found in available texts (Larson 2005; Malkin 2017). Some factors that can affect the rheology of the medium, and consequently the rheology of the nanocellulose suspension, are discussed in the subsections that follow. Issues related to ionic strength and pH will be deferred to a later section, which focusses on colloidal chemistry effects.

Temperature

In ordinary aqueous media, increasing temperature tends to decrease the coefficient of viscosity in a smooth, predictable way. The viscosity of pure water decreases markedly as the temperature is raised (Korson et al. 1969). That generally implies that water’s contribution to the viscosity of a suspension will decrease with increasing temperature. However, Agoda-Tandjawa et al. (2010) observed no additional important effect of temperature on the viscosity of a NFC suspension. Such findings are consistent with a dominant effect of the nanocellulose on the measured viscosity, noting that the temperature also can affect such factors as the degree of dispersion of the solids and the flexibility of the fibrils.

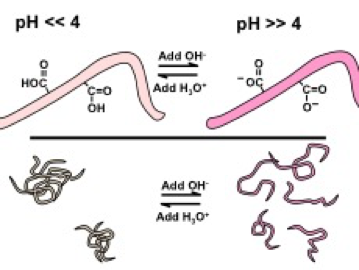

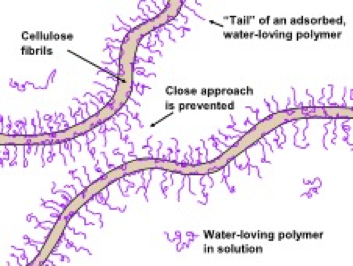

Polyelectrolytes in solution

When considering viscosities of aqueous mixtures, the effects of polyelectrolytes need to be considered. Dissolved polyelectrolytes, when present in aqueous mixtures with nanocellulose, may remain in the water phase either when they have a low adsorption affinity or when the amount exceeds the adsorption capacity of the surfaces. The emphasis in this review is on system in which polyelectrolytes, if present, are not so concentrated as to dominate viscous effects, relative to the effects of the nanocellulose. The incremental effects of such dissolved polyelectrolytes on the solution viscosity can be estimated from the concentration, molecular mass, and the tendency of the polymer to adopt an expanded conformation (Larson 2005; Malkin 2017). In principle, the viscosity characteristics of polyelectrolytes solutions serving as the suspending medium for solids particles, will be related to the observed viscosities of suspensions, but in a complex way, due to particle-solution interactions.

Even when water-soluble polymers are to be present in the final mixture, it sometimes can be advantageous to initially disperse nanocellulose in their absence. Thus, Going et al. (2015) studied the dispersion of CNC into poly(vinylpyrrolidone, PVP). They dispersed CNC into water prior to the subsequent addition of methanol as a co-solvent in the polymer matrix, which reduced the viscoelasticity properties of the solution. They attributed this reduction to less agglomeration of the nanocellulose.

In the work by Butchosa and Zhou (2014), CMC was adsorbed on the colloidal NFC, and its effect on the system viscosity was monitored. They reported, at the level of 2.3 wt% CMC, that a fully redispersible NFC was achieved. A pertinent example is viscosity reduction of NFC solution as a result of xyloglucan adsorption, which was studied by Ahola et al. (2008)

Unusual viscosity behavior of CNCs dispersion in polyoxyethylene (PEO) solution was reported by Ben Azouz et al. (2012). With increasing addition of CNC, up to 9 wt.%, the viscosity continued to decrease; however, this trend became reversed at higher levels. These observations are in agreement with Cox-Merz rule that will be discussed later in this article.

Bridging effects of nanocellulose

At the limit of relatively low additions of nanocellulose to solutions of polymers in water, the cellulose nanofibrillar aggregates suspended in a gel-like matrix can sometimes function as a kind of cross-linking agent, linking some of the polymers to each other and building the viscosity. For instance, Yang et al. (2014) studied addition of CNC to polyethylene glycol solutions. Strong enhancements in viscosity were observed. Rheological behavior of a 1.0% water solution of hydroxyethyl cellulose mixed with carboxymethyl cellulose (CMC) was studied by Boluk et al. (2012). They observed a significant increase in the viscoelasticity and formation of a gel-like solution, upon addition of cellulose nanocrystal (CNC) into the system. Related effects have been widely reported (e.g. by Guo and Ding 2006; Vesterinen et al. 2010; Boluk et al. 2012; Hu et al. 2014; Lu et al. 2014c; Ahn and Song 2016; Oguzlu et al. 2016).

At ranges of polymer concentration sufficient to dominate viscous effects, when adding nanocellulose, it may be more appropriate to refer to the mixture as a nanocomposite (Hubbe et al. 2008; Eichhorn et al. 2010; Moon et al. 2011; Hubbe et al. 2017) rather than as an aqueous suspension. The rheological properties of nanocellulose-reinforced polymer matrices have been reviewed elsewhere (Moon et al. 2011; Ching et al. 2016).

PHYSICAL ASPECTS OF SUSPENSION VISCOSITY

Rheology of Particle Suspensions

Factors that can affect the viscosity and viscoelasticity of suspensions of nanomaterials generally can be assigned to the categories “physical” and “chemical”. The physical aspects, which will be considered in this section, include sizes, shapes, mechanical properties of materials, flow, formation of flocs, certain yield-point issues, and “wall slip” effects, etc. Many of these physical aspects have general applicability to a broad range of mixtures, so it makes sense to consider them first. Details about the non-hydrodynamic forces of interaction between surfaces tend to be dominated by chemistry – and these will be considered in a later section.

Einstein’s theory

Einstein derived a fundamental relationship to predict the viscosity of Newtonian fluids that contain neutrally-buoyant, non-interacting spheres (Einstein 1911; Mueller et al. 2010). The presence of the spheres was predicted to increase the viscosity, relative to that of the pure liquid (ho), according to Mueller et al. (2010),

h = ho (1 + Bo f) (1)

where f is the volume fraction of the spheres (assumed to be of equal size). According to Einstein, the coefficient Bo should be 5/2, but others have assigned values between 1.5 and 5, based on other sets of assumptions. To be able to apply the equation beyond the highly dilute range, subsequent workers have derived higher-order terms. For instance, the viscosity can be expressed as,

h = ho (1 + 5/2 f + B1 f 2) (2)

where the coefficient B1 has been assigned values between 2.5 and 7.35 (Mueller et al. 2010), depending on whether one accounts for effects of Brownian motion and inertia. Alternatively, to extend the range of accuracy up to about 4% by volume, Brinkman (1952) proposed the following equation (Mahbubul et al. 2012):

h = ho (1 – f)2.5 (3)

Experimental data are often fitted to semi-empirical equations of the form (Krieger 1959; Chen et al. 2007; Mahbubul et al. 2012),

![]() (4)

(4)

where the relative viscosityhr is the ratio between the viscosity of the mixture and that of the suspending liquid, B is the Einstein coefficient, and fm is the maximum packing density volume fraction (equal to about 0.64 for equal spheres). Similar models have been employed for nanocellulose materials by considering them as elongated particles (Nechyporchuk et al. 2016). A relationship similar to Eq. 4 was derived by Dougherty (1959) and Krieger (1972), except that the exponent was –[h] . A yet simpler form, in which the exponent was given as -2, was reported by Maron and Pierce (1956) and Quemada (1982).

Several researchers have employed relationships such as that shown in Eq. 5 to report their results (see Table A). In other words, the measured viscosity can be reported to be dependent on the volume concentration raised to an empirically determined coefficient.

![]() (5)

(5)

As noted in the review by Klemm et al. (2011), the storage modulus of nanocellulose suspensions is often found to follow an analogous relationship,

![]() (6)

(6)

in which the exponent should be 2.25 according to scaling theory (de Gennes 1979). The exponent has been found to be about 3 for volume concentrations above 0.5% (Klemm et al. 2011).

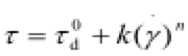

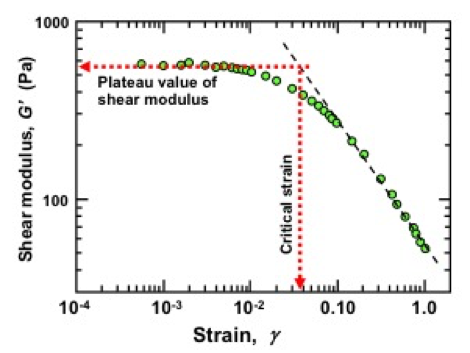

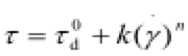

Rheological behavior of nanocellulose suspensions is usually determined by fitting of experimental data of flow curves. The viscosity is commonly observed to decrease with increasing shearing as a power law according to the Oswald de-Waele empirical model; this relationship can be expressed as Eq. 7 (Lasseuguette et al. 2008; Divoux et al. 2013),

![]() (7)

(7)

where k and n are the flow index and the power-law exponent, respectively. The parameter g is the shear rate, usually expressed in s-1. An exponent value of zero indicates a Newtonian fluid, and n > 0 pseudo-plastic (shear thinning) behavior (Dimic-Misic et al. 2014).

Nanocellulose gels prepared from NFC have shown agreement with Eq. 7, where n-values reveal the gel strength (Naderi et al. 2014a; 2016; Lasseuguette et al. 2008). Gel strength is generally characterized by a large degree of independence of elastic moduli (elastic modulus (G´) and loss modulus (G´´) with respect to angular frequency (ɷ), which has more impact at higher frequencies, and higher flocculation within suspension can be revealed with frequency-dependent elastic moduli responses. Pääkönen et al. (2016) found that the shear modulus and viscosity of NFC suspensions decreased with the removal of xylan, a water-binding polysaccharide of hemicellulose, unevenly distributed on the fibril’s surface. Since the removal of xylan also decreased the water retention, it was proposed that a swollen sheath of xylan accounted for the shear modulus of the gel structures.

Aspect ratio of elongated particles

Subsequent investigators have extended Einstein’s predictions to non-spherical particles including ellipsoids (Marchessault et al. 1961; Mueller et al. 2010; Mewis and Wagner 2012) and stiff rods (Berry and Russel 1987; Dhont and Briels 2003; Boluk et al. 2011; Wu et al. 2017). The aspect ratio, i.e. the ratio of length (l) to diameter (d), has been shown to be a key variable governing the rheology of such suspensions. The aspect ratio of fiber suspensions has been predicted to have significant effects on suspension viscosity, even at sufficient dilution such that viscous effects are not affected by inter-particle collisions (Simha 1940; Araki et al. 1998).

For highly dilute suspensions of rods, in systems where the rate of particle Brownian rotation is fast enough to preclude significant alignment of the particles, the intrinsic viscosity can be estimated from (Onsager 1932; Weirenga and Philipse 1998),

![]() (8)

(8)

where r stands for the aspect ratio L/d.

At higher solids levels, effects of interactions between adjacent particles become significant, and it has been found that the following expression can be used to predict the relative viscosity, h/ho (Weirenga and Philipse 1998):

![]() (9)

(9)

The parameter L is the scale length, v is number density of rods, and b is a measure of the degree of freedom from “tube constraints” that prevent rodlike particles from turning around due to crowding by surrounding particles. Sato and Teramoto (1991) added a further term using a mean-field approach under the assumption of no entanglement:

![]() (10)

(10)

where D is the rotational diffusion coefficient.

To relate nanocellulose aspect ratios to observed viscosities, the fm term in Eq. 4 can be estimated from the gel crowding factor (see later discussion) (Celzard et al. 2009). Under the assumption that the alignment of the nanocellulose particles remains chaotic, the definition of the gel crowding factor gives the following,

fm = 64/[(2/3) (L/d)2] = 96 (L/d)-2 (11)

A key challenge in applying such an approach lies in the strong tendency of elongated particles to become aligned when exposed to flow, which is another topic to be discussed in this article. The take-away message at this point is that although Eqs. 4 and 11 appear to have suitable characteristics to enable one to estimate the effects of aspect ratio on suspension viscosity, as a function of volume fraction, such a calculation would require bold assumptions regarding the maximum packing density under the applied hydrodynamic conditions.

Chen et al. (2017) found that in a system containing both polyvinyl alcohol (PVOH) and CNC, the value of fm calculated based on CNC alone was 17.3%, which was much lower than the expected value based on percolation theory. The cited authors proposed that the downward shift was attributable to the space occupied by the loops and tails of adsorbed PVOH. The authors did not observe a corresponding downward shift of fm in the presence of CMC, and they attributed this to a general lack of adsorption of the CMC on the CNC under the conditions of testing. Another possibility is that the relatively stiff nature of CMC at low ionic strength favors flat adsorption onto cellulosic surfaces (Ueno et al. 2007).

Xu et al. (2013) define a related quantity fc, which they identified with the “onset of perculation”. This quantity was predicted to follow the relationship:

fc = 0.7(d/L) (12)

Hill (2008) suggested that a somewhat higher coefficient than 0.7 may be more accurate. Moberg et al. (2017) evaluated values of fc for a series of CNC and NFC suspensions that had been prepared with different aspect ratios and with sufficient negative surfaces charges to achieve excellent dispersion of the particles. Values of fc were found to range from 0.31 to 0.36 for two NFC samples. Higher values of fc in the range 0.75 to 1.92 were determined for various CNC preparations. It is tentatively proposed that the difference can be attributed to the relatively straight nature of typical CNC particles, compared to the curled shapes that are often assumed by NFCs. A non-straight shape in suspension implies a much lower end-to-end distance (Wierenga and Philipse 1998).

Flexibility

Although real fibers are flexible, many of the derivations related to the viscosity of suspensions have, for simplicity, assumed rigid rods. Ishii et al. (2011) found that the flexibility of nanocellulose particles (NFC or CNC) made an important contribution to their rheological behavior beyond the yield point, i.e. flow initiation of suspensions. The length of nanocellulose fibrils and surface charge affect flocculation, with shorter fibrils generally producing smaller agglomerates, and lower surface charge producing higher flocculation within the suspension matrix. Therefore, differences in equilibrium flocculation and/or agglomeration for the different nanocellulose systems depend on the solids content, with obvious strain dependence/hardening for highly flocculated MFC suspensions (Fall et al. 2011).

Switzer and Klingenberg (2003) considered a model that incorporated the bending of fibers. Flexibility generally reduces the observed rigidity of a suspension, compared to predictions based on rigid particles that are otherwise identical (Férec and Ausias 2015). Similarly, swelling of nanocellulose fibrils can reduce the friction between fibrils in a suspension, thus allowing their movement upon application of shear.

Batches of NCF that are produced with chemical treatment typically have higher surface charge and are generally more water-swollen and flexible than low-charged MFC produced by mechanical action alone. They therefore create less friction while in shearing conditions; as a consequence they tend to exhibit more pronounced decreases in viscosity parameters as a consequence of flow (Dimic-Misic et al. 2013b,c). Shear-thinning effects tend to be more pronounced, and the onset of shear thinning generally starts at lower applied shear stress (Keshtkar et al. 2009).

Iwamoto et al. (2014) were better able to account for the viscosity of NFC suspensions by assuming that flexibility made an important contribution. However, Tanaka et al. (2015) were unable to detect any significant contribution of fiber flexibility to the intrinsic viscosities of CNC or NFC suspensions. Thus, it would appear that the flexibility mainly affects systems in which nanocellulose entities are mutually interacting in flow, but maybe not so much when they are widely separated from each other.

Lubrication effects

Friction between contacting surfaces is believed to play an important role with respect to the elastic modulus and other strength characteristics of entangled fibrillar material (Lowys et al. 2001). According to Mewis and Wagner (2009), surface roughness can decrease frictional effects by preventing the close approach of the opposing surfaces. But on the other hand, roughness also can impede the sliding of one surface relative to the other, so the net effect may be hard to predict. Gallier et al. (2014) conducted simulations and showed that surface roughness and inter-particle friction can be expected to contribute significantly to the flocculation within the suspensions and also affect its rheological properties.

Lubrication effects were considered by Bououa et al. (2016a,b). The idea is that liquid medium can tend to hold solid surfaces apart from each other, thereby delaying contact and diminishing the development of frictional forces. As shown by Brenner (1974), such hydrodynamic interactions are expected to significantly affect rheological behavior. Under static or low shear conditions, beyond the yield point, the presence of gels – including nanocellulose suspensions of sufficiently high solids content – can exhibit diverse rheological behavior, depending on the surface charge and the water binding property of fibrils. In the case of high aspect ratio NFC, the application of strain under low shear (beyond the yield point) for continued periods can lead to structure ensemble orientation. The strong mutual electrostatic repulsion of the highly charge nanoparticles and the immobilization of the trapped interstitial water act together to create highly elastic structured zones, that are manifested as rheopectic behavior, i.e. a time-dependent increase in viscosity (Dimic-Misic et al. 2016).

Quantification of Resistance to Flow

Viscometers and rheometers serve various functions in science and in process monitoring. Rotational viscometers measure viscosity at fixed rotational speeds by driving a spindle immersed in the test fluid. By contrast, a rheometer is a device used for measuring the rheological properties over a varied and extended range of conditions. A rheometer can measure both the viscosity and viscoelastic properties of fluids, semi-fluids and solids. It can provide information on the following rheological properties:

- Viscosity as a function of shear rate, shear stress, time, or temperature

- Viscoelastic properties, such as storage (elastic) and loss (viscous) modulus with respect to time, temperature, frequency, and stress/strain

- Transient response-creep and recovery, relaxation modulus

There are two main types of rheometers: controlled strain rheometers and controlled stress rheometers. Controlled strain rheometers apply rotation and measure torque. Controlled stress rheometers apply torque and measure strain. The advantages of a controlled strain rheometer are that the rheological properties of stiff materials and solids can be measured, measurements can be made over a greater dynamic range, and better normal force and dynamic measurements can be made since sample strain is controlled. The advantage of a controlled stress rheometer is that the sample is not forced to move before measurement, enabling weak forces of interaction to be detected. Also, its mechanical design is simpler, and through software control, such devices can mimic controlled strain rheometers. Modern equipment often can perform both controlled-strain and controlled-stress analyses.

Rotational viscometers and rheometers are based in principle on the Searle method of measurement, in which a geometry of known surface area (bob, couette, plate) is in contact with a fluid sample that rests between the geometry and an adjoining surface. The device starts from rest and begins spinning at a preset rotational speed (shear rate). The spinning of the geometry is resisted (shear stress) by the fluid sample. This viscous drag results in a torque value, which can be measured mechanically. The viscosity is calculated from the torque measurement and shear rate. The shear rate is calculated from rotational speed and gap distance between the fixed surface and geometry. In addition to reporting viscosity at a single shear rate, rheometers enable continuous measurements under increasing and decreasing rates of shear to enable a rheogram to be produced. Rheograms are helpful in predicting the flow behavior of materials under several orders of shear and enable the shear thinning and flow recovery of materials to be examined.

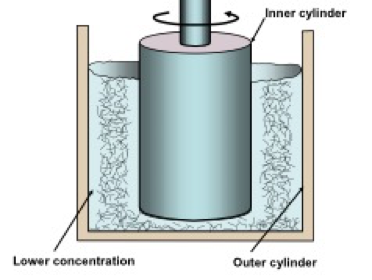

Wall Depletion Effects

It is well known that, in simple shear flow, particles and macromolecules will tend to become depleted at the solid boundaries of flow (Chow et al. 1994; Barnes 1995; Mewis and Wagner 2012; Mosse et al. 2012). For instance, such “wall depletion” has been considered to be a serious issue by those wishing to quantify the rheology of macroscopic fiber suspensions (Bennington et al. 1990; Derakhshandeh et al. 2011; Moss et al. 2012). Figure 9 provides a schematic illustration, assuming couette-type (co-axial cylinder) flow under laminar conditions. Related observations have been reported in the case of nanocellulose suspensions (Saarikoski et al. 2012; Mohtaschemi et al. 2014b; Nechyporchuk et al. 2014, 2015; Saarinen et al. 2014; Kumar et al. 2016b; Naderi and Lindström 2016; Nazari et al. 2016). A variety of explanations for wall depletion have been advanced, and the situation can be summarized by noting that a relatively clear layer near the wall will result in a lower energy state during laminar shearing, i.e. an energetically favorable situation. Slippage effects at the walls of cylindrical-type viscometer devices often can be overcome, at least within certain ranges of experimentation, by installation of vanes or by roughening the walls (Bennington et al. 1990; Barnes 1995; Swerin 1998; Mosse et al. 2012; Mohtaschemi et al. 2014b; Nechyporchuk et al. 2014, 2015; Naderi and Lindström 2016).

Fig. 9. Schematic illustration of depletion of suspended material at the walls (wall slip) when suspensions are exposed to laminar shear flow, especially when the cylinder surfaces are smooth and there are no vanes extending into the annular region

Avoiding apparent wall-slip, or more precisely solids depletion at the sample-wall interface, in such systems requires use of profiled surfaces or specific measuring geometry, e.g. a serrated surface in plate-plate geometry and a vane-in-cup spindle in cylindrical geometry (Mosse et al. 2012; Mohtaschemi et al. 2014a,b). During rheological measurements complicating interparticle interactions in the system are accompanied by those at the particle-geometry interfaces, inducing further instrumental limitations.

Rheological investigations of highly fibrillated cellulose systems have generally followed the classical demand for industrial applications, i.e. low to high shear viscosity and structure recovery. Such measurements may be well suited for the paper and board industry, for example, but for some applications extended low shear conditions are necessary, where it is favorable that the gel properties are preserved. For these applications where applied stress is necessarily below the yield stress, any required dewatering must occur within the initially linear viscoelastic region (LVE). Apparent wall-slip is one of the major challenging effects when measuring rheology of these materials, where the depletion of dispersed particles from the contact region with the measurement geometry walls leaves a liquid layer with dramatically lower viscosity than the bulk viscosity (Nechyporchuc et al. 2015; Nazari et al. 2016; Puisto et al. 2012a).

The magnitude of applied shear on fibrillar hydrogels in bob in cup geometry, without adopting the vane, was found to induce changes in floc structure and a strong wall-slip effect (Karppinen et al. 2012; Martoia et al. 2015), causing phase separation tendency and influencing the thixotropic properties (Dimic-Misic et al. 2015b; Puisto et al. 2012a,b; Nazari et al. 2016; Buscall 2010). The term bob in cup implies that a cylindrical solid rotor, which may have a flat or shallow pointed end, is rotating within a cylindrical cup, often with a narrow annular space. The effects of the electrosteric properties of suspension constituents, temperature of the mixture, and the consistency on the rheological properties were also studied. It was unsurprisingly observed that different systems displayed different rheological behavior. Such findings make it possible in principle to use the technique to probe these properties, albeit in a state requiring deconvolution of the multiple effects described above (Lasseuguette et al. 2008; Fall et al. 2011; Dimic-Misic et al. 2013b,c; Tanaka et al. 2014).

The fact that modifications of ordinary rheology-measuring devices often are needed to assess the effects of structures present in nanocellulose suspensions prompts a question of whether or not the resulting test data represent situations of practical interest in industrial applications. It is proposed here that the presence of highly uniform suspensions of nanocellulose, especially at solids levels where it is possible for cellulosic structures to fill the whole space, may be the exception rather than the rule. It is proposed that many industrially important processes will themselves be subject to the effects of wall depletion.

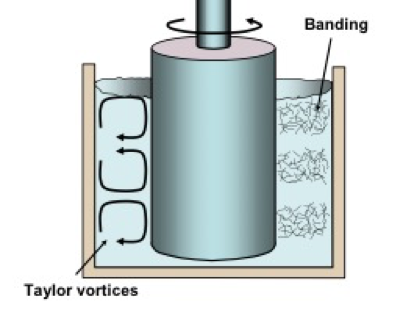

Shear Banding

The term “banding” refers to the development of periodic thickened regions and depleted regions relative to the axis of a couette-type viscometer apparatus (Ovarlez et al. 2009). It appears that the periodicity is related to the phenomenon of Taylor vortices (see Fig. 10), which develop when inertial effects start to become large enough to disrupt the purely laminar flow prevailing at lower velocities (Marcus 1984; Mohtaschemi et al. 2014b). According to Overlez et al. (2009) the phenomenon has its roots in a competition between floc destruction due to flow and floc building and strengthening over the course of time. Such a dynamic situation favors the segregation of relatively strong flocculated network fragments, separated by areas in which the solids are either depleted or more dispersed into individual particles.

Several authors have reported band formation when nanocellulose suspensions have been evaluated in the gap between a rotating cylinder and a stationary cylinder (Karppinen et al. 2012; Mohtaschemi et al. 2014b; Nechyporchuk et al. 2014; Saarinen et al. 2014; Dimic-Misic et al. 2015c; Martiola et al. 2015). However, due to lower centripetal force, there should be less chances of shear band formation at relatively lower speed of rotating cylinders.

Fig. 10. Schematic diagram of couette transitional flow in a rotating viscometer, illustrating the development of Taylor vortices, and the further tendency for formation of bands enriched with suspended particles

MFC and NFC suspensions are thixotropic and prone to form areas of shear banding within the gel suspension. The fibrils of MFC and NFC have both crystalline and amorphous regions (Usov et al. 2015), which both play a role in low-shear induced structuration, as was addressed in previous publications (Dimic-Misic et al. 2015b).

When these fibrillar suspensions are exposed to ultralow shearing for a prolonged time, an observed rheopectic response suggests the development of fibril-fibril collective structure arising from the axially symmetric shear that leads to fibril alignment (Dimic-Misic et al. 2014; Usov et al. 2015). Depending on the fibril charge and aspect ratio, this alignment can result in the conditions ripe for structure condensation (Dalpke and Kerekes 2005; Naderi et al. 2016a; Dimic-Misic et al. 2013c).

Although a vane spindle in cup geometry decreases the effect of apparent wall-slip, shear banding may be present between regions of different stress. This is a manifestation of the thixotropic nature of such systems, i.e. the viscosity depends on the time of application of different levels of shear. The described conditions can lead to the formation of intra-structural regions of different viscosity and thus flow properties, which, when having in mind the highly crystalline nature of the fundamental elements in NFC or MFC, act to as a precursor for aligned planar structures (Martoia et al. 2015; Nechyporchuk et al. 2014, Nazari et al. 2016).

In nanocellulose suspensions it appears that the tendency of band formation can be enhanced by both the tendency for alignment in flow and the tendency for formation of entangled structures. Dimic-Misic et al. (2015c) proposed that the essentially one-dimensional NFC becomes structured as a two-dimensional band of twisted fibrils under the prolonged influence of low shear that is below the yield point.

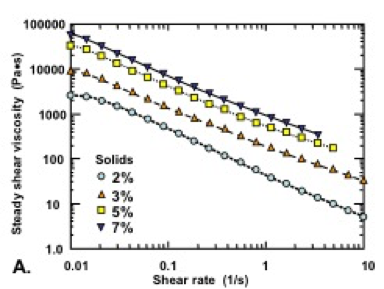

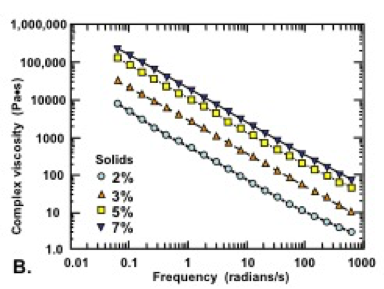

Viscosity vs. Solids Content

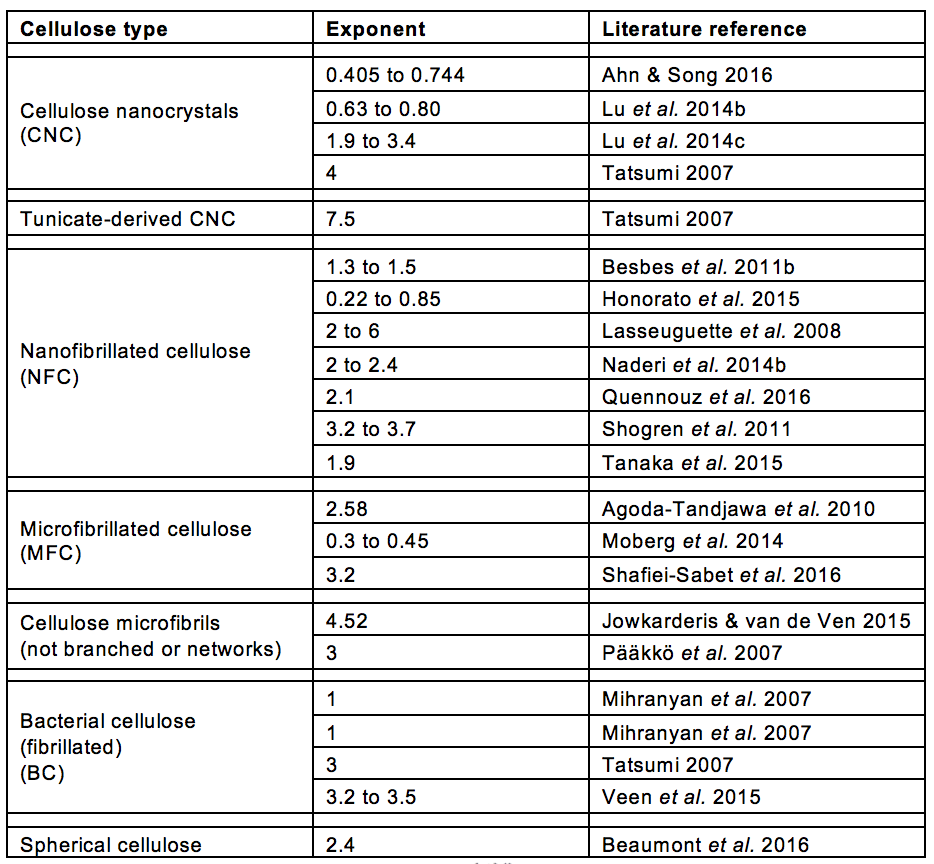

Because of such phenomena as lubrication effects, entanglements, irregular shapes, and fiber flexibility, among others, the relationship between measured viscosity and nanocellulose solids content is likely to be irregular, not necessarily conforming to versions of Eqs. 1 through 12. Table 6, which provides a subset of data from Table A, shows that a range of different values have been observed for the exponent in Eq. 5.

Under flow conditions, an increase of shear rate tends to enhance both the aggregation and fragmentation of MFC (Saarikoski et al. 2012; Saarinen et al. 2014). In the case of NFC, increased shear rate results in deformation of the predominantly gel-like structure, resulting in flow curves showing hysteresis and thixotropic behavior (Illa et al. 2013; Puisto et al. 2012a,b). In complex colloid systems, such as suspensions of NFC or MFC, the final equilibrium state is governed by a number of parameters describing hydrodynamic shear stress that distorts or pulls structures apart, which are often incorporated into the modeling of thixotropy (Coussot et al. 2002, Divoux et al. 2013, Dullaert and Mewis 2006; Hill 2008; Mewis and Wagner 2009).

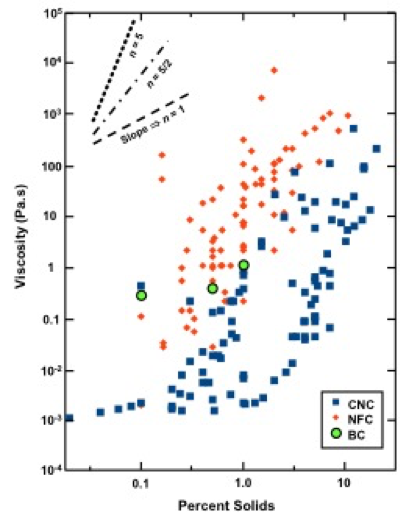

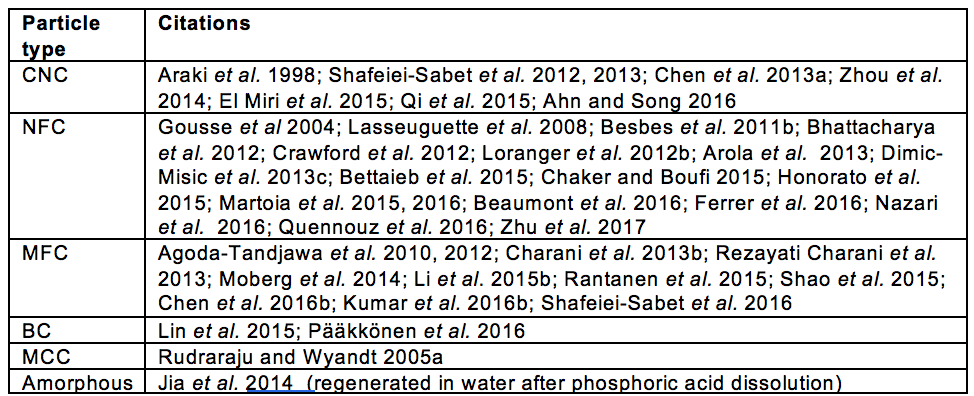

Inspection of Table 6 shows, first of all, that the value of n determined in different studies of nanocellulose suspensions varied widely. Many studies reported values of n in the range of about 1.5 to 6. Certain studies reported much lower values (Mihranyan et al. 2007; Lu et al. 2014b; Moberg et al. 2014; Honorato et al. 2015; Ahn and Song 2016), and the reason for this difference is not readily apparent. The most interesting results were those of Tatusmi (2007) who showed, under the same conditions of testing, that tunicate-derived CNC, having a very high aspect ratio, yielded a much higher value of n in comparison to more usual CNC particles in suspension.

Table 6. Reported Exponents* for Viscosity-Solids Results for Aqueous Suspensions of Nanocellulose

* Exponents refer to the following equation: ![]()

To provide some additional insight into the value of n, data collected from 40 studies considered in the present review are compiled in Fig. 11. In each case, the data correspond to the viscosities (in Pa×s) vs. percent solids, evaluated at a shear rate of 1 s-1 in an aqueous solution having water-like viscosity (not dominated by polyelectrolytes). As shown in the graph, MFC and NFC suspensions (represented by red diamonds) generally exhibited much higher viscosity, at a given solids level, than the CNC suspensions (shown with dark blue squares. This difference is understandable in terms of the much higher aspect ratio of typical highly fibrillated samples, compared to CNC. The bacterial cellulose results (green circles), of which there were only a few data sets reported in the specified manner, generally fell within the range occupied by the highly fibrillated cellulose suspensions. Another point of reference, when considering Fig. 11, is the viscosity of pure water, which can account for the fact that the most dilute suspensions of CNC did not show viscosity values below about 0.001 Pa×s.

Fig. 11. Representation of viscosity-solids data from 40 studies for 1% solids nanocellulose suspensions, under the conditions of a shear rate of 1 s-1 and water-like viscosity of the aqueous solution

It is worth noting that the results corresponding to CNC appeared to follow two contrasting “tracks” in the solids range between about 0.5% and 5%. Two factors appear to be responsible for this separation of the data. On the one hand, relatively high viscosity of CNC suspensions at low shear rates has been observed in studies involving CNCs having relatively high aspect ratio (Lu et al. 2014a; Tang et al. 2014; Wu et al. 2014). Other authors reported relatively high low-shear-rate viscosities of CNC suspensions when the aqueous conditions favored the presence of net attractive forces between the cellulosic surfaces, leading to the development of structures (Li et al. 2015b; Lewis et al. 2016). The gels have inherently high viscosity at the start of shearing, but once the shearing has started, their viscosities drop. Also, if shear rate is constant, (low shear rate for longer periods of time) due to the thixotropic properties, their transient viscosity slowly decreases, or it increases in the case of longer fibrils. The various systems represented in Fig. 11 also would have involved a wide range of ionic strengths, surface charges, and other details of experimentation.

The trend lines at the upper left of the figure represent three possible values of the exponent in Eq. 5. Note that the middle slope, with n = 5/2, represents the trend predicted by Einstein for non-interacting, equal spheres at very low concentration. The steepest slope corresponds to the maximum slope discussed by Mueller et al. (2010). The lower slope, shown here for comparison, represents an exponent of 1.

The high viscosity values at low suspension solids and broad variability between reported values emphasizes two of the greatest challenges for advancing the application and use of these materials in commercial applications. The broad variability causes concern for product consistency, and high viscosity values at low suspension solids imply high costs for pumping and shipping.

Particle Interactions in Flow

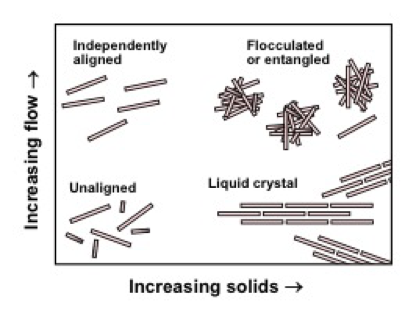

Orientation in flow

For low consistency and non-interacting solid suspensions, particles will have a random arrangement due to Brownian motion of the particles. However, if the particles are interacting, or at relatively high solids concentrations, the particles can aggregate, become aligned, or form or network structure, even forming gel structures having yield behavior, meaning that the viscosity becomes infinite as the shear rate approaches zero. Flow can influence each of these phenomena.

When suspensions of elongated particles are exposed to flow, several related phenomena can occur, including preferential orientation, shear-thinning, and the formation of flocs or entangled groups of fibers. Such phenomena are well known for suspensions of macroscopic fibers (Rahnama et al. 1995; Cui and Grace 2007; Férec et al. 2009; Phan-Thien 2016). For instance, a tendency for cellulosic fibers to become oriented in the direction of flow, which is often perpendicular to the shear fields during laminar flow, has been observed for papermaking pulp fibers (Mason 1954). Alignment in shear flow is brought about by the fact that each half-cycle of shear-induced rotation of an elongated fiber involves a speeding up and a slowing down, where the slowest turning coincides with the flow-aligned condition (Phan-Thien 2016). These phenomena have been carefully studied in laminar shear flow regimes, within which it is possible to precisely predict the rotational, “tumbling” motions of individual fibers (Mewis and Wagner 2012). Berry and Russel (1987) predict that the aligning effects of flow can be reinforced by Brownian motion. Pryamitsyn and Ganesan (2008) predicted a screening effect of Brownian motion, which interacted with the effects of shear in suspensions of rods.

More recently, many authors have reported evidence of orientation of nanocellulose suspensions exposed to laminar shear (Orts et al. 1995, 1998; Ebeling et al. 1999; Bercea and Navard 2000; Noroozi et al. 2014; Hakansson et al. 2016). Ebeling et al. (1999), who used small angle synchrotron X-ray scattering, found that a shear rate of 5 s-1 or higher was sufficient to orient CNCs in a sheared suspension. At lower values of shear rate there was some alignment of larger clusters of CNCs, acting as a group, but such clusters were dispersed by intermediate shear, and the CNCs were oriented as individual particles in the higher shear range.

Shear-thinning

Mongruel and Cloitre (1999) and Switzer and Klingenberg (2003) established that shear thinning behavior, in the case of suspensions of macroscopic fibers, could be attributed to the break-up of clusters and that Newtonian flow behavior was observed at shear rates sufficient to prevent the existence of such clusters. Shear thinning behavior has been widely reported also in the case of nanocellulosic suspensions. Many such cases are listed in Table 7. Based on such reports it is clear that shear-thinning can be regarded as a characteristic feature of nanocellulose suspensions, if the solids content is high enough.

Table 7. Shear Thinning Behavior Reported for Aqueous Suspensions of Nanocellulose

Key: CNC = cellulose nanocrystals; NFC = nanofibrillated cellulose; MFC – microfibrillated cellulose; BC = bacterial cellulose; MCC = microcrystalline cellulose

An interesting question, which might be the subject of future work, is the degree to which shear thinning effects in nanocellulose suspensions can be attributed to particle alignment, which was discussed in the previous section. When particles become aligned, they can be more easily packed into smaller volumes. Likewise, if the volume and amount of particles remain constant, then the mixture may behave as if it is less crowded when there is increasing alignment. Such effects may explain why Bercea and Navard (2000) observed a transition from dilute behavior to gel behavior at a concentration of about (d2/L2) in CNC suspensions under slow shearing conditions, but the transition was shifted to much higher values (approximately d/L) at higher shear rates of shearing. Oguzlu et al. (2017) used similar logic to explain increases in suspension viscosity when the polyelectrolyte carboxymethylcellulose (CMC) was added to nanocellulose suspensions.

Thixotropic systems, i.e. those that exhibit reversible shear-thinning behavior, often show a characteristic time of recovery (Barnes 1997). Thixotropy is important because it can greatly impact the leveling properties of a material after application or during metering. Bercea and Navard (2000) described such processes of recovery in liquid-crystal suspensions of CNC as “fast” in contrast with liquid crystal polymer solutions. Derakhshandeh et al. (2013), in the case of CNC suspensions, found the characteristic recovery time to be generally less than a second and dependent on the shear rate. Orts et al. (1995) found that the relaxation effect occurred more rapidly for shorter microfibrils having aspect ratios near 30. In related work, Le Goff et al. (2014) showed that minutes were required to complete the gelling of suspensions of relatively long CNC particles. In general, the relaxation effects appear to be related to Brownian motion, which tends to restore the random orientation of particles within a characteristic time period.

History-dependent and Irreversible Effects

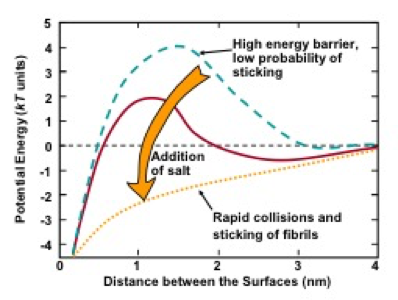

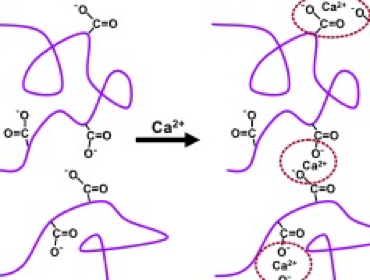

Quasi-irreversible, non-equilibrium effects have been reported in aqueous suspensions of nanocellulose (Puisto et al. 2012b; Derakhshandeh et al. 2013; Mohtaschemi et al. 2014b). According to Mohtaschemi et al. (2014b) such behavior of NFC suspensions implies that viscosity measurements made at relatively low shear rates can be regarded as non-unique and dependent on the flow history. Whereas ideally thixotropic systems can be counted on to return to their previous steady-state viscosity, at a specified shear rate after a delay time, the concern here is about systems that appear to remain trapped in non-equilibrium states, possibly due to non-equilibrium aspects of either the forming or the breaking down of structures.