Volume 18 Issue 4

Latest articles

- Researchpp 6971-6985Yang, S., Choi, G., Kim, J., Lee, H., and Kang, S. (2023). “Comparison of mechanical properties according to the structural materials of lumber, GLT, CLT, and Ply-lam CLT,” BioResources 18(4), 6971-6985.AbstractArticlePDF

The mechanical properties of materials such as lumber (L), glued laminated timber (GLT), cross-laminated timber (CLT), and Ply-lam CLT (P), which are laminated in cross layers, were compared. As a result, the modulus of elasticity (MOE) was 9.7 to 10.3 GPa, showing no significant difference between the materials. Modulus of rupture (MOR) of L and GLT showed higher strength than that of CLT and P. MOR of CLT and P was at the same level, and there was no difference in strength according to the plywood and lumber arranged alternately. Alternatively, there was a difference in the coefficient of variation of the materials, and CLT and P was 20.2% and 11.8%, respectively; therefore, uniform properties can be secured when using plywood. The compression strength showed the highest compression strength in the order of GLT, L, P, and CLT. P was failure by buckling+delamination, but other materials showed failure by only buckling. The adhesion of P passed the glulam standard (7.0 MPa), and the delamination ratio was very low at 0.41%. It can be used together with CLT. This study is expected to be used as basic data for establishing quality standards.

- Researchpp 6986-7002Romyen, P., Pianroj, Y., Punvichai, T., Karrila, S., Chotikhun, A., and Jumrat, S. (2023). “Utilization of used bleaching clay in pellet fuel production with torrefied oil palm fronds,” BioResources 18(4), 6986-7002.AbstractArticlePDF

Torrefaction oil palm fronds was studied as a renewable biomass resource for efficient and sustainable pellet fuel production. Employing microwave heating during torrefaction, the process optimized the conditions to enhance the fuel properties. At 300 °C for 40 minutes, the torrefied oil palm fronds exhibited a remarkable rise in net calorific value to 23 MJ/kg, accompanied by a substantial increase in fixed carbon content to 46%. These enhancements signify a significant boost in energy content and carbon richness, which is crucial for cleaner and greener energy solutions. Comparing pellet fuels derived from raw and torrefied biomass, a striking difference in calorific values was observed. While raw biomass pellets reached 12.24 MJ/kg, their torrefied counterparts achieved an impressive 18.40 MJ/kg. This undeniable advantage highlights the effectiveness of torrefaction in elevating energy output. To optimize the composition of the pellet fuel, an ideal mass proportion of torrefied oil palm fronds and used bleaching clay was identified as 70:30. This blend resulted in the highest recorded calorific value, further endorsing the viability of the approach. In conclusion, torrefaction at 300 °C for 40 minutes proved to be a potent technique for enhancing oil palm fronds as a valuable source of pellet fuel. These findings underscore its potential to revolutionize renewable energy production, promoting sustainability and mitigating environmental impact.

- Researchpp 7003-7024Žiūra, K., Zvicevičius, E., Černiauskienė, Ž., Tilvikienė, V., Bakšinskaitė, A., and Pilipavičius, J. (2023). “Effect of thermochemical treatment on the physicochemical properties of fiber hemp (Cannabis sativa L.) by-product,” BioResources 18(4), 7003-7024.AbstractArticlePDF

The growing demand for biomass is forcing attention toward alternative resources, including agricultural by-products such as fiber hemp (Cannabis sativa L.). Growing hemp for seed produces about 10 tons of dry matter by-products per hectare. Processing-conversion technologies used in practice change the properties of primary raw materials, give them higher added value, and prepare them for various needs. In addition to economic benefits, biochar contributes to carbon sequestration and increases the sustainability of agricultural production. This study evaluated the effect of thermochemical treatment in an oxygen-free environment on some physicochemical properties of the fiber hemp by-products of the Felina 32 variety. At a heating temperature of 700 °C, the biomass yield of biochar from stems was 28.4 ± 0.5% and from seed husks was 30.6 ± 0.6%. At that time, the carbon concentration in fiber hemp stems biochar increased 1.82 times, from 45.0 ± 2.26% to 81.9 ± 8.46%, and in seed husk biochar by 1.20 times, from 56.5 ± 11, 6% to 67.9 ± 7.47%. Furthermore, the changes in the fractional composition, density, calorific value, ash content, and ash melting characteristics that occurred during the conversion of primary raw material of fiber hemp into biochar were evaluated.

- Researchpp 7025-7040Özlüsoylu, I. (2023). “The effect of varnish type, glue amount, and density on the surface properties of low density particleboards produced from waste wood bark,” BioResources 18(4), 7025-7040.AbstractArticlePDF

Particleboards, which are widely used in various fields, are commonly coated with solid and liquid surface coating materials to achieve better physical, mechanical, and aesthetic results. This study produced low-density particleboards from waste wood bark using different adhesive mixtures and densities. These particleboards were then coated with three types of varnish: water-based (Aq), polyurethane-based (Pu), and oil/wax-based (Ow). The color, gloss, and surface roughness values of the coated boards were determined to investigate the effect of varnish type, total adhesive usage, and density on these properties. In the board groups produced with the same glue ratio and density, the roughness values obtained with Ow varnish application were mostly higher compared to Aq and Pu. In the Ow varnish type, the roughness (Rmax) decreased linearly with increasing total adhesive amount in particleboards produced at low density (320 kg/m3). The highest color change (ΔE*) values for all variations were obtained in the Ow varnish type, while the highest gloss values were achieved at 85° and in the B2 (4%-420 kg/m3) board group. It was concluded that higher density should be preferred for smoother and glossier surfaces, which are important in terms of surface properties and aesthetics. Overall, these findings highlight the preference for higher density to achieve smoother and glossier surfaces in areas where surface properties and aesthetics are significant.

- Researchpp 7041-7053Yang, Q., Huang, X., Cai, Z., Ding, Z., Yang, X., and Yan, X. “Preparation of dehydroabietyl polyethylene glycol aldehyde modified hydroxyethyl chitosans and their physicochemical properties,” BioResources 18(4), 7041-7053.AbstractArticlePDF

A series of polymeric surfactants based on monodehydroabietyl polyoxyethylene(5) ether (DHA(EO)5H) and hydroxyethyl chitosan (HEC) were prepared through a three-step process. First, DHA(EO)5H was oxidized using activated MnO2 and transformed into dehydroabietyl polyethylene glycol(5) aldehyde (DHA(EO)4CH2CHO). Then, the DHA(EO)4CH2CHO was reacted with HEC and converted into Schiff-base. Finally, the polymeric surfactant, DHA(EO)4CH2CHO modified HEC (DHA(EO)4CH2CHO-m-HEC), was obtained by reducing the Schiff-base with sodium borohydride. The grafting degree (DG) of DHA(EO)4CH2CHO substitution onto HEC for DHA(EO)4CH2CHO-m-HECs was determined using elemental analysis (EA), and the surface activities and foam performance of DHA(EO)4CH2CHO-m-HECs in aqueous solution were investigated respectively. The emulsifying capacities of DHA(EO)4CH2CHO-m-HECs were evaluated according to the stability times of emulsion composed of water and liquid paraffin. The experimental results showed the DG could have significant influence on the critical micelle concentration (cmc) of DHA(EO)4CH2CHO-m-HECs and their surface tensions at cmc (γcmc), but nearly no effect on their minimum surface tensions (γmin) in aqueous solution. Among the synthetic polymeric surfactants in this investigation, DHA(EO)4CH2CHO-m-HEC with DG of 56.95% exhibited the best emulsification and foam properties.

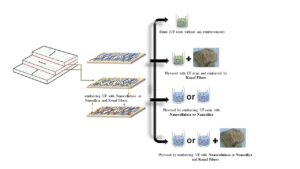

- Researchpp 7054-7065Omrani, P., Abdolzadeh, H., Roshan, F., and Ganjkhani, M. (2023). “Applicational properties of reinforced plywood with nanomaterials and kenaf fiber,” BioResources 18(4), 7054-7065.AbstractArticlePDF

Kenaf fibers were added as a reinforcement between wood veneers of poplar (Populus deltoides) bonded with urea–formaldehyde (UF) resin to improve the applicational properties of standard three-layered plywood. Additionally, the influence of two different nanomaterials (nanocellulose and nanosilica)-modified UF resins on the performance of plywood was evaluated. Then, thickness swelling (TS), water absorption (WA), shear strength, and flexural properties were examined. Results indicated that reinforced composites with kenaf fibers improved the modulus of rupture (MOR) and modulus of elasticity (MOE) in both directions. In addition, physical properties, such as TS and WA after 24 h, improved in the reinforced plywood with kenaf and use of nanosilica (KNS) as a filler. The results of the mechanical properties were better than blanks. The treated adhesive, with nanocellulose and nanosilica revealed similar mechanical behaviors. The shear strength of plywood in KNC specimens showed the best result (increased 64.6% compared to blank) and MOR for both the parallel and perpendicular directions to the grain of the surface layers for KNS (105% and 158%, respectively), and MOE for KNS (92.9% and 152%, respectively) compared to the blank.

- Researchpp 7066-7077Ebner, D. H., Gryc, V., Barbu, M.-C., and Čermák, P. (2023). “Physical properties of silver fir (Abies alba L.) wood cladding modified by traditional Japanese charring method,” BioResources 18(4), 7066-7077.AbstractArticlePDF

Silver fir (Abies alba L.) wood samples were charred on one surface using an enhanced version of the traditional Japanese Yakisugi method. The 15 charred boards obtained from five charring chimneys were divided into three different zones and investigated for their physical properties. The density profile, water absorption after 24 h of water submersion, and Brinell hardness were analyzed. In general, the temperature-time regime, which causes inside surface carbonization, was more evident at the bottom than at the top of the chimney. The density profile of the specimens revealed that the surface charring treatment decreased the surface density of the wood significantly. A gradient was visible from 383 kg/m² at the bottom to 424 kg/m² at the top. Water absorption measurements showed that a thicker carbonized layer could take up more water as a result of increased porosity. While 3,684 g/m² were absorbed at the bottom, the top accounted for only 2,533 g/m². Furthermore, with increasing thickness of the charred layer, the hardness gradually decreased. The average of the charred specimens reached only 3.2% of the hardness of the uncharred back side of the specimens.

- Researchpp 7078-7097Amir, M. A., Othman, K., Ratnasingam, J., Latib, H. A., Jegatheswaran, N., and Lim, C. L. (2023). “Discerning the supply chain of Bumiputera entrepreneurs in the Malaysian wood products and furniture industry: Status, challenges, and remedial measures,” BioResources 18(4), 7078-7097.AbstractArticlePDF

Supply chain management has been identified as the major constraint on the growth of Bumiputera entrepreneurs in the Malaysian wood products and furniture sector. Therefore, a study to examine the characteristics of supply chain among Bumiputera entrepreneurs in the wood industry registered with the Malaysian Timber Industry Board was conducted. The results revealed that most of the respondents were micro- and small-sized enterprises, with a sales focus on the domestic and contract-market. They were predominantly wooden furniture manufacturers, who had a relatively low level of knowledge about supply chain management. The respondents also indicated that their major challenges include lack of finances, small volume of production, and the lack of government support. The factor analysis and regression analysis conducted revealed that for Bumiputera entrepreneurs to gain better supply chain management they need to improve their frequency of engagement, trust, culture, and maturity with their supply chain actors and partners. The results of this study are unique, as it implies that policymakers should take heed of improving supply chain management, to reverse the flagging fortune of Bumiputera entrepreneurs in the Malaysian wood products and furniture sector.

- Researchpp 7098-7108Ren, J., Wang, Y., Sun, X, Liu, L., Liu, X., and Li, G. (2023). “Digested slurry analysis for utilization based on irrigated crop water demand,” BioResources 18(4), 7098-7108.AbstractArticlePDF

To rationally utilize digested slurry, and thereby promote the integrated development of planting and breeding in breeding industry, the water-fertilizer requirement analysis of typical winter wheat-summer corn rotation tillage model in Zhengzhou was completed based on the water/nutrient requirement of crops. The results showed that the water demand and effective rainfall of winter wheat during the whole growth period were 492 and 190 mm, and the application amount of digested slurry was 3090 m³. The N, P, and K provided were 3600, 197, and 1310 kg, respectively, which exceeded the normal nutrient requirement of wheat. During the whole growth period of summer corn, the water demand was 354 mm, the effective rainfall was 290 mm, and the application amount of digested slurry was 763 m³. The amount of N, P, and K provided was 890, 48.6, and 324 kg, respectively. The amount of N and K exceeded the normal nutrient demand of corn, while the P was insufficient. Therefore, digested slurry can provide full nutrient requirements in winter wheat planting season in Zhengzhou, and P fertilizer should be added when applying digested slurry in corn planting season. If long-term application, excessive nutrient loss may cause non-point source pollution.

- Researchpp 7109-7123Yu, C., Wang, G., Liu, X., Zhang, H., Ma, Q., Liu, H., Zhang, Y., and Li, H. (2023). “Effect of Sesbania and Triticale rotation on plant characteristics and soil quality in coastal saline-alkaline land: A two-year field experiment,” BioResources 18(4), 7109-7123.AbstractArticlePDF

Soil salinization and nutrient deficiency limit agricultural production in the Yellow River Delta region. This study investigates the green manure-forage grass rotation on soil quality and productivity. A two-year field experiment was conducted to investigate the effects of different varieties of Sesbania cannabina and ᵡTriticosecale Wittm rotations on soil properties, biological characteristics, and adaptability in coastal saline-alkali land. Four cropping rotation systems were set: Gaoyuan 2 – Lujing 2 (G2L2), Gaoyuan 2 – Lujing 5 (G2L5), Gaoyuan 1640 – Lujing 2 (G1640L2), and Gaoyuan 1640 – Lujing 5 (G1640L5). The G2L5 rotation demonstrated superior enhancement of soil quality. The soil organic matter increased by 35.8%, and the soil electric conductivity (CEC) increased by 20.2%. Compared with T. Wittm, S. cannabina had a significant positive effect on soil physical and chemical properties. S. cannabina L5 showed improved performance in mass density, fresh weight of stem, leaf and aboveground part, etc. After S. cannabina returned to the field, T. Wittm G2 had greater plant height, thousand-grain weight, and stem weight, and the yield reached 322 kg per 667 m2. In conclusion, G2L5 is the recommended planting model in saline-alkali soil. This research offers valuable insight for the efficient planting and sustainable development of coastal saline-alkali land.