Abstract

The impact of cold temperatures on the shear strength of Scots pine (Pinus sylvestris) joints glued with seven commercially available adhesives was studied in this work. The cold temperatures investigated were: 20, −20, −30, −40, and −50 °C. Generally, within the temperature test range, the shear strength of Scots pine solid wood and wood joints were more resistant to the effect of temperature than those of Norway spruce. As the temperature decreased, only some of the joints’ shear strength significantly decreased. In most cases, PUR adhesive yielded the strongest shear strength and MUF adhesive yielded the weakest shear strength. MF adhesive responded to temperature changes in a similar manner to that of PUR and PVAc adhesives. The shear strengths of wood joints with PRF and EPI adhesives were more sensitive to temperature change. For dynamic tests of shear strength, the values for 12-h and 6-day tests under temperature cycles (−20 and 0 °C) were compared. The values for 6-day tests were lower than those for 12-h tests. Therefore, the duration of the samples subjected to the same temperature had a significant impact on shear strength. Our results indicate that PUR adhesive is the most stable; whereas the stability of MUF and PRF adhesives decreased significantly.

Download PDF

Full Article

Shear Strength of Scots Pine Wood and Glued Joints in a Cold Climate

Xiaodong (Alice) Wang,a,* Olle Hagman,a Bror Sundqvist,b Sigurdur Ormarsson,c Hui Wan,d and Peter Niemz e

The impact of cold temperatures on the shear strength of Scots pine (Pinus sylvestris) joints glued with seven commercially available adhesives was studied in this work. The cold temperatures investigated were: 20, −20, −30, −40, and −50 °C. Generally, within the temperature test range, the shear strength of Scots pine solid wood and wood joints were more resistant to the effect of temperature than those of Norway spruce. As the temperature decreased, only some of the joints’ shear strength significantly decreased. In most cases, PUR adhesive yielded the strongest shear strength and MUF adhesive yielded the weakest shear strength. MF adhesive responded to temperature changes in a similar manner to that of PUR and PVAc adhesives. The shear strengths of wood joints with PRF and EPI adhesives were more sensitive to temperature change. For dynamic tests of shear strength, the values for 12-h and 6-day tests under temperature cycles (−20 and 0 °C) were compared. The values for 6-day tests were lower than those for 12-h tests. Therefore, the duration of the samples subjected to the same temperature had a significant impact on shear strength. Our results indicate that PUR adhesive is the most stable; whereas the stability of MUF and PRF adhesives decreased significantly.

Keywords: Cold temperatures; Shear strength; Scots pine; Adhesives; Dynamic tests

Contact information: a: Wood Technology an Engineering, Luleå University of Technology, Forskargatan 1, SE-931 87 Skellefteå, Sweden; b: SP Technical Research Institute of Sweden, SP Sustainable Biult Environment, Skeria 2, SE-931 77 Skellefteå, Sweden; c: Department of Construction Engineering, Linnaeus University, Växjö, Sweden; d: Department of Sustainable Bioproducts, Mississippi State University, Mississippi State, MS 39762-9820, United States; e: Department of Civil Engineering, ETH Zurich, Switzerland; *Corresponding author: alice.wang@ltu.se

INTRODUCTION

The use of engineered wood products has increased in the building industry worldwide. Engineered wood applications (such as glued-laminated timber (glulam), laminated veneer lumber (LVL), and cross-laminated timber (CLT)) in bridges are also common in Europe and North America. Concerns have arisen about the adhesive qualities and bondline integrity of these engineered wood products, which require that the adhesive joints in the engineered wood products are as strong and durable as the wood itself. This issue is important in regions such as Scandinavia, Greenland, the Alps, Canada, Alaska, Russia, Mongolia, northern China, and northern Japan. Wooden constructions in these areas are frequently exposed to low temperatures for a large portion of each year. As a result, the strength properties of the engineered wood products (for example glued laminated timber and cross laminated timber) may be temporarily or permanently affected by both low temperatures and significant temperature changes. However, thermal effects are usually not considered in the design and estimation of the service lifetime of wooden constructions.

The influence of cold temperature on wood’s mechanical properties has been studied since the 1960s. It is known that as wood is cooled to below-normal temperatures, its mechanical properties tend to increase (Kollmann and Cote 1968; Geissen 1976; Gerhards 1982; USDA 2010; Jiang et al. 2014; Niemz et al. 2014). These studies found that wood’s modulus of elasticity, compression, and bending strength were significantly increased with decreasing temperature. However, the shear strength of wood has rarely been studied at low temperatures; only Yu and Östman (1983) have investigated the tensile strength properties of particle boards between −15 and 45 °C.

For engineered wood, there are concerns not only about the wood itself, but also adhesives and the joints between the adhesives and wood, specially their behaviours after many years. Egner and Kolb (1966) investigated on the ageing of glues for supporting structural wooden elements. After that in 1990s, Deppe and Schmidt (1994) made the additional tests for the ageing behavior of filled glueline products. Raknes (1997) reported the durability if structural wood adhesives after 30 years ageing. More recently, Radovic and Rothkopf (2003) demonstrated the suitability of 1-compoment PUR adhesives for wood construction, taking into account 10 years of experience.

Wood and adhesives have different properties. Therefore, the interaction between wood and adhesive were studied, especially when the bonded wood products were exposed to high temperatures. For example, the performance of bondlines at elevated temperatures has been reported (Frangi et al. 2004; Falkner and Teutsch 2006; Clauss et al. 2011). With increased temperature, the shear strength of solid wood and glued wood joints decreased (Clauss et al. 2011). There were significant differences in the thermal stability and failure behaviour between different adhesive systems. However, not much information is available on the strength of bondlines at low temperatures, especially under extremely cold conditions, and only some studies have been conducted on timber bridges in cold climates (Kainz and Ritter 1998; Wacker 2003, 2009). Therefore, understanding the effect of temperature on strength properties is very important if the engineered wood products are used for construction applications in which they are subjected to low temperatures and significant temperature changes.

The objective of the study was to determine the effect of low temperatures (20 to −50 °C) on the shear properties of Scots pine wood and glued joints. Seven commercially available adhesives were tested at the selected temperatures according to the test protocol provided in EN 302-1 (2011).

MATERIALS AND METHODS

Bondline experiments were carried out on Scots pine (Pinus sylvestris) and Norway spruce (Picea abies) (Wang et al. 2015). These are the two most popular species for engineered wood in Scandinavia. The results of the bondline shear tests of the bonded Scots pine specimens were compared with the strength of solid wood in shear parallel to grain. To test the bondline integrity of Scots pine under cold conditions, the same seven different commercially available adhesives from different producers were chosen as those used in the previous study on Norway spruce (Wang et al. 2015). Of the adhesives tested, poly-condensation adhesives such as PRF, MF, and MUF have been certified according to EN 301 (2013) and EN 302 (2011) standards for application in engineered wood products. In addition, PUR has also been certified in EN 15425 (2008). In this study, the shear strength of solid wood and glued wood joints were tested at different temperatures according to EN 302-1 (2011).

Data were analyzed using the statistical software package IBM SPSS Statistics, Version 20 (IBM Corporation, New York, USA). An analysis of variance (ANOVA) was carried out using a 5% level of significance. When significant differences were found, Duncan’s multiple-range test was performed to reveal any differences caused by the different adhesives at different temperatures. Significant differences are designated by different letters in the tables below.

Materials

Scots pine (Pinus sylvestris) samples with an average oven-dried density of (473 ± 31) kg/m3 and a moisture content (MC) of (12 ± 1%) were used. The growth ring angle (angle between growth rings and glued surface of the specimen) of the wood was between 30 and 90°.

The same adhesives were used in this experiment as in the previous study (Wang et al. 2015):

- One-component polyurethane adhesive (PUR)

- Poly(vinyl acetate) adhesive (PVAc)

- Emulsion-polymer-isocyanate adhesive (EPI)

- Melamine-formaldehyde adhesive (MF)

- Melamine-urea-formaldehyde adhesives (MUF1 and MUF2)

- Phenol-resorcinol-formaldehyde adhesive (PRF)

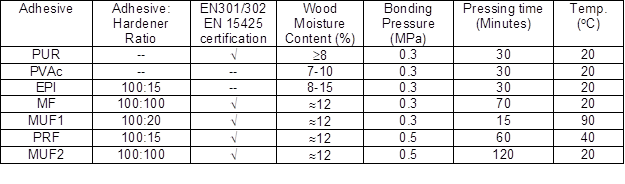

For pine testing samples (as shown in Table 1), the same pressure and pressing time were used, and the same adhesive amount (one-side application with a spread per side of 200 g/m2) was applied according to the adhesive suppliers’ and engineered wood products companies’ recommendations as for spruce tests (Wang et al. 2015).

Table 1. Adhesives and Optimal Gluing Process Information According to the Manufacturer (Wang et al. 2015)

Methods

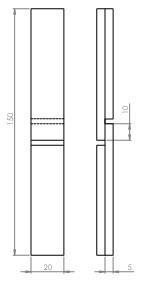

The production of specimens for pine was prepared using the same methods as described in the previous paper (Wang et al. 2015). The bonded samples were also cut into specimens with dimensions of 150 mm x 20 mm x 10 mm, according to EN 302-1 (2011) (Fig. 1). To obtain a reference value for the strength of the glued specimens, non-glued solid wood specimens with the same dimensions were tested. These specimens were prepared according to the requirements of EN 302-1 (2011).

Fig. 1. Schematic of a tested sample (adapted from EN 302-1 (2011) (Fig. 2(a))

To investigate the influence of temperature on shear strength, 15 specimens of each test set were tempered in a special climate chamber (Vötsch industrietechnik vcv7120-5) (at the Department of Civil Engineering at Technical University of Denmark) for 12 h at 20, −20, −30, −40, and −50 °C, respectively. There was one more batch of 15 samples tested for six cycles of temperature changes (0 and –20 °C). That means the 15 samples were kept in the climate chamber for 12 h at −20 °C, then the chamber temperature was subsequently changed to 0 °C for another 12 h, and this was continuously repeated for six cycles (days). After that, the test subjects were tested at −20 °C. The tests were executed on the same universal testing machine in the climate chamber at the designed temperature as for Norway spruce (Fig. 2). The tests were performed in a position-controlled model with a feed speed of 2 mm/min.

Fig. 2. Climate chamber, shear test machine, and test specimens

SEM analyses of bondlines were carried out on small sample blocks (ca. 3 mm × 3 mm × 7 mm) using a JSM-5200 (JEOL, Japan) electron microscope operated at an accelerating voltage of 15 kV. Section blocks were prepared on a sliding microtome (Reichert, Austria) and sputter-coated with gold (DESK II Denton Vacuum, USA) prior to SEM examination.

RESULTS AND DISCUSSION

Impact of Temperature on Shear Strength for Each Type of Adhesive

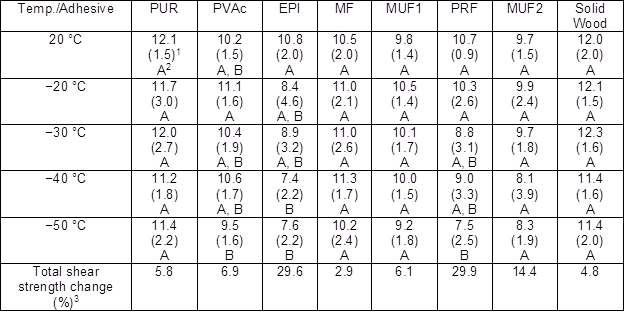

Presented in Tables 2 and Fig. 3 are the shear strength of Scots pine bondlines and control samples at different temperatures. Scots pine did not show a clear trend of decreasing shear strength as temperature decreased, compared with Norway spruce (Wang et al. 2015). A detailed discussion follows.

Table 2. Shear Strengths (MPa) of Scots Pine Wood Joints at Different Temperatures

1 Values in parentheses are sample standard deviations.

2Values with the same capital letter in each column are not statistically different at the 0.05 significance level.

3 Total shear strength change (%) = (Shear Strength 20 °C − Shear Strength −50 °C)/Shear Strength 20 °C*100.

Solid wood specimens

As the temperature decreased from 20 to −50 °C, the shear strength of tested solid Scots pine wood specimens decreased from 12.0 to 11.4 MPa. It dropped only 4.8%, indicating that temperature changes had no statistically different at the 0.05 significance level impact on wood shear strength. The shear strength was always higher than 10 MPa at 20 to −50 °C, meeting the standard requirement EN 301 (2013), even though that standard was made of beech wood with a density of 700 ± 50 kg/m3.

Compared with Norway spruce (Wang et al. 2015), when subjected to different temperatures, Scots pine did not show a clear trend of decreasing shear strength as temperature decreased. Further research is needed to determine the reason for this.

PUR

Similarly to solid wood, as the temperature decreased from 20 to −50 °C, the shear strength of tested PUR bondlines with Scots pine wood joints decreased from 12.1 to 11.4 MPa (only 5.8%), showing that the temperature change had no significant impact on shear strength. The shear strength was always higher than 10 MPa at 20 to –50 °C, meeting the standard requirement of EN 301 (2013).

PVAc

As temperature decreased from 20 to −50 °C, the shear strength of PVAc resin-bonded Scots pine wood joints decreased from 10.2 to 9.5 MPa, a drop of 6.9%. The shear strength was significantly different at −50 °C. The shear strength of all PVAc resin-bonded wood joints were lower than that of solid wood and PUR resin bonds at all temperatures tested.

Compared with the shear strength of PVAc-bonded Norway spruce joints (Wang et al. 2015), the shear strength of Scots pine joints was stronger, and only at −50 °C was lower than 10 MPa. While the shear strength of PVAc-bonded Norway spruce joints were all lower than 10 MPa even at 20 °C. This indicated a large difference between these two species of wood. It may demonstrate that more species are needed to test in the future work to better investigate the effect of temperature change.

EPI

For Scots pine samples, the shear strength of tested EPI resin-bonded wood joints decreased significantly when the temperature decreased from 20 to −20 °C (10.8 to 8.4 MPa), indicating that shear strength developed by EPI resin was sensitive to temperature changes. As the temperature decreased from 20 to −50 °C, the shear strength of EPI resin-bonded Scots pine wood joints decreased from 10.8 to 7.6 MPa, a decrease of 29.6%.

The shear strength of EPI resin-bonded wood joints was lower than that of solid wood and PUR resin bonds at any lower temperature tested. Statistically, the shear strengths tested were categorized into two temperature zones with no overlap: 1) 20 °C; and 2) −20 to −50 °C. Within Zone 2, as temperature decreased from −20 to −50 °C, the shear strength did not decrease significantly.

MF

The shear strength of MF adhesive-bonded Scots pine wood joints was not significantly different (2.9%) when the temperature decreased from 20 to −50 °C. Compared with solid wood and PUR adhesive bonds, the shear strength of MF adhesive-bonded wood joints was lower at all temperatures tested, but always higher than 10 MPa from 20 to −50 °C, meeting the standard requirement (EN 301 2013), indicating a relatively good bondline quality developed by the MF adhesive compared with those of the PUR and PVAc adhesives.

UF (MUF1 and MUF2)

The shear strength of MUF1 adhesive-bonded wood joints showed no significant decrease from 20 to −50 °C, and the average shear strength decreased by only 6.1%. The data showed that as the temperature dropped from 20 to −20 °C, the shear strength increased slightly (from 9.8 MPa to 10.5 MPa). Further decreasing temperature seems to not affect shear strength. Generally, MUF1 resulted in a lower shear strength than solid wood at the temperature range tested.

As the temperature decreased from 20 to −50 °C, the shear strength of MUF2 adhesive-bonded wood joints decreased from 9.7 to 8.3 MPa. These values were the lowest of all tested adhesive types and the shear strength was always lower than 10 MPa at 20 to −50 °C, which did not meet the standard requirement (EN 301 2013). The total decrease in shear strength was 14.4%.

PRF

Conventional PRF adhesive is historically the most established adhesive for cold setting bondline applications. The data in Table 2 indicate that the shear strength of PRF adhesive-bonded Scots pine did not meet the EN 301 (2013) requirement when the temperature was lower than −30 °C. As the temperature decreased from 20 to −50 °C, the shear strength of PRF adhesive-bonded wood joints decreased from 10.7 to 7.5 MPa, a drop of 30%, indicating that temperature changes had a significant impact on shear strength. The shear strength of PRF adhesive-bonded wood joints was significantly lower at −50 °C, and had the lowest value among all adhesives (only 7.5 MPa). Statistically, shear strengths were categorized into two temperature sectors with no overlap: 1) 20 to −20 °C; and 2) −30 to −50 °C. In Sector 1 at 20 °C to −20 °C, the shear strength rose above 10 MPa, meeting the standard requirement (EN 301 2013). However, in Sector 2 at −30 to −50 °C, the shear strengths were lower than 10 MPa (8.8 to 7.5 MPa), and did not meet the standard requirement (EN 301 2013), indicating that as temperature dropped below −30 °C, the shear strength of the PRF adhesive bonded with Scots pine joints decreased significantly. This shows that the bondline integrity was quite sensible during temperature changes.

Figure 3 shows the shear strength of the bondline with adhesives at different temperatures. Again, as the temperature changed from −50 to 20 °C, the shear strength of the bondline with PRF and EPI had the greatest variation. Actually, from 20 to –30 °C, the shear strength of the bondline did not change significantly, and that of some of them even increased. However, at −40 °C and lower, it decreased significantly.

Fig. 3. Bondline shear strength of Scots pine wood joints bonded with specified adhesives at different temperatures

The difference in shear strength of different adhesive bonded Scots pine may originate from the adhesives structure differences. For example: PRF adhesive is mainly constructed with benzene rings, whereas MUF adhesive is composed of urea component and melamine ring. It is assumed that these structures will react different at different temperature, but the reactions to wood for the different adhesives is quite speculative, and we cannot to draw any conclusions on this, because of the limitations of this work and test / analysis methods we used.

Besides, the shear strength difference at different temperatures may be due to the difference in the elastic property of different adhesives. Though we do not have data, as Gindl-Altmutter et al. (2012) mentioned stiffness of adhesive affected wood bonds shear strength, low temperature affect the elastic properties of an adhesive, resulting in stress distribution in bondline difficulty thus reduce the shear strength.

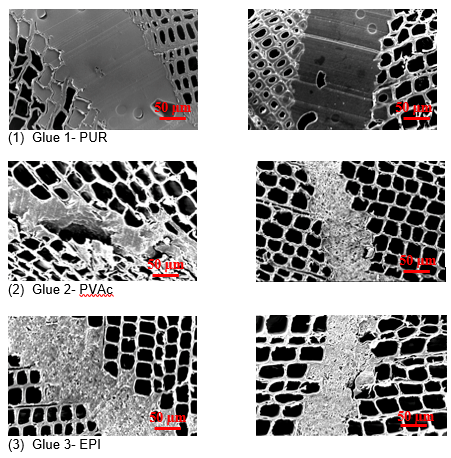

Scanning Electron Microscope (SEM) Analyses of Bondlines

Figure 4 shows SEM images of bondlines for the wood bonds with seven types of adhesives at −30 °C. The distances were measured, including the distance the adhesive penetrated into the wood. The images on the left side of Fig. 4 are bondlines of Norway spruce (Wang et al. 2015). The images on the right side of Fig. 4 are bondlines of Scots pine. PUR showed the best adhesive penetrations of the three lumens; the average bondline width was 178 mm for Norway spruce and 134 mm for Scots pine; both are much thicker than the designed bondline thickness of 100 mm. They both showed a smoother bondline surface than the other types of adhesives. The other bondline width was followed by MUF2 bonds (118 mm for Scots pine and 101 mm for Norway spruce), MUF1 bonds (101 for Scots pine and 83 mm for Norway spruce), EPI bonds (95 mm for Scots pine and 113 mm for Norway spruce), MF (90 mm for Scots pine and 98 mm for Norway spruce), and PRF (88 mm for Scots pine and 65 mm for Norway spruce). The thinnest bondline widths were formed by PVAc bonds: 85 mm for Scots pine, and 91 mm for Norway spruce.

Fig. 4. SEM images of bondlines for wood bonds with seven types of adhesives (left: Norway spruce; right: Scots pine)

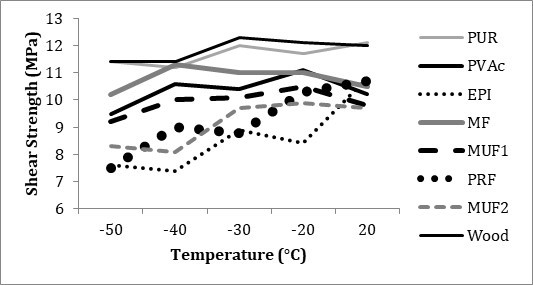

Dynamic Tests of Shear Strength

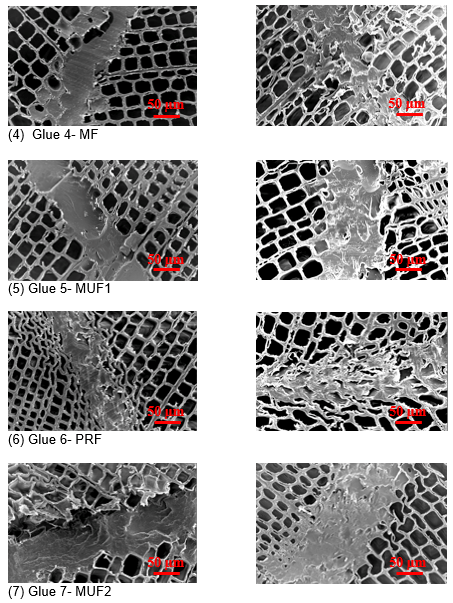

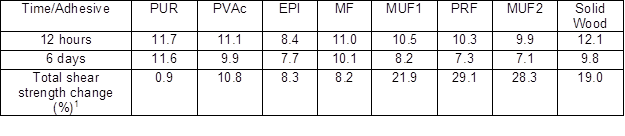

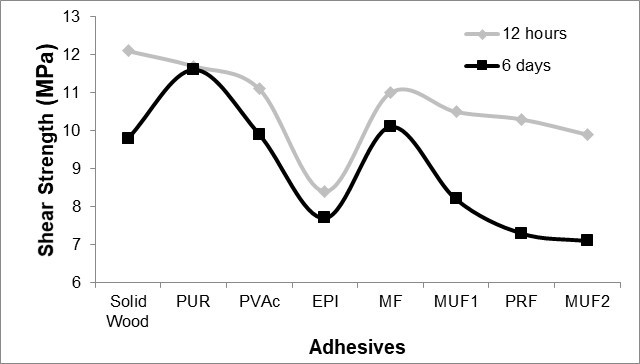

Table 3 and Fig. 5 show the values for the 12-hour tests and 6-day cycling tests. Both were performed at −20 °C. There was a clear change in the shear strength of the two types of tests. For 6-day tests, the values for the various types of adhesives were lower than those for 12-hour tests. Therefore, the duration of the samples subjected to the same temperature had an obvious impact.

Figure 5 also shows that PUR was the most stable adhesive both for 12-hour or 6-day tests when temperature changes. The shear strength of the bondline with PUR adhesive was almost the same (11.7 to 11.6 MPa). However, the shear strength with MUF and PRF, and even the wood itself, changed significantly.

Table 3. Shear Strengths (MPa) of Scots Pine Wood Joints after Different Durations (12 hours and 6 days) at −20 °C

1Total shear strength change (%) = (Shear Strength 12 hours − Shear Strength 6 days)/Shear Strength 12 hours*100.

Fig. 5. Difference between shear strength after 12 hours and 6 days

CONCLUSIONS

- The shear strengths of Scots pine wood and PUR, PVAc, EPI, MF, MUF1, PRF, and MUF2 adhesive-bonded wood joints at temperatures of 20, −20, −30, −40, and −50 °C were studied. Generally, within the temperature test range, the shear strength of Scots pine solid wood and wood joints resisted the effects of temperature better than that of Norway spruce. PUR adhesive resulted in the strongest shear strength at most temperatures tested. MUF adhesive resulted in the weakest. MF adhesive responded to temperature changes in a similar manner to that of PUR and PVAc adhesives. The shear strengths of wood joints with PRF and EPI adhesives were more sensitive to temperature change.

- For dynamic tests of shear strength, the values for 12-h and 6-day tests under cycles of temperature (−20 and 0 °C) were compared. For 6-day tests, the values for the various types of adhesives were lower than those for 12-h. Therefore, duration significantly influenced the shear strength of samples subjected to the same temperature. PUR is the most stable adhesive; the stability of MUF and PRF decreased significantly under extreme temperatures.

- The data created through the experiment did, for the most part, meet the shear strength requirements of EN 301 (2013) and EN 302 (2011), unlike Norway spruce (Wang et al. 2015). This suggests that the influence of low temperatures on the diminished shear strength of bondlines for the load-carrying capacity of glulam should be studied further with different species.

- The shear strength difference at different temperatures may be due to the difference in the elastic property of different adhesives. Stiffness of adhesive affected wood bonds shear strength, low temperature affect the elastic properties of an adhesive, resulting reduce the shear strength should be more investigated in the near future.

ACKNOWLEDGMENTS

The authors are grateful for the technical support of Mr. Per Anders Fjellström and Mr. Urban Häggström at SP Wood Technology, Skellefteå, Sweden, and the student Tóki Vang and the technicians at the Department of Civil Engineering, Technical University of Denmark, Denmark.

REFERENCES CITED

Clauss, S., Joscak, M., and Niemz, P. (2011). “Thermal stability of glued wood joints measured by shear tests,” Eur. J. Wood Prod. 69(1), 101-111. DOI: 10.1007/s00107-010-0411-4

Deppe, H. J., and Schmidt, K. (1994). “Ergänzende Untersuchungen zum Alterungsverhalten gestreckter Holzmontageverleimung,” [“Additional tests for the ageing behaviour of filled glueline products”], Holz als Roh- und Werkstoff [Eur. J. Wood Prod.] 52, 355-360.

Egner, K., and Kolb, H. (1966). “Versuche über das Alterungsverhalten von Leimen für tragende Holzbauteile,” [“Investigations on the Aging of Glues for Supporting Structural Wooden Elements”], Holz als Roh- und Werkstoff [Eur. J. Wood Prod.] 24: 439-442.

EN 301 (2013). “Adhesives, phenolic and aminoplastic, for load bearing timer structures – Classification and performance requirements,” European Committee for Standardization, Brussels, Belgium.

EN 302-1 (2011). “Adhesives for load-bearing timber structures – Test methods – Part 1: Determination of longitudinal tensile shear strength,” European Committee for Standardization, Brussels, Belgium.

EN 302-2 (2011). “Adhesives for load-bearing timber structures – Test methods – Part 2: Determination of resistance to delamination,” European Committee for Standardization, Brussels, Belgium.

EN 15425 (2008). “Adhesives, one component polyurethane for load bearing timber structures – Classification and performance requirements,” European Committee for Standardization, Brussels, Belgium.

Falkner, H., and Teutsch, M. (2006). “Load-carrying capacity of glued laminated wood girders under temperature influence,” Bautechnik 83(6), 391-393. DOI: 10.1002/bate.200610032

Frangi, A., Fontana, A., and Mischler, A. (2004). “Shear behavior of bond lines in glued laminated timber beams at high temperatures,” Wood Sci. Technol. 38(2), 119-126. DOI: 10.1007/s00226-004-0223-y

Geissen, A. (1976). Uber den Einfluss von Temperatur und Holz- Feuchtigkeit auf die Elastizita ̈Ts- und Festigkeitseigenschaften des Holzes im Gefrierbereich (Influence of Temperature and Wood Moisture on the Elastic and Strength Properties of Timber in Freezing Range), Ph.D. dissertation, University of Hamburg, Germany.

Gerhards, C. C. (1982). “Effect of moisture content and temperature on the mechanical properties of wood: An analysis of immediate effects,” Wood Fiber 14(1), 4-36.

Gindl-Altmutter, W., Müller, U., and Konnerth, J. (2012). “The significance of lap-shear testing of wood adhesive bonds by means of Volkersen’s shear lag model,’’ Eur. J. Wood Prod. 70, 903-905.

Jiang, J., Lu, J., Zhou, Y., Zhao, Y., and Zhao, L. (2014). “Compression strength and modulus of elasticity parallel to the grain of oak wood at ultra-low and high temperatures,” BioResources 9(2), 3571-3579. DOI: 10.15376/biores.9.2.3571-3579

Kainz, J., and Ritter, M. (1998). “Effect of cold temperatures on stress-laminated timber bridge deck,” in: Proceedings of the 5th World Conference on Timber Engineering Vol. 2, J. Natterer and J. L. Sandoz (eds.), Swiss Federal Institute of Technology Lausanne, Montreux, Switzerland, pp. 42-49.

Kollmann, F. F. P., and Cote, W. A. (1968). Principles of Wood Science and Technology. I: Solid Wood, Springer Verlag, Berlin.

Niemz, P., Hug, S., and Schnider, T. (2014). “Einfluss der Temperatur auf ausgewahlte mechanische Eigenschaften von Esche, Buche, Ahorn und Fichte,” [“Influence of temperature on selected mechanical properties of ash, beech, maple and spruce”], Forstarchiv 85(5), 163-168.

Radovic, B., and Rothkopf, C. (2003). “Eignung von 1K-PUR-Klebstoffen für den Holzbau unter Berücksichtigung von 10-jähriger Erfahrung,” [“Suitability of 1K PUR adhesives for wood construction, taking into account 10 years of experience,”] Sonderdruck aus bauen mit Holz [Reprint from building with wood] 6, 1-6.

Raknes, E. (1997). “Durability of structural wood adhesives after 30 years ageing,” Holz als Roh- und Werkstoff [Eur. J. Wood Prod.] 55, 83-90.

USDA (2010). Wood Handbook: Wood as an Engineering Material, General Technical Report FPL-GTR- 190, U.S. Department of Agriculture, Forest Service, Forest Products Laboratory, Madison, WI, pp. 5-36.

Wacker, J. P. (2003). “Cold temperature effects on stress-laminated timber bridges—A laboratory study,” Res. Pap. FPL-RP-605, U.S. Department of Agriculture, Forest Service, Forest Products Laboratory, Madison, WI.

Wacker, J. P. (2009). “Performance of stress-laminated timber highway bridges in cold climates,” in: Proceedings of the 14th Conference on Cold Regions Engineering, August 31–September 2, Duluth, MN, pp. 637-649.

Yu, D., and Östman, B. (1983). “Tensile strength properties of particle boards at different temperatures and moisture contents,” Holz als Roh-und Werkstoff 41, 281-286. DOI: 10.1007/BF02610832

Wang, X., Hagman, O., Sundqvist, B., Ormarsson, S., Wan, H., and Niemz, P. (2015). “Impact of cold temperatures on the shear strength of Norway spruce joints glued with different adhesives,” Eur. J. Wood Prod. 73, 225-233. DOI: 10.1007/s00107-015-0882-4

Article submitted: August 28, 2015; Peer review completed: November 1, 2015; Revised version received: November 16, 2015; Accepted: November 17, 2015; Published: December 3, 2015.

DOI: 10.15376/biores.11.1.944-956