Volume 17 Issue 4

Latest articles

- Editorialpp 5557-5561French, A. (2022). "How crystalline is my cellulose specimen? Probing the limits of x-ray diffraction," BioResources 17(4), 5557-5561.AbstractArticlePDF

Cellulose serves as a skeleton for many of the useful products upon which we rely on each day. When we want to learn about a skeleton, it makes sense to think about X-ray methods. The same can be said when it comes to learning about the crystallinity of cellulose. Over the past six decades, the Segal X-ray diffraction (XRD) method has been popular for judging the percent crystallinity of powder samples. However, XRD patterns for ideal cellulose crystals can be easily simulated, and limitations of the Segal and other methods become obvious. Calculated patterns for model 100% crystalline powder particles are predicted to be less crystalline by the Segal method. Except for the Rietveld method, current approaches do not account for particle orientation or different shapes of crystallites. The Rietveld method has so many variables that it can easily overfit the data. The take-away message is that routine XRD examination is important for showing sample characteristics, but fractional crystallinity values are affected by constraints related to simplifications required for the analysis.

- Editorialpp 5562-5564Lucia, L. A. (2022). "Compositomics: A timely conceptual framework for future advancements in green materials’ design and development," BioResources 17(4), 5562-5564.AbstractArticlePDF

Higher-order systems found in nature continue to be a source of inspiration for designing highly functional artificial systems. However, compositing these systems requires a precise understanding of how the components required can affect final desired responses. This non-trivial task is daunting and therefore will require a multiplicity of approaches elaborated under the umbrella of compositomics, a proposed –omics cluster dedicated to fabricating green materials through modeling, systems thinking, and machine learning.

- Editorialpp 5565-5567Jablonsky, M., and Šima, J. (2022). "Let's contribute to protecting our planet by reducing the brightness of paper: Less is more," BioResources 17(4), 5565-5567.AbstractArticlePDF

Sustaining life on the Earth with its ever-growing population is forcing changes in people’s way of life, industrial and agricultural production, exploitation of energy resources, and approaches to ecology. We face continual growth in the world’s population, and the demand for materials is growing even more rapidly. Every manufacturing and consumer sector is looking for ways to save energy and materials, attempting to minimize their negative impacts on the environment. In the pulp and paper industry, one of the segments in which progress can be made and help protect the planet is to reduce the brightness of paper. Such a reduction would lead to a lowering in the energy and material costs associated with paper production.

- Researchpp 5568-5577Yang, M., Fang, C., Su, J., Cheng, Y., Zhang, Q., and Liu, M. (2022). "Synthesis mechanism of carbon microsphere from waste office paper via hydrothermal method," BioResources 17(4), 5568-5577.AbstractArticlePDF

Carbon microsphere was successfully synthesized from waste office paper via hydrothermal method and high temperature treatment in nitrogen atmosphere. The process of carbon microsphere synthesis from waste office paper fiber using concentrated sulfuric acid was studied, and the influence of H2SO4 concentration and reaction time on the hydrolysis reaction was considered. To investigate the mechanism of conversion of waste office paper to carbon microsphere, Fourier transform infrared spectrometry was used to analyze the chemical composition of the supernatant liquid product and the non-carbonized carbon microsphere. The weight loss of the non-carbonized carbon microsphere was assessed through thermogravimetry. Scanning electron microscopy was used to analyze the morphology. The hydrolysis reaction of waste office paper fiber and synthesis mechanism of carbon microsphere under different conditions were evaluated. The results showed that when the reaction time reached 24 h, the product had uniform particle size and was well dispersed, and the more sulfuric acid present led to the waste office paper fiber being more thoroughly hydrolyzed.

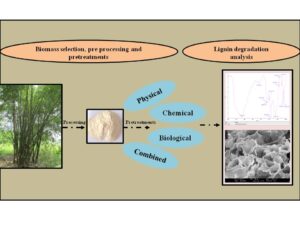

- Researchpp 5578-5599Parveen, H., Tewari, L., Pradhan, D., and Chaudhary, P. (2022). "Comparative study of diverse pretreatment approaches to degrade lignin from Bambusa balcooa," BioResources 17(4), 5578-5599.AbstractArticlePDF

Bamboo biomass is a potential source of monomeric sugars containing a high cellulose content with a low amount of lignin. However, for efficient hydrolysis, an effective biomass pretreatment technique is required to minimize the lignin content and other barrier components. In the present study, bamboo biomass was treated with different physical, chemical, biological, and combined treatments to reduce the lignin content. Among all the pretreatments, the maximum lignin removal amount (14.5%) was obtained with the combined chemical and biological treatment under 2% NaOH + 1% H2O2 + WDP2 fungal culture (5 plugs) conditions. In addition, the ligninolytic fungus and NaOH pretreatment was primarily effective in removing lignins, whereas the H2O2 pretreatment efficiently minimized cellulose crystallinity. Scanning electron microscopy and Fourier-transform infrared spectroscopy was utilized to analyze the structural changes of the raw and treated biomass. The structural analysis indicated that all the treatments caused disruption in the biomass structure and reduced the compactness of the biomass, which facilitated the biomass conversion during the hydrolysis process. The findings of the present study indicated effective pretreatment methods in overcoming the recalcitrancy of potential lignocellulosic biomass for maximum hydrolysis.

- Researchpp 5600-5611Park, C.-W., Han, S.-Y., Park, J.-S., Lee, E.-A., Bandi, R., Dadigala, R., Kim, J.-K., Kwon, G.-J., Kim, N.-H., and Lee, S.-H. (2022). "Deep eutectic-like solvent-assisted isolation of lignin from Pinus densiflora and its characteristics," BioResources 17(4), 5600-5611.AbstractArticlePDF

Lignin, the most abundant aromatic biopolymer on Earth, has great potential to replace petrochemical-based polymers in the production of value-added products. However, lignin is difficult to extract from lignocellulose because of the recalcitrance of the latter. Herein, the extraction of lignin from lignocellulose using deep eutectic-like solvents (DESs) as green solvents was investigated. Three types of DESs were used, and the effects of treatment temperature (100, 110, and 130 °C) and time (6, 12, and 24 h) on lignin yield and its characteristics were studied. For each DES, the yield of DES-lignin increased with reaction temperature and time. At the same time, the lignin yield obtained using different DESs decreased in the order of choline chloride/lactic acid > betaine/lactic acid > K2CO3/glycerol. At higher temperatures and longer reaction times, lignin with a high molecular weight was produced, which was attributed to the recondensation of lignin fragments. Furthermore, the methoxyl and hydroxyl group contents decreased with increasing reaction temperature and time. Thermal stability studies revealed that the increased molecular weight of DES-lignin enhanced its thermal resistance.

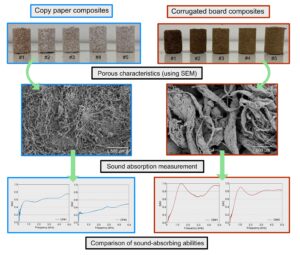

- Researchpp 5612-5621Chanlert, P., Jintara, A., and Manoma, W. (2022). "Comparison of the sound absorption properties of acoustic absorbers made from used copy paper and corrugated board," BioResources 17(4), 5612-5621.AbstractArticlePDF

Due to the increasing demand for eco-friendly, inexpensive sound absorbers, this study investigated composites made from recycled paper pulp and urea-formaldehyde adhesive. By varying the pulp contents, five samples from used copy paper and five samples from used corrugated board were fabricated. For the same type of porous absorber, one with a lower bulk density has a higher total porosity, resulting in a higher sound absorption coefficient (SAC) spectrum. Sound-absorbing performance of copy paper composites with bulk densities below 442.4 kg/m3 and corrugated board composites with densities of less than 474.8 kg/m3 can be alternatives to commercial polyurethane foam of the same thickness. The noise reduction coefficient (NRC), as well as the average SAC of all corrugated board composites at medium (αM) and high (αH) frequencies were greater than those of copy paper composites. However, the average SAC at low frequency (αL) was not explicitly different for copy paper and corrugated board composites. In conclusion, corrugated board composites are a better candidate as sound absorbers than copy paper composites with the same pulp content.

- Researchpp 5622-5631Gao, R., Li, J., Xia, J., Lin, Q., and Wang, L. (2022). "Influence of polyethylene oxide (PEO) on the performance of Chinese lacquer films," BioResources 17(4), 5622-5631.AbstractArticlePDF

The Chinese lacquer composite films were prepared by modifying raw lacquer with polyethylene oxide. The film was characterized via Fourier-transform infrared spectroscopy, thermogravimetric analysis, and scanning electron microscopy. The infrared spectra confirmed the interaction between the polyethylene oxide and urushiol. The heat-resistance of the film was found to have decreased due to the presence of polyethylene oxide via thermogravimetric analysis. Additional pores and wrinkles were observed in the scanning electron microscopy image of polyethylene oxide modified lacquer films. The mechanical properties were tested according to the national standard. The results indicated that the gloss and flexibility of the modified film was enhanced by the presence of polyethylene oxide. When the ratio of polyethylene oxide was 3%, the gloss was increased from 59.8 to 81.6 and the flexibility changed from 15 mm to 1 mm. The alkaline-resistance, hardness, and adhesion were also increased via the modification of polyethylene oxide.

- Researchpp 5632-5644Xin, Y., Liu, W., Chen, C., and Wang, D. (2022). "Effect of biochar on methane production and structural characteristics in the anaerobic digestion (AD) of rape straw," BioResources 17(4), 5632-5644.AbstractArticlePDF

This study investigated the mesophilic and thermophilic anaerobic fermentation of rape straw with biochar addition. The effects of biochar on the biogas yield, degradation of lignocellulose, bacterial community, and crystallinity were explored. The results showed that the biogas yield and methane content increased as the biochar concentration was increased. The biochar concentration of 5.0% resulted in a high biogas yield in mesophilic and thermophilic anaerobic digestion at 142.2 mL/g and 193.5 mL/g, respectively, which were 40.5% and 21.0% improvements compared with the control. The corresponding methane contents were 59.4% and 57.0%, respectively. For the lignocellulose degradation, the cellulose content in the mesophilic AD decreased from 54.0% in the pretreated rape straw to between 18.7% and 25.0%. The microbial community results showed that as the biochar concentration was increased, the relative abundance of Firmicutes initially increased before it decreased. Among the microbial community results, the relative abundances of Firmicutes and Bacteroides in the biogas residue of the mesophilic anaerobic digestion were the highest in the biogas residue with the 5.0% biochar concentration sample in the mesophilic AD, at 27.06% and 39.20%, respectively. This result revealed the mechanism of biochar to improve the biogas production of rape straw in anaerobic fermentation.

- Researchpp 5645-5654Esen, R., Likos, E., and Zengin, G. (2022). "The effects of using different adhesive on the thickness swelling ratio of LVL produced from scotch pine," BioResources 17(4), 5645-5654.AbstractArticlePDF

Most wood properties are affected by changes in moisture content below the wood fiber saturation point. In this study, the thickness swelling ratios of laminated veneer lumber (LVL) produced from Scotch pine (Pinus sylvestris L.) bonded by using polyvinyl acetate (PVAc), polymeric diphenyl methane diisocyanate (pMDI), and a mixture of them were evaluated. Thickness swelling of the samples was calculated after different waiting times under water. While the lowest thickness swelling ratio (1.65%) was determined from bonding with PVAc 92%- pMDI 8%, for 2 hours, the highest thickness swelling ratio (6.35%) was observed from bonding with PVAc 98%- pMDI 2% adhesive for 96 hours. As a result, adding pMDI to the PVAc adhesive reduced the rate of swelling of the test specimens. For this reason, the material can be used potentially in wet or humid places.