Volume 18 Issue 4

Latest articles

- Researchpp 7124-7142Sun, P., Liang, K., and Wang, S. (2023). “Comparative analysis of mechanical properties for wood frame and reinforced concrete frame based on deformation energy decomposition method,” BioResources 18(3), 7124-7142.AbstractArticlePDF

As a typical orthotropic material, the mechanical properties of wood in the parallel and perpendicular-to-grain directions are very different. Based on mathematical orthogonality, mechanical force balance condition, and energy comparability, the deformation energy decomposition method of planar wood element is proposed, and then the quantitative and visual analysis of the basic deformation performance of wood structure is realized. The basic deformation performance of wood structure and isotropic structure is analyzed using the deformation energy decomposition method, and the seismic performance of wood frame structure and concrete frame structure is compared. The results show that the lateral resistance and beam ductility of wood frame are greater than those of concrete frame under seismic load. However, the reduction of deformation energy proportion of wood frame beam leads to greater deformation energy of the frame column, so it is suggested to take targeted strengthening measures to the bottom of the wood frame column and the joint area.

- Researchpp 7143-7153Kim, J.-K., Bandi, R., Dadigala, R., Hai, L. V., Han, S.-Y., Kwon, G-J., Cho, S.-W., Ma, S.-Y., and Lee, S.-H. (2023). “Esterification of nanofibrillated cellulose using lauroyl chloride and its composite films with polybutylene succinate,” BioResources 18(4), 7143-7153.AbstractArticlePDF

Esterified nanofibrillated cellulose (eNFC) with varying degrees of substitution was prepared using fatty acid chloride. Furthermore, the effect of esterification on properties of pure NFC and its composites with polybutylene succinate (PBS) was investigated. Lauroyl chloride (LC) with 12 carbon atoms was used for esterification. An increase in the amount of LC increased the degree of substitution (DS), which significantly decreased the water contact angle and improved the hydrophobicity of NFC. The addition of fatty acid to NFCs lowered their crystallinity. However, the fatty acid increased the hydrophobicity of NFCs, thereby improving their dispersibility in nonpolar solvents. Compared with pure NFCs, eNFC exhibited enhanced compatibility with PBS, and the addition of eNFC with an appropriate DS increased the tensile strength and elastic modulus of PBS. These findings suggest the potential of NFC esterification for improving the performance of NFC-based composite materials.

- Researchpp 7154-7171Pei, P., Sun, Y., Zou, R., Wang, X., Liu, J., Liu, L., Deng, X., Li, X., Yu, M., and Li, S. (2023). “Comparing four kinds of lignocellulosic biomass for the performance of fiber/PHB/PBS bio-composites,” BioResources 18(4), 7154-7171.AbstractArticlePDF

A new class of bio-composites was developed by utilizing four kinds of lignocellulosic biomass fiber (bagasse, bamboo, rice husk, and rice straw) as filling fibers. Poly-β-hydroxybutyrate (PHB) and poly(butylene succinate) (PBS) in a mixture ratio of 7:3 were used as matrix materials with hot-press molding. The performance of the resulting composites was evaluated by compositional analyses, mechanical analysis, Fourier transform infrared (FTIR) spectroscopy, thermogravimetry, and morphological analysis. The interfacial adhesion, thermal stability, and comprehensive mechanical properties of the alkali treated bamboo/PHB/PBS composite were highest among the four bio-composites. The bending strength, tensile strength, and impact strength for alkali treated bamboo/PHB/PBS composite was 19.82 MPa, 12.97 MPa, and 4.30 kJ/m2, respectively. The thermal stability for NaOH modified bamboo/PHB/PBS composite was slightly superior to the other three composites, with the initial pyrolysis temperature of 248 °C, moderate pyrolysis speed, and the amount of pyrolysis residue (5.81%). The results showed the suitability of biomass fiber and biodegradable polymer for producing environmentally friendly composite materials.

- Researchpp 7172-7185Atilgan, A. (2023). “Effect of silane-siloxane based water-repellent impregnant on the dimensional stability of some wood species,” BioResources 18(4), 7172-7185.AbstractArticlePDF

A silane-siloxane based water-repellent substance (S-WR) was used as an impregnation material for Scots pine (Pinus sylvestris L.), black pine (Pinus nigra Arnold), sessile oak (Quercus petraea Liebl.), and cedar (Cedrus libani A. Rich). In the impregnation process, the immersion method was carried out for various periods (30 min, 3 h, and 24 h). Following impregnation, physical properties of the wood (retention, contraction, expansion, water intake rate, specific gravity, etc.) were determined. The retention was highest in sessile oak wood (0.96%) and lowest in black pine wood (0.24%). The highest specific gravity value was found in stemless oak (0.86 g/cm³) impregnated for 24 h, and the lowest air-dry specific gravity value was found in Scots pine (0.40 g/cm³) impregnated for 30 minutes Absolutely dry (0% humidity) specific gravity was highest in sessile oak for 24 h (0.83 g/cm³). Shrinkage was highest in the sessile oak control sample (13.5%). The expansion amount was highest in the cedar wood control sample (17.5%) and lowest in sessile oak wood (1.66%). The highest water uptake rate (SAO) was determined in Scots pine wood at 96 h (105%), and the lowest in sessile oak wood in 24 h (8.80%). In summary, silane-siloxane based water-repellent impregnation material was found to be effective in providing dimensional stability in wood.

- Researchpp 7186-7201Demirel, G. K. (2023). “Evaluation of lauric-myristic acid as phase change material in thermally modified wood for thermal energy storage,” BioResources 18(4), 7186-7201.AbstractArticlePDF

Thermally modified Scots pine samples were impregnated with lauric acid (LA) and myristic acid (MA) as phase change material (PCM) by vacuum process. The LA-MA mixture was prepared at a eutectic ratio of 66 to 34 wt%. Some properties of the wood samples such as hygroscopicity, mechanical, thermal energy storage (TES), and lab-scale thermo-regulative performance were investigated. Fourier transform infrared spectroscopy (FT-IR) was utilized to analyze the physicochemical characteristics of wood samples that underwent thermal treatment. The thermal degradation stability, cycling chemical/thermal reliability, and TES properties of the samples were assessed through TG (thermogravimetric analysis) and DSC (differential scanning calorimetry) analyses. The DSC results of thermally modified wood (TMW)/LA-MA samples showed good energy storage or release capacity with appropriate phase. These analyses also indicated that TMW samples infused with PCM exhibited reduced residue compared to the control samples. The experimental evaluation conducted on a small scale demonstrated that the PCM integrated within the wood effectively retains excess heat within the surrounding environment, thereby restricting heat dissipation. Moreover, the presence of PCM visibly decreased water absorption and enhanced the dimensional stability in wood. The impregnation with LA-MA improved mechanical properties of thermally modified wood despite the thermal modification that normally decreases mechanical properties.

- Researchpp 7202-7211Liu, Q., Yang, C., and Ding, Y. (2023). “Effect of wood microstructure on the quality of gas-assisted laser cutting of cherry,” BioResources 18(4), 7202-7211.AbstractArticlePDF

To improve the processing quality of wood products, the effects of different wood microstructure on the cutting quality of cherry wood were studied in the experimental process of gas-assisted laser processing. Based on the absorption ability of wood relative to laser wavelength, the composite processing of CO2 laser and inert gas was carried out. Kerf width and surface roughness were used as evaluation indexes, with analysis by factor experiments. The results showed that under the same parameter conditions, due to the difference in internal structure of wood, the cavity structure in the tracheid was more conducive to the diffusion and absorption of laser energy during perpendicular cutting. In addition, the kerf width and surface roughness of parallel cutting were smaller than that of perpendicular cutting. The microscopic morphology and surface carbon content of the kerf surface showed that during perpendicular cutting, due to the plugging effect of small holes, heat accumulation was not conducive to the flow of flue gas and carbide; thus carbon particles remained in the tracheid, and the carbon content of kerf surface was higher.

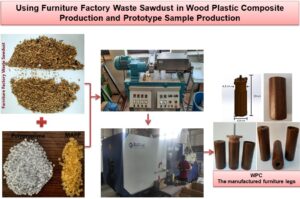

- Researchpp 7212-7229Kılıç, I., Avcı, B., Atar, I., Korkmaz, N., Yılmaz, G., and Mengeloğlu, F. (2023). “Using furniture factory waste sawdust in wood-plastic composite production and prototype sample production,” BioResources 18(4), 7212-7229.AbstractArticlePDF

This study investigated the possibility of furniture factory waste sawdust (FFWS) utilization in polypropylene (PP) composites and producing furniture support leg prototypes. Test samples were manufactured using a single screw extruder and injection molding machine utilizing 10, 15, 20, 25, 30, and 35% by weight of FFWS and 0% or 3% maleated polypropylene (MAPP). Selected mechanical and physical properties of manufactured samples were determined. The presence of FFWS and MAPP significantly improved mechanical properties compared to neat PP. The higher FFWS amount increased the flexural strength, flexural modulus, tensile modulus, impact resistance, and density. Tensile strength and elongation at break decreased with filler amount, but the addition of MAPP caused a dramatic increase in tensile strength. In addition, flexural strength, flexural modulus, tensile strength, elasticity modulus, and density values of the composites containing MAPP had higher values than the ones without MAPP. However, impact resistance and elongation at break values were slightly decreased with the addition of MAPP. Optimization results showed that formulation mixtures containing 20% filler and 3% MAPP fit best for prototype furniture legs manufacturing.

- Researchpp 7230-7238Jardim, P. I. L. G., Morales, E. A. M., Panzera, T. H., Mascarenhas, F. J. R., Araujo, V. A., Santos, H. F., Faustino, E., Almeida, D. H., Lahr, F. A. R., and Christoforo, A. L. (2023). “Prediction of flexural stiffness of wooden beams with cross-sectional loss that are reinforced with screwed steel plate based on numerical simulation,” BioResources 18(4), 7230-7238.AbstractArticlePDF

As a biodegradable material, wood is subject to deterioration if proper conservation techniques are not observed. Thus, several buildings, especially those of historical heritage, present pathological manifestations that can cause accidents. The interventions in these constructions must be planned to maintain the original elements and the aesthetics of the environment, with the indication of fixing additional elements in the degraded structure. The modification of the section of structural elements is commonly observed in the literature; however, few studies have been intended to analyze the effects of reinforcement in these geometrically discontinuous elements. Furthermore, the use of screwed steel plates guarantees greater ease of execution, even though it is not yet a method that has been well explored in the scientific literature. The objective of this study was to propose an equation for estimating the flexural stiffness of wooden beams with loss of cross-section that are then reinforced with screwed steel plates using a regression model. The considered variables correlated the elastic modulus of the wood and the reinforcement, the configuration of the defect, and the reinforcement. It was possible to identify that the properties of the wood and the position of the defect were variables with a significant impact on the stiffness of the reinforced beam.

- Researchpp 7239-7250Lee, I.-H., Song, Y.-J., and Hong, S. I. (2023). “Creep behavior and prediction of fiber-reinforced polymer reinforced timbers under changing temperature and relative humidity,” BioResources 18(4), 7239-7250.AbstractArticlePDF

The creep behavior of fiber-reinforced polymer (FRP) reinforced larch laminar timber was studied with respect to temperature and humidity fluctuations. There was a control group of larch laminated with two small-diameter timbers with FRP (carbon FRP (CFRP), glass FRP (GFRP)) produced; the laminated lumber had the same cross-sectional area as the two laminated lumber specimens with reinforced tensile parts. A creep test with fluctuating temperature and humidity was conducted by applying a load of 25% of the bending strength of the control specimen. A total of 8 specimens, 2 for each type, were measured for creep deformation at 9:00 am and 6:00 pm daily for approximately 14,000 h. Temperature and humidity fluctuations were measured every hour. The equilibrium moisture content and humidity of the creep test space exhibited a proportional relationship, and the moisture content of each specimen did not show a noticeable correlation with humidity and equilibrium moisture content. The average relative creep was measured as approximately 0.67 for the control, 0.4 for Glulam, and 0.43 for both the CFRP- and GFRP-reinforced specimens. Thus, the creep deformation of all the reinforced pieces was confirmed to be lower than that of the control specimen.

- Researchpp 7251-7294Başboğa, H. I. (2023). “Polypropylene-based composites reinforced with waste tropic wood flours: Determination of accelerated weathering resistance, tribological, and thermal properties,” BioResources 18(4), 7251-7294.AbstractArticlePDF

This study investigated the effects of Iroko wood flour (WF) and nano-titanium dioxide (TiO2) concentration on the properties of polypropylene (PP)-based composites, including accelerated weathering resistance, tribological behavior, thermal stability, physical characteristics, mechanical strength, morphological features, color changes, and surface roughness. The results showed that the presence of WF and TiO2 significantly influenced the density, hardness, thermal stability, crystallinity, coefficient of friction, and wear rate of the composites. Both fillers positively impacted the tensile strength, flexural strength, and flexural modulus of the composites, although the elongation at break values decreased. TiO2 addition enhanced thermal stability and protection against UV radiation, whereas using wood flour negatively affected color properties. Moreover, the surface roughness of the composites was affected by weathering time and wood flour content. These findings highlight the potential of WF and TiO2 as effective fillers for enhancing PP-based composites’ properties and weathering resistance.