Research Articles

Latest articles

- Researchpp 6668-6678Imren, E. (2022). "Effect of weathering conditions on wood surface roughness: Optimal parameters determined via Taguchi analysis," BioResources 17(4), 6668-6678.AbstractArticlePDF

Wood when exposed to accelerated weathering conditions is deteriorated as a result of factors such as UV rays, temperature, and relative humidity changes. The surface roughness of wood also undergoes substantial changes. In this study, the effect of accelerated weathering conditions on surface roughness changes on Scots pine (Pinus sylvestris L.) and poplar (Populus x euroamericana) wood surfaces were investigated using the Taguchi method. The parameters most affecting the surface roughness were radial direction, 0.5 W/m2 UV, 4 h conditioning time, and 45 min water for Scots pine, and tangential direction, 0.5 W/m2 UV, 2 h conditioning, and 15 min water for poplar wood. The variables that most affected the surface roughness were conditioning with 38% in Scots pine wood and wavelength with 31% in poplar wood.

- Researchpp 6679-6691Li, Y., Wei, H., Liu, S., He, Z., and Zhao, W. (2022). "Mechanical properties and flow characteristics of dolomite-based porous supports for catalysts using different pore-forming agents," BioResources 17(4), 6679-6691.AbstractArticlePDF

Three kinds of pore-forming agents (corn flour, starch, and biochar) were selected to prepare dolomite-based porous ceramic catalyst carriers with good mechanical properties. Pore-forming agents occupy space within preformed agglomerates, such that after the pyrolysis and sintering have been completed there are spaces within the resulting ceramic material. Porous ceramic samples prepared with biochar exhibited high apparent porosity and water absorption. By contrast, the apparent porosity of the porous ceramic samples prepared with starch as the pore-forming agent was low. When the ratio of the dolomite to quartz sand in the ceramic aggregate was changed from 4:6 to 3:7, the change of the apparent porosity of the porous ceramic samples made with starch as a pore-forming agent was very small, with high bulk density and compressive strength. Compared with corn flour and biochar, starch was less suitable as a pore-forming agent for porous ceramics. The apparent porosity and water absorption of the porous ceramics prepared with biochar as a pore-forming agent decreased slightly. But its bulk density and thermal conductivity were increased. This is mainly attributable to the fact that biochar is lighter, but it performs well in terms of mechanical strength and thermal conductivity.

- Researchpp 6692-6705Cai, Z., Wang, X., Song, X., and Xu, S. (2022). "Performance of binderless board manufactured using camphor tree residue," BioResources 17(4), 6692-6705.AbstractArticlePDF

Residue of the branch wood of camphor tree (Cinnamomum camphora) was used to manufacture binder-free biodegradable biomass fiberboard (bio-board) by the wet method. To investigate the mechanical properties of the bio-board, bending rupture stress and tensile rupture stress tests were measured and the effect of heating temperature and applied pressure on the performance of the bio-board was evaluated. Scanning electron microscopy (SEM) and Fourier transform infrared spectroscopy (FTIR) were used to analyze the influencing factors on the microstructure and bond quality of the bio-boards. The overall density of the bio-boards exceeded 0.8 g/cm3 and the moisture content was below 10%, which conformed to the JIS A 5908 standard (2014) for the hardboard S20 type design specification. The bending rupture stress and tensile rupture stress continued to increase, and the dimensional stability continuously improved as the applied pressure and the heating temperature increased. However, when the heating temperature exceeded 170 °C, the increase in the rupture stress slowed down and the dimensional stability had been improved. Furthermore, increasing the heating temperature was more conducive for optimizing the bio-board’s performance than increasing the applied pressure.

- Researchpp 6706-6717Du, H., Ma, Y., Li, R., Lei, T., and Wu, P. (2022). "Effect of vibrational frequency on alfalfa opening compression process," BioResources 17(4), 6706-6717.AbstractArticlePDF

To reveal the action mechanism of vibration frequency in alfalfa opening compression, a self-developed vibration compression test system was used to evaluate the variation of compression force during alfalfa open compression. A faster vibration frequency yielded a smaller compression force required for compressing alfalfa into blocks. Compared with free vibration compression, vibration compression was beneficial to release the internal stress of alfalfa block, reduce the forming pressure, and stabilize the high density. In the range of test vibration frequency, when the frequency was 15 Hz, the residual internal stress release ratio of alfalfa block was the highest, and the stable density of alfalfa block was the largest. Considering the pressure and alfalfa block density comprehensively, the optimized vibration frequency was approximately 15 Hz.

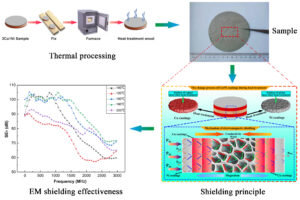

- Researchpp 6718-6739Pan, Y., Dai, M., Zheng, X., Yun, L., Qiu, F., Yang, D., Deng, C., Guo, Q., and Huang, J. (2022). "Micro-nanoarchitectonics of electroless Cu/Ni composite materials based on wood via heat treatment," BioResources 17(4), 6718-6739.AbstractArticlePDF

This research aims to optimize the comprehensive performance of wood-based electromagnetic shielding interference (EMI) materials and master the effect of heat treatment on its coating density, interfacial morphology, conductivity, and hydrophobic and electromagnetic shielding. The results showed that the surface roughness of composite coatings was 11.0 μm when the wood was conducted via electroless two deposition Cu and one Ni and the heat treatment temperature was 150 °C. The composite coating’s surface gradually became more uniform with increasing temperature. The coating’s thickness via 120 °C heat treatment was 97.5 μm. Energy Dispersive Spectroscopy (EDS) spectra verified the existence of Cu and Ni particles. The heat treatment had an obvious influence on conductivity of composite materials and the pore network structure. The contact angle of composite materials reached 119°. The average electromagnetic shielding efficiency via 180 °C heat treatment was up to 91.4 dB in the frequency ranging from 300 to 3.0 GHz, which verified that the composite materials can shield 99.99% of the incident electromagnetic wave energy. The conductivity gradient structure can realize multi-dielectric interface loss and multiple reflection loss.

- Researchpp 6740-6760Kim, M., Oh, J., and Kim, G. (2022). "Comparison of fungal diversity on woods with different fungal susceptibility during above-ground exposure," BioResources 17(4), 6740-6760.AbstractArticlePDF

Sequential fungal changes that occur on three types of wood are described, namely naturally durable wood, preservative-treated wood, and radiata pine (considered as untreated wood) for above-ground use, during a four-year survey period. The surveys were conducted thrice at 1, 2, and 4 years of exposure. During the first and second years of exposure, both total fungal isolates and species diversity were low in each wood sample, with ascomycetes being the most prevalent. Additionally, the predominant species displayed a trivial impact on wood decay. However, after two years of exposure, the number of fungal communities increased sharply, accompanied by a considerable shift in the diversity of basidiomycetes, some of which established themselves as dominant species. The survey provides a snapshot of the initial stages of wood decay. Further, it reiterates that while fungal communities on wood are influenced by spores or hyphae in the surrounding air, colonization is further modulated by fungal susceptibility on the basis of durability. An expanded study is necessary for better comprehension of the processes involved in wood decay in their entirety.

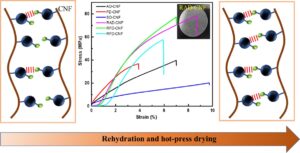

- Researchpp 6761-6774Liang, C., Zhang, J., Fu, G., Jin, Z., Lu, Q., Li, X., and Yue, D. (2022). "Effect of bonding on the structure and properties of nanocellulose films," BioResources 17(4), 6761-6774.AbstractArticlePDF

In this study, cellulose nanofibers (CNF) were obtained by chemical pretreatment using a rubberwood substrate. Different forms of drying were used to prepare three CNF film variants. Each of the films was rehydrated and hot-pressed to introduce more hydrogen bonds, and the films were characterized in terms of density and porosity, micromorphology, and mechanical properties. The mechanical properties of the films improved substantially after rehydration and hot-press drying. The tensile strengths of the films increased to approximately two to three times that of the original CNF films. These results with micromorphological observations suggest that adjusting the water content during CNF drying can significantly improve the formation of 3D networks in the films, thus imparting higher hydrogen bonding content to the films and improving the mechanical properties of the substrates. This study provides a theoretical basis for the formation of high-strength materials through water molecule-induced assembly and broadens the application of biomass cellulose materials in emerging fields.

- Researchpp 6775-6788Zhang, M., Liu, Q., Twebaze, C. B., Zhuang, X., Kimani, M., Zheng, G., Wang, Z., Zhao, J., Zhu, R., and Wang, R. (2022). "The effect of activated water degumming technique on alkali-pretreated banana fiber," BioResources 17(4), 6775-6788.AbstractArticlePDF

There is a need for sustainable ways of processing plant fibers. Most chemical degumming methods pose a threat to the eco-system because of the presence of toxins during disposal. This study aimed to find sustainable ways of processing banana fiber with less harm to the environment. Sodium hydroxide (NaOH) and activated water were utilized for degumming and softening of the banana fiber. Activated water is an aqueous solution of electrolyte with strongly oxidizing active substances prepared by an electrochemical method. The alkali-pretreated banana fiber were immersed in activated water to refine banana fiber. The results from the study show that activated water further refined the fibers down to 39.7 µm diameter after NaOH pretreatment and also achieved better whiteness at 74.7%. The electrochemically activated water solutions displayed a promising effect in removing lignin, hemicellulose, and other impurities. The fibers of this quality could be used in the spinning of yarn and for other textile applications. Various analytical techniques, including digital microscope, scanning electron microscope, Fourier transform Infrared spectroscopy, X-ray diffractometry, tensile test, and whiteness test were utilized. These tests confirmed that the activated water used on banana fiber enhanced physical, chemical, and morphological properties.

- Researchpp 6789-6803Aysal Keskin, S., and Sahin Kol, H. (2022). "Effects of manufacturing conditions on the properties of boric acid/melamine-urea-formaldehyde microcapsules prepared by in situ polymerization: Its inhibition behavior on wood destroying fungi," BioResources 17(4), 6789-6803.AbstractArticlePDF

Water-soluble boric acid (BA) was microencapsulated by in situ polymerization with a melamine-urea formaldehyde shell. The effects of core-shell ratio, time, and temperature on the microcapsule characteristics were investigated. The microencapsulated BA was tested for its effectiveness against wood-destroying fungi. The results showed that the core:shell ratio affected the individuality of the microcapsules (MCs), and the most individual microcapsules were those with the 1:1 core:shell ratio. The microencapsulation temperature at the 1:1 core:shell ratio affected the surface porosity and size spectrum of MCs. The surface was porous, and the size spectrum was narrow at 50 °C. The microencapsulation reaction time at the 1:1 core-shell ratio did not have a considerable effect on the MC size. Although the MC size spectrum varied in the studied parameters (core: shell ratio, temperature, time), the average MC sizes were large enough to pass through the bordered pits of the softwood cell wall. Slow boron release was obtained by optimizing the MC preparation parameters. The optimum microencapsulation parameters for slow release of BA were the 1:1 core:shell ratio, 50 °C, and time of 120 min. The capsules produced at optimum microencapsulation parameters were biologically active against the fungus Coniophora puteana and leaching resistance was improved.

- Researchpp 6804-6817Spirchez, C., and Lunguleasa, A. (2022). "Torrefaction of spruce, beech, and oak pellets in order to improve calorific value," BioResources 17(4), 6804-6817.AbstractArticlePDF

Native spruce, beech, and oak pellets were treated by torrefaction. The torrefaction was performed without oxygen, in an electric oven, at temperatures of 170 °C, 190 °C, and 210 °C and treatment periods of 1, 2, and 3 h. The results showed an increase in the calorific value of the pellets by raising the parameters of the treatment regime (temperature and duration), achieving maximum values of 18.93 MJ/kg in the case of beech pellets for 3 h and 190 °C, 18.97 MJ/kg for the roughest regime with 3 h and 210 °C in the case of spruce pellets, and 18.84 MJ/kg in the case of oak pellets with 3 h and 190 °C. The torrefaction process for beech and oak must be stopped at 190 °C and 3 hours, becoming ineffective after these values of the treatment regime. The shear strength of the pellets were decreased slightly (10 to 15%) by the torrefaction treatment, but ash content slightly increased from 17.7% for spruce pellets to 29.1% for beech pellets. The results suggest that direct torrefaction of native pellets is possible without the use of nitrogen, i.e., by turning off the oxygen intake in the torrefaction oven, with good results for increasing the calorific value with 8.7% for beech pellets, 7.5% for spruce pellets, and 7.9% for oak pellets.