Research Articles

Latest articles

- Researchpp 5548-5573Rahman, M. R., James, A. A., Marwani, H. M., Hamdan, S. Said, K. A. M., Bakri, M. K., Uddin, J., Matin, M. M., Madkhali, O., Aljabri, M. D., and Rahman, M. M. (2023). “Synthesis and characterization of ground biochar (GB) reinforced composites for removal of heavy metal from palm oil mill effluent (POME),” BioResources 18(3), 5548-5573.AbstractArticlePDF

Heavy metal contamination ruins the ecosystem and water quality. The adsorption method for heavy metal remediation is preferred because of its low cost and high efficiency. This work created eco-friendly ground biochar (GB) biomass-based derivatives reinforced polylactic acid (PLA) with titanium dioxide (TiO2). The composites improved palm oil mill effluent (POME) conditions, and H2SO4 activation increased pores by 80%. PLA and TiO2 altered GB characteristics, according to FTIR analysis. A significant adhesion interaction showed that GB, PLA, and TiO2 particles were compatible. Ball milling’s shear force increased surface area, according to Brunauer-Emmett-Teller (BET) research. Particle size reduction increased GB porosity. Scanning electron microscopy (SEM) was used to study the porous structure of GB and the synergistic effect of PLA and TiO2 on POME during treatment. The SEM showed several components on the composite surface, demonstrating its efficacy. Atomic absorption spectroscopy (AAS) showed that sample C’s composite, which had the most GB, decreased POME heavy metals by 94.4% manganese (Mn), 88.4% cadmium (Cd), and 94.4% zinc (Zn). The resulting POME met the Malaysian Department of Environment’s POME discharge limit by reducing chemical oxygen demand (COD), total suspended solids (TSS), turbidity, and pH.

- Researchpp 5574-5584Yang, G., Wang, X., and Zhong, D. (2023). “Properties of engineered wood flooring with cold-pressing and emulsion polymer isocyanate adhesive,” BioResources 18(3), 5574-5584.AbstractArticlePDF

For the sake of improving the product quality and economy, a series of cold-pressing experiments were carried out to investigate the material properties of engineered wood flooring with emulsion polymer isocyanate adhesive. Effect of pressing time, pressure, and adhesive spreading rate on modulus of elasticity (MOE) and modulus of rupture (MOR) was analyzed based on orthogonal experimental design. According to the results, both the MOE and MOR were positively correlated with pressing pressure and adhesive spreading rate. The MOE first increased and then decreased with the increase of pressing time, and MOR showed an increasing trend with the pressing time. Meanwhile, pressing time had the greatest effect on the MOE, followed by adhesive spreading rate, and pressing pressure. However, adhesive spreading rate had the greatest influence on the MOE, followed by pressing time and pressure. Furthermore, pressing time had a significant contribution to both MOE and MOR, and adhesive spread rate had a significant effect on only the MOR. Finally, the optimal cold-pressing condition was determined as 18 s pressing time, 1.25 MPa pressure, and 200 g/m3 adhesive spreading rate, and it is proposed for application in the industrial cold pressing of engineered wood flooring for the highest MOE, MOR, and production benefit.

- Researchpp 5585-5598Limhengha, S., Chueangchayaphan, N., Karrila, S., Madmaeroh, N., and Yangthong, H. (2023). “Properties and cost of natural rubber latex foam using biomass ash filler from agarwood pellets,” BioResources 18(3), 5585-5598.AbstractArticlePDF

The purpose of this work was to add value to biomass ash, which is a waste product from combustion of agarwood pellets as fuel. Ash was used as filler in accordance with the Bio-Circular-Green economy model to reduce the cost of manufacture of natural rubber latex foam (NRLF) produced with the Dunlop technique. The agarwood pellet biomass fuel was heated in an incinerator at 700 to 750 °C for 6 h to start the process. The mixture was then passed through a 120-mesh sieve after ball milling for 72 h. The next step involved dispersing 10% agarwood pellet biomass ash (APBA) at 0, 1.5, 2.5, 3.5, or 4.5 phr loadings in latex. This was followed by other actions such as visual inspection of the foaming and gelling stages. The influence of APBA loading on density, hardness, compression set and morphological properties of NRLF were investigated, and also the cost of production was estimated. The findings revealed that NRLF with 1.5 phr of APBA exhibited good physical properties, having a smooth surface and small foam cells. Moreover, the compression set properties of NRLF with 1.5 phr APBA comply with the Thai Industrial Product Standard (TIS 173-2529) for NRLF (Industrial Product Standard Act, 1986). Regarding the production costs, they were below those of filler- free NRLF by 0.03 USD/kg.

- Researchpp 5599-5622Kanking, S., Pulngern, T., Rosarpitak, V., and Sombatsompop, N. (2023). “Mechanical performance and anti-fungal and anti-algal properties for teakwood/parawood/PVC composites in UV-weathering and seawater immersion conditions,” BioResources 18(3), 5599-5622.AbstractArticlePDF

This work examined teakwood and parawood in wood/poly(vinyl chloride) composite (WPVC) materials under UV-weathering and seawater immersion. The mechanical properties as well as anti-fungal and anti-algal performance were considered. Teakwood and parawood (a rubberwood product) in WPVC materials at ratios of 0:100, 20:80, 40:60, 50:50, 60:40, 80:20, and 100:0 were investigated. UV-weathering ageing periods of 0 to 32 days and seawater immersion periods of 0 to 90 were studied. Aspergillus niger TISTR 3012 and Chlorella vulgaris TISTR 8580 were used as marine fungi and marine algae, respectively. Higher parawood content (in formulations of 0:100, 20:80 and 40:60) in WPVC composite materials enabled better mechanical properties than those of higher teakwood content (in formulations of 60:40, 80:20 and 100:0). Seawater immersion caused more deterioration of WPVC composite materials than UV-weathering ageing. Both anti-microbial agents and wood particles are potentially used in WPVC composite materials for anti-microbial properties, including the percentage reduction of fungal and algal growth. Increasing UV-weathering ageing and seawater immersion periods decreased the percentage reduction of fungal growth, but increased the percentage reduction of algal growth in WPVC composite materials. The results suggested higher parawood content (in a formulation of 20:80) for WPVC composite materials for coastal environment applications.

- Researchpp 5623-5634Foti, D., Amiandamhen, S. O., Fernando, D., Letoffe, A., and Adamopoulos, S. (2023). “Heat treatment’s effect on properties of polystyrene from building demolitions,” BioResources 18(3), 5623-5634.AbstractArticlePDF

Polystyrene (PS) is a synthetic polymer widely used as a packaging material and in thermal insulation of buildings. At end-of-life, there are not many recycling management options of PS because of the reduced incentive and high cost. PS is non-biodegradable, and consequently, the disposal of this product causes serious health and environmental concerns. This study discusses the application of thermal treatment to modify the properties of PS waste foams. Both expanded and extended polystyrene were collected from building demolitions and subjected to different temperature treatments and duration. The effect of the treatment was investigated on the density, structure, glass transition temperature, mechanical properties (hardness, compression strength), thermal conductivity, and sound absorption of treated PS. The results showed that density increased with treatment temperature, which had a corresponding effect on the evaluated properties. The study concluded that thermal treatment is a beneficial way to improve the mechanical properties of PS waste from buildings. However, a trade-off between application and relevance still needs to be ascertained, as the thermal and acoustic insulation properties of PS decreased with the treatment.

- Researchpp 5635-5654Pařil, P., Baar, J., and Rousek, R. (2023). “Innovative, low-cost eco-composite boards produced from high-energy milled wood, plastic waste, and bio-polymer,” BioResources 18(3), 5635-5654.AbstractArticlePDF

Currently, there is a big issue with waste, its processing and subsequent use. While there are many initiatives to replace materials that are poorly biodegradable, it is necessary to process and ideally use the waste that is already produced. In this study, the properties of composite boards made of waste materials and biodegradable polymer were investigated. The composite boards were made from wood and plastic waste using high-energy milling technology. This technology for material preparation is promising, as it includes controlling the morphology of particles, homogenizing the mixture, and drying the material during the milling process. The results showed higher flexural strength of high-density fiberboard (HDF) boards compared with tested composites with one exception. Wood/poly(3-hydroxybutyrate-co-3-hydroxyvalerate) [PHBV] composite exhibited 30% higher modulus of elasticity (MOE) than HDF due to the higher modulus of PHBV. The lowest thickness swelling (3%) and water absorption (12%) were measured for wood/recycled high density polythene (rHDPE) composite. The HDF boards recorded the lowest dimensional stability. The highest water absorption of tested composites was measured for wood/PHBV composite. The resistance to wood-rotting fungi was greatest for wood/PHBV composite containing marble powder, which corresponded to the results of scanning electron microscopy.

- Researchpp 5655-5664Li, Y., Ma, Y., Yang, X., Du, H., Meng, F., and Xuan, C. (2023). “Effects of moisture and particle size on alfalfa’s thermal conductance, diffusivity, and heat capacity,” BioResources 18(3), 5655-5664.AbstractArticlePDF

Researching the thermal characteristic parameters of alfalfa is of fundamental importance for accurately measuring heat transfer and distribution during the compression process. Therefore, the thermal characteristic parameters were measured using the transient plane heat source method. Additionally, the study examined the impact of moisture content and particle size on the thermal characteristic parameters of alfalfa. The experimental results indicated that the thermal conductivity of alfalfa increased with higher moisture content, and it decreased with the increase of particle size. Similarly, the specific heat capacity increased with higher water content, while the particle size had little effect on specific heat capacity. The thermal diffusion coefficient initially decreased and then stabilized with higher water content. Moreover, the influence of particle size on thermal diffusion coefficient was not significant. The obtained thermal characteristic parameters are valuable for investigating temperature changes during the densification process of alfalfa.

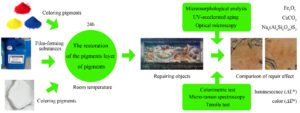

- Researchpp 5665-5682Li, Q., Sang, T., Li, Y., Li, M., and Sun, Q. (2023). “Intangible cultural heritage complexes in China: Representation and restoration of pigmented reliefs in Kaiping Diaolou,” BioResources 18(3), 5665-5682.AbstractArticlePDF

Restoration techniques were explored for the patterns, materials, and surface pigments of the pigments decoration art of Kaiping Diaolou and Villages, a world cultural heritage site in southern China. Field investigation was supplemented by scanning electron microscopy, microscopic Raman spectroscopy characterization, colorimetric tests, and tensile tests. Materials and concepts for the restoration of the Kaiping Diaolou pigments were analyzed. Raman spectroscopy was used to characterize the surface pigments display of pigments decorative patterns. The main colors of restoration included green, red, white, and blue. The green color was a mixture of colored copper arsenate minerals. The red color was made of hematite (Fe2O3). White was calcite, and blue was lapis lazuli or synthetic ultramarine. SEM revealed both pigments show similar flake flocculent section morphologies. UV accelerated aging experiments showed that the Ultraviolet absorber and antioxidants effectively inhibited the degradation of the interface matrix. The interface was less prone to cracking. The tension test showed that the bond stress reached a maximum value of 0.193 MPa at a curing temperature of 20 °C under 95% ambient humidity. The results provide strong evidence for pigment restoration in Kaiping Diaolou. This study also provides a scientific reference for the pigment conservation of other architectural decorations from the same historical period.

- Researchpp 5683-5702Pei, P., Zou, R., Wang, X., Liu, J., Liu, L., Deng, X., Li, X., Yu, M., Tan, J., and Li, S. (2023). “Biocomposite optimization with NaOH-modified bagasse fiber, polybutylene succinate, and poly(lactic acid) using RSM approach,” BioResources 18(3), 5683-5702.AbstractArticlePDF

Alkali-treated bagasse fiber was used as a process variable for optimization of the properties of polybutylene succinate/poly(lactic acid)-based biocomposites using Box-Behnken design (BBD) and response surface methodology (RSM). The optimum conditions for three factors, i.e., NaOH-treated bagasse fiber (0.55 to 1.65 g), polybutylene succinate (1.1 to 2.3 g), and poly(lactic acid) (2.2 to 3.4 g) on the bending strength of biocomposite were investigated. The optimum combination was 0.91 g of NaOH-treated bagasse fiber, 1.14 g of polybutylene succinate, and 3.10 g of poly(lactic acid). The bending strength for NaOH-treated bagasse fiber/polybutylene succinate/ poly(lactic acid) composite was 27.0 MPa, which was 26.0% higher than native bagasse fiber-based composite. The composites were also characterized by thermogravimetric analysis, mechanical testing, Fourier transform infrared, scanning electron microscopy, water absorption, and contact angle tests. Results demonstrated that the bending strength, impact strength, and tensile strength of alkali treated bagasse fiber-based biocomposite increased by 26.0%, 15.5%, and 23.3%, separately, compared with native bagasse-based composite after sequential homogenization, compounding, and hot pressing. The hydrophobicity for alkali-treated bagasse fiber/PBS/PLA was also improved. Thus, NaOH-treated biomass materials/biodegradable polymer was judged to be suitable for preparing green composite materials.

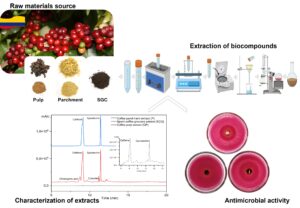

- Researchpp 5703-5723Arango-Agudelo, E., Rendón-Muñóz, Y., Cadena-Chamorro, E., Santa, J. F., and Buitrago-Sierra, R. (2023). “Evaluation of Colombian coffee waste to produce antioxidant extracts,” BioResources 18(3), 5703-5723.AbstractArticlePDF

During coffee production, several types of waste such as pulp, mucilage, husk, parchment, coffee silver skin, and spent coffee grounds are generated. The amount of coffee waste and their environmental issues require effective valorization. Those wastes can be used as a source of bioactive compounds. In this work, solid-liquid extraction was used to obtain different solutions, and their phenolic contents, antioxidant capacities, fatty acid profiles, and antimicrobial activities were evaluated. Characterization of the waste materials showed that the highest yield (18.8%) was obtained for spent-coffee grounds. The highest total phenolic contents, caffeine and epicatechin, was observed for coffee pulp extract. Catechin was only observed for parchment. The lipid fraction in the coffee by-products extracts indicated that the spent coffee ground had a higher amount of total lipids, followed by the pulp, and finally the parchment. The most predominant fatty acids in all the extracts were palmitic, stearic, linoleic, oleic, arachidic, and behenic. However, parchment and coffee pulp extracts exhibited an inhibition halo against E. coli bacteria growth.