Abstract

Green composites based on ramie fiber yarn and cellulose acetate resin were prepared via hot pressing. The ramie fiber yarns were treated with NaOH and 3-glycidoxypropyltriethoxysilane. The effect of surface treatment on the fiber adhesion to the resin surface and the mechanical properties of the green composites were studied. The chemical properties of the modified ramie fiber yarn were studied via Fourier-transform infrared (FTIR) spectroscopy. The adhesion performance between the fiber and resin was evaluated. The tensile strength of the composites was measured through tensile testing. A single-fiber tensile experiment was used to determine the influence of the tensile strength of the single fibers after surface-treatment. The surface morphology changes were observed via scanning electron microscopy. The results showed fiber–resin adhesion was improved by the surface treatments. However, the surface treatments negatively affected the single-fiber mechanical properties, with the alkali treatment causing greater damage than the silane treatment.

Download PDF

Full Article

Effect of Alkali and Silane Treatments on Properties of Green Composites Based on Ramie Fibers and Cellulose Acetate Resin

Ye Sun,a Anchang Xu,b Changjie Chen,c Chao Luo,a and Limin Bao d,*

Green composites based on ramie fiber yarn and cellulose acetate resin were prepared via hot pressing. The ramie fiber yarns were treated with NaOH and 3-glycidoxypropyltriethoxysilane. The effect of surface treatment on the fiber adhesion to the resin surface and the mechanical properties of the green composites were studied. The chemical properties of the modified ramie fiber yarn were studied via Fourier-transform infrared (FTIR) spectroscopy. The adhesion performance between the fiber and resin was evaluated. The tensile strength of the composites was measured through tensile testing. A single-fiber tensile experiment was used to determine the influence of the tensile strength of the single fibers after surface-treatment. The surface morphology changes were observed via scanning electron microscopy. The results showed fiber–resin adhesion was improved by the surface treatments. However, the surface treatments negatively affected the single-fiber mechanical properties, with the alkali treatment causing greater damage than the silane treatment.

DOI: 10.15376/biores.17.2.2390-2402

Keywords: Green composite; Natural fiber; Adhesion; Mechanical testing

Contact information: a: Graduate School of Science and Technology, Shinshu University, Nagano, Japan; b: Jiangsu College of Engineering and Technology, Nantong, China; c: College of Textiles, Donghua University, Shanghai, China; d: Faculty of Textile Science and Technology, Shinshu University, Nagano Japan; *Corresponding author: baolimin@shinshu-u.ac.jp

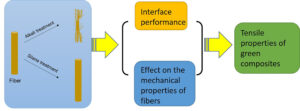

GRAPHICAL ABSTRACT

INTRODUCTION

Recently, the application of fiber-reinforced composites has become increasingly prevalent; however, most of the raw materials, such as composites based on carbon fiber and glass fiber, are derived from petroleum and minerals. Consequently, they do not easily decompose and are challenging to recycle (Lu et al. 2003). With the increase in global environmental pollution and the depletion of natural resources, the discovery of new environmentally friendly materials has gradually become a new research direction in the materials industry. Among these materials, natural fiber-based composites have attracted a lot of attention for development and application (Peijs et al. 1998).

The application of natural fibers in composites is widely studied. Components of composites used in automotive applications include abaca fibers, kenaf fibers, hemp fibers, and flax fibers (Shibata et al. 2002; Arbelaiz et al. 2005; Chen et al. 2005; Müssig et al. 2006). These fibers are currently used in the manufacture of car shell parts and consumer plastic products.

Cai et al. (2016) immersed abaca fibers in NaOH solutions of various concentrations for 2 h, and the influences of the NaOH solutions on the interfacial performances and mechanical characteristics of the composite based on abaca fiber and epoxy resin were evaluated. Asumani et al. (2012) studied the effect of treating short fiber nonwoven kenaf-reinforced polypropylene composites with NaOH solution followed by 3-aminopropyltriethoxysilane and investigated the flexural and tensile properties of the composites. Furthermore, numerous studies on the mechanical properties of composites containing hemp fiber (Haghighatnia et al. 2017), sisal fiber (Zuccarello et al. 2018), flax fiber (Baley et al. 2019), jute fiber (Mistri et al. 2011), and bamboo fiber (Kalali et al. 2019) have been studied. These studies explored the influences of the chemical treatment on the mechanical and interfacial properties of the composites. Results indicated that the interfacial properties of composites can be improved by proper surface treatment. Recently, jute and ramie fibers have received considerable attention (Alves et al. 2011; Choi and Lee 2012). In Choi and Lee’s study, the filament diameter of ramie fiber was generally in the range of 20 to 30 µm, and the lengths were prepared as 3 cm. The mechanical and interfacial properties of composites reinforced with ramie fibers treated with alkali, silane and peroxide were studied. Being an environmentally friendly, low-cost biological resource, ramie fiber has gradually become one of the preferred materials for reinforcement fibers (Koronis et al. 2013; Yang et al. 2021). Ramie fiber, also known as the “king of natural fibers,” has the advantages of large elastic modulus, high crystallinity, and long length (Auras et al. 2004; Rehman et al. 2019), and its application in green composites has been extensively studied. Yu et al. (2010) used polylactic acid and ramie fiber to synthesize green composites. They found that the alkali treatment of ramie fiber improved the composite mechanical properties. The influences of surface treatment on interfacial properties were investigated in these studies. Yu et al. (2010) found that after alkali treatment, the surface impurities and some of lignin were removed and the surface of ramie fiber became rough. Therefore, the interfacial adhesion between fiber and matrix was improved. For silane treatment, the silanol formed by the reaction of silane with water reacts with hydroxyl groups on the glucose units of cellulose molecules in the ramie fiber cell-wall, thereby bonding itself to the cell-wall. Chemical bonding could be established between the ramie fiber and the matrix.

Fig. 1. Completed prepreg of ramie yarn

In the current study, green composites with ramie fiber (as the reinforcement) and cellulose acetate (as the main component of the matrix) were prepared via a hot-pressing method. The prepreg was prepared by winding the ramie fiber on the mold. The completed prepreg is shown in Fig. 1. The purpose of this research was to investigate better surface treatment method for ramie fiber–cellulose resin green composites. It is hoped that the surface treatment can minimize the damage to the ramie fiber and the interface adhesion can be improved, thereby improving the green composite tensile strength.

EXPERIMENTAL

Materials

In this study, the authors selected ramie fiber yarn (Wuhan Textile University, Wuhan, China) as the reinforcement material. The ramie fiber yarn had gone through several steps: dipping, degumming, carding, drawing, and spinning. Cellulose acetate resin Selbrene EC 210 (Daicel Polymer Co., Ltd., Osaka, Japan) was used as the matrix material. The chemical reagents used in the experiment are as follows: plasticizer: diethyl phthalate (Kanto Chemical Co., Inc., Tokyo, Japan); solvent: acetone, 99.5% (Junsei Chemical Co., Ltd., Tokyo, Japan); UV curable resin (Kyoeisha Chemical Co., Ltd., Osaka, Japan); epoxy ester 80 MFA (Kyoeisha Chemical Co., Ltd., Osaka, Japan); sodium hydroxide pellets (Yoneyama Yakuhin Kogyo Co., Ltd., Osaka, Japan); and 3-glycidoxypropyltriethoxy silane (Shin-Etsu Chemical Co., Ltd., Tokyo, Japan).

Surface Treatment

A unidirectional reinforcement method for ramie fiber yarn was constructed by wrapping the yarns around a mold. Then, the yarns were surface-treated to improve the interface adhesion of green composites.

Alkali treatment

Initially, for ensuring that the initial state of the fibers was consistent, the ramie fibers were washed with acetone solution and then vacuum-dried at 60 °C for 24 h. The ramie fibers were then soaked in 5 wt% NaOH solution at room temperature for 3 h. Afterwards, the material was washed using deionized water for removing the NaOH from the fiber surface. Then, the ramie fibers were dried for 72 h under room temperature. Finally, the ramie fibers were vacuum-dried for 6 h at 60 °C (Yu et al. 2010).

Silane treatment

The ramie fibers’ surface was first washed with acetone solution and then vacuum-dried at 60 °C for 24 h. A 2% solution of the silane coupling agent was prepared at the same time, and then the fibers were soaked in the silane coupling agent solution at room temperature, and finally the fiber-containing solution was ultrasonically vibrated (US-106; SND Co., Ltd., Suwa, Japan) for an hour.

Subsequently, the fiber surface was cleaned with deionized water until the silane was removed and then the ramie fibers were then dried at room temperature for 72 h. Finally, the ramie fibers were vacuum-dried for 6 h at 60 °C (Xie et al. 2010).

Composite Preparation

Initially the plasticizer (10 wt% of resin) was added to acetone, and then 15 wt% cellulose resin was added. The mixture was then stirred until the resin was completely dissolved. To construct a unidirectional reinforcement of ramie yarn, the ramie yarn was wrapped around a mold, after which the lateral direction of the fiber was fixed with nylon fiber and UV resin. Then, the resin solution was evenly spread on the fiber surface to impregnate the fiber. The impregnated fiber was then dried under vacuum conditions at 60 °C for 2 h to let the acetone solvent completely volatilize. Finally, the fiber was hot pressed at 190 °C to form the prepreg. The process is illustrated in Fig. 2.

Fig. 2. Green composite material preparation process

Characterization

Fourier transform infrared spectroscopy

Fourier transform infrared (FTIR) spectra were recorded on a Shimadzu IR Prestige-21 spectrometer (Shimadzu Corporation, Kyoto, Japan) in the range 400 to 4000 cm-1, using compression-molded film samples.

Interlaminar shear strength test

An interlaminar shear test was performed using an Autograph machine (AG-20KND, Shimadzu, Kyoto, Japan). Figure 3 shows the sample used for the test. After the test, the interlaminar shear strength was calculated with the test force obtained from the shear test and the lap area of the test piece. The distance between the fixtures and the test velocity was determined by JIS K 6851 (1994). The test velocity used was 1.0 mm/min, and the fixture’s distance was 90 mm.

Fig. 3. Shear strength test: (a) the state of test; and (b) the fracture surface

Tensile test of green composites

The tensile strength test was performed using an Autograph machine (AG-20KND, Shimadzu, Kyoto, Japan) following the standard JIS K 7165 (2008). The test velocity was 1.0 mm/min and the fixtures distance was 60 mm in this test. The dimensions of the tensile sample are shown in Fig. 4. Five effective samples were assessed, and the average value was calculated.

Fig. 4. Schematic diagram of the tensile test setup

Tensile test of single ramie fibers

The tensile test of single fibers was performed with a small table-top tester (EZ-Test main unit EZ-SX 50 N outer set, Shimadzu, Kyoto, Japan). The fiber diameter was measured at the fracture point, and the ramie single fibers tensile strength was calculated using the average value from 10 effective fibers. The effective fiber means the samples were removed that broke due to stress concentration during single fiber tensile testing. When subjected to a tensile test, the single ramie fiber can easily break at the fixture; thus, an auxiliary support needed to be prepared beforehand. The dimensions of the fixture are shown in Fig. 5.

Fig. 5. (a) Size of fixture and (b) the test of single fiber

The measurement conditions used were as follows: a stretching velocity of 20 mm/min, room temperature of 20 °C, and humidity of 65%, and fixture distance of 20 mm. The fiber strength was calculated as in Eq. 1,

where σb denotes fiber strength (MPa), F is load (N), and r is fiber radius (mm2).

Scanning electron microscopy

The surface morphologies of the fractured tensile samples were observed on a JSM-6010LA InTouch Scope scanning electron microscope (JEOL Co., Ltd., Tokyo, Japan). In order to collect high quality images during observation, a thin layer of gold was plated on the fracture surface of the observed samples with an automatic sputter (JFC-1600; JEOL Ltd., Tokyo, Japan) in an argon environment.

RESULTS AND DISCUSSION

Chemical Analysis of Samples

The comparison of the characteristics of FTIR spectra of the untreated, alkali-treated, and silane-treated ramie fibers are shown in Fig. 6. The figure displays that the untreated and alkali-treated ramie fibers were different. The spectrum of the silane-treated fiber showed a peak at 710 cm−1, which can be attributed to the -Si-C bond (Choi and Lee 2012). Moreover, the peak at 918 cm−1 could be attributed to asymmetric stretching of cellulose-O-Si or Si-O-Si bonds (Hong et al. 2008). In addition, the spectrum of the ramie fiber featured a peak around 1391 cm−1, which could be related to the cellulose–Si–O or Si–O–Si linkage (Abdelmouleh et al. 2004). When untreated and silane-treated fibers are compared, the peaks at 1630 and 830 cm-1 of alkali-treated fiber could not be observed. It can be attributed to lignin and hemicelluloses on the surfaces of ramie fiber that were removed during the alkali treatment (Colom et al. 2003).

Fig. 6. FTIR spectra of composites based on untreated, alkali-treated, and silane-treated fibers

Adhesion Performance of the Green Composites

Figure 7 shows the adhesion performance of green composites with untreated, alkali-treated, and silane-treated ramie fiber yarns. The interlaminar shear strengths of the green composites containing silane-treated and alkali-treated yarns were approximately 33% and 43% higher than that of the green composite containing untreated yarn. The alkali treatment and silane treatment positively influenced the adhesion of green composites.

Fig. 7. Interlaminar shear strengths of fiber-reinforced thermoplastics

Tensile Properties of the Green Composites

The tensile strengths of green composites with untreated, alkali-treated, and silane-treated ramie fibers are shown in Fig. 8. The tensile strength of the green composite with alkali-treated fibers (103.3 MPa) was approximately 50% higher than that of the green composite with untreated fiber (68.8 MPa). In addition, the tensile strength of the green composite with silane-treated fibers (109.8 MPa) was about 60% higher than that of the green composite with untreated fiber. This higher strength can be attributed to surface treatment-induced improvement of the fiber to resin adhesion (Cai et al. 2016).

Fig. 8. Tensile strengths of fiber-reinforced thermoplastics

Furthermore, the tensile strength of the green composite treated with silane coupling agent (109.81 MPa) was even higher. Although there were some differences in the error range, the tensile strength of the green composite prepared with silane-treated fibers was on average 6% higher than that of the green composite with alkali-treated fibers. This was probably because the green composite with silane-treated fiber experienced less damage than the green composite with alkali-treated fiber. When standard deviation is taken into account, the effects of the treatment using silane coupling agent and the alkali treatment on the tensile strength were almost the same.

As indicated in the section “Adhesion Performance of the Green Composites”, it is known that compared with silane treatment, alkali treatment is better for improving the adhesion performance of the green composites, but the tensile properties of green composites are weaker than silane treatment. Therefore, the effect of the surface treatments on the fiber itself needs to be further explored.

Tensile Properties of Single Fibers

The tensile strengths of the untreated, alkali-treated, and silane-treated single ramie fibers are shown in Fig. 9. The tensile strengths of the single ramie fibers treated with alkali and silane were approximately 34% and 16% less than that of the untreated fiber, respectively. However, the tensile strength of the silane-treated single fiber was approximately 26% higher than that of the alkali-treated fiber. The alkali-treated cellulose fibers had a lower tensile strength because after the treatment, the lignin content of the fibers decreased, resulting in damage to the fibers, thereby reducing the mechanical properties of the single fibers.

In the section “Adhesion Performance of the Green Composites”, the authors experimentally verified that the surface treatment improved the adhesion of fibers to the resin, so the results of tensile strengths of single fibers explain the variation in tensile properties of green composites.

Fig. 9. Tensile strengths of single fibers

Morphology of Samples

Figure 10 reveals that the ramie fiber yarn after alkali-treatment was damaged, and fine fibers were formed due to the fibrilization of the fibers. From the Fig. 7, the tensile properties of the green composite were deteriorated, which was largely affected by the decrease in ramie single fiber strength. However, cellulose resin can be seen on the ramie fibers surface, which indicated that the interfacial adhesion was improved. The adhesiveness of the green composite based on the silane-treated fiber, that is, the adhesion degree between the resin and the fiber surface was improved. For the untreated fiber, almost no resin was observed on the surface, indicating that the adhesiveness of the green composite was low. These results further confirm the effectiveness of the alkali and silane treatments for ramie fibers. Additionally, it was also confirmed that the alkali treatment caused greater damage to the fiber.

Fig. 10. Fracture surfaces of tensile samples based on untreated fiber (a), alkali-treated fiber (b), and silane-treated fiber (c)

CONCLUSIONS

- The study results showed that surface treatment of ramie fibers by either NaOH or 3-glycidoxypropyltriethoxy silane improved the adhesiveness of green composites prepared with cellulose acetate resin and a plasticizer.

- According to the FTIR analysis and mechanical properties test results, the alkali and silane are effective surface treatment agents. After silane treatment, the surface of ramie fiber formed chemical bonds which could react with resin. According to the fracture surface morphologies, the surface of the ramie fiber became rough could be observed.

- The single-fiber tensile test results revealed that after alkali treatment the mechanical properties of the single ramie fiber were decreased. As shown in the fracture surface morphologies of the green composites, the adhesion of the surface-treated ramie fiber and cellulose resin interfaces were improved.

ACKNOWLEDGMENTS

This research was supported by the Natural Science Foundation of Hubei Province [Grant No. 2019CFB346] and JSPS KAKENHI [Grant No. 20H00288].

REFERENCES CITED

Abdelmouleh, M., Boufi, S., Belgacem, M., Duarte, A., Salah, A. B., and Gandini, A. (2004). “Modification of cellulosic fibres with functionalised silanes: Development of surface properties,” Int. J. Adhes. Adhes. 24(1), 43-54. DOI: 10.1016/S0143-7496(03)00099-X

Alves, C., Ferrão, P. M. C., Silva, A. J., Reis, L. G., Freitas, M., Rodrigues, L. B., and Alves, D. E. (2011). “Ecodesign of automotive components making use of natural jute fiber composites,” J. Clean. Prod. 18(4), 313-327. DOI: 10.1016/j.jclepro.2009.10.022

Arbelaiz, A., Fernández, B., Cantero, G., Llano-Ponte, R., Valea, A., and Mondragon, I. (2005). “Mechanical properties of flax fibre/polypropylene composites. Influence of fibre/matrix modification and glass fibre hybridization,” Compos. Part A- Appl. S. 36(12), 1637-1644. DOI: 10.1016/j.compositesa.2005.03.021

Asumani, O., Reid, R., and Paskaramoorthy, R. (2012). “The effects of alkali–silane treatment on the tensile and flexural properties of short fibre non-woven kenaf reinforced polypropylene composites,” Compos. Part A- Appl. S. 43(9), 1431-1440. DOI: 10.1016/j.compositesa.2012.04.007

Auras, R., Harte, B., and Selke, S. (2004). “An overview of polylactides as packaging materials,” Macromol. Biosci. 4(9), 835-864. DOI: 10.1002/mabi.200400043

Baley, C., Goudenhooft, C., Perré, P., Lu, P., Pierre, F., and Bourmaud, A. (2019). “Compressive strength of flax fibre bundles within the stem and comparison with unidirectional flax/epoxy composites,” Ind. Crop. Prod. 130(4), 25-33. DOI: 10.1016/j.indcrop.2018.12.059

Cai, M., Takagi, H., Nakagaito, A. N., Li, Y., and Waterhouse, G. I. (2016). “Effect of alkali treatment on interfacial bonding in abaca fiber-reinforced composites,” Compos. Part A- Appl. S. 90(11), 589-597. DOI: 10.1016/j.compositesa.2016.08.025

Chen, Y., Sun, L. F., Chiparus, O., Negulescu, I., Yachmenev, V., and Warnock, M. (2005). “Kenaf/ramie composite for automotive headliner,” J. Polym. Environ. 13(2), 107-114. DOI: 10.1007/s10924-005-2942-z

Choi, H. Y., and Lee, J. S. (2012). “Effects of surface treatment of ramie fibers in a ramie/poly (lactic acid) composite,” Fiber. Polym. 13(2), 217-223. DOI 10.1007/s12221-012-0217-6

Colom, X., Carrasco, F., Pages, P., and Canavate, J. (2003). “Effects of different treatments on the interface of HDPE/lignocellulosic fiber composites,” Compos. Sci. Technol. 63(2), 161-169. DOI: 10.1016/S0266-3538(02)00248-8

Haghighatnia, T., Abbasian, A., and Morshedian, J. (2017). “Hemp fiber reinforced thermoplastic polyurethane composite: an investigation in mechanical properties,” Ind. Crop. Prod. 108(1), 853-863. DOI: 10.1016/j.indcrop.2017.07.020

Hong, C. K., Hwang, I., Kim, N., Park, D. H., Hwang, B. S., and Nah, C. (2008). “Mechanical properties of silanized jute–polypropylene composites,” J. Ind. Eng. Chem. 14(1), 71-76. DOI: 10.1016/j.jiec.2007.07.002

JIS K 6851 (1994). “Testing methods for tensile shear strength of wood-to-wood adhesive bonds,” Japanese Industrial Standards Committee, Tokyo, Japan.

JIS K 7165 (2008). “Plastics – Determination of tensile properties – Part 5: Test conditions for unidirectional fibre-reinforced plastic composites,” Japanese Industrial Standards Committee, Tokyo, Japan.

Kalali, E. N., Hu, Y., Wang, X., Song, L., and Xing, W. (2019). “Highly-aligned cellulose fibers reinforced epoxy composites derived from bulk natural bamboo,” Ind. Crop. Prod. 129(3), 434-439. DOI: 10.1016/j.indcrop.2018.11.063

Koronis, G., Silva, A., and Fontul, M. (2013). “Green composites: A review of adequate materials for automotive applications,” Compos. Part B- Eng. 44(1), 120-127. DOI: 10.1016/j.compositesb.2012.07.004

Lu, X., Zhang, M. Q., Rong, M. Z., Shi, G., and Yang, G. C. (2003). “Self-reinforced melt processable composites of sisal,” Compos. Sci. Technol. 63(2), 177-186. DOI: 10.1016/S0266-3538(02)00204-X

Mistri, E., Routh, S., Ray, D., Sahoo, S., and Misra, M. (2011). “Green composites from maleated castor oil and jute fibres,” Ind. Crop. Prod. 34(1), 900-906. DOI: 10.1016/j.indcrop.2011.02.008

Müssig, J., Schmehl, M., von Buttlar, H. B., Schönfeld, U., and Arndt, K. (2006). “Exterior components based on renewable resources produced with SMC technology – considering a bus component as example,” Ind. Crop. Prod. 24(2), 132-145. DOI: 10.1016/j.indcrop.2006.03.006

Peijs, T., Garkhail, S., Heijenrath, R., van den Oever, M., and Bos, H. (1998). “Thermoplastic composites based on flax fibres and polypropylene: Influence of fibre length and fibre volume fraction on mechanical properties,” Macromol. Symp. 127(1), 193–203. DOI: 10.1002/masy.19981270126

Rehman, M., Gang, D., Liu, Q., Chen, Y., Wang, B., Peng, D., and Liu, L. (2019). “Ramie, a multipurpose crop: potential applications, constraints and improvement strategies,” Ind. Crop. Prod. 137(11), 300-307. DOI: 10.1016/j.indcrop. 2019.05.029

Shibata, M., Takachiyo, K. I., Ozawa, K., Yosomiya, R., and Takeishi, H. (2002). “Biodegradable polyester composites reinforced with short abaca fiber,” J. Appl. Polym. Sci. 85(1), 129-138. DOI: 10.1002/app.10665

Xie, Y., Hill, C. A., Xiao, Z., Militz, H., and Mai, C. (2010). “Silane coupling agents used for natural fiber/polymer composites: A review,” Compos. Part A- Appl. S. 41(7), 806–819. DOI: 10.1016/j.compositesa.2010.03.005

Yang, X., Fan, W., Ge, S. B., Gao, X. Z., Wang, S. J., Zhang, Y. H., Foong, S. Y., Liew, R. K., Lam, S. S., and Xia, C. L. (2021). “Advanced textile technology for fabrication of ramie fiber PLA composites with enhanced mechanical properties,” Ind. Crop. Prod. 162(4), article no. 113312. DOI: 10.1016/j.indcrop.2021.113312

Yu, T., Ren, J., Li, S., Yuan, H., and Li, Y. (2010). “Effect of fiber surface-treatments on the properties of poly(lactic acid)/ramie composites,” Compos. Part A- Appl. S. 41(4), 499-505. DOI: 10.1016/j.compositesa.2009.12.006

Zuccarello, B., Marannano, G., and Mancino, A. (2018). “Optimal manufacturing and mechanical characterization of high performance biocomposites reinforced by sisal fibers,” Compos. Struct. 194(15), 575-583. DOI: 10.1016/j.compstruct.2018.04.007

Article submitted: December 28, 2021; Peer review completed: February 20, 2022; Revised version received and accepted: February 27, 2022; Published: March 4, 2022.

DOI: 10.15376/biores.17.2.2390-2402