Volume 16 Issue 4

Latest articles

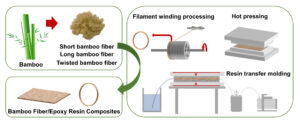

- Researchpp 7416-7427Shi, J., Zou, Y., Zhang, W., and Chen, H. (2021). "Effects of the molding process on properties of bamboo fiber/epoxy resin composites," BioResources 16(4), 7416-7427.AbstractArticlePDF

Filament winding is an advanced technology for fabrication of high-performance composites. Pressure-free fabrication can be achieved for non-planar composites with complicated shapes using resin-immersed twisting fibers. In this study, twisted bamboo fiber (TBF) composites were prepared by a filament winding processing (FWP). Short bamboo fiber (SBF), long bamboo fiber (LBF), and TBF composites were prepared by hot pressing (HP) and resin transfer molding (RTM). The results showed that the bamboo fiber/epoxy resin composites were positively related to the fiber size. The bamboo fiber/epoxy resin composites fabricated by FWP exhibited optimal shear performance, while those generated by RTM exhibited optimized bending performance. Dynamic thermomechanical analysis revealed that composites made by FWP had optimized interfaces. The FWP mechanism of bamboo fiber composites was resin immersion and alignment of TBF; upon resin immersion the TBF were coated by resin and could not enter the internal tubes or parenchyma tissues of the TBF. The TBF was aligned by winding equipment. After heated solidification of the resin, several bubble pores were distributed on both sides of the TBF, whose positions remained static over time. The filament winding processing for bamboo fiber composites enhanced their performance and could lead to the applications in bamboo fibers composites.

- Researchpp 7428-7443Zuo, H., Qin, X., Liu, Z., and Fu, Y. (2021). "Preparation and characterization of modified corn stalk biochar," BioResources 16(4), 7428-7443.AbstractArticlePDF

To increase the added value of corn stalk and improve the performance of corn stalk biochar, magnesium chloride (MgCl2) was used to modify biochar, and the effects of temperature on the structure and properties of modified biochar were considered. With the increase of temperature, the yield of biochar decreased. There was a marked increase in the number of mesopores and micropores, but the mesopore pore diameter changed to a smaller pore diameter, and the specific surface area remarkably increased. As the temperature increased, the content of C increased, while the range of H and O decreased. In addition, the number of oxygen-containing functional groups and methyl groups decreased, indicating that the structure of biochar became more aromatized. An obvious Mg(OH)2 crystal peak appeared in the X-ray diffraction pattern, which meant that Mg ions were loaded on the surface of biochar. Moreover, the highest removal rate of methylene blue dye by biochar was 83.6%. The authors conclude that temperature and magnesium chloride modification can improve and enhance the performance of corn stalk biochar. These findings will help deepen people’s understanding of biochar modification and serve as a reference for future related research.

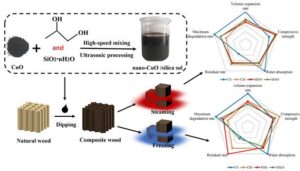

- Researchpp 7444-7460Zhao, P., Yang, H., Xu, G., Huang, C., and Zhong, Y. (2021). "Combination of nano-CuO/silica sol preservative with various post-treatments to improve the compressive strength, water resistance, and thermal stability of wood," BioResources 16(4), 7444-7460.AbstractArticlePDF

A nano-CuO/silica sol wood preservative was obtained by dispersing CuO nanoparticles in propylene glycol and silica sol. Scanning electron microscopy, Fourier transform infrared spectroscopy, X-ray diffraction analysis, thermogravimetric analysis, and compressive tests were conducted to investigate the effects of different post-treatments, i.e., steaming at 100 °C and freezing at -30 °C, on the variations in microstructure, mechanical, physical, and thermal stability properties of the preservative-impregnated wood. The results revealed that the mechanical properties, water resistance, and thermal stability of the impregnated specimens were greatly ameliorated. The steaming treatment resulted in a more uniform and dense distribution of the preservative in the blocks. The steaming treatment performed better in terms of enhancing the compressive strength of the specimens, while the freezing treatment was more effective in improving the thermal stability of the specimens. Both the steaming and freezing treatments can considerably improve the water resistance of the specimens. The different post-treatments retain the basic properties of the wood; however, they differ in the improved wood properties and provide a basis for their selection in the industrial production of nano-preservatives.

- Researchpp 7461-7473Lee, I.-H., and Kim, K.-H. (2021). "Influence of adhesive and layer composition on compressive strength of mixed cross-laminated timber," BioResources 16(4), 7461-7473.AbstractArticlePDF

Different types of wood can be used for making cross-laminated timber (CLT), which is useful as a structural material. Therefore, to assess the viability of mixed cross-laminated timbers prepared with different adhesives, their compressive strength performances were evaluated. Laminae of Japanese larch, red pine, and yellow poplar were used to manufacture eight types of mixed CLTs, which were then tested in a universal testing machine for obtaining the compressive strength. The results were then compared to those obtained from the finite element (FEM) simulation of the CLTs at proportional limit load. The compressive strength of CLTs consisting of Japanese larch laminae, with a high modulus of elasticity, tended to increase. Mixed CLT with polyurethane adhesives showed an average compressive strength that was 14% lower than that of larch CLT, while mixed CLT consisting of red pine and yellow poplar showed an average compressive strength that was 18% lower than that of the larch CLT. The CLT prepared with phenol-resorcinol-formaldehyde adhesive yielded the highest compressive strength among the three adhesives. The FEM-predicted strengths were found to be close to the actual values in all specimens. The obtained results will be useful for selecting material and adhesive for future endeavors.

- Researchpp 7474-7491Mendieta, C. M., Felissia, F. E., Arismendy, A. M., Kruyeniski, J., and Area, M. C. (2021). "Enzymatic hydrolysis and fermentation strategies for the biorefining of pine sawdust," BioResources 16(4), 7474-7491.AbstractArticlePDF

This work aims to evaluate second-generation bioethanol production from the soda-ethanol pulp of pine sawdust via two strategies: separate hydrolysis and fermentation and simultaneous saccharification and fermentation. A kinetics study of the enzymatic hydrolysis of separate hydrolysis and fermentation was included as a design tool. Three soda-ethanol pulps (with different chemical compositions), Cellic® Ctec2 cellulolytic enzymes, and Saccharomyces cerevisiae IMR 1181 (SC 1181) yeast were employed. The obtained kinetic parameters were as follows: an apparent constant (k) of 11.4 h-1, which represents the link frequency between cellulose and cellulase; a Michaelis-Menten apparent constant (KM) of 23.5 gL-1, that indicates the cellulose/cellulase affinity; and the apparent constant of inhibition between cellulose-glucose and cellulase (KI), which was 2.9 gL-1, 3.1 gL-1, and 6.6 gL-1 for pulps 1, 2, and 3, respectively. The kinetic model was applicable, since the calculated glucose values fit the experimental values. High bioethanol yields were obtained for pulp 3 in the separate hydrolysis and fermentation and simultaneous saccharification and fermentation processes (89.3% and 100% after 13 h and 72 h, respectively).

- Researchpp 7492-7508Fabisiak, E., and Fabisiak, B. (2021). "Relationship of tracheid length, annual ring width, and wood density in Scots pine (Pinus sylvestris L.) trees from different social classes of tree position in the stand," BioResources 16(4), 7492-7508.AbstractArticlePDFThis study investigated the relationship between the length of the tracheids, the width of annual rings, and the wood density of Scots pine (Pinus sylvestris L.) obtained from the dominant, intermediate, and suppressed classes of a 60-year-old stand. Measurement of tracheid length was performed on the material macerated from the following annual rings: 3, 6, 9, 12, 15, and thence every 5 annual rings. Basic density was determined on samples that included five annual rings from the core to bark. Tree position in the stand had a significant impact on the examined properties of wood. In a given biosocial class, tracheid length decreased as the width of annual rings increased. As the biosocial position of a tree in the stand improved, the length of the tracheids increased, and wood density decreased. In wood of the same density range, the increment in tracheid length was the greatest in wood of dominant trees and the lowest in wood of suppressed trees.

Keywords

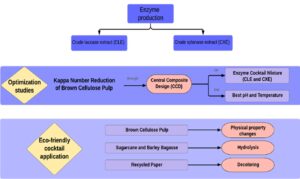

- Researchpp 7509-7529Pinheiro, V. E., Ferreira, J. A., Betini, J. H. A., Kamimura, E. S., and Polizeli, M. L. T. M. (2021). "Utilizing a novel fungal enzymatic cocktail as an eco-friendly alternative for cellulose pulp biobleaching," BioResources 16(4), 7509-7529.AbstractArticlePDF

Enzyme cocktails can alter the lignin and hemicellulose content in wood cell walls, improving the bleaching process during pulp production and offsetting the need for toxic chemicals. In this study, brown pulp was biobleached with a mixture of crude fungal extracts rich in xylanase and laccase, respectively produced from Aspergillus tamarii Kita and Trametes versicolor on waste materials. The optimal conditions for biobleaching were a mixture of xylanase and laccase crude extracts (1 to 2 v/v), at a temperature of 36 °C and a pH of 5.5. The treated brown cellulose pulp showed a reduction in the Kappa number by 1.83 points, representing an efficiency of 20.3%. In addition, the brightness increased by 4.65 points in comparison to the control. Hence, studies involving the application of the standardized cocktail during the hydrolysis of lignocellulosic residues, e.g., barley residue and sugarcane bagasse, led to the formation of 85 g/L and 25 g/L of reducing sugars, respectively. Moreover, the standardized cocktail caused greater deinking of the recycled paper pulp.

- Researchpp 7530-7549Erken, K. (2021). "Investigation of vegetative properties and generative production of the potential ornamental and narrow endemic species Verbascum yurtkuranianum (Scrophulariaceae) for ex situ conservation," BioResources 16(4), 7530-7549.AbstractArticlePDF

Verbascum yurtkuranianum is a narrow endemic species occurring in a single location, the northern Bursa province (Turkey). It is an endangered and potentially ornamental plant. No conducted study on its life and biology, production, and aesthetic features is available. This study aimed to reveal its vegetative properties, seed characteristics, methods and requirements for seed germination, germination speed, and potential ornamental value so it can be conserved ex situ and produced. Verbascum yurtkuranianum has potential value as an ornamental plant regarding its aesthetic features as a flower. This study revealed that the total number of individuals in the species is 788. Without any treatment, 70.7% germination rate is achieved if the seeds are stored at 4 °C. The optimum germination temperature was from 15 to 20 °C (77.3% and 78.7%, respectively), and the photoperiod regulation for seed germination was 12/12 or 8/16 (light/dark) hours (74.7% and 76.0%, respectively). The most effective treatment to promote germination rate was found by implementation of 60 min ultrasonic waves (94.3%) or application of 120 min vacuum (95.3%). Germination occurred between 8 and 10 days. A parcel of ex situ conservation was constituted with the seedlings obtained from the germination studies.

- Researchpp 7550-7561Spulle, U., Meija, A., Kūliņš, L., Kopeika, E., Liepa, K. H., Šillers, H., and Zudrags, K. (2021). "Influence of hot pressing technological parameters on plywood bending properties," BioResources 16(4), 7550-7561.AbstractArticlePDF

Different types of wood are used to manufacture of various wood products. In direct production processes, additional resources such as energy, adhesives, labor, etc. are also used. In line with sustainable environmental policies, all resources must be used more rationally, while simultaneously increasing the efficiency of the direct production processes. This research examined whether it is possible to reduce energy and labor resources in the technological process of hot pressing of birch plywood (nominal thickness 9 mm), by varying the holding time under pressure, pressure, and adhesive consumption. The Box-Behnken experimental design for a multifactor experiment was used to investigate the influence of technological parameters of plywood pressing. The highest strength in static bending both parallel and perpendicular to the plywood grain was achieved by pressing plywood with the following gluing parameters: highest pressing pressure, 3.2 MPa; minimal holding time under pressure, 9 minutes; and average phenol-formaldehyde adhesive consumption 150 grams per square meter.

- Researchpp 7562-7577Cao, S., Cai, J., Wu, M., Zhou, N., Huang, Z., Cai, L., and Zhang, Y. (2021). "Surface properties of poplar wood after heat treatment, resin impregnation, or both modifications," BioResources 16(4), 7562-7577.AbstractArticlePDF

To investigate the surface properties of different modified poplar (Populus tomentosa Carr.) wood samples, the color, surface roughness, and wettability of untreated poplar wood (control) and poplar modified via heat treatment, resin impregnation, and impregnation combined heat treatment were analyzed and compared in this study. The impregnant used in the test was a modified urea-formaldehyde resin with a low molecular weight and low viscosity. The results showed that the lightness of the samples was sorted in order as follows: the control was lighter than the resin impregnated sample, which was lighter than the impregnation combined heat treatment sample, which was lighter than the heat treatment sample. The surface of the control samples was relatively smooth, while after the impregnation, heat, and impregnation combined heat treatments, the Ra and Rz values increased, which indicated increased surface roughness due to the modifications. Among them, the heat-treated samples had the roughest surface, and the surface roughness of the impregnation combined heat treated samples at 160 °C had no major difference from the resin impregnated sample. The wettability of the samples decreased after heat treatment and increased after impregnation combined heat treatment. It was concluded that after the modification treatments, the color of the wood became darker, and the surface roughness and hydrophobicity increased.