Volume 19 Issue 2

Latest articles

- Researchpp 3571-3596Tasdemir, C., Yildirim, Y., Uysal, M., Angin, N., and Ertas, M. (2024). “Investigation of indoor noise pollution level and air quality of furniture manufacturers,” BioResources 19(2), 3571-3596.AbstractArticlePDF

Indoor air quality has become a more prominent concern since the arrival of the COVID-19 pandemic. Manufacturing industries have always been prone to occupational health risks, which depend on the dynamics of the production shop floors. The furniture industry is one of these sectors with a unique work environment. Although a typical furniture manufacturing facility involves physical, chemical, and noise pollution-producing elements, this industry has been studied relatively less for indoor air quality and noise-related risks. This study investigated nine furniture manufacturing organizations’ indoor air quality and noise pollution levels through comprehensive quantitative techniques. The results of the measurements were compared against reference values set by specific guidelines to explore the degree of occupational health risk associated with the World Health Organization’s (WHO) suggested levels. Repetitive measurements from five pre-designated workstations were taken at each facility. The study’s results indicated that organization size and department were significant factors for PM 2.5 and HCHO parameters, while only department type was substantial for noise exposure levels. However, across all departments and organization sizes, LAeq noise levels were below the safety threshold of 85 dB(A). Most organizations presented a lack of proper use of personal protective equipment and poor ventilation across shop floors.

- Researchpp 3597-3613Tao, Y., Tian, H., Zhao, K., Yu, Y., Guo, L., Liu, G., and Bai, X. (2024). “High-precision discrimination of maize silage based on olfactory visualization technology integrated with chemometrics analysis,” BioResources 19(2), 3597-3613.AbstractArticlePDF

Rapid, reliable and non-destructive detection of the quality of maize silage is essential to high-efficiency animal husbandry and food safety. In this study, the colorimetric sensor array (CSA) integrated with chemometric methods is innovatively proposed for qualitative discrimination of maize silage. First, 12 color-sensitive dyes were selected to fabricate colorimetric sensor arrays to be used as artificial olfactory sensors for obtaining odor fingerprints of maize silage. Machine vision algorithms were utilized to extract the color features, and principal component analysis was applied to reduce the dimensionality of the obtained data. Finally, the PCA results were input variables to develop different qualitative discrimination models. These models involve support vector machines (SVM), extreme learning machine (ELM), and random forest (RF). The analysis results show the 100% correct identification rate for independent samples. The general results sufficiently reveal that olfactory visualization technology integrated with chemometrics analysis has promising applications for high-precision discrimination of maize silage.

- Researchpp 3614-3636Ba, S., Ban, Y., Lyu, K., Liu, Y., Wen, J., and Li, W. (2024). “Finite element explicit dynamics simulation of an impact cutting mechanism analysis of Populus tomentosa branches,” BioResources 19(2), 3614-3636.AbstractArticlePDF

The branch impact failure mechanism has gradually received attention from scholars, along with the application of impact cutting methods in plantation forest pruning. In this paper, the impact cutting failure mechanism of Populus tomentosa branches was mainly studied. The impact cutting process of branches was simulated by using Finite Element Method (FEM)-based explicit dynamics. The stress change and deformation characteristics in the branch failure process were studied. A theoretical model of branch impact cutting mechanism with branch diameter, cutting clearance, and branch angle as the main factors was proposed. The model describes the branch cutting damage process and the changing characteristics of cutting force. A branch failure state equation was proposed to describe the branch impact cutting failure patterns. The forest experiment was conducted to validate the branch impact cutting mechanism and the branch failure state equation. This work fills a vacancy of relevant theory and provides a theoretical basis for the future development of forestry and agricultural equipment using impact cutting.

- Researchpp 3637-3652Wu, K., Lv, N., Bai, W., Meng, Y., Han, M., Xue, Y., Song, Y., Xie, X., Wang, T., Gong, P., and Zhang, L. (2024). “Response of corn yield to water retaining agents, inhibitors, and corn stalks addition in semi-arid cropland,” BioResources 19(2), 3637-3652.AbstractArticlePDF

Drought, excessive use of nitrogen fertilizer, and decline in soil organic matter threaten corn production. This study investigated the potential of water retaining agents, inhibitors, and corn stalks in enhancing soil physicochemical properties to bolster corn yield in semi-arid farmlands. In our study, polyacrylamide addition increased the content of ammonium nitrogen (NH4+-N) and nitrate nitrogen (NO3–-N) in the seedling stage, exchangeable potassium (K) in the mature stage but decreased the content of available phosphorus (P) in the seedling stage. Potassium polyacrylate addition increased the content of NH4+-N and decreased the content of available P in the seedling stage. The addition of inhibitors decreased the content of NH4+-N and available P in the seedling stage, NO3–-N and available P in the jointing stage, and NH4+-N in the mature stage, respectively. Corn stalks returning could maintain soil moisture, decrease the content of NH4+-N in the seedling stage and exchangeable K in the mature stage, and increase the content of available P and exchangeable K in the seedling stage. Combined application of inhibitors and corn stalks could increase soil organic carbon (SOC) and ensure corn yield, which was the best fertilization mode in semi-arid cropland.

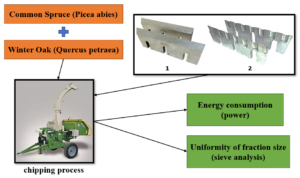

- Researchpp 3653-3667Krilek, J., Gendek, A., Aniszewska, M., Szewczyk, G., Ťavodová, M., Spinelli, R., Kováč, J., Malaťák, J., Kormanek, M., Mancel, V., and Kuvik, T. (2024). “Research of chipper knives with a modified cutting edge for the production of dimensionally uniform wood chips,” BioResources 19(2), 3653-3667.AbstractArticlePDF

The paper is focused on the research of chipper knives with a straight and modified cutting edge in order to determine the energy consumption of the chipping process and the uniformity of the size of the fractions of the designed chipper knife for the production of dimensionally uniform chips. The research took place on two different tree species where the representative of the coniferous tree was the common spruce (Picea abies) and the deciduous tree was the winter oak (Quercus petraea). The research took place on a PTO-powered (power take off) disc chipping machine where it was not modified for research purposes. The results showed that a knife with a modified cutting edge is higher in terms of energy consumption than chipper knives with a straight cutting edge. From the evaluation of the sieve analysis for a chipper knife with a modified cutting edge, the energy chip of uniform granulometric composition is a homogeneous bulk material.

- Researchpp 3668-3680Ma, H., Zhao, J., Pin, L., Ma, H., Zhou, J., and Liu, J. (2024). “Cooperative treatment and resource utilization of municipal solid waste by industrial coke ovens: Effects of doping ratio and management,” BioResources 19(2), 3668-3680.AbstractArticlePDF

For the collaborative treatment and resource utilization of an industrial coke oven on municipal solid waste (MSW), this study used MSW to prepare refuse-derived fuel (RDF). The influence of different mix ratio between RDF and coal on coking products was considered, and technical and economic analyses were conducted. The results showed that under the low mixture ratio (3%), the pyrolytic carbon obtained basically met the class III standard of metallurgical carbon. In the experiment of medium mixture ratio (25%, 30%, 35%), the product contained a certain amount of calorific value, lower than that of the metallurgical coke. It might be that the ash content increased, and such product can be used for civil coke or chemical coke. When the mixture ratio was 100%, the calorific value of pyrolysis carbon was 7.53 MJ/kg, representing 25.7% of the calorific value of ordinary coke. The gas production rate of the discharged gas was 0.35, and the calorific value is 14.0 MJ/kg, reaching 73.6% of the coke oven gas. Under the condition of no coal input, the MSW was converted into usable energy. The results demonstrated that coke oven pyrolysis with 100% RDF addition is the most feasible way to recycle resources and energy.

- Researchpp 3681-3698Liu, J., Yang, H., Zhou, Y., Shi, B., and Tao, H. (2024). “Parameter identification procedure for hysteretic shear-resistant properties of beech wood dowels,” BioResources 19(2), 3681-3698.AbstractArticlePDF

To evaluate the shear-resistant behavior of wooden dowels used in Blockhaus shear walls under cyclic load, 19 specimens under ten groups of conditions were prepared and tested. The failure modes, hysteresis curves, mechanical properties, stiffness degradations, and energy dissipation capacities of the specimens were studied. The test results showed that with the increase in the number of dowels, the initial stiffness and peak load of the specimens increased greatly. The diameter of the dowels had little influence on the mechanical properties of the specimens. Furthermore, the test findings demonstrated that the pretension load between the walls greatly enhanced the initial stiffness and energy dissipation capacity of specimens. A simplified finite element model was established in Opensees. Considering the effect of material variability, the parameters of single dowel shear spring and friction spring were identified by Genetic Algorithm with modified objective function in Matlab. The identified parameters were applied to the finite element model of the multi-dowel specimens. The simulation results were in good agreement with the test results, and the validity of the numerical model and parameter identification method was verified.

- Researchpp 3699-3724Sinniha, S., Chowdhury, Z. Z., Ibrahimy, A. I., Ahmed, M., Johan, M. R. B., Khandaker, M. U., Badaruddin, I. A., Kamangar, S., and Hussien, M. (2024). “Two step synthesis and application of porous carbon for removal of copper (II) from wastewater: Statistical optimization and equilibrium isotherm analysis,” BioResources 19(2), 3699-3724.AbstractArticlePDF

In this study, activated carbon (ACs) adsorbent was synthesized using the lignocellulosic waste (LCB) seed from Adansonia digitata L. (BSP) using two steps of hydrothermal carbonization (HTC) followed by activation. The hydrothermally produced char of BSP was activated to produce porous activated carbon BSPAC, where K2CO3 was used as a chemical activating agent. Box Behnken Design was used to optimize the input variables of pyrolysis temperature (A1), residence time (B1), and ratio (C1) for the pyrolysis process. Removal percentage (β1), percentage carbon yield (β2), and fixed carbon (β3) percentage were chosen as output responses. The analysis of variance was utilized to generate appropriate mathematical models with subsequent statistical analysis. Physiochemical characterizations were carried out for the hydrothermally carbonized sample (BSPC) and the optimized activated sample (BSPAC). Langmuir, Freundlich, and Temkin models were employed to estimate the isotherm model parameters. The results demonstrated that HTC with subsequent mild activation using K2CO3 can be considered as a greener route to obtain better-quality porous carbon having surface area of 599 m2/gm for removal of Cu(II) cations from wastewater.

- Researchpp 3725-3739Jopek, M., Ridky, R., Kral, P., Pipiska, T., Rahel, J., Reh, R., and Kristak, L. (2024). “Determining the dynamic properties of spruce wood using the Taylor anvil test,” BioResources 19(2), 3725-3739.AbstractArticlePDF

Spruce wood is one of the most widely used materials in the production of lightweight wood-based composites in central Europe. The quality, weight, and geometric parameters of wood chips have a significant impact on the resulting quality of the manufactured composite product. Numerical simulations are necessary for advanced optimization of the quality of composite components and the manufacturing process itself. These simulations require adequate input material data and a model to produce results applicable to the output of industrial practice. In this study, a material model for spruce wood was established using the Taylor anvil test (TAT). This, in contrast to the commonly used Hopkinson compression test, corresponds better to the actual loading process. A new measurement method for shock pulses was developed to implement TAT obtained data for a realistic material model. The method was compared with numerical simulations in Ansys LS DYNA. Based on the results, parameters for the Johnson-Cook equation were determined, which can be applied in the production of disintegrations and, consequently, in the dynamic loading of spruce composite materials.

- Researchpp 3740-3754Arumaiselvan, U., Kalimuthu, M., Nagarajan, R., Mohan, M., Ismail, S. O., Mohammad, F., Al-Lohedan, H. A., and Krishnan, K. (2024). “Mechanical, physical and thermal properties of polylactic acid filament composite reinforced with newly isolated Cryptostegia grandiflora fiber,” BioResources 19(2), 3740-3754.AbstractArticlePDF

By leveraging the properties of natural or plant fibers and possibilities through three-dimensional (3D) printing technology, a composite filament was fabricated by incorporating newly isolated Cryptostegia grandiflora fiber (CGF), as a reinforcement with polylactic acid (PLA) by using a twin-screw extruder. The fabricated composite filament and pure PLA filament were 3D-printed, using fused deposition modeling (FDM). This study investigated the mechanical, physical, and thermal properties of the 3D-printed CGF reinforced composite filament samples. The mechanical properties of the samples fabricated with 10 wt% CGF were better than that of samples with pure PLA. In addition, impact, tensile, flexural strengths and hardness were increased by 35.6, 33.6, 14.1, and 1.7%, respectively, when compared with the sample with pure PLA. The fractured surface morphology of tensile samples showed a uniform distribution of CGF within the PLA. The addition of CGF improved the thermal stability of the 3D-printed CGF/PLA composite sample by 15%. Therefore, the printed structure could serve as an alternative material for various uses, considering contemporary concepts of sustainability, availability, environmental friendliness, and cost effectiveness.