Abstract

This study demonstrated the reinforcing potential of kenaf core fiber (KCF) to complement and sustain oil palm fiber supply chain in the production of natural fiber-thermoplastic biocomposites. The lignin-rich KCF was incorporated into cellulose-rich oil palm empty fruit bunch fiber (EFBF)- and oil palm mesocarp fiber (OPMF)-poly(lactic acid) (PLA) composites, aimed at achieving synergism. The hybrid biocomposites developed by melt blending and subsequent compression molding were characterized for possible application as an alternative to medium-density fiberboards. The mechanical properties and dimensional stability of both single fiber- and hybrid fiber-PLA biocomposites were evaluated and compared. The test results showed a synergistic improvement as a consequence of fiber hybridization. Also, the findings suggested the best material performance with the incorporation of 5% KCF into 55% EFBF or OPMF and 40% PLA matrix. The OPMF-KCF-PLA hybrid biocomposites gave better results than the EFBF-KCF-PLA hybrid biocomposites.

Download PDF

Full Article

Influence of Kenaf Core Fiber Incorporation on the Mechanical Performance and Dimensional Stability of Oil Palm Fiber Reinforced Poly(lactic acid) Hybrid Biocomposites

Abubakar Umar Birnin-Yauri,a,b Nor Azowa Ibrahim,a,c,* Norhazlin Zainuddin,a Khalina Abdan,d Yoon Yee Then,a,e and Buong Woei Chieng a,c

This study demonstrated the reinforcing potential of kenaf core fiber (KCF) to complement and sustain oil palm fiber supply chain in the production of natural fiber-thermoplastic biocomposites. The lignin-rich KCF was incorporated into cellulose-rich oil palm empty fruit bunch fiber (EFBF)- and oil palm mesocarp fiber (OPMF)-poly(lactic acid) (PLA) composites, aimed at achieving synergism. The hybrid biocomposites developed by melt blending and subsequent compression molding were characterized for possible application as an alternative to medium-density fiberboards. The mechanical properties and dimensional stability of both single fiber- and hybrid fiber-PLA biocomposites were evaluated and compared. The test results showed a synergistic improvement as a consequence of fiber hybridization. Also, the findings suggested the best material performance with the incorporation of 5% KCF into 55% EFBF or OPMF and 40% PLA matrix. The OPMF-KCF-PLA hybrid biocomposites gave better results than the EFBF-KCF-PLA hybrid biocomposites.

Keywords: Hybrid biocomposite; Oil palm empty fruit bunch fiber; Oil palm mesocarp fiber; Kenaf core fiber; Poly(lactic acid)

Contact information: a: Department of Chemistry, Faculty of Science, Universiti Putra Malaysia , 43400 UPM Serdang, Selangor, Malaysia; b: Department of Pure and Applied Chemistry, Kebbi State University of Science and Technology, P.M.B 1144, Aliero, Kebbi State. Nigeria; c: Materials Processing and Technology Laboratory, Institute of Advanced Technology, Universiti Putra Malaysia, 43400 UPM Serdang, Selangor, Malaysia; d: Department of Biological and Agricultural Engineering, Faculty of Engineering, Universiti Putra Malaysia, 43400 UPM Serdang, Selangor, Malaysia; e: Department of Pharmaceutical Chemistry, School of Pharmacy, International Medical University, 126, Jalan Jalil Perkasa 19, Bukit Jalil, 57000 Kuala Lumpur, Malaysia; *Corresponding author: norazowa@upm.edu.my

INTRODUCTION

Current research in the area of polymer composites has experienced increasing attention to the fabrication of green materials to curtail some of the problems associated with the production and use of traditional polymer composites, which are largely dependent on petroleum resources, for supply of both raw materials and energy (Kim et al. 2006; Mukherjee and Kee 2011; Dicker et al. 2014). In addition to the fact that some petroleum-based polymers have no biodegradability properties and exorbitant prices, petroleum resources are also non-renewable, quickly depleting, and threatening to run out in the next century (Bentley 2002; Hashim et al. 2012).

Conventional fiber reinforcement uses inorganic materials (e.g., glass and carbon) as reinforcements with a petroleum-based or bio-polymer matrix (Zhang et al. 2012). However, conventional fiber reinforcement has shown quite a number of environmental, health, and economic issues (Abdul Khalil et al. 2012). These conventional fibers have been found to cause serious ecological and health hazards to employees working in polymer composite industries (Jawaid and Abdul Khalil 2011).

However, there is currently growing interest in natural fibers such as banana, pineapple, hemp, sisal, kenaf, oil palm, and bamboo, which have shown attractive advantages over conventional fiber reinforcements (Faruk et al. 2012; Then et al. 2014a). These benefits include natural abundance (Eichhorn et al. 2001), renewability (Mukherjee and Kee 2011), biodegradability (Kim et al. 2006), low cost (Leão et al. 2008), low energy requirements (Jawaid and Abdul Khalil 2011), low density (Hashim et al. 2012), attractive specific properties (Li 2004), good thermal and insulating properties (Khazaeian et al. 2015), lower wear and tear during processing (Nayak et al. 2009), relatively less abrasiveness, and sustainability (Abdul Khalil et al. 2010a, 2012).

A number of studies have been conducted to mix two or more natural and/or synthetic fibers together with biodegradable or non-degradable polymer matrices to develop hybrid fiber-polymer biocomposites (Jacob et al. 2004; Thiruchitrambalam et al. 2009; Jawaid et al. 2010; Pandita et al. 2014). The idea behind mixing two or more fibers is to achieve synergistic performance, complement material properties, or sustain the supply chain of raw material (Jawaid and Abdul Khalil 2011). The properties of weak fibers in the hybrid could be enhanced, thereby improving the overall material performance of the biocomposites. These properties include fiber orientation, length, and density. Moreover, the properties of hybrid biocomposites are related to individual fiber content, degree of fiber intermingling, and fiber-matrix interfacial bonding (Jawaid and Abdul Khalil 2011).

The combination of two or more materials often follows the rule of mixtures, which can best be used to explain the properties of natural fiber hybrid system. When the hybrid composites consist of only two different fibers, the rule of mixtures can be stated as PH = P1V1 + P2V2 (Thwe and Liao 2003; Jawaid and Abdul Khalil 2011). The property of the entire mixture (PH) relates proportionally to the corresponding properties of the first (P1) and second (P2) fiber components and also to their volume fractions, V1 and V2, respectively (Jawaid et al. 2012).

Some previous reports on hybrid natural fiber-synthetic fiber composites include epoxy resin-based glass-carbon fiber reinforced hybrid composites (Zhang et al. 2012), rooflite resin-based palmyra-glass (Velmurugan and Manikandan 2007), bamboo-glass fiber reinforced USP and VE resin (Mandal et al. 2010), jute-glass and kenaf-glass reinforced polyester (Akil et al. 2010), wood flour-glass thermoplastic composites (Valente et al. 2011), and oil palm empty fruit bunch-glass reinforced polypropylene hybrid composites (Rozman et al. 2001). There have also been reports on natural fiber-natural fiber reinforced hybrid biocomposites, including banana-kenaf reinforced polyester biocomposites (Thiruchitrambalam et al. 2009), oil palm empty fruit bunch fiber-jute reinforced epoxy resin hybrid biocomposites (Jawaid et al. 2010), and polypropylene-based kenaf fiber-wood flour hybrid biocomposites (Ghasemi et al. 2008).

Herein, novel natural fiber-natural fiber reinforced poly(lactic acid) (PLA) hybrid biocomposites were fabricated by a combination of EFBF-KCF and OPMF-KCF, and their mechanical and dimensional stability properties were compared with their corresponding single fiber reinforced PLA based biocomposites. The primary goal of the present work was to enhance the mechanical performance of the single oil palm fiber-based PLA biocomposites by incorporation of KCF. To the best of our knowledge, this is the first attempt to incorporate KCF into oil palm fibers to form hybrid fiber reinforced PLA biocomposites.

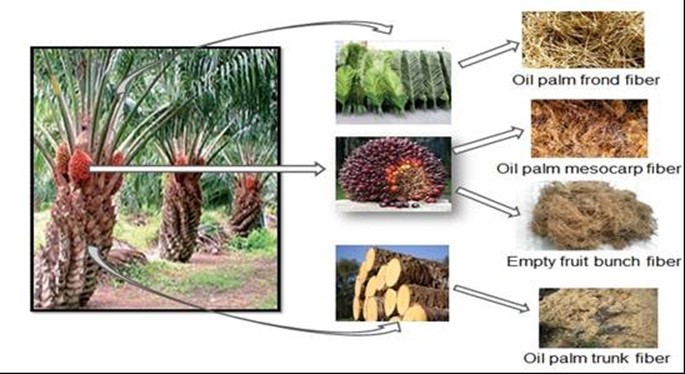

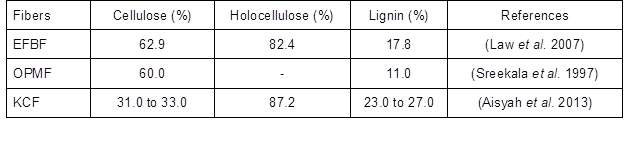

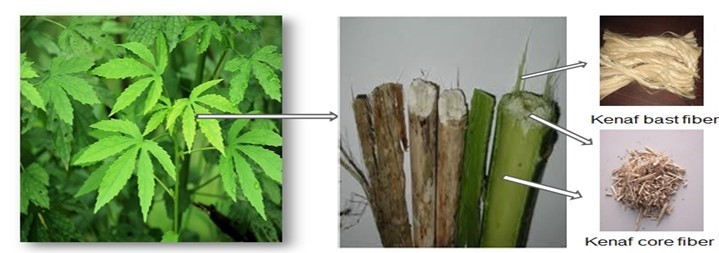

The EFBF and OPMF (Fig. 1) are the biomass obtained, respectively, from fresh fruit bunch and oil palm fruits (Abdul Khalil et al. 2012). These two biomass types have distinct chemical properties (Table 1) from KCF (Fig. 2), which originates from the stem of the kenaf plant (Sreekala et al. 1997; Ververis et al. 2004; Deka et al. 2013).

Fig. 1. Oil palm tree and biomass

The primary reason for mixing these hybrid fibers was that EFBF and OPMF are cellulose-rich, while KCF is lignin-rich (Table 1). Many studies have reported the reinforcing potential of lignin to enhance the mechanical and dimensional stability of natural fiber reinforced polymer biocomposites (Nasir et al. 2013; Ghaffar and Fan 2014; Thakur et al. 2014; Reza Barzegari et al. 2012); thus, incorporating KCF into the EFBF or OPMF may enable this presumed synergistic performance.

Table 1. Chemical Properties of Oil Palm Fibers and Kenaf Core Fibers

Fig. 2. Kenaf plant and fiber resources

EXPERIMENTAL

Materials

Poly(lactic acid) was purchased from Nature Work LLC (USA) under the trade name polylactide resin 4042D. It has a melting point range between 170 and 190 °C and density ranging from 1.4 to 1.5 g/cm-3. The oil palm fibers, i.e., EFBF and OPMF, were obtained from Sabutek (M) Sdn. Bhd., Malaysia and FELDA Serting Hilir Oil Palm Mill, Malaysia, respectively. KCF was kindly supplied by Lembaga Kenaf dan Tembakau, Malaysia.

Methods

Fiber purification

To remove impurities from the EFBF, OPMF, and KCF, they were physically treated by sorting, soaking in distilled water for 24 h at 25 °C, washing with heated water at 60 °C, cleaning with acetone, and oven-drying at 60 °C for 24 h. The oven-dried fibers were then ground into smaller particles, followed by sieving into fiber sizes ranging from 300 to 400 µm. The purified fibers were then stored in sealed plastic bags at 25 °C for further investigation.

Fabrication of single and hybrid fiber–PLA biocomposites

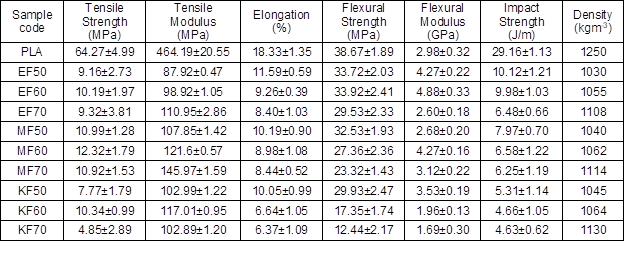

To prepare the single fiber-PLA biocomposites, the oven-dried EFBF, OPMF, and KCF together with the PLA were melt blended at various fiber-to-PLA loading formulations (Table 2) using a Brabender Internal Mixer (Germany) at 170 °C with a rotor speed of 50 rpm for 15 min, in accordance with the method reported by Then et al. (2015a). Initially, the PLA was loaded into the mixing chamber to melt for 2 min; then, the fibers were added to the molten PLA and mixing continued for 13 more minutes. The compounded single fiber-PLA biocomposites were further compression molded into sheets with dimensions of 1 mm × 150 mm × 150 mm and 3 mm × 150 mm × 150 mm (thickness × length × width). The compression molding was performed using a hydraulic hot press at 170 °C, 150 kgfm-2, and 10 min molding temperature, pressure, and time, respectively. Furthermore, cooling was performed at 30 °C for 5 min.

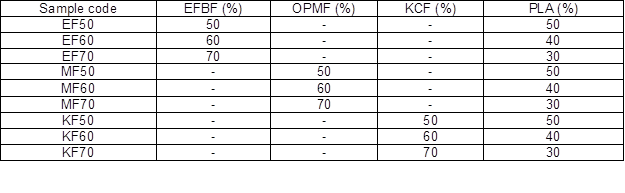

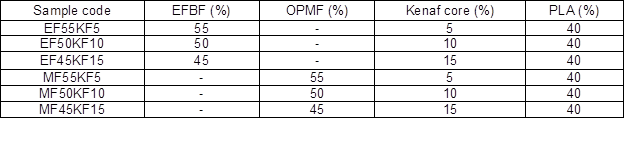

The hybrid fiber-PLA biocomposites were prepared following a similar method. The hybrid fiber-PLA biocomposites were fabricated by randomly mixing two different fibers together manually prior to melt blending with PLA. The various hybrid fiber mixing formulations are presented in Table 3.

Table 2. Single Fiber-PLA Loading Formulations

Table 3. Hybrid Fiber-PLA Loading Formulations

Mechanical properties analysis

The tensile properties of neat PLA and single and hybrid fiber-PLA biocomposites were tested using a Universal Testing Machine-Instron 3365 (USA) equipped with a 5-kN load cell at a 5-mm/min crosshead speed. The test was performed at 25 °C. Five dog-bone-shaped specimens were tested, as specified by ASTM D638-5 (2000). Average values of tensile strength, tensile modulus, and elongation at break are reported.

The flexural properties (i.e., three-point testing) of the composites were determined using a Universal Testing Machine-Instron 3365 (USA) equipped with a 5-kN load cell at a 1.3-mm/min crosshead speed and 48-mm span length. The test was performed at 25 °C on five specimens with dimensions of 127.0 × 12.7 × 3.0 mm3 (length × width × thickness) in accordance with ASTM D790 (2000). Average values of flexural strength and flexural modulus are reported.

The impact strength of the composites was examined following the un-notched IZOD impact test, as specified by ASTM D256 (2000). The impact tester (India) was equipped with a 7.5-J pendulum. The test was performed at 25 °C on five specimens having dimensions of 63.5 x 12.7 x 3.0 mm3, and the average value is reported.

Density measurement

The density of the biocomposites was measured in accordance with BS EN 323 (1993) (European Committee for Standardization 1993; Abdul Khalil et al. 2010a). The masses of the test samples were obtained and recorded by weighing using an analytical balance. Thereafter, the volume of the test samples was also obtained and noted by measuring their dimensions, i.e., multiplying their length, width, and thickness, respectively. The density was subsequently calculated using the following formula:

Density = mass/volume (1)

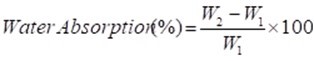

Dimensional stability measurement

To test for water absorption and thickness swelling of the biocomposites, test samples with dimensions of 10.0 × 10.0 × 1.0 mm3 were cut according to ASTM D570 (2005) and European standard EN 317 (1993), respectively. The initial weight (W1) and thickness (T1) of the oven-dried test samples were measured and noted. Test samples were then immersed in distilled water for 24 h at 25 °C. Thereafter, they were removed, excess water was wiped off with a tissue, and their weight (W2) and thickness (T2) were measured again. Duplicate tests were conducted to determine the average, mean, and standard deviation. The water uptake and thickness swelling were calculated using the following equations:

(2)

(2)

(3)

(3)

Scanning electron microscopy (SEM)

The surface morphologies of the pure fibers (EFBF, OPMF, and KCF) and the fractured surfaces of neat PLA and the various fiber-PLA biocomposites were analyzed using scanning electron microscopy. The instrument used to conduct the test was a LEO 1455 VP scanning electron microscope (Japan) operated at 10-kV accelerating voltage. The metal holder of the instrument was used to hold the oven-dried samples in place. Thereafter, the samples were coated with gold for 3 min using a Bio-rad coating system (USA) to enhance conductivity before the commencement of analysis.

Fourier transform infrared spectroscopy (FTIR)

The chemical properties, i.e., functional groups, bond types, and chemical components, of the pure oil palm fibers (EFB, OPMF, and KCF) were analyzed using a Perkin Elmer Spectrum 100 series spectrophotometer (USA). The instrument was equipped with attenuated total reflectance (ATR) capacity. The wavenumber range from 400 to 4000 cm-3 was employed to record the FTIR spectra.

RESULTS AND DISCUSSION

Single Fiber-PLA Biocomposites

Initially, water-treated EFBF, OPMF, and KCF at 90%, 80%, 70%, 60%, and 50% were melt-blended with 10%, 20%, 30%, 40%, and 50% poly(lactic acid) (PLA). This was done to develop single fiber-PLA biocomposites and investigate the effect of fiber loading on the mechanical properties and dimensional stability of PLA to optimize the single fiber-PLA biocomposites as control samples. It was observed that the fibers at 90% and 80% loadings could not be wetted with 10% and 20% PLA, respectively, resulting in poor fiber-polymer bonding. This was in accordance with observations made by Then et al. (2013). Therefore, the 90% and 80% fiber loadings were removed from the research. The PLA can sufficiently wet the fibers at 30% PLA loading.

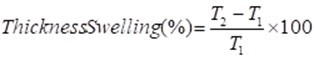

However, the TS dropped broadly at 70:30 fiber-to-PLA loading and presented comparable results for the EFBF and OPMF composites, while the KCF composite showed the least TS. The TS at 50:50 fiber-to-PLA loading showed reduced values relative to those at 60:40 fiber-to-PLA loading. This is a result of the high composition of PLA, which is relatively brittle and makes the material easily breakable (Brostow and Hagg 2010). Generally, The TS shows optimum results at a 60% fiber loading, with 40% PLA. The KCF-filled biocomposites had the lowest TS, which is expected considering that KCF fibers possess low quality for this sort of application because of the high contents of holocellulose and lignin and the low content of α-cellulose (Abdul Khalil and Suraya 2011). The fiber also has a low aspect ratio (i.e., fiber length to fiber diameter).

Table 4. Mechanical Properties and Densities of Single Fiber-PLA Composites

OPMF had a better TS than did EFBF. This could be because the OPMF possesses a more soft and flexible nature and thus has a greater tendency to be more uniformly distributed and oriented in the PLA matrix, thereby bringing about higher TS and reinforcing ability than EFBF. This conforms to the findings observed by Then et al. (2013).

The elongation at break (EB) of the biocomposites decreased with low PLA loading and high fiber content, as shown in Table 4. This may be due to the poor interfacial bonding between the fiber and the PLA, producing micro cracks which can easily propagate in the composites, causing them to break (Okubo et al. 2005; Then et al. 2013). The decrease in EB with increasing lignocellulosic fiber loading in biocomposites has also been observed and reported elsewhere (Habibi et al. 2008).

The results for the tensile modulus (TM), which measures the stiffness of PLA biocomposites, are given in Table 4. The TM of neat PLA had the highest value, but upon reinforcement with EFBF and OPMF, it declined and tended to rise with increased fiber loading which could be because of stiffness variation between the fibers and the PLA matrix. This finding was also observed by (El-Shekeil et al. 2012). Though, the TM for the KCF-PLA composites appeared to be low at 70% fiber loading, which can be ascribed to the poor interfacial bonding resulting from poor quality of KCF. The extent of fiber-polymer bonding capacity have been shown to influence the TM (Nor Azowa et al. 2010). Thus, in terms of TS, EB, and TM, the optimum fiber and PLA loadings were 60% and 40%, respectively.

The flexural strength (FS) and flexural modulus (FM) of single fiber-PLA biocomposites are presented in Table 4. The FS of neat PLA declined upon reinforcement, and the decrease tended to be lower with higher fiber loading and appeared to be smallest for EFBF, moderate for OPMF, and greatest for the KCF. This disparity could be due to the strength of the three fibers and poor fiber-PLA bonding as a result of the presence of hemicellulose and wax, which makes the fiber surface unclean and impermeable and does not allow strong adhesion to occur (Then et al. 2014a). The FM of the neat PLA was 2.98 GPa, which increased upon introduction of fibers. This increase could be clearly seen for EFBF (50% and 60%), OPMF (60%), and KCF (50%), respectively. A similar trend was also observed by previous researchers, who attributed the FM increase upon fiber incorporation to the relative fiber stiffness compared with the polymer matrix (Then et al. 2015a).

The results obtained in the un-notched IZOD impact strength test for neat PLA and EFBF-, OPMF-, and KCF-PLA biocomposites (Table 4) showed that the neat PLA had the highest impact strength (IS). The EFBF-PLA biocomposites recorded the highest IS amongst the fiber-PLA biocomposites, while the KCF-biocomposites had the least IS. This is expected, as the EFB fiber has the toughest fiber surface and higher cellulose content, enabling it to properly mix with the PLA matrix to form a stronger interfacial bond. The KCF, being weak because of its low cellulose content and high content of hydrophilic groups, such as holocellulose, could not be properly be wetted by the PLA matrix, consequently forming poor interfacial bonding, which results in low IS because of low resistance to crack propagation at the point of impact. The OPMF-PLA biocomposites showed moderate performance, which could be due to the softness of the fiber as compared with the EFBF and better fiber quality than the KCF-PLA biocomposites. Generally, the IS of all the fiber-PLA biocomposites decreased with increasing fiber loading. This could be because the PLA could not properly wet the fibers as the fiber loading increased, resulting in stress concentration because the PLA matrix was unable to effectively transfer stress to the fibers, thereby hampering the ability of the biocomposites to absorb impact energy (Tawakkal et al. 2012).

Density is one of the important parameters used for the assessment of natural fiber thermoplastic composites fabricated for use as alternative medium-density fiberboards (MDF). It has been reported that the density of MDF is between 496 to 801 kgm-3; therefore, natural fiber- or wood-thermoplastic biocomposites with densities within this reported range can be used as alternatives to MDF (Rivela et al. 2007). The density of the composites is the mass per unit volume. Table 4 presents the results of the densities of neat PLA and EFBF-PLA, OPMF-PLA, and KCF-PLA biocomposites at various fiber loadings.

The results demonstrate that the density of the neat PLA composite declines upon incorporation of natural fiber reinforcements. The densities of the natural fiber-PLA biocomposites increase with increasing fiber content, with the EFBF-PLA biocomposites having the lowest densities and the KCF-PLA biocomposites the highest densities. The decline in the density of the neat PLA biocomposite after reinforcement with the natural fibers could be due to the density variation between the PLA and the fibers. The PLA is denser than each of the individual fibers. It has been reported that the density of commercial PLA is between 1.25 and 1.28 gcm-3 (Drumright et al. 2000). The natural fibers have densities of 0.70 to 1.55 gcm-3 for oil palm fibers (Jawaid et al. 2015) and 0.21 gcm-3 for KCF (Abdul Khalil 2010b; Jawaid and Abdul Khalil 2011). These density variations could have a bearing on the overall densities of the natural fiber-PLA biocomposites.

Moreover, the increase in the density of the fiber-PLA biocomposites with increasing fiber loading could be due to the hydrophilic groups on the fiber surfaces, which are likely to attract moisture from the atmosphere and consequently add to the densities of the composites.

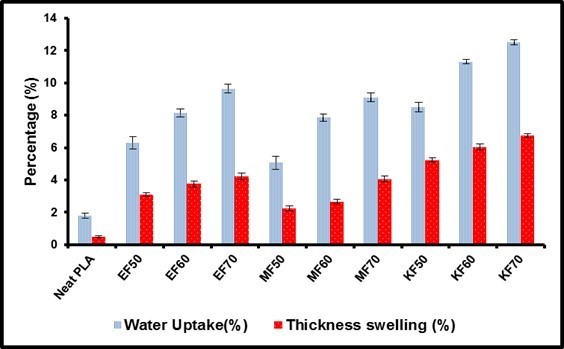

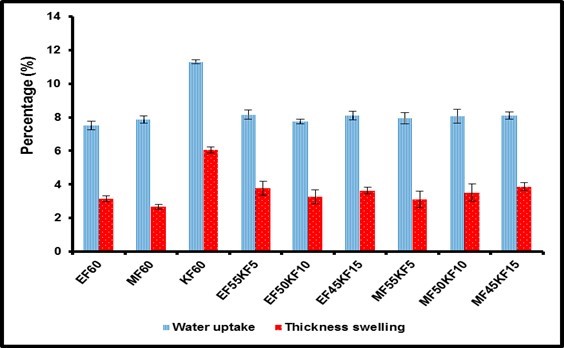

The neat PLA had low water uptake and thickness swelling, while the water uptake and thickness swelling for the single fiber-PLA biocomposites increased with increasing fiber loading (Fig. 3). This is in agreement with findings observed elsewhere (Tawakkal et al. 2012). The neat PLA absorbed less than 2% water, while the biocomposites with 70% fiber loading absorbed up to approximately 13% moisture. This is expected, as the fibers have only been treated with distilled water, which could not efficiently remove impurities and hemicellulose. Thus, an increase in the amount of the fiber will increase the amount of alcohol hydroxyl functional groups on the fiber surface. These hydroxyl groups are capable of attracting water from the atmosphere, thereby making the fibers and their corresponding composites more hydrophilic (Shinoj et al. 2011; Then et al. 2014b).

Fig. 3. Dimensional stability of single fiber-PLA composites

Because the natural fibers (EFBF, OPMF, and KCF) are hydrophilic, their internal bonding with the hydrophobic polymer will be very difficult, which consequently renders the biocomposites poor, weak, and brittle (Kalia et al. 2013).

However, KCF is known to contain more hydrophilic groups on its surface because of its higher content of holocellulose, which shows a greater tendency to absorb water during immersion and swell (Fig. 3). The oil palm fibers showed lower water uptake and thickness swelling because they have better fiber surface quality, which, even though hydrophilic, could not attract moisture to the extent of the KCF. Generally, the water uptake appeared to be directly proportional to the thickness swelling for all the PLA composites.

Hybrid Fiber-PLA Biocomposites

The optimum sample formulation for the single fiber-PLA biocomposites based on the mechanical properties and density was a fiber to PLA weight ratio of 60:40. This formulation was used as a control to fabricate the hybrid fiber-PLA biocomposites. The sample formulations are presented in Table 3. The KCF was incorporated as a secondary fiber into the EFBF and OPMF composites.

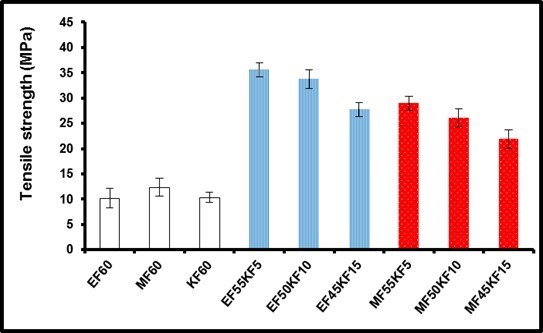

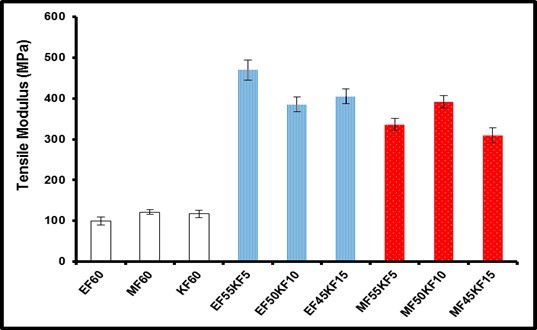

The TS and TM (Figs. 4 and 5) showed positive hybrid effects, which could be a result of the incorporation of KCF into the oil palm fibers.

Fig. 4. Tensile strength of hybrid fiber-PLA composites

Fig. 5. Tensile modulus of hybrid fiber-PLA composites

The main reason for the improved TS and TM with KCF incorporation could be the rich lignin content of the KCF, which facilitated interfacial bonding between the oil palm fibers and the PLA matrix.

Lignin is made up of polar hydroxyl groups and non-polar hydrocarbons and hence could act as a compatibilizer between the hydrophilic fiber and hydrophobic polymer, thereby improving the mechanical properties of the biocomposites (Rozman et al. 2000). The decrease in TS and TM with increasing amount of KCF could be attributed to the formation of agglomerates and non-uniform dispersion of the KCF in the hybrid, thereby causing stress concentration in the glassy PLA. The stress concentration could generate crack formation and propagation along the interface, leading to mechanical failure. This decrease in the tensile properties of polymer composites as a result of the presence of lignin was also observed by Reza Barzegari et al. (2012).

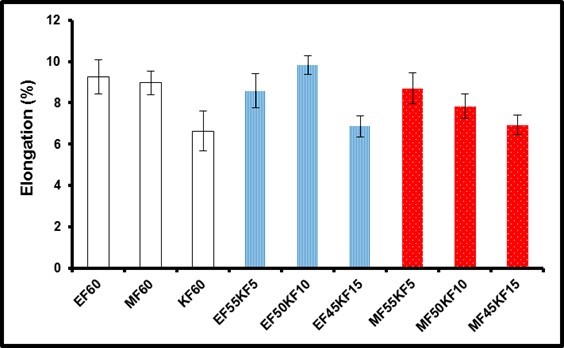

The percentage EB (Fig. 6) of the EFBF- and OPMF-PLA composites did not show much disparity before and after the incorporation of KCF. The EB tends to be lower at high KCF, which may be due to micro crack generation as a result of KCF agglomerate formation. Similarly, at high KCF loadings, the amount of hydrophilic groups would be high and the propensity of the biocomposites to attract water molecules from the atmosphere would also increase. Thus, with the incorporation of more hydrophilic constituents in the composites, the fiber-PLA interfacial bonding would become poorer and weaker and the tendency to create micro defect that could easily cause failure during stress would increase, consequently lowering the EB.

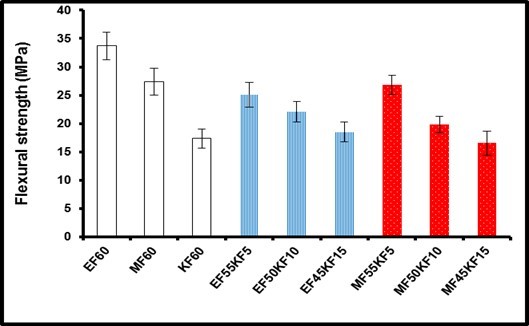

With the addition of 5% KCF, the flexural strength (FS) dropped by approximately 34% and 2% for the EFBF- and OPMF-PLA, respectively (Fig. 7). This diminution in FS could be because of residual fiber surface impurities, and the increased fiber-fiber interaction due to KCF addition which disallowed sufficient wetting of the fiber by the PLA, hence preventing the even distribution of stress. Generally, the incorporation of KCF in the OPMF-PLA gave better flexural strength than the addition of KCF in the EFBF-PLA. OPMF has been previously reported to have better flexural strength than EFBF (Then et al. 2013).

Fig. 6. Elongation at break of hybrid fiber-PLA composites

Fig. 7. Flexural strength of hybrid fiber-PLA composites

Similarly, increasing the KCF content in both EFBF-PLA and OPMF-PLA decreased the FS. Perhaps, this could be associated with the high content of hydrophilic groups in the KCF, which weaken the fiber-PLA interface, and also the possibility of agglomerate formation of the KCF as its content increased. Fiber agglomeration has been observed to weaken the interfacial region (Thwe and Liao 2003). These agglomerates formed because of uneven fiber distribution and are difficult to manually separate, leading to poor stress transfer between the oil palm fibers and the PLA. Previous researchers have also pointed out that kenaf fiber agglomerates are very difficult to separate manually (Zampaloni et al. 2007). In addition, the presence of these KCF agglomerates at the point of flexure during testing could easily cause the composites to break because of the poor quality of the KCF.

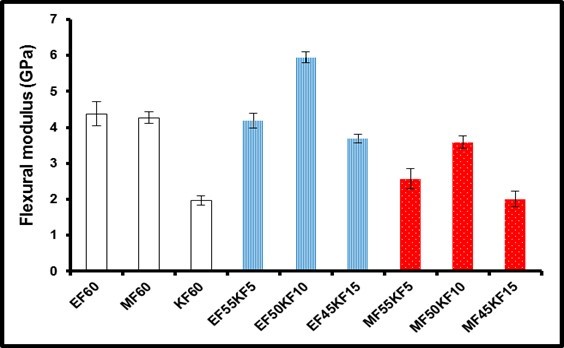

Conversely, the flexural modulus (FM) of the hybrid fiber-PLA biocomposites, presented in Fig. 8, indicates better improvement for the KCF-EFBF-PLA than the KCF-OPMF-PLA, particularly at 10% KCF content, at which an approximately 36% improvement compared with the EFBF-PLA biocomposites was seen. This could be associated with the fiber surface toughness of the EFBF. The fluctuation in the FM of the KCF-incorporated oil palm fiber-PLA composites could be a result of the uneven dispersion of the KCF, the heterogeneity of the fiber mixture, the weak fiber-PLA interface, and increased fiber-fiber contact of the two fibers in the biocomposites. The mechanical properties of hybrid fiber biocomposites has been reported to be related to the fiber orientation and the manner of the hybrid combination (Çöpür et al. 2008).

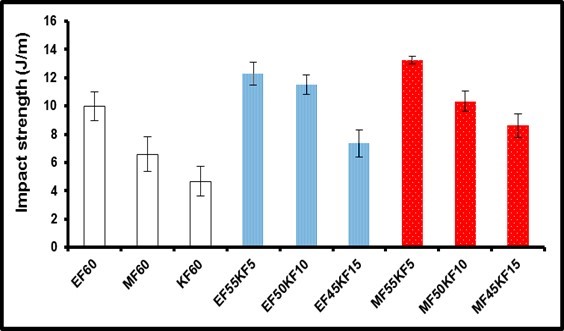

The impact strength (IS) of the biocomposites, presented in Fig. 9, showed improvements with KCF addition to the oil palm fibers. The optimum IS was observed with 5% KCF incorporated into both EFBF-PLA and OPMF-PLA biocomposites, which could be due to enhanced fiber-PLA bonding. Perhaps the KCF as a secondary fiber at 5% loading was able to be uniformly distributed in the oil palm fiber-PLA biocomposites, and the relatively higher lignin content in the KCF (hydrophilic as well as hydrophobic features) served as a bridge between the hydrophilic oil palm fibers and the hydrophobic PLA, enhancing their interface and consequently improving their IS.

Fig. 8. Flexural modulus of hybrid fiber-PLA composites

Previous researchers also observed improvement in IS because of lignin, particularly when modification is done on the lignin to harness its optimum reinforcing abilities (Thakur et al. 2014). It can also be seen that the IS tended to decline with more KCF as a secondary fiber (Fig. 9). This may have occurred because of increased inter fiber interaction resulting in fiber breakage thereby restricting effective stress transfer between the fibers and PLA (Sreekala et al. 2002). KCF can also easily form fiber clumps at high concentrations, thereby making the biocomposites easily breakable under impact.

Fig. 9. Impact strength of the hybrid fiber-PLA composites

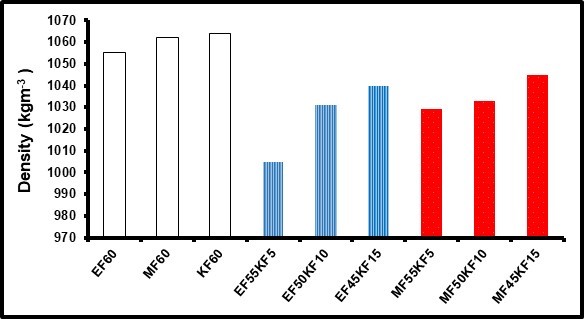

Interestingly, the densities of the oil palm fiber-PLA biocomposites decreased upon addition of 5% KCF as a secondary fiber, by approximately 5% and 3% for EFBF-PLA and OPMF-PLA, respectively. This decrease could be associated with the low density profile of the KCF compared with the oil palm fibers: kenaf core fiber (0.21 gcm-3) and oil palm fibers (0.70 to 1.55 gcm-3), as reported in the literature (Jawaid and Abdul Khalil 2011; Abdul Khalil 2010b). Moreover, the density appeared to increase with increasing KCF loading. This could be due to the increased hydrophilicity of the biocomposites because of the high content of holocellulose in the KCF, which is capable of attracting water molecules from the atmosphere, hence increasing the density of the biocomposites (Khazaeian et al. 2015).

Fig. 10. Density of the hybrid fiber-PLA composites

The results for dimensional stability of the hybrid fiber-PLA biocomposites presented in Fig. 11 indicate that the water uptake and thickness swelling of the oil palm fiber-PLA biocomposites slightly increased with the introduction of 5% KCF.

Fig. 11. Dimensional stability of hybrid fiber-PLA composites

The increase in the water uptake was 8.37% and 1.02%, while thickness swelling increased by 19.36% and 16%, for EFBF-PLA and OPMF-PLA biocomposites, respectively. However, both water uptake and thickness swelling of the hybrid fiber-PLA biocomposites decreased compared with those of the KCF-PLA biocomposites. The increase in water uptake and thickness swelling with the incorporation of 5% KCF as a secondary fiber into the oil palm fiber-filled PLA composites could be attributed to the high holocellulose content of the KCF. It can also be seen that increasing the amount of the KCF, particularly in the OPMF-PLA biocomposites, tended to increase the water uptake and thickness swelling of the hybrid fiber-PLA biocomposites.

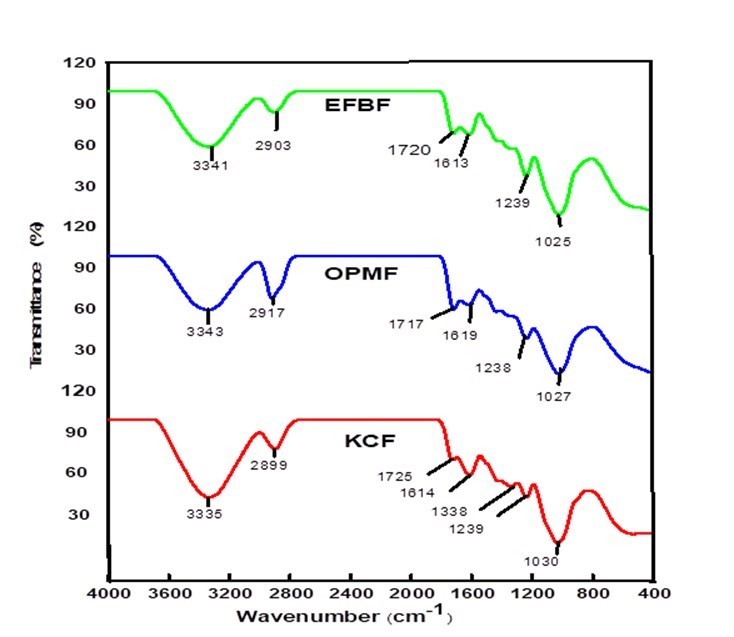

Fourier Transform Infrared Spectroscopy (FTIR)

FTIR was employed in order to study the various functional groups, chemical composition, and types of bonds. The spectra, showing different absorption bands for the three natural fibers, are presented in Fig. 12.

Fig. 12. Fourier transform infrared spectroscopy of pure fibers

The FTIR spectra showed broad peaks at 3335, 3343, and 3341 cm-1 corresponding to the O-H (hydroxyl) stretching of cellulose and hemicellulose in the KCF, OPMF, and EFBF, respectively. The peak intensity was slightly broader for OPMF and EFBF compared to KCF, which implies variation in cellulose content among the fibers. The absorption bands that appeared at 2899, 2917, and 2903 cm-1 represent the C-H stretching of cellulose and hemicellulose in KCF, OPMF, and EFBF, respectively. This concurred with previous findings by Sgriccia et al. (2008) and Then et al. (2015a).

The peak corresponding to C=O stretching of carbonyl groups in hemicellulose or lignin compounds of the three fibers appeared at 1725, 1717, and 1720 cm-1 for the KCF, OPMF, and EFBF, respectively. Clearly, the absorption band for the C=O stretching was somewhat broader for KCF, which can be ascribed to its high lignin and hemicellulose content relative to OPMF and EFBF. The absorption bands at 1614, 1619, and 1613 cm-1 represent the C=C stretching of aromatic rings in lignin (Then et al. 2015a). This band range can also be attributed to vibrational stretching of unconjugated C=O groups in hemicellulose, as well as conjugated carbonyl groups existing in lignin (Merlini et al. 2011).

The absorption peaks seen at 1239, 1238, and 1239 cm-1 in KCF, OPMF, and EFBF, respectively, represent C-O stretching of alcohols, ethers, and phenols in waxy residues as well as the acetyl groups in lignin. This conforms with observations by Liu et al. (2004), Sgriccia et al. (2008), and Merlini et al. (2011).

However, a band at 1338 cm-1 was noted only in the spectra of KCF. This band can be ascribed to the C=C bond stretching of benzene present in lignin. A similar finding was obtained by Liu and Wang (2009). Also, its appearance only in the spectra of KCF implies a high lignin content compared with the OPMF and EFBF.

The absorption peaks at 1030, 1027, and 1025 cm-1 in the spectra of KCF, OPMF, and EFBF, respectively, can be ascribed to C-H and C-O stretching vibrations (Merlini et al. 2011). The C-O vibration within this region of the absorption band was previously described by Maizatul et al. (2013) to be associated with aliphatic and aromatic primary alcohols present in cellulose, hemicellulose, and lignin.

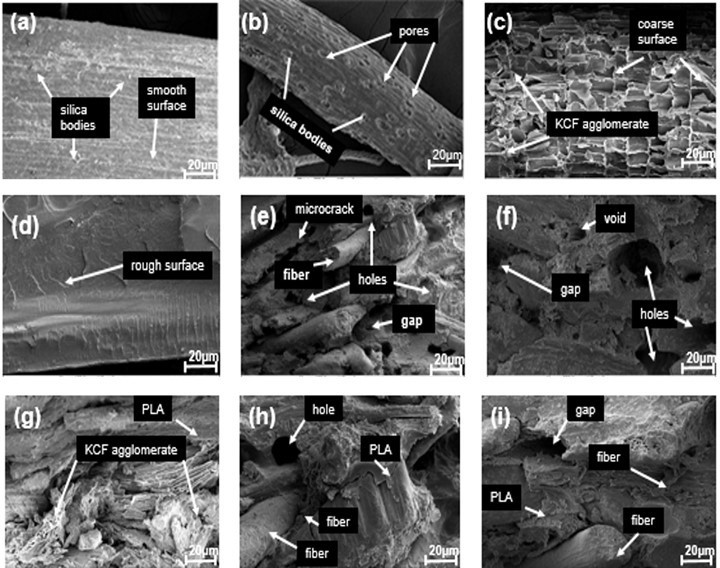

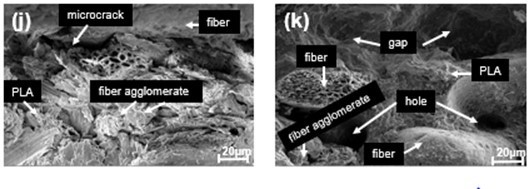

Scanning Electron Microscopy (SEM)

The morphologies of the natural fibers, i.e., pure EFBF, pure OPMF, and pure KCF, as well as the fractured surfaces of neat PLA, single fiber-PLA biocomposites, and hybrid fiber-PLA biocomposites, are presented in Fig. 13.

The pure EFBF (Fig. 13a) appeared smoothly intact, with few residual impurities, as also observed by Then et al. (2013). Residual impurities and few pores were noted on the OPMF (Fig. 13b); perhaps the pores appeared because of the removal of impurities, as previously observed by Nordin et al. (2013) and Then et al. (2014 a,b). The KCF (Fig. 13c) looked roughly disfigured, which could be ascribed to its high hydrophilicity. Previous works have reported similar features and described them as pit structures, considered the weak point that decreases the fiber strength ( Abdul Khalil et al. 2010b).

The brittle behavior of the neat PLA (Fig. 13d) made it present a rough surface, although it was smoother than those of its biocomposites. The roughness of neat PLA has been reported elsewhere (Alam et al. 2014). The single oil palm fiber-PLA biocomposites (Fig. 13e through 13f) revealed fiber pullout, gaps, voids, and micro cracks, suggesting poor fiber-PLA bonding.

Fig. 13. SEM micrographs of (a) EFBF, (b) OPMF, (c) KCF, (d) neat PLA, (e) EFBF-PLA, (f) OPMF-PLA, (g) KCF-PLA, (h) EFBF/KCF(55%:5%)-PLA, (i) OPMF/KCF(55%:5%)-PLA, (j) EFBF/KCF(50%:10%)-PLA, and (k) OPMF/KCF(45%:15%)-PLA

The KCF-PLA biocomposite (Fig.13g) showed gaps as well as fiber clumps, which perhaps contributed to its poor mechanical behavior and dimensional stability. Moreover, the micrographs of the hybrid fiber-PLA biocomposites (Fig. 13h through 13i) showed that the fiber pullout, fibers protruding from the surface, and holes were relatively reduced with 5% KCF, implying an improved fiber-PLA interface because of fiber hybridization. A similar observation was reported by Jawaid et al. (2013). On the other hand, KCF clumps, voids, gaps, and micro cracks can be seen (Fig. 13j through 13k) at higher KCF loadings (i.e., 10 and 15%), which translates to poor mechanical behavior and dimensional stability for these hybrid fiber-PLA biocomposites.

Generally, the micrographs of both the single fiber-PLA biocomposites and the hybrid fiber-PLA biocomposites (Fig. 13) showed weak features (e.g. gaps and voids), which is reasonable considering the fact that the fibers were treated with distilled water only, which may not effectively eliminate impurities from the fiber surfaces in order to enable stronger interface bonding to occur. Further fiber treatment methods such as alkalization as reported by (Manikandan et al. 2012; Fiore et al. 2014; Then et al. 2015b) can be employed to enhance the fiber-polymer interfacial adhesion.

CONCLUSIONS

- KCF was successfully incorporated into EFBF-PLA and OPMF-PLA biocomposites, yielding improved mechanical properties.

- A synergistic performance was observed because of the hybridization of lignin-rich KCF and cellulose-rich EFBF and OPMF.

- Improved mechanical properties (e., tensile and flexural strengths), impact strength, and density of the hybridized fiber-PLA biocomposites were obtained with the addition of 5% KCF to EFBF-PLA and OPMF-PLA biocomposites.

- The dimensional stability was considerably better at 5% KCF than at higher loadings because of its high hydrophilicity.

- This study revealed that KCF incorporation into oil palm-based fibers could offer synergism, complement the material performance of KCF, and sustain the supply chain of oil palm fibers.

ACKNOWLEDGMENTS

The authors would like to acknowledge the Strength of Materials Laboratory, Department of Mechanical and Manufacturing Engineering, Faculty of Engineering, Universiti Putra Malaysia for mechanical properties analysis. Also, the authors would like to thank the leadership of the Polymer Research Group, Department of Chemistry, Faculty of Science, Universiti Putra Malaysia and the Tertiary Education Trust Fund (TETFUND), Nigeria, for financial support.

REFERENCES CITED

ASTM D256 (2000). “Standard test methods for determining the Izod impact resistance of plastics,” ASTM International, West Conshohocken, PA.

ASTM D570 (2005). “Standard test methods for determining the water absorption of plastics,” ASTM International, West Conshohocken, PA.

ASTM D638 (2000). “Standard test methods for tensile properties of plastics,” ASTM International, West Conshohocken, PA.

ASTM D790 (2000). “Standard test methods for flexural properties of unreinforced and reinforced plastics,” ASTM International, West Conshohocken, PA.

Abdul Khalil, H. P. S., and Suraya, N. L. (2011). “Anhydride modification of cultivated kenaf bast fibers: Morphological, spectroscopic and thermal studies,” BioResources 6(2), 1122-1135. DOI: 10.15376/biores.6.2.1121-1135

Abdul Khalil, H. P. S., Nurul Fazita, M. R., Bhat, A. H., Jawad, M., and Nik Fuad, N. A. (2010a). “Development and material properties of new hybrid plywood from oil palm biomass,” Materials and Design 31(1), 417-424. DOI:10.1016/j.matdes.2009.05.040

Abdul Khalil, H. P. S., Ireana Yusra, A. F., Bhat, A. H., and Jawad, M.(2010b). “Distribution and chemical composition of Malaysian cultivated kenaf fiber,” Industrial Crops and Products 31, 113-121. DOI: 10.1016/j.indcrop.2009.09.008.

Abdul Khalil, H. P. S., Jawad, M., Hassan, A., Paridah, M. T., and Zaidon, A. (2012). “Oil palm biomass fibers and recent advancement in oil palm biomass fibers based hybrid biocomposites,” In N. Hu (ed), Composites and Their Applications [E-reader version],187-220. DOI:10.5772/3353

Aisyah, H. A., Paridah, M. T., Sahri, M. H., Anwar, U. M. K., and Astimar, A. A. (2013). “Properties of medium density fiberboard (MDF) from kenaf (Hibiscus cannabinus L.) core as function of refining conditions,” Composites Part B: Engineering 44(1), 592-596. DOI: 10.10116/j.compositesb.2012.02.029

Akil, H. M., De Rosa, I. M., Santulli, C., and Sarasini, F. (2010). “Flexural behavior of pultruded jute/glass and kenaf/glass hybrid composites monitored using acoustic emission,” Materials Science and Engineering A 527(12), 2942-2950. DOI: 10.1016/j.msea.2010.01.028

Alam, J., Alam, M., Raja, M., Abduljaleel, Z., and Dass, L. (2014). “MWCNTs-reinforced epoxidized linseed oil plasticized Polylactic acid nanocomposites and its electroactive shape memory behaviour,” International Journal of Molecular Science 15 (11), 19924-19937. DOI: 10.3390/ijms151119924

Bentley, R. W. (2002). “Global oil and gas depletion: An overview,” Energy Policy 30(3), 189-205. DOI: 10.1016/S0301-4215(01)00144-6

Brostow, W., and Hagg, H. E. (2010). “Brittleness of materials: Implications for composites and a relation to impact strength,” Journal of Materials Science 45(1) 242-250. DOI: 10.1007/s10853-009-3926-5

Çöpür, Y., Güler, C., Taşçioǧlu, C., and Tozluoǧlu, A. (2008). “Incorporation of hazelnut shell and husk in MDF production,” Bioresource Technology 99(15), 7402-7406. DOI: 10.1016/j.biortech.2008.01.021

Deka, H., Misra, M., and Mohanty, A. (2013). “Renewable resource based ‘all green composites’ from kenaf biofiber and poly(furfuryl alcohol) bioresin,” Industrial Crops and Products 41(1), 94-101. DOI: 10.1016/j.indcrop.2012.03.037

Dicker, M. P. M., Duckworth, P. F., Baker, A. B., Francois, G., Hazzard, M. K., and Weaver, P. M. (2014). “Green composites: A review of material attributes and complementary applications,” Composites Part A: Applied Science and Manufacturing 56, 280-289. DOI: 10.1016/j.compositesa.2013.10.014

Drumright, R. E., Gruber, P. R., and Henton, D. E. (2000). “Polylactic acid technology,” Advanced Materials 12(23), 1841-1846. DOI: 10.1002/1521 4095(200012)12:23<1841::AID-ADMA1841>3.0.CO;2-E

Eichhorn, S. J., Baillie, C. A, Mwaikambo, L. Y., Ansell, M. P., and Dufresne, A. (2001). “Current international research into cellulosic fibers and composites,” Journal of Materials Science 36(9), 2107-2131. DOI: 10.1023/A:1017973432592

El-Shekeil, Y. A., Sapuan, S. M., Abdan, K., and Zainudin, E. S. (2012). “Influence of fiber content on the mechanical and thermal properties of Kenaf fiber reinforced thermoplastic polyurethane composites,” Materials and Design, Elsevier Ltd, 40, 299–303. DOI: 10.1016/j.matdes.2012.04.003

EN 323 (1993). “Wood-based panels – Determination of density,” British Standards Institute, London, UK.

Faruk, O., Bledzki, A. K., Fink, H. P., and Sain, M. (2012). “Biocomposites reinforced with natural fibers: 2000-2010,” Progress in Polymer Science 37(11), 1552-1596. DOI: 10.1016/j.progpolymsci.2012.04.003

Fiore, V., Di Bella, G., and Valenza, A. (2014). “The effect of alkaline treatment on mechanical properties of kenaf fibers and their epoxy composites,” Composites Part B: Engineering 68, 14-21. DOI: 10.1016/j.compositesb.2014.08.025

Ghaffar, S. H., and Fan, M. (2014). “Lignin in straw and its applications as an adhesive,” International Journal of Adhesion and Adhesives 48, 92-101. DOI: 10.1016/j.ijadhadh.2013.09.001

Ghasemi, I., Azizi, H., and Naeimian, N. (2008). “Rheological behaviour of polypropylene/kenaf fibre/wood flour hybrid composite,” Iranian Polymer Journal 17(3), 191-198.

Habibi, Y., El-Zawawy, W. K., Ibrahim, M. M., and Dufresne, A. (2008). “Processing and characterization of reinforced polyethylene composites made with lignocellulosic fibers from Egyptian agro-industrial residues,” Composites Science and Technology 68(7-8), 1877-1885. DOI: 10.1016/j.compscitech.2008.01.008

Hashim, M., Zaidi, A., Mujahid, A., and Ariffin, S. (2012). “Plant fiber reinforced polymer matrix composite: A discussion on composite fabrication and characterization technique,” Seminar to Faculty of Civil and Environmental Engineering (FKAAS), Universiti Tun Hussein Onn Malaysia (UTHM). Retrieved from http://eprints.uthm.edu.my/2541/[2/5/2015]

Jacob, M., Thomas, S., and Varughese, K. T. (2004). “Mechanical properties of sisal / oil palm hybrid fiber reinforced natural rubber composites,” Composite Science and Technology 64(7-8), 955-965. DOI: 10.1016/S0266-3538(03)00261-6.

Jawaid, M., and Abdul Khalil, H. P. S. (2011). “Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review,” Carbohydrate Polymers 86(1), 1-18. DOI: 10.1016/j.carbpol.2011.04.043

Jawaid, M., Abdul Khalil, H. P. S., and Abu Bakar, A. (2010). “Mechanical performance of oil palm empty fruit bunches/jute fibres reinforced epoxy hybrid composites,” Materials Science and Engineering A 527(29-30), 7944-7949. DOI: 10.1016/j.msea.2010.09.005

Jawaid, M., Khalil, H. A., Bakar, A. A., Hassan, A., and Dungani, R. (2012). “Effect of jute fibre loading on the mechanical and thermal properties of oil palm-epoxy composites,” Journal of Composite Materials 47(13), 1633-1641. DOI: 10.1177/0021998312450305

Jawaid, M., Abdul Khalil, H. P. S., Hassan, A., Dungani, R., and Hadiyane, A. (2013). “Effect of jute fibre loading on tensile and dynamic mechanical properties of oil palm epoxy composites,” Composites Part B: Engineering 45(1), 619-624. DOI: 10.1016/j.compositesb.2012.04.068

Jawaid, M., Khalil, H. P. S. A., and Bakar, A. A. (2015). “Effect of jute fibre loading on the mechanical and thermal properties of oil palm – epoxy composites,” Journal of Composite Materials 47(13), 1633-1641. DOI: 10.1177/0021998312450305.

Kalia, S., Thakur, K., Celli, A., Kiechel, M. A., and Schauer, C. L. (2013). “Surface modification of plant fibers using environment friendly methods for their application in polymer composites, textile industry and antimicrobial activities: A review,” Journal of Environmental Chemical Engineering 1(3), 97-112. DOI: 10.1016/j.jece.2013.04.009

Khazaeian, A., Ashori, A., and Dizaj, M. Y. (2015). “Suitability of sorghum stalk fibers for production of particleboard,” Carbohydrate Polymers 120, 15-21. DOI: 10.1016/j.carbpol.2014.12.001

Kim, H. S., Kim, H. J., Lee, J. W., and Choi, I. G. (2006). “Biodegradability of bio-flour filled biodegradable poly(butylene succinate) bio-composites in natural and compost soil,” Polymer Degradation and Stability 91(5), 1117-1127. DOI: 10.1016/j.polymdegradstab.2005.07.002

Law, K.-N., Daud, W. R. W., and Ghazali, A. (2007). “Morphological and chemical nature of fiber strands of oil palm empty-fruit-bunch (OPEFB),” BioResources 2(3), 351-362. DOI: 10.15376/biores.2.3.351-362

Leão, A. L., Fernandes Teixeira, R. M., and Ferrão, P. C. (2008). “Production of reinforced composites with natural fibers for industrial applications – Extrusion and injection WPC,” Molecular Crystals and Liquid Crystals 484(1), 157/[523]-166/[532]. DOI: 10.1080/15421400801904393

Li, X. (2004). Physical, Chemical, and Mechanical Properties of Bamboo and Its Utilization Potential for Fiberboard Manufacturing, M.S. thesis, Louisiana State University, Baton Rouge, LA.

Liu, W., and Wang, B. (2009). “Preparation and application of Norfloxacin-MIP/polysulfone blending molecular imprinted polymer membrane,” Journal of Applied Polymer Science 113(2), 1125-1132. DOI: 10.1002/app.30052

Liu, W., Mohanty, A. K., Drzal, L. T., Askel, P., and Misra, M. (2004). “Effects of alkali treatment on the structure, morphology and thermal properties of native grass fibers as reinforcements for polymer,” Journal of Materials Science 39(3), 1051-1054. DOI: 10.1023/B:JMSC.0000012942.83614.75

Maizatul, N., Norazowa, I., Yunus, W. M. Z. W., Khalina, A., and Khalisanni, K. (2013). “FTIR and TGA analysis of biodegradable poly(lactic acid)/treated kenaf bast fibre: Effect of plasticizers,” Pertanika Journal of Science and Technology 21(1), 151-160.

Mandal, S., Alam, S., Varma, I. K., and Maiti, S. N. (2010). “Studies on bamboo/glass fiber reinforced USP and VE resin,” Journal of Reinforced Plastics and Composites 29(1), 43-51. DOI: 10.1177/0731684408095048

Manikandan, V., Winowlin Jappes, J. T., Suresh Kumar, S. M., and Amuthakkannan, P. (2012). “Investigation of the effect of surface modifications on the mechanical properties of basalt fibre reinforced polymer composites,” Composites Part B: Engineering 43(2), 812-818. DOI: 10.1016/j.compositesb.2011.11.009

Merlini, C., Soldi, V., and Barra, G. M. O. (2011). “Influence of fiber surface treatment and length on physico-chemical properties of short random banana fiber-reinforced castor oil polyurethane composites,” Polymer Testing 30(8), 833-840. DOI: 10.1016/j.polymertesting.2011.08.008

Mukherjee, T., and Kao, N. (2011). “PLA based biopolymer reinforced with natural fibre: A review,” Journal of Polymers and the Environment 19(3), 714-725. DOI: 10.1007/s10924-011-0320-6

Nasir, M., Gupta, A., Beg, M. D. H., Chua, G. K., and Kumar, A. (2013). “Fabrication of medium density fibreboard from enzyme treated rubber wood (Hevea brasiliensis) fibre and modified organosolv lignin,” International Journal of Adhesion and Adhesives 44, 99-104. DOI: 10.1016/j.ijadhadh.2013.02.013

Nayak, S. K., Mohanty, S., and Samal, S. K. (2009). “Influence of short bamboo/glass fiber on the thermal, dynamic mechanical and rheological properties of polypropylene hybrid composites,” Materials Science and Engineering A 523(1-2), 32-38. DOI: 10.1016/j.msea.2009.06.020

Nor Azowa, I., Wan Yunus, W. M. Z., Othman, M., Abdan, K., and Kamarul, A. H. (2010). “Poly(lactic acid) (PLA)-reinforced kenaf bast fiber composites: The effect of triacetin,” Journal of Reinforced Plastics and Composites 29(7), 1099-1111. DOI: 10.1177/0731684409344651

Nordin, N. I. A. A., Ariffin, H., Andou, Y., Hassan, M. A., Shirai, Y., Nishida, H., and Ibrahim, N. A. (2013). “Modification of oil palm mesocarp fiber characteristics using superheated steam treatment,” Molecules 18(8), 9132-9146. DOI: 10.3390/molecules18089132

Okubo, K., Fujii, T., and Yamashita, N. (2005). “Improvement of interfacial adhesion in bamboo polymer composite enhanced with micro-fibrillated cellulose,” JSME International Journal Series A 48(4), 199-204. DOI: 10.1299/jsmea.48.199

Pandita, S. D., Yuan, X., Manan, M. A., Lau, C. H., Subramanian, A. S., and Wei, J. (2014). “Evaluation of jute/glass hybrid composite sandwich: Water resistance, impact properties and life cycle assessment,” Journal of Reinforced Plastics and Composites 33(1), 14-25. DOI: 10.1177/0731684413505349

Reza Barzegari, M., Alemdar, A., Zhang, Y., and Rodrigue, D. (2012). “Mechanical and rheological behavior of highly filled polystyrene with lignin,” Polymer Composites 33(3), 353-361. DOI: 10.1002/pc.22154

Rivela, B., Moreira, M. T., and Feijoo, G. (2007). “Life cycle inventory of medium density fibreboard,” The International Journal of Life Cycle Assessment 12(3), 143-150. DOI: 10.1007/s11367-006-0290-4

Rozman, H. D., Tan, K. W., Kumar, R. N., Abubakar, A., Mohd. Ishak, Z. A., and Ismail, H. (2000). “The effect of lignin as a compatibilizer on the physical properties of coconut fiber–polypropylene composites,” European Polymer Journal 36(7), 1483-1494. DOI: 10.1016/S0014-3057(99)00200-1

Rozman, H. D., Tay, G. S., Kumar, R. N., Abusamah, A., Ismail, H., and Ishak, Z. A. M. (2001). “Polypropylene ± oil palm empty fruit bunch ± glass fibre hybrid composites: A preliminary study on the flexural and tensile properties,” European Polymer Journal 37(6), 1283-1291. DOI: 10.1016/S0014-3057(00)00243-3

Sgriccia, N., Hawley, M. C., and Misra, M. (2008). “Characterization of natural fiber surfaces and natural fiber composites,” Composites Part A: Applied Science and Manufacturing 39(10), 1632-1637. DOI: 10.1016/j.compositesa.2008.07.007

Shinoj, S., Visvanathan, R., Panigrahi, S., and Kochubabu, M. (2011). “Oil palm fiber (OPF) and its composites: A review,” Industrial Crops and Products 33(1), 7-22. DOI :10.1016/j.indcrop.2010.09.009

Sreekala, M. S., George, J., Kumaran, M. G., and Thomas, S. (2002). “The mechanical performance of hybrid phenol-formaldehyde-based composites reinforced with glass and oil palm fibres,” Composites Science and Technology, 62(3), 339–353. DOI: 10.1016/S0266-3538(01)00219-6

Sreekala, M. S., Kumaran, M. G., and Thomas, S. (1997). “Oil palm fibers: Morphology, chemical composition, surface modification, and mechanical properties,” Journal of Applied Polymer Science 66(5), 821-835. DOI :10.1002/(SICI)1097-4628(19971031)66:5<821::AID-APP2>3.0.CO;2-X

Tawakkal, I. S. M. A., Talib, R. A., Abdan, K., and Ling, C. N. (2012). “Mechanical and physical properties of kenaf- derived cellulose (KDC)-filled polylactic acid (PLA) composites,” BioResources 7(2), 1643-1655. DOI: 10.15376/biores.7.2.1643-1655

Thakur, V. K., Thakur, M. K., Raghavan, P., and Kessler, M. R. (2014). “Progress in green polymer composites from lignin for multifunctional applications: A review,” ACS Sustainable Chemistry and Engineering 2(5), 1072-1092. DOI: 10.1021/sc500087z

Then, Y. Y., Ibrahim, N. A., Zainuddin, N., Ariffin, H., and Wan Yunus, W. M. Z. (2013). “Oil palm mesocarp fiber as new lignocellulosic material for fabrication of polymer/fiber biocomposites,” International Journal of Polymer Science 2013, 797452. DOI: 10.1155/2013/797452

Then, Y. Y., Ibrahim, N. A., Zainuddin, N., Ariffin, H., Wan Yunus, W. M. Z., and Chieng, B. W. (2014a). “The influence of green surface modification of oil palm mesocarp fiber by superheated steam on the mechanical properties and dimensional stability of oil palm mesocarp fiber/poly(butylene succinate) biocomposite,” International Journal of Molecular Sciences 15(9), 15344-15357. DOI: 10.3390/ijms150915344

Then, Y. Y., Ibrahim, N. A., Zainuddin, N., Ariffin, H., Wan Yunus, W. M. Z., and Chieng, B. W. (2014b). “Surface modifications of oil palm mesocarp fiber by superheated steam, alkali, and superheated steam-alkali for biocomposite applications,” BioResources 9(4), 7467-7483. DOI: 10.15376/biores.9.4.7467-7483

Then, Y. Y., Ibrahim, N. A., Zainuddin, N., Chieng, B. W., Ariffin, H., and Wan Yunus, W. M. Z. (2015a). “Influence of alkaline-peroxide treatment of fiber on the mechanical properties of oil palm mesocarp fiber/poly(butylene succinate) biocomposite,” BioResources 10(1), 1730-1746. DOI: 10.15376/biores.10.1.1730-1746.

Then, Y. Y., Ibrahim, N. A., Zainuddin, N., Ariffin, H., Wan Yunus, W. M. Z., and Chieng, B. W. (2015b). “Static mechanical, interfacial, and water absorption behaviors of alkali treated oil palm mesocarp fiber reinforced poly(butylene succinate) biocomposites, ” BioResources 10(1), 123-136. DOI: 10.15376/biores.10.1.123-136

Thiruchitrambalam, M., Alavudeen, A., Athijayamani, A., Venkateshwaran, N., and Elaya Perumal, A. (2009). “Improving mechanical properties of banana/kenaf polyester hybrid composites using sodium laulryl sulfate treatment,” Materials Physics and Mechanics 8, 165-173.

Thwe, M. M., and Liao, K. (2003). “Durability of bamboo-glass fiber reinforced polymer matrix hybrid composites,” Composites Science and Technology 63(3-4), 375-387. DOI: 10.1016/S0266-3538(02)00225-7

Valente, M., Sarasini, F., Marra, F., Tirillò, J., and Pulci, G. (2011). “Hybrid recycled glass fiber/wood flour thermoplastic composites: Manufacturing and mechanical characterization,” Composites Part A: Applied Science and Manufacturing 42(6), 649-657. DOI: 10.1016/j.compositesa.2011.02.004

Velmurugan, R., and Manikandan, V. (2007). “Mechanical properties of palmyra/glass fiber hybrid composites,” Composites Part A: Applied Science and Manufacturing 38(10), 2216-2226. DOI: 10.1016/j.compositesa.2007.06.006

Ververis, C., Georghiou, K., Christodoulakis, N., Santas, P., and Santas, R. (2004). “Fiber dimensions, lignin and cellulose content of various plant materials and their suitability for paper production,” Industrial Crops and Products 19(3), 245-254. DOI: 10.1016/j.indcrop.2003.10.006

Zampaloni, M., Pourboghrat, F., Yankovich, S. A., Rodgers, B. N., Moore, J., Drzal, L. T., and Misra, M. (2007). “Kenaf natural fiber reinforced polypropylene composites: A discussion on manufacturing problems and solutions,” Composites Part A: Applied Science and Manufacturing 38(6), 1569-1580. DOI: 10.1016/j.compositesa.2007.01.001

Zhang, J., Chaisombat, K., He, S., and Wang, C.H. (2012). “Hybrid composites reinforced with glass/carbon woven fabrics for lightweight load bearing structures,” Materials and Design 36, 75-80. DOI: 10.1016/j.matdes.2011.11.006

Article submitted: December 4, 2015; Peer review completed: January 22, 2016; Revised version received: January 26, 2016; Accepted: February 5, 2016; Published: February 17, 2016.

DOI: 10.15376/biores.11.2.3332-3355