Proceeding Articles

Latest articles

Poor cross-directional (CD) tension profiles of paper webs cause runnability problems in paper mills as well as in printing presses. This study explored the formation of the cross-directional web tension profile in paper machines. The research programme was implemented in a period of four years. Tension measurements were made during the production in both paper machines and printing machines.

The finite element method (FEM) was applied to explore the build-up mechanisms of the web tension profile. In FEM modelling, the web was constructed from continuum elements and the physical interactions of the elements were defined, for example, by the Hookean law. The FEM analysis has numerous advantages and it is important to investigate the influences of the mechanical conditions and the material properties of the paper web. The simulations made by FEM could quantitatively predict the shape of the tension profile.

The paper web is stretched in many stages through the drying section. Stretching in the machine direction (MD) causes a non-homogeneous stress field in the web because the paper is subjected to mechanical shrinkage which is defined by the Poisson’s ratio of the paper. This typically causes a situation where the edges of the web are slacker than the middle areas, the so-called crying shape. The uneven stress fields in the web also cause a lower MD and CD tensile stiffness because of lower frozen-in-stress in the paper sheet. Further on, the slacker edge areas are affected by higher CD drying shrinkage which further diminishes the tensile stiffness and also leads to higher relaxation in the machine direction.

Several trials were made to control the web tension profile. These included moisture profiling, jet-wire speed, edge flow, strain rate and nip trials. The most effective control was by moisture profiling with the steam box in the press section. The drier sections of the web became tenser and vice versa. This was because the moisture content of the paper has a strong effect on the formation of the tensile stiffness of the paper. The principal shape of the tension profile is convex. According to this study it is impossible to reach an even tension profile with the existing dryer section configurations. However, the tension profile can be adjusted within certain limits by controlling, for example, the development of the moisture profile. These controls play an important role in improving the runnability of the paper machine, the winder and the printing press.

Two different instruments were used to measure web tension. IQTension measures the pressure within an air film that is formed between the paper web and the curved metallic deflection plate. The curved deflection plate is perforated at intervals, so that the pressure sensors connected to the orifices in the plate measure the cross directional (CD) profile of the air pressure, which correlates with the web tension profile. The web tension is measured at a high sampling rate in several parallel positions across the whole web width. In addition, the tensile stiffness profile can be defined by measuring the tension at different draws.

Scanning by Tenscan was used, when there was only a limited space for the measurement, or there was a need for measuring simultaneously with IQTension. Tenscan uses a laser beam to measure the passing time of a propagating membrane wave in the web. Other measurements included normal online measurements in the paper machines. The TSO and shrinkage profile measurements were made in the laboratory.

As the title implies, this paper will discuss papermaking on-line instrumentation, concentrating on sensors for paper quality measurements. The review is intended to explore not just the techniques for measurement, but also the evolution of a particular measurement and the research behind it.

On-line instrumentation will be the primary focus, covering not only the usual structural, mechanical and appearance properties of paper but also certain water system measurements around the papermaking thin/thick stock loop. These measurements will include a discussion of the sensors pertaining to “wet end chemistry” and consistency, with their incorporation into retention control schemes.

Discussion of off-line, laboratory measurements will be included where pertinent to provide a prediction of future on-line sensor availability. The usual papermaking process measurements such as pH, temperature, level, pressure and flow will not be covered.

This paper covers the use of thermoporosimetry to measure the pore size distribution (PSD) of pulp fibers. Thermoporosimetry is based on the melting temperature depression of an absorbate in a porous structure. A discreet or “step” melting procedure, rather than the usual continuous method, is used to melt the absorbate. This method eliminates thermal lag and gives the high temperature accuracy required for measuring large pores.

Measurement of water-saturated chemical pulp fibers using this technique, combined with solute exclusion, indicates a bimodal distribution of cell wall pores. The interpretation of data from water-saturated fibers is complicated by several factors: 1) distortion of the cell wall by ice crystal growth; 2) the depression of water’s melting temperature by osmotic pressure; and 3) inadequate range to cover the larges pores. One way to correct these problems is by replacing the water with cyclohexane. The major disadvantage of this approach is that the cell wall contracts in cyclohexane and its pore structure may change in other ways which are not understood.

Like water, the cyclohexane analysis shows a bimodal distribution of pores. The smaller pores, “micropores”, are less than about 5 nm in diameter, the “macropores” are about 15–700 nm. It was found that there is a quantity of cyclohexane in the cell wall which does not freeze. Analysis of nonfreezing cyclohexane indicates a surface area of about 400 m2/g for kraft pulp. The cyclohexane method is very suitable for studying beating, which primarily involves the opening of larger pores.

Thermal conductivity of paper is a property of importance in the understanding of conductive heat transfer in the pulp and paper industry. For example, heat transfer between a paper web and a heated roll in a nip during calendering. Besides, the trends in the calendering area are to replace machine calenders by soft calenders and to replace cotton filled rolls by polymeric rolls in the supercalenders. As a result, temperatures of heated rolls in calenders are increasing constantly. There is a need for measuring thermal conductivity of paper. Some measurement methods and some values of thermal conductivity are available in the literature. But measurement methods are often reserved to specialists and values of conductivity show great variations. This drove us to develop a rapid method to measure the thermal conductivity of semi-insulated films. Our objective was to be able to measure the thermal conductivity of papers, of polymers and of model coating layers–with simplicity and rapidity, if necessary at the expense of the accuracy. Indeed heat transfer calculations often used a lot of restrictive hypotheses and a measurement of the thermal conductivity with an accuracy of less than 10% is quite sufficient.

NA

- 2001

Oxfordpp 975-998Experimental Technique for Tracking the Evolution of Local Moisture Nonuniformity in Moist Paper from Wet to DryAbstractPDFLocal nonuniformity of moisture content, a basic characteristic of moist paper, affects efficiency and hence cost of paper drying, and may influence product quality. Such local nonuniformity may become even more of a problem with the current interest in combining higher intensity air convection drying and cylinder drying to produce the required higher capacity hybrid dryer sections of the future.

Direct determination of local sheet moisture content under dynamic conditions during drying is unacceptable because the measuring instrument presence would change local moisture content. A novel indirect technique was developed for quantitative, precise determination of local nonuniformity of moist paper by monitoring continuously the local exit pore air temperature at many positions immediately below a moist sheet subjected to air through flow. This technique was used to investigate local non-uniformity for moist machine-formed papers of grammage 19–55 g/m2, and 20–100 g/m2 handsheets of variable formation. The effect of formation and basis weight on local nonuniformity was

quantitatively documented. Formation was characterized using the new method of partitioning formation nonuniformity into its components as a function of scale of formation. The results provide some evidence that it is the components of formation nonuniformity in the range of larger scale of formation, 8 to 37 mm, which most affect moisture local nonuniformity while the formation components at 0.8 to 3 mm scale of formation appear less important. Such knowledge is relevant to the development of the improved drying processes of the future. Calendering is the papermaker’s last chance to reduce thickness variations along the length and width of the finished sheet, and to improve the sheet smoothness. A smoother sheet results in improved print quality, while more uniform thickness profiles improve the winding process. The calendering operation thus improves the quality of the finished product. In recent years there has been an increase in the loads, speeds and temperatures at which soft-nip calenders, whether on or off line, can be operated without mechanical failure of the cover; the result has been an improvement in the surface and printing properties achievable with mechanical printing grades of paper, and an increase in the production rates which can be sustained. As a result, these calenders have slowly replaced traditional machine calenders in new and retrofit installations.

The best available design and trouble-shooting tools for modern machine calenders are based on empirical models, whose coefficients have not been related to fundamental paper or fibre properties. New furnishes therefore require experimental determination of these coefficients, and extrapolation to new calendering conditions involves some risk. As well, there are no published models, empirical or otherwise, for the design and troubleshooting of soft-nip calenders, an unfortunate state of affairs given the increased number of installations of these machines. The purpose of this review is to outline the current understanding of the process, and to identify areas where further research could be useful to allow better prediction of paper properties arising from a change in the equipment or operating conditions.

- 2001

Oxfordpp 1037-1042On the Distribution of Pore Heights in Random Layered Fibre NetworksAbstractPDFNA

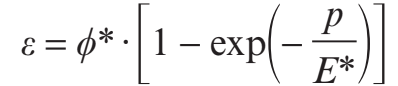

We study the compression behavior in the thickness direction of paper using quasi-static pressure cycles from 0–10 MPa. The reversible component of compression agreed reasonably well with

the following equation:

where

is the volume fraction (porosity) of compressible pores, and E* is the effective elastic modulus characterizing the compression of the pores. The model can be derived both from the height distribution of pore space and from the general linear relationship between logarithmic strain and pressure. In handsheets, the fitted porosity parameter

is the volume fraction (porosity) of compressible pores, and E* is the effective elastic modulus characterizing the compression of the pores. The model can be derived both from the height distribution of pore space and from the general linear relationship between logarithmic strain and pressure. In handsheets, the fitted porosity parameter  ranged from 0.13–0.22 depending on sheet density. The values of the elastic modulus E* varied between 4 and 5 MPa. They could even be set constant at ca. 4.5 MPa without a significant loss of model agreement. Our results suggest that the reversible compression behavior of paper depends primarily on the porosity of the fiber network and only a little on the furnish composition.

ranged from 0.13–0.22 depending on sheet density. The values of the elastic modulus E* varied between 4 and 5 MPa. They could even be set constant at ca. 4.5 MPa without a significant loss of model agreement. Our results suggest that the reversible compression behavior of paper depends primarily on the porosity of the fiber network and only a little on the furnish composition.- 2001

Oxfordpp 1069-1113Surface Treatment: Sizepress Tradition, Current Development and a Pigmented Chemical FutureAbstractPDFEvolution of surface improvements on paper are driven by tech- nical needs, in respect of printing and writing, economical drivers, such as mineral versus fibre cost and market niche exploitation, runnability and aesthetic requirements. From the simple anti- feathering absorption control of hydrophobisers, such as starch, to the sophistication of digital printing, the need to modify the surface of paper is an accepted criterion for investment in our industry. Simple pond and roll application has, through increases in speed and the application of pigmentising, developed in recent times to controlled film application processes. The demands throughout these developments for the scientific understanding of the interactional processes between fluids and substrate: absorption, hydraulic penetration, basepaper fibre debonding and roughening: and the complex rheology of pigment suspensions, based on stability, surface chemical and hydrodynamic criteria, have usually been met retrospectively. The machine concept or application is developed, installed, trouble-shooting achieves compatibility in the industrial environment and only latterly does the question of optimisation through a thorough scientific analysis come to the fore. By studying the models and accepted design criteria that have emerged throughout this evolution, it is pro- posed that advances through extrapolation of the models and by seeking new untried dimensions of the models can be made which can act to fuel the development further. Notwithstanding that current knowledge in multivariate applications inevitably remains inexact, the author attempts to demonstrate how the concepts available today could be extended to build potential for develop- ment in the future. Mechanics of suspension flow, dewatering and network absorption remain the primary controlling parameters and a critical review of past and present assumptions and new research is timely in order to re-fashion the directions that can be deduced. Rates of absorption as a function of available fluid vol- ume arising from the resistance dynamics of rapid dewatering provide a key opportunity for improving surface coating holdout especially in the challenging on-machine context where the time- scale for hydrophobising is too short and the wettability and moisture profiles are at their most critical. On the basis of this review, it is proposed that high rate absorption, through the use, for example, of ultra-high surface area filler pigments in the substrate, together with rapid low solids immobilisation of pig- mentised formulations with disparate coating and basepaper permeabilities, provides a means of maximising the potential for surface treatment applications both at high speed and in the con- text of sophisticated niche product development. The roles of basepaper and pigment structure are therefore also an integral part of the review.