Volume 17 Issue 2

Latest articles

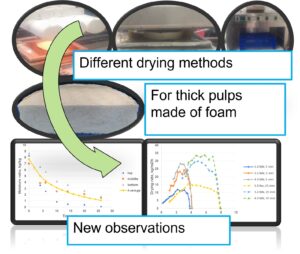

- Researchpp 2547-2562Timofeev, O. N., Jetsu, P., and Keranen, J. T. (2022). "Drying of thick foam formed mats comprising chemithermomechanical pulp fibers," BioResources 17(2), 2547-2562.AbstractArticlePDF

This paper focuses on the drying studies of foam-formed wood fibre based relatively thick materials via infrared drying, impingement drying, and microwave drying. The drying experiments were carried out for materials with three initial moisture ratios and thickness levels. Material selection was guided by the possibility of using these kinds of materials in packaging and construction applications. The motivation for this study was the fact that in water-based manufacturing a lot of energy is consumed during the drying phase; therefore, the better understanding of drying kinetics is essential for improving the environmental friendliness and cost efficiency of material production. The results revealed differences in the results of drying methods and limitations for thick, porous wood fibre-based materials. The differences in these methods affected the drying rates and material quality, which both can arise as the limiting factor for material production. The highest drying rate was observed using microwave drying, the intermediate drying rate was achieved using impingement drying, and the lowest using infrared drying.

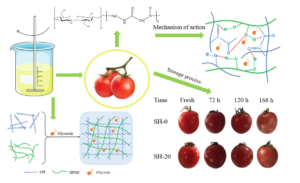

- Researchpp 2563-2575Zhang, T., Yun, Y., Chu, M., Bai, X., Sun, J., Zhang, Y., and Wang, L. (2022). "Coating of fruit with an edible soybean protein isolate film doped with hydroxypropyl methyl cellulose for improved preservation," BioResources 17(2), 2563-2575.AbstractArticlePDF

Coating a film on the surface of fruits to prolong the shelf life is an often-used method. However, wax coating is not sustainable and environmentally compatible. In this study, soybean protein isolate (SPI) and hydroxypropyl methyl cellulose (HPMC) were dissolved to form a coating solution with glycerin added as a plasticizer. The results showed that the tensile strength (TS) of the films increased from 6.52 to 20.76 MPa and the elongation at break (EAB) decreased from 68.07% to 12.67% when HPMC content increased from 0% to 20%, respectively. The intermolecular forces between the SPI and HPMC molecules made the polymers film-forming and the obtained film more continuous and stronger. The obtained film was tested on grapes and cherry tomatoes, which tightly coated with the film without any cracks. This greatly delayed their deterioration. By comparing the mass loss, total soluble solids, hardness, titratable acids, and pH values, the results showed that the coated grapes and cherry tomatoes exhibited higher freshness than the bare ones. This study fabricated an environmentally friendly coating that could prolong the shelf life of fruits, which will potentially promote the healthy development of the fruit industry.

- Researchpp 2576-2597Kamran, M. J., Jayamani, E., Heng, S. K., Wong, Y. C., Rahman, M. R., Al-Bogami, A. S., Huda, D., Bin Bakri, M. K., and Rahman, M. M. (2022). "Characterization and comparative study on chemically treated luffa fiber as reinforcement for polylactic acid bio-composites," BioResources 17(2), 2576-2597.AbstractArticlePDF

Luffa reinforced polylactic acid (PLA) bio-composites were prepared and examined. The luffa surface was treated using three chemicals, i.e., sodium hydroxide, 3-aminopropyltriethoxysilane, and acetic anhydride, which enhanced luffa compatibility with PLA. Mechanical testing was done on the chemically modified luffa reinforced PLA bio-composites, i.e., tensile, flexural, hardness, and thermal. Infrared spectral functional group and morphological analyses were performed on each sample. The results showed increases in tensile and flexural strength of 7.1% and 6.9% for sodium hydroxide, 5.7% and 1.4% for silane, and 4.3% and 0.4% for acetylation, respectively, especially to the surface-treated samples at 15 wt.% fiber volume, and a decrease in water uptake (%). Fourier transform infrared spectroscopy confirmed that the chemical surface treatments were successful with the removal of lignin and hemicellulose structures, which cause the surface structure of the modified fiber to be rough. Smooth surfaces were observed through SEM images. Thermal stability was enhanced due to improved interfacial bonding between luffa and PLA, eliminating other constituents and impurities. Moreover, the morphological analysis showed improved bonding compatibility between the luffa and PLA matrix.

- Researchpp 2598-2614Segovia, F., Blanchet, P., and Jiloul, A. (2022). "Performance evaluation of a wood treatment for connections with dowel-type bolts," BioResources 17(2), 2598-2614.AbstractArticlePDF

Recent studies have shown the advantage of wood impregnation on increasing the dowel-bearing strength of black spruce wood by almost 50%. The aim of the present study was to improve the mechanical performance of a dowel-type connection through an impregnation method for black spruce wood. The results showed that wood treatments improved the mechanical performance of dowel-type connections. The dowel-bearing strength increased up to 25%, while the stiffness increased up to 52%. The increase obtained was lower in comparison with the previous studies, however. A lower polymer quantity, resulted in a shorter vacuum time, and a lower temperature polymerization used in wood treatment brought the process closer to an industrial application.

- Researchpp 2615-2631Meng, W., Wang, S., Lv, H., Wang, Z., Han, X., Zhou, Z., and Pu, J. (2022). "Porous cellulose nanofiber (CNF)-based aerogel with the loading of zeolitic imidazolate frameworks-8 (ZIF-8) for Cu(II) removal from wastewater," BioResources 17(2), 2615-2631.AbstractArticlePDF

A novel biobased porous aerogel was synthesized using physical mixing, freeze-drying, and in-situ growth methods. Zeolitic imidazolate frameworks-8 (ZIF-8) were grafted onto the surface of the CS/CNF solid composite to form a ZIF-8@CS/CNF aerogel. The structural characteristics and the adsorption potential of the ZIF-8@CS/CNF aerogel were investigated. It was found that the specific surface area of the ZIF-8@CS/CNF aerogel was 206 m2/g, and the water stability of the CNF aerogel was enhanced by incorporating the CS. Meanwhile, the adsorption isotherm and kinetics of the composite aerogel fit the pseudo-second-order kinetic model (R2 = 0.96) and the Langmuir isotherm model (R2 = 0.97) with the copper(II) oxide (Cu(II)) theoretical adsorption capacity of 245 mg/g, respectively. Furthermore, this aerogel, which combined metal-organic frameworks (MOFs) and CNF, was easy to fabricate and it was biodegradable. These characteristics suggest it has a broad potential for wastewater treatment.

- Researchpp 2632-2651Alipraja, I., Hernandez, R. E., Cáceres, C. B., and Koubaa, A. (2022). "Towards strand production in primary log breakdown: Effects of the counter-knife and temperature on size distribution of Jack pine strands," BioResources 17(2), 2632-2651.AbstractArticlePDF

Effects of counter-knife and wood temperature were studied relative to the size distribution of Jack pine strands processed by a strander-canter. Studied factors included the counter-knife angle (60°, 75°, 90°, and 105°) and the distance between the edges of the counter-knife and knife (6 mm, 11 mm, and 16 mm). The nominal cutting speed was fixed at 25 m/s. Rotation and feed speeds were adjusted to obtain a target strand length of 102 mm, while the target strand thickness was 0.9 mm. The stranding process was performed under two log temperatures, i.e., -13.4 °C (frozen condition) and 18.6 °C (unfrozen condition). Results showed that the proportion of strands, fines, pin chips, and strands’ width were affected by the counter-knife angle and wood temperature. The proportion of strands and the mean strand width increased as the counter-knife angle decreased, while conversely, the proportion of fines and pin chips decreased. Frozen logs produced narrower strands and more fines and pin chips than unfrozen logs. The highest strand proportion, lowest fines and pin chips proportions, and wider strands were obtained with a counter-knife angle of 60° for frozen wood and 75° for unfrozen wood.

- Researchpp 2652-2666Zhou, Y., Chen, S., Fu, H., Mohrmann, S., and Wang, Z. (2022). "Sound absorption performance of light-frame timber construction wall based on Helmholtz resonator," BioResources 17(2), 2652-2666.AbstractArticlePDF

In order to improve the sound absorption performance of the light-frame timber construction wall, this paper combined the aperture embedded wall unit structure with the actual building wall structure based on the Helmholtz resonance structure principle to design and fabricate two sets of wall structures: a new aperture embedded Helmholtz resonance structure (experimental group) and a conventional structure (control group). The sound absorption coefficients of the two wall structures were measured by the reverberation chamber test, and related analysis was carried out. The results showed that the aperture embedded Helmholtz resonance wall structure exhibited good sound absorption performance in the low frequency range; in particular, a perfect sound absorption effect was basically achieved at a frequency of 100 Hz. Compared with the conventional wall structure, the sound absorption performance of the aperture embedded Helmholtz resonance wall structure in the test frequency range was enhanced greatly. While the value of the sound absorption coefficient was increased in the low frequency range, the bandwidth of sound absorption frequency was expanded to a certain extent, and the average sound absorption coefficient and noise reduction coefficient were both improved. This paper explored the applicability of Helmholtz resonance structure in practical wall structure. The research results could provide reference for reducing indoor noise pollution and creating a better living environment.

- Researchpp 2667-2679Ebrahimpour Kasmani, J., and Samariha, A. (2022). "Effects of different levels of nanocellulose and chemical pulp on the optical and mechanical properties of money paper made with bottom combers pulp," BioResources 17(2), 2667-2679.AbstractArticlePDF

Simultaneous effects of using cellulose nanocellulose and chemical pulp in paper money were studied with bottom combers cotton pulp. The bottom combers pulp and chemical pulp were prepared in a factory that produced durable paper, and their products were transferred to the laboratory. The nanocellulose was prepared by Nano Novin Polymer Co. and was consumed at 4 levels, i.e., 0%, 0.3%, 0.6%, and 0.9%. After commixing the pulp with the nanocellulose at the identified percentages, handsheets of 90 g∙m-2 papers were produced. The results showed that by increasing the amount of nanocellulose, up to 0.9%, the tensile strength index, burst strength index, tear strength index, and folding endurance increased 22.7%, 38.9%, 7.7%, and 348%, respectively, when compared with the control sample. Enhancement via nanocellulose up to 0.9% increased the surface smoothness up to 7.9% compared with the control sample, while the air resistance and Cobb decreased 69% and 7.9% in comparison with control sample, respectively. By increasing the nanocellulose content up to 0.9% the opacity increased 0.7%; moreover, the brightness and whitening decreased 3.5% and 10.6, respectively. The scanning electron microscopy results indicated that enhancement via nanocellulose decreased the air resistance.

- Researchpp 2680-2695Liu, H., Wang, J., He, Y., Zhang, W., Lei, L., Chen, L., Chen, Y., Zhu, J., Tu, J., and Li, K. (2022). "Investigation of the binding properties of 3,4-dihydroxybenzaldehyde from Salvia miltiorrhiza (Bunge) with human serum albumin via multi-spectroscopic and molecular docking techniques," BioResources 17(2), 2680-2695.AbstractArticlePDF

To investigate the binding properties of 3,4-dihydroxybenzaldehyde with human serum albumin, as well as the structural changes of human serum albumin under a simulated physiological pH value (a pH of 7.4) and a high 3,4-dihydroxybenzaldehyde concentration, a series of techniques, i.e., fluorescence, synchronous fluorescence, ultraviolet-visible absorption, Fourier-transform infrared spectroscopy, and molecular docking simulation, were employed. Steady state fluorescence showed that 3,4-dihydroxybenzaldehyde quenched the intrinsic fluorescence of human serum albumin via a static mechanism. The 3,4-dihydroxybenzaldehyde-human serum albumin complex had a strong affinity (Kb = 105 M-1) at various temperatures. It was shown that 3,4-dihydroxybenzaldehyde was bound to the IB subdomain of human serum albumin primarily via hydrogen bonding and van der Waals forces at high 3,4-dihydroxybenzaldehyde concentrations, based on the results of the thermodynamic and molecular docking. Furthermore, the fluorescence emission spectrum and Fourier-transform infrared spectroscopy results indicated that the binding distance between 3,4-dihydroxybenzaldehyde and human serum albumin was 4.42 nm. In addition, 3,4-dihydroxybenzaldehyde induced conformational changes of human serum albumin. These findings provide reasonable evidence for further understanding the distribution of 3,4-dihydroxybenzaldehyde when it spreads into human blood serum, which may be helpful in food and medicine research.

- Researchpp 2696-2704Luo, P., Yang, C., and Wang, T. (2022). "Making ultra-thin high density fiberboard using old corrugated container with kraft lignin," BioResources 17(2), 2696-2704.AbstractArticlePDF

Ultra-thin high-density fiberboards (HDFs), a newly developed variety of fiberboards, broaden and extend the applications of medium thick medium- and high-density fiberboards and are capable of replacing cardboards for most applications. Old corrugated container (OCC) is an important packaging solid waste. The mechanical strength of OCC deteriorates after repeated recycling processes. Application of OCC fibers for value-added ultra-thin HDFs can be of much interest. Because the OCC fibers have more surface area than the wood particles, the resin coverage per surface area of the OCC is much lower than wood particles during panel board formation. Therefore, the performance of the OCC fiber-based board is poor and the resin adhesive consumption is high. To overcome these problems, a novel method of using OCC to make ultra-thin HDFs was developed and investigated. In this work, the OCC was shredded and pulped before making the ultra-thin HDFs. To protect consumers from exposure to harmful formaldehyde, kraft lignin was used as a binder. The target density and thickness of the ultra-thin HDFs were 1.0 kg/m3 and 2 mm respectively. The resulting ultra-thin HDFs were evaluated for their physical and mechanical properties. Comparisons with the Chinese Standards