Volume 16 Issue 4

Latest articles

- Researchpp 7884-7900Rajko, Ľ., Koleda, P., Barcík, Š., & Koleda, P. (2021). "Technical and technological factors’ effects on quality of the machined surface and energetic efficiency when planar milling heat-treated meranti wood," BioResources 16(4), 7884-7900.AbstractArticlePDF

As heat-treated wood has an ever-increasing application, the research of its machining is the subject of many studies. This article investigated the technical, technological, material, and tool-related factors that influence the quality of the machined surface (average roughness Ra) and energy consumption during the process of planar milling of heat-treated meranti wood. The experimental measurements were performed on samples that were treated by four methods at temperatures of 160 °C, 180 °C, 200 °C, and 220 °C. One sample was in its natural state. The cutting conditions were as follows: feed rates 6 m × min-1, 10 m × min-1, and 15 m × min-1, cutting speeds of 20 m × s-1, 40 m × s-1, and 60 m × s-1, and tool rake angles of 20°, 25°, and 30°. Experimental measurement of the surface roughness was performed using an LPM – 4 profilometer. Individual measurements of cutting power were performed via a frequency converter. The experiments determined the effects of the individual parameters on surface roughness in the following order: rake angle, heat treatment of the material, feed rate, and cutting speed. The effects of observed parameters on energetic efficiency were in the order: cutting speed, feed rate, rake angle, and heat treatment.

- Researchpp 7901-7915Büyüksarı, Ü., and Özyürek, Ö. (2021). "Dimensional stability and mechanical properties of bio-based composites produced from hydro-thermal treated wheat straw," BioResources 16(4), 7901-7915.AbstractArticlePDF

Bio-composites were produced from untreated (UT) and hydro-thermally treated (HTT) wheat straw (WS) particles and wood, and their dimensional stability and mechanical properties were investigated. The HTT treatment consisted of subjecting the WS particles to a steam explosion process for 8 min at 180 °C. The HTT and UT WS particles were mixed with the wood particles at 10, 20, 30, and 40% ratios. The physical properties, including density, water absorption (WA), and thickness swelling (TS), were determined for the bio-based composites. The mechanical properties evaluated included the modulus of rupture, modulus of elasticity, and internal bond strength. Statistical analyses showed that the hydro-thermal treatment and the WS ratio had significant effects on the dimensional stability and mechanical properties of the bio-composites. The WA of the composites after 2-h and 24-h rose significantly when the HTT WS particle ratio was increased from 10 to 40%. The 2-h and 24-h WA values of HTT-10 were 6.3% and 5.3% lower than those of UT-10, respectively. Improvements in the 2-h TS value were achieved by the HTT WS particles at the 10% ratio, and in the 24-h TS value at the 10 and 40% ratios. The mechanical properties of the composites were higher in the HTT group, but decreased in both the UT and HTT groups as the WS ratio increased.

- Researchpp 7916-7934Aluvihare Gedara, A. K., Chianella, I., Bhattacharyya, D., Endrino, J. L., and Zhang, Q. (2021). "Alkali-treated wheat gluten cross-linked with sodium alginate as a bio-based wood adhesive for interior grade particleboard," BioResources 16(4), 7916-7934.AbstractArticlePDF

A bio-based wood adhesive formulation free of formaldehyde and made from alkali-treated wheat gluten (WG) and sodium alginate (SA) was developed. Its formulation was optimised, and it was characterised by Fourier Transform Infrared (FT-IR) spectroscopy. The bio-adhesive was utilized to make particleboards both with virgin wood particles and recycled wood particles. A dry bio-adhesive content of 35% (w/w) was used to make samples with both type of particles. Single-layer samples of 10 mm thickness were obtained using wood particles of 1 mm (both virgin and recycled). These samples then were subjected to 3-point bending tests. Whereas the bending strength of samples made with recycled wood particles was 18.09 N/m2 and therefore satisfied Type 18 of the Japanese industrial standards (JIS A 5908:2015), the bending strength of the samples made with virgin wood particles was 8.08 N/m2 and satisfied ‘Type 8 Base particleboard Decorative particleboard’ of the Japanese standards. The density of particleboard samples made from recycled wood particles was 916 kg/m3, while that of samples made from virgin wood particles was 732 kg/m3. The alkali-treated WG and SA bio-adhesive has the potential to be used to re-manufacture particleboards, which can then be recycled and not disposed in landfills.

- Researchpp 7935-7952Tsalagkas, D., Börcsök, Z., Pásztory, Z., Gryc, V., Csóka, L., and Giagli, K. (2021). "A comparative fiber morphological analysis of major agricultural residues (used or investigated) as feedstock in the pulp and paper industry," BioResources 16(4), 7935-7952.AbstractArticlePDF

The suitabilities of major agricultural residues were assessed as papermaking feedstocks. All the examined agricultural residues were assumed as potential candidates for substituting hardwood fibers in mixed pulp blends from a fiber morphological perspective. Wheat, barley, rice, rapeseed, maize, sunflower, sugarcane bagasse, coconut husk, and two genotypes of miscanthus grass underwent identical maceration. The fiber length, fiber width, cell wall thickness, and lumen diameter were measured to calculate the slenderness ratio, flexibility coefficient, and Runkel ratio. The average fiber length ranged from 0.50 mm ± 0.32 mm (MG-S-02-V) to 1.15 mm mm ± 0.58 mm (sugarcane bagasse). The fiber width ranged from 10.77 μm ± 3.28 μm (rice straw) to 22.99 mm ± 5.20 mm (sunflower stalk). The lumen diameter ranged from 4.52 μm ± 2.52 μm (rice straw) to 13.23 μm ± 4.87 μm (sunflower stalk). The cell wall thickness ranged from 3.02 μm ± 0.95 μm (rice straw) to 4.80 μm ± 1.48 μm (sunflower stalk). The slenderness ratio, flexibility coefficient, and Runkel ratio values ranged between 28.08 to 58.11, 37.97 to 60.8, and 0.62 to 1.68, respectively. Wheat, maize, rapeseed, sugarcane bagasse, and coconut husk were found to be appropriate residue sources for papermaking feedstocks.

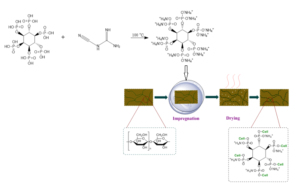

- Researchpp 7953-7965Chen, Q., Rong, Z., Liu, Z., You, N., and Xie, G. (2021). "Application of modified phytic acid as flame retardant in cellulosic paper," BioResources 16(4), 7953-7965.AbstractArticlePDF

A flame retardant containing phosphorus and nitrogen was synthesized using phytic acid and dicyandiamide, and it was subsequently used to prepare flame-retardant cellulosic paper via an impregnation method. Vertical flame and limiting oxygen index (LOI) were used to evaluate the flame retardancy of the paper. The paper containing modified phytic acid was characterized with Fourier transform infrared spectroscopy (FTIR), thermogravimetry (TG), X-ray diffraction (XRD), and scanning electron microscopy (SEM). When the concentration of modified phytic acid was 20%, the char length of the treated paper decreased from 12.5 cm to 4.1 cm, the LOI value increased from 19.6% to 41.5%, and the tensile index was only 3.66% lower than that of the control paper. The modified phytic acid was judged to have good flame-retardant effects on the paper.

- Researchpp 7966-7990Cachet, N., and Benjelloun-Mlayah, B. (2021). "Comparison of organic acid-based organosolv lignins extracted from the residues of five annual crops," BioResources 16(4), 7966-7990.AbstractArticlePDF

Organosolv lignins were extracted from corn stover, wheat, rice straw, reed straw, and sugarcane bagasse using a mixture of acetic and formic acids, at relatively low temperature and atmospheric pressure. Lignin content, residual carbohydrates, ash levels, proteins, and molecular weights were determined in each extracted lignin. The lignin content of all samples was relatively high, confirming the performance of the pretreatment process. The low molecular weights were in a narrow range, in accordance with the organosolv lignin molar masses. However, some differences between studied lignins were highlighted, in particular in rice straw lignin, which contained the highest silica, calcium, and nitrogen contents. Nuclear magnetic resonance spectroscopies (31P and semi-quantitative Heteronuclear Single Quantum Correlation) underlined the structural similarities and differences between these organosolv lignins. Corn stover and sugarcane bagasse lignins were rich in non-methoxylated (H-Unit) or mono-methoxylated (G-Unit) phenolic units, making them the best promising candidates for production of phenolic resins. Wheat straw lignin was richer in aliphatic OH than in phenolic OH. This is an advantage for use as polyol substitute in polyurethane synthesis. Reed straw lignin was less specific, with a balanced content of OH groups. However, it contained a high concentration of β-O-4 linkages, which is favorable for depolymerization.

- Researchpp 7991-8005Kopra, R., Vanhatalo, K., Päärnilä, S., Pappinen, A., and Dahl, O. (2021). "Bleaching microcrystalline cellulose using hydrogen peroxide, peracetic acid, and ozone," BioResources 16(4), 7991-8005.AbstractArticlePDF

AaltoCell™ based microcrystalline cellulose was bleached using hydrogen peroxide, peracetic acid, and ozone. The target brightness was set at 85% ISO brightness of the sheet (93% Y-brightness), which is white enough for the traditional use of microcrystalline cellulose. Both the paper pulp and dissolving pulp can be hydrolyzed using the AaltoCell™ process. Using paper pulp as a raw material, the brightness of the final microcrystalline cellulose decreased. The higher the temperature and retention time during the hydrolysis process, the greater the brightness loss. This effect can be explained by the so-called caramelization reaction. Due to this phenomenon, the microcrystalline cellulose should be bleached before using the product in food and pharmaceutical applications. The results showed that the target brightness was reached with ozone at doses of approximately 5 kg/ton with a reaction time of a few minutes; peroxide and peracetic acid required approximately twice the dose and a reaction time of at least 30 min. The concentrations of the chemical oxygen demand and total organic carbon in the pulp filtrate fraction varied with the bleaching chemicals used, with both values being low with ozone and the highest with peracetic acid.

- Researchpp 8006-8021Kukla, M., and Warguła, Ł. (2021). "Wood-based boards mechanical properties and their effects on the cutting process during shredding," BioResources 16(4), 8006-8021.AbstractArticlePDF

In order to design effective shredding machines dedicated to shredding wood-based waste, information about the mechanical properties of materials subjected to shredding is necessary. A number of mechanical properties of particleboard, oriented strand boards, and medium-density fibreboards in the aspect of shredding process have been experimentally determined in the article. The influence of material type, blade geometries, and cutting depth on cutting force and elasticity coefficient were analysed. Blade geometries reflect different phases of rotation of the cylindrical wood chipper’s knife. It has been shown that a knife with the most favourable geometry is characterized by the lowest values of the stiffness coefficient for each of the materials. This is the geometry of the cylindrical wood chipper’s knife exactly halfway into the cutting process. By contrast, the least favourable geometry is characterized by a knife corresponding to the beginning of the cutting process. Among the tested materials, the medium density board requires the most energy to change its structure, and the laminated particleboard requires the least. The presented results can be a set of input data necessary to model the work required to implement the cutting process, but also enable validation of existing cutting models.

- Researchpp 8022-8037Chopngam, K., Luengchavanon, M., Khangkhamano, M., Chetpattananondh, K., and Limbut, W. (2021). "Coating activated carbon from coconut shells with Co3O4/CeO2 for high-performance supercapacitor applications: An experimental study," BioResources 16(4), 8022-8037.AbstractArticlePDF

Activated carbon from coconut shells is a low-cost, environmentally friendly material that is available for fabricating the electrodes for electric double-layer capacitance supercapacitors. As such, activated carbon derived from coconut shells was coated with Co3O4/CeO2, and its electrical and ionic conductivity were evaluated. The ternary technique for selecting materials was systematically investigated with an economical process. The Co3O4/CeO2 coating that was formed on the activated carbon coconut shells was deemed AC-Co3O4-CeO2. The 90-05-05 composite was the best electrode for electric double-layer capacitance supercapacitors, resulting in high conductivity (0.62 x 103 S·cm2), low series resistance and internal resistance (based on the Nyquist plot), and the charge-discharge was able to reach 0.56 V for 90 seconds (1A/g). Therefore, activated carbon coconut shells coated in Co3O4/CeO2 can promote the necessary characteristics of electrodes needed for electric double-layer capacitance supercapacitors.

- Researchpp 8038-8048Yagüe, M., and Lobo, M. (2021). "Comparison of laboratory methodologies to determine soil nitrogen mineralization from organic residues," BioResources 16(4), 8038-8048.AbstractArticlePDF

Recycling organic waste for use as fertilizer requires prior knowledge of mineral nitrogen (N) availability for crops. Estimation of soil N release or potentially mineralizable N is an important tool for the design of fertilization strategies that aim to minimize the use of N fertilizer. The aerobic incubation method is considered a standard technique to measure soil potential to mineralize N. In this study, alternative methods of aerobic incubation were evaluated to help overcome its limitations (long time and equipment). In this regard, biological methods (anaerobic incubation at 7 and 14 days) and chemical extraction (hot KCl) procedures were examined. To determine potentially mineralizable N, a silty clay loam soil was fertilized with spent mushroom substrates and anaerobic digestates from different origins (C/N ratio of 4 to 38). Based on the results, chemical extraction emerges as a reliable alternative to the aerobic incubation method, particularly when the C/N ratio of the organic residues ranges from 12 to 15. Moreover, its implementation in routine soil laboratories is straightforward and faster, and it does not require any special equipment.