Volume 16 Issue 4

Latest articles

- Researchpp 8205-8218Krilek, J., Tichý, B., Kováč, J., Melicherčík, J., and Kuvik, T. (2021). "Design of a stationary disc chipper project for dendromass chipping with stress analysis FEM methods," BioResources 16(4), 8205-8218.AbstractArticlePDF

The design of a stationary disc wood chipping machine was considered, as well as the stress-strain analysis of a cutting knife with a flat and shaped cutting edge, which will produce a dimensional chip. The design consisted of the conceptual design of a cutting knife, a cutting mechanism, and an entire disc chipping machine, which includes cutting tools. The design solution is based on mathematical calculations of the individual parts of the cutting device. Calculations of the cutting mechanism and the cutting tool were performed using the finite element method. The results of the stress analysis found that the maximum stress acting on the edge of the knife during cutting corresponded to the permissible stresses of the knife material and subsequent use in practice. Based on the design and physical parameters of the wood cutting process, the design of the entire chipping machine was simulated and then was modeled using the PTC Creo parametric 5.0 program. Additional finite element analysis was performed using the Creo Simulate 5.0 software.

- Researchpp 8219-8226Guedes, U. H., Paulino, D. M. S., Penteado, L. D., Ruthes, H. C., Fraga, I. F., Mascarenhas, F. J. R.,, Wolenski, A. R. V.,, Saraiva, R. L. P., Carvalho, C. M., Aquino, V. B. M., Lahr, F. A. R., and Christoforo, A. L. (2021). "Chemical evaluation of two tropical wood species for use as grilling planks," BioResources 16(4), 8219-8226.AbstractArticlePDF

This research evaluated the possible use of tropical hardwood species (Myrocarpus frondosus and Ocotea porosa) for grilling plank production. Physical, chemical, and organoleptic properties were evaluated and compared with properties of a well-used wood species for grilling planks, western red cedar (Thuja plicata). For chemical analysis, one technique was used: hydrodistillation. Normality tests and analyses of variance (ANOVA) were used for the comparisons between Thuja plicata and tropical hardwoods. The results of the organoleptic, chemical, and statistical analyses demonstrated the possibility of using Myrocarpus frondosus and Ocotea porosa in grilling plank production.

- Researchpp 8227-8238Baek, S.-Y., Song, Y.-J., Yu, S.-H., Kim, D.-H., and Hong, S.-I. (2021). "Bending performance of cross-laminated timber-concrete composite slabs according to the composite method," BioResources 16(4), 8227-8238.AbstractArticlePDF

Bending strength tests were conducted of cross-laminated timber (CLT)-concrete composite slabs according to the shear connection method and carbon fiber reinforced plastic (CFRP) reinforcement. The bending strength of the composite slab that was shear-connected with an epoxy adhesive was 17% higher than that of a composite slab that was shear-connected with a self-tapping screw. In addition, the CLT-concrete slip of the former composite slab was also measured as 20% lower than the latter under the same load, showing a behavior close to that of a full composite. Both shear connection methods generated a failure in a low load-deformation section when there was a defect in the outermost tensile laminae of the CLT. In contrast, the CFRP reinforcement in the tension part of the composite slab suppressed the failure at the defect in the outermost tensile laminae. This reinforcement effect increased the reliability of the bending performance of the composite slab by preventing the failure of the composite slab while in a constant failure mode. Furthermore, the slip of the composite slab decreased 49% after its reinforcement with CFRP, showing a behavior close to that of a full composite.

- Researchpp 8239-8257Svrzic, S., Djurkovic, M., Danon, G., Furtula, M., and Stanojevic, D. (2021). "On acoustic emission analysis in circular saw cutting beech wood with respect to power consumption and surface roughness," BioResources 16(4), 8239-8257.AbstractArticlePDF

A sound or a noise that accompanies wood machining processes is introduced by the tool rotation itself, by the friction of moving machine parts, or by wood-tool interaction. The sounds generated during machining with a circular saw could be analysed in order to monitor and possibly control the cutting process. Applying altered cutting parameters while cutting beech wood (Fagus sylvatica L.), which is the most common wood species in the Republic of Serbia, caused acoustic emissions that could be analysed throughout corresponding spectra. As shown in previous studies, altering the cutting parameters, e.g., the feed speed and tool override, resulted in variations in power consumption, surface roughness, and acoustic emission (or acoustic pressure). The aim of this paper was to provide a possible correlation between the applied cutting parameters and the acoustic emission spectra with respect to consumed power and the state of the machined surface. Along with acoustic emissions, the power consumption and surface roughness data were also acquired in order to make a possible relationship. By associating the idle circular saw acoustic spectra with background noise and comparing them with those obtained during machining, it was possible to indicate spectrum areas of particular interest for further analysis.

- Researchpp 8258-8272Zhao, Y., Shen, Q., Duan, Y., Wu, S., Lei, P., Yang, L., Qin, Y., and Yang, F. (2021). "Wood fiber-reinforced polylactic acid sheets enabled by papermaking," BioResources 16(4), 8258-8272.AbstractArticlePDF

Polylactic acid is a biodegradable thermoplastic polyester derived from renewable polysaccharides. In this work, softwood fibers were used to reinforce the paper sheet made from polylactic acid fibers, thus addressing the challenges regarding low density, rough surface, and weak strength. The impact of wood fibers and calendering on the physical properties (density, roughness, tensile strength, and folding endurance) of the composite paper were identified. Furthermore, the morphology of papers with different fiber contents and those that had been calendered was characterized with a scanning electron microscope. The use of wood fibers resulted in the improvement of the physical properties of the polylactic acid paper, and the enhanced refining of wood fibers had a favorable role in improving paper density, smoothness, and mechanical strength. The tensile index increased 37.9% when the beating degree of wood fibers increased from 25 to 60 °SR. After calendering, the density, smoothness, tensile strength, folding endurance, and air barrier property of the paper were improved 60.2%, 45.8%, 15.5%, 148.1%, and 79.4%, respectively. The calendering-based papermaking process involving the combined use of wood fibers and polylactic acid fibers would be a promising strategy for designing composite materials for tailorable end-uses.

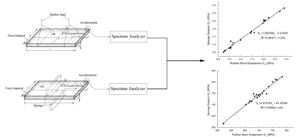

- Researchpp 8273-8288Huang, Y., Chen, S., Dauletbek, A., Yang, X., Wang, J., Sun, X., Xie, W., and Wang, Z. (2021). "Dynamic testing of the elastic modulus and shear modulus of full-scale laminated veneer lumber," BioResources 16(4), 8273-8288.AbstractArticlePDF

The feasibility of the dynamic testing was explored for the elastic modulus and shear modulus of full-scale laminated veneer lumber in batches at the production site. In order to do so, dynamic testing and analysis, involving a hammer blow and detection of frequencies, were carried out on the laminated veneer lumber free-plate placed in two ways: suspended and placed on a sponge. The results showed that the mode shape and modal frequency value of the suspended laminated veneer lumber free-plate obtained from the modal test were consistent with those of the specimens placed on the sponge. The elastic modulus and shear modulus values of the laminated veneer lumber free-plate obtained in sponge mode based on the transient excitation method were 3.99% and 3.08% higher than the elastic modulus and shear modulus values of the laminated veneer lumber obtained in suspension mode obtained based on the modal test method. The feasibility and reliability of the elastic modulus and shear modulus values obtained by the laminated veneer lumber free-plate in sponge mode were verified.

- Researchpp 8289-8308Yan Yi, L., Ab Latib, H., Ratnasingam, J., Mariapan, M., Choon Liat, L., Othman, K., Amir, M. A., and Jegatheswaran, N. (2021). "Readiness for and adoption of Industry 4.0 among small and medium sized enterprises in the Malaysian furniture industry," BioResources 16(4), 8289-8308.AbstractArticlePDF

The furniture industry is the fastest growing sub-sector in the Malaysian wood-based industry. Although it has grown tremendously over the years, it is characterized by stagnating value-addition. To improve industrial competitiveness, automation and technology application has emerged as a possible solution. A study was conducted to evaluate the influence of company size towards their readiness and adoptability of automation and Industry 4.0. A questionnaire-based survey involving large-, medium-, small-, and micro-sized furniture manufacturers throughout Malaysia was conducted with 160 respondents. The analysis of the results from the survey showed that there was a significant relationship between company size and their readiness for Industry 4.0. The results showed that small- and medium-sized enterprises (SMEs) are more hesitant in adopting technology due to the high cost required and the lack of skilled workers to cope with the new technology, compared to the large sized companies. The factor analysis revealed that the three main groups of the factor affecting decisions towards adopting industry 4.0 are government policy, difficulty in implementation, and expected benefit. This study suggests that providing incentives for the application of automation and technology will be required when the goal is greater uptake of technology among furniture manufacturers.

- Researchpp 8309-8319Van Duong, D., and Hasegawa, M. (2021). "Predicting mechanical properties of clear wood from Acacia mangium provenances using ultrasound," BioResources 16(4), 8309-8319.AbstractArticlePDF

Ultrasound was considered as a means for determining mechanical properties of clear wood in six different Acacia mangium provenances from a trial forest planted in Vietnam. A total of 30 trees (5 trees from each provenance) with no major defects were selected, and a 50-cm-long log was obtained at 1.3 m above the ground from each tree for the assessment of mechanical properties. The measured average ultrasound velocities for provenances tested in the longitudinal direction ranged from 4094 m/s to 4271 m/s. The predicted average dynamic modulus of elasticity (Ed) values varied from 7.42 GPa to 8.70 GPa among provenances. The Ed indicated significant positive correlation coefficients with modulus of elasticity (0.64 to 0.96), modulus of rupture (0.44 to 0.87), and compression strength (0.54 to 0.92) for provenances examined in this study. The results indicated that the use of ultrasound was feasible to determine the mechanical properties of A. mangium provenances planted in Vietnam.

- Researchpp 8320-8337Nandika, D., Darmawan, W., Karlinasari, L., Hadi, Y., Abdillah, I., and Putri, J. (2021). "Physical-mechanical properties and durability enhancement of glued laminated lumber made from inner part of Gewang (Corypha utan Lam.) trunk: The effect of lamina densification and lumber smoking," BioResources 16(4), 8320-8337.AbstractArticlePDF

The inner part of gewang (Corypha utan Lam.) trunk has significantly lower physical-mechanical properties as well as biodeterioration resistance, compared to outer parts. This study investigated a method for improving the physical-mechanical properties and biodeterioration resistance of glued laminated lumber made from the inner part of gewang trunk (GLIT). The effects of pretreating the lamina with densification and exposing the GLIT to smoking process were investigated. The seven layers of GLIT samples were bonded with isocyanate adhesive at a glue spread of 280 g/m2, then smoked for 15 days. Solid lumber pieces made from the inner part as well as the outer part of GLIT were also prepared for comparative purposes. Physical and mechanical properties of the lumber samples were tested according to Japanese agricultural standards. Meanwhile, dry-wood termite and wood decaying fungi resistances of the lumber samples were determined according to Indonesian standard. Results showed that overall physical-mechanical properties as well as dry-wood termite and decay resistances of densified-smoked GLIT were enhanced significantly. Pretreating of lamina and post-production smoking can be considered as a potential method to improve physical-mechanical properties and biodeterioration resistance of the GLIT.

- Researchpp 8338-8352Dömény, J., Brabec, M., Rousek, R., Rautkari, L., and Čermák, P. (2021). "Effect of microwave and steam treatment on the thermo-hygro-plasticity of beech wood," BioResources 16(4), 8338-8352.AbstractArticlePDF

The effects of microwave and steam treatment were analyzed relative to the immediate (thermo-hygro-plasticity) and post-assessed (permanent changes) properties of wood. The study was conducted using European beech (Fagus sylvatica L.) standard and 1.5 times up-scaled (only for microwave-heated and reference samples) bending specimens tested in a static three-point loading mode. The specimens were plasticized by heat and moisture (1) separately and (2) simultaneously by heating moist specimens using (i) various microwave regimes in continuous mode, and (ii) heated saturated steam in discontinuous mode. Oven-dried specimens tested at 20 °C served as references. The thermo-hygro-plasticity was studied immediately after treatment, whereas the permanent changes were assessed after oven-drying of plasticized specimens to 0% moisture content. Permanent structural changes were analyzed using scanning electron microscopy. Microwave treatment increased the plasticity of wood (decreasing the modulus of elasticity by 70%) comparably to steam treatment, when the output moisture content was 30% or higher. A similar degree of plasticity was found in up-scaled specimens heated by microwaves. Further analyses confirmed that microwave treatment did not cause any permanent damage to wood structure or reduce mechanical performance. The results showed that microwave treatment is an efficient alternative to steaming when plasticizing moist wood.