Research Articles

Latest articles

- Researchpp 6891-6909Han, X., Dai, J., Qian, W., Zhu, Z., and Li, B. (2021). "Effects of dowels on the mechanical properties of wooden composite beams in ancient timber structures," BioResources 16(4), 6891-6909.AbstractArticlePDF

In order to provide more accurate suggestions for the restoration of ancient timber buildings, five types of specimens were designed for static loading tests. The tree species used for the specimens was larch. The wooden composite beams were composed of purlins, tie plates, and fangs. The study analyzed the effects of the number and position of dowels on the mechanical behaviors of wooden composite beams in ancient timber buildings. The bending moment, slippage, strain of the wooden composite beams under the deflection of the beam allowed according to code, and the ultimate bearing capacity of the wooden column composite beams under failure conditions were examined. The test results showed that the dowels could improve the bending capacity of the wooden composite beams. The even distribution of the dowels was beneficial in reducing the sliding effect of the wooden composite beams. Under the amount of deflection allowed by the code, the mid-span section strain along the height of the wooden composite beam approximately conformed to the plane section assumption. The wooden composite beam still had bending capacity after each member failed. The results of this study illustrated that dowels improved the overall mechanical properties of the wooden composite beams.

- Researchpp 6910-6920Yan, F., Tian, S., Du, K., and Wang, X. (2021). "Effects of steam explosion pretreatment on the extraction of xylooligosaccharide from rice husk," BioResources 16(4), 6910-6920.AbstractArticlePDF

Rice husk, which contains hemicellulose, can be used as a renewable resource to produce xylooligosaccharide (XOS). However, it is difficult to destroy the lignin structure of rice husk. Steam explosion (SE) is an effective method in destroying the lignin structure to enhance the release of hemicellulose and cellulose. In this study, SE pretreatment was used at different high pressures. The results showed that the lignin structure of rice husk could be collapsed by SE pretreatment, and the chemical structures of rice husk were evaluated by Fourier transform infrared spectroscopy (FTIR). The SE pretreatment resulted in the significant increase of XOS content and antioxidant activities. In summary, SE pretreatment under 2.5 MPa was chosen as a good option for the production of XOS from rice husk.

- Researchpp 6921-6932Sinković, T., Jambreković, B., and Sedlar, T. (2021). "Interpreting research results for the physical and mechanical properties of wood: An approach not dependent on a juvenile/mature wood boundary," BioResources 16(4), 6921-6932.AbstractArticlePDF

The interpretation and presentation of research on the physical and mechanical properties of wood in the radial direction is important for the estimation of technological properties in primary wood processing. It is common practice to define the boundary between the juvenile and mature wood zone of tree growth because of the differences in wood properties in these two zones. The juvenile and mature wood zones can be determined statistically based on the significance of the difference in the properties in a particular zone. This paper presents the insufficiency in the statistical determination of the boundary between juvenile and adult wood. Such limitations detract from the potential value and technological exploitation of wood as raw material. Statistical tests yielded zones that were too wide for the transition of juvenile wood to mature wood. Representations of the distribution of properties in the radial direction also complement the knowledge for assessing the technological properties based on the researched use of the presentation of polynomials of the second degree and the display of the Tukey HSD test in the form of comparison tables. The graphical representations by groups of the tested annual rings of fir wood also help to assess the technological properties.

- Researchpp 6933-6942Zhu, Y., Zhang, Y., and Pan, B. (2021). "The viscoelasticity and deformation mechanism of Taxodium hybrid ‘Zhongshanshan’ wood by dynamic mechanical analysis," BioResources 16(4), 6933-6942.AbstractArticlePDF

The viscoelasticity of Taxodium hybrid ‘Zhongshanshan’ wood, while undergoing hydrothermal processing, was investigated via dynamic thermomechanical analysis. The results showed that the elastic deformation and viscous deformation of the Taxodium hybrid ‘Zhongshanshan’ heartwood were greater than the sapwood. The heartwood average storage modulus and average loss modulus were greater than the sapwood. The difference between the heartwood and sapwood had little effect on the average glass transition temperature of their hemicellulose, which was approximately 74 °C. The radial average storage modulus was greater than the tangential, and the difference between the average loss modulus in the radial and tangential directions was negligible. The average glass transition temperature in the radial direction was slightly lower than the tangential direction. As the moisture content increased, the average storage modulus and its average hemicellulose glass transition temperature decreased. The average glass transition temperature tended to be lower as the moisture content increased. This study revealed the structural deformation and molecular movement of Taxodium hybrid ‘Zhongshanshan’ wood, while undergoing hydrothermal processing; this has important theoretical value for understanding its characteristics as well as its rational and efficient usage.

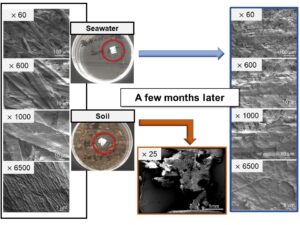

- Researchpp 6943-6953Hosaka, A., Yoshida, M., Horikawa, Y., and Kose, R. (2021). "Morphology and color change of pulp fiber sheet in seawater and soil," BioResources 16(4), 6943-6953.AbstractArticlePDF

Paper, or a pulp fiber sheet, is biodegradable and it can be a promising alternative to plastics, thus avoiding a serious form of marine pollution. However, its degradability in marine environments has not been well studied. This study investigated how a network of pulp fibers disintegrates in seawater compared with soil. Samples of pulp fiber sheets were exposed to seawater and soil for 4 months under stationary conditions at 25 °C. Digital photo images and scanning electron microscopy (SEM) images were used for morphological and color change investigations, while Fourier transform infrared (FT-IR) analysis was used to compare the chemical components of the samples before and after degradation. The area of the sample decreased by 22.3% in the seawater. The degradation rate in seawater was much lower than in the soil. The degradation mechanism in seawater was different from that in the soil because of the different microorganisms in each environment.

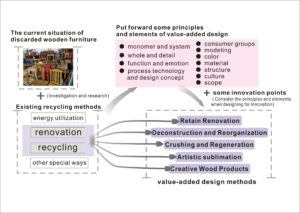

- Researchpp 6954-6964Yang, D., and Zhu, J. (2021). "Recycling and value-added design of discarded wooden furniture," BioResources 16(4), 6954-6964.AbstractArticlePDF

In the process of the “green revolution”, individuals have realized the importance of recycling waste materials. However, with ongoing individual changes in lifestyle, the huge resource of discarded wooden furniture is still considerably underutilized. This paper aims to provide new ideas for the recycling of discarded wooden furniture and to create added value to used furniture. Based on the summarization of existing recycling technology and methods, the diversified innovation and reuse of discarded wooden furniture integrating the current aesthetic and demand of people from multiple aspects are analyzed for the purpose of revealing the hidden value of waste materials. Waste recycling is of great importance to the country and enterprises in line with the concept of circular economy. For the sake of further excavating the hidden value of discarded wooden furniture products, the additional in-depth research in optimizing and upgrading green production and manufacturing in furniture industry is called for in the paper.

- Researchpp 6965-6983Ilias, N. N., Mohd Rozalli, N. H., and Mohamad Kassim, M. H. (2021). "Exploring the role of chemo-mechanical technique on the properties of nanocellulose isolated from different varieties of rice bran," BioResources 16(4), 6965-6983.AbstractArticlePDF

Nanocellulose (NC) was isolated from an underutilized agricultural residue, defatted rice bran (DRB), obtained from three major paddy varieties in Malaysia, MARDI Rice (MR): MR 220, MR 219, and MR 297. The DRB was subjected to alkali (NaOH) and bleaching treatments prior to the isolation of NC. The NC from DRB was produced through the acid hydrolysis technique using 55%wt sulphuric acid (H2SO4) with the assistance of ultrasonication. The morphological structure of NC was analyzed through transmission electron microscopy (TEM). Based on the observation, a needle-like structure was observed for NC 219 while NC 220 and NC 297 showed nano-web structures. All obtained NC dimensions ranged from 183 to 263 nm long and 4.70 to 4.97 nm wide. Fourier transform infrared (FTIR) spectroscopy revealed the presence of all important compositions for the cellulose of each variety, indicating that the chemical structure of DRB cellulose has not been altered by acid hydrolysis. Particle size distributions portrayed a unimodal graph for NC 220 and NC 219. This comparative study provides an insight into the possibility of using DRB as a potential source of NC. The promising characteristics of NC from MR 219 allowed its application as an emulsifier for stabilizing a solid particle-based emulsion.

- Researchpp 6984-6992Hassanpoor Tichi, A. (2021). "Investigation of the use of old railroad ties (Fagus orientalis) and citrus branches (orange tree) in the particleboard industry," BioResources 16(4), 6984-6992.AbstractArticlePDF

Effects of two widely available and underutilized lignocellulosic materials on the mechanical and physical properties of particleboards were investigated in this work. The ratio of mixtures lignocellulosic flakes at four levels (100% aspen wood), (50% aspen wood: 25% citrus: 25% old railroad ties), (50% aspen wood: 50% citrus), and (50% aspen wood: 50% old railroad ties), and the percentage of resin in two levels (8 and 12%) were considered as variable factors. The 100% aspen wood (Populus tremula) was mixed as a control board (100% aspen wood). Then the mechanical and physical properties of the samples including modulus of rupture, modulus of elasticity, internal bond, water absorption, and thickness swelling after 2 h and 24 h of immersion (EN 310-319) and fire resistance (ISO 11925-2) were measured. The results showed that with increasing poplar wood in mixtures, modulus of rupture, modulus of elasticity, internal bond increased, while water absorption and thickness swelling decreased. Also, in comparison with the control boards, the boards that were made by mixing 50% poplar and 50% citrus branches with 12% glue had the highest mechanical strength. The results also showed that increasing the amount of old railroad ties chips in mixing caused a significant decrease in the fire retardancy of the boards.

- Researchpp 6993-7005Zhang, F., Wu, Z., Hu, Y., Zhu, Z., and Guo, X. (2021). "Prediction of cutting temperature in the milling of wood-plastic composite using artificial neural network," BioResources 16(4), 6993-7005.AbstractArticlePDF

In the milling of wood-plastic composites, the cutting temperature has a great influence on tool life and cutting quality. The effects of cutting parameters on the cutting temperatures in the cutting zone were analyzed using infrared temperature measurement technology. The results indicated that the cutting temperature increased with the increase of spindle speed and cutting depth but decreased with the increase of feed rates. In addition, based on experimental data, a BP neural network model was proposed for predicting the cutting temperatures. The value of R2 was 0.97354 for the testing data, which indicates that the developed model achieved high prediction accuracy, respectively. The results of the study can play a guiding role in the prediction and control of cutting temperature, which is of great importance in the improvement of tool life, machining quality, and machining efficiency.

- Researchpp 7006-7020Acosta, R., Montoya, J. A., and Londoño, C. A. (2021). "The influence of thermal treatment on the compressive strength and density of bamboo (Guadua angustifolia Kunth)," BioResources 16(4), 7006-7020.AbstractArticlePDF

Lignocellulosic materials that are thermally treated via hydrolysis react chemically, modifying their internal structure, which in turn modifies their physical and mechanical properties, as well as their dimensional stability. Bamboo (Guadua angustifolia Kunth) samples 3 years old, without nodes and without skin, obtained from their basal area were subjected to thermal treatment with temperatures between 160 and 200 °C and duration times between 1 h and 4 h. The severity of the thermal treatment affects the modulus of rupture and modulus of elasticity in compression. The modulus of rupture increased at temperatures up to 180 °C with treatment times of 2 h, i.e., the severity, defined as the product of the temperature and the time varied between 320 (°C*h) and 360 (°C*h). An inflection point was obtained at a temperature of 180 °C after 2 h with a maximum value of 115.1 MPa. The modulus of elasticity increased as the temperature and time increased. The modulus of rupture and the modulus of elasticity of the treated samples increased up to 14.7% and 36.1%, respectively, compared to the not thermal treated samples. Additionally, when the density increased, the resistance and the compression stiffness also increased.