Volume 18 Issue 1

Latest articles

- Researchpp 1206-1214Pugovics, K., Spulle, U., Arhipova, I., Grants, E., and Klancbergs, K. (2023). '"Influence of glue-free zones on the withdrawal capacity of glued-in steel threaded rods," BioResources 18(1), 1206-1214.AbstractArticlePDF

The hidden nature of a glued-in rod joint presents considerable challenges with regards to quality control, and there has been minimal research on the subject to fully understand the influence of defects on the joint performance. In this study, voids in adhesive line or glue-free zones were simulated in various depths of the embedded rod, and the results were compared to a reference sample population without defects. Withdrawal capacity of glued-in steel threaded rods were lower compared to reference group samples without gluing defects, when glue simulated voids or glue-free zones were positioned in the middle part and upper (closer to sample crosscut surface) part of the glued-in rods. And no difference was observed of simulated glue-free zones in the lower (the deepest) part, closer to the end of the glued-in rod, compared to reference group samples without gluing defects.

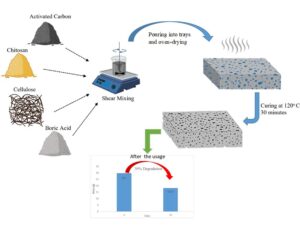

- Researchpp 1215-1231Ergun, M. E. (2023). "Activated carbon and cellulose-reinforced biodegradable chitosan foams," BioResources 18(1), 1215-1231.AbstractArticlePDF

Chitosan foams with promising mechanical properties, heat-insulating ability, and flame retardancy were produced through oven drying. The chitosan foams were reinforced with cellulose, boric acid, and different ratios of activated carbon. The foams showed desirable low density (80.2 to 109.8 kg/m3) and compression properties. The compression resistance and compression modulus of foams ranged between 53.6 and 98.5 KPa and 214 to 394 KPa, respectively. Thermal conductivity tests revealed that the foams endowed low thermal conductivity values (0.035 to 0.051 W/mK). The limiting oxygen index (LOI) of the foams was as high as 32.9% for activated carbon (20 g/L). The activated carbon reinforcement produced higher thermal properties and decreased the mass loss 48.1% at 600 °C. The produced foams exhibited good biodegradability (39% degradation in 15 days). The overall test results showed that the chitosan foams can be utilized as a promising environmentally friendly material in thermal insulation fields.

- Researchpp 1232-1250Siam, N. A., Abdullah, N. A., Uyup, M. K. A., Che Amri, C. N. A., Ahmad Juhari, M. A. A., and Talip, N. (2023). "Wood anatomical features of Anacardiaceae from Malaysia," BioResources 18(1), 1232-1250.AbstractArticlePDF

This study examined the anatomical features of Anacardiaceae from Malaysia. A total of 31 species from 13 genera of the family Anacardiaceae in Malaysia were obtained from Kepong Xylarium (KEPw), Forest Research Institute Malaysia. The genera in Anacardiaceae were distinguished based on anatomical features. The diagnostic anatomical features that were used to separate the genera are scalariform perforations plates present in Campnosperma, larger rays in Pentaspadon and Spondias, and radial canals in some genera. Mineral inclusion, i.e., crystals and silica also could be diagnostic features to distinguish the genera in Malaysian Anacardiaceae; silica was observed in Gluta, Parishia, and Swintonia. Anatomical features could be used as indicators to the other wood properties and lead to potential usage of timber in Anacardiaceae. However, the presence of druses in individual Toxicodendron succedaneum indicated its adaptation to the local microclimatic conditions.

- Researchpp 1251-1259Xing, T., Dong, C., Hu, X., Zhang, J., Zhao, Y., Wang, X., Xue, J., and Zhang, X. (2023). "Heat treatment’s effect on the wettability of cellulose membranes via a top-down approach," BioResources 18(1), 1251-1259.AbstractArticlePDF

Cellulose is a potential alternative to petroleum-derived polymers, and cellulose membranes are used in many applications such as sensors, flexible materials, and functional membranes. Most bottom-up methods are energy-, chemical-, and time-intensive compared to top-down methods for preparing cellulose membranes. Additionally, most methods to improve the hydrophobicity of cellulose membranes to increase their lifetime are complex and require large amounts of organic solvents. To balance sustainability, degradability, and service life from a whole life cycle perspective, which is the biggest challenge for the industrialization of cellulose membranes, a top-down approach was used here to prepare cellulose membranes using camphor pine, walnut, and loofah materials. The effect of low temperature heat treatment on the prepared membranes’ wettability and water stability were investigated. The results showed that the water stability of loofah cellulose membrane was influenced by both surface and internal wettability due to the non-homogeneous structure. The heat treatment temperature of 200 °C for loofah cellulose membrane, 150 °C for camphor pine cellulose membrane, and 225 °C for walnut cellulose membrane was more effective.

- Researchpp 1260-1278Ren, J., Zhang, C., Wang, J., and Cai, J. (2023). "Optimization of weathered coal biodegradation by Penicillium aculeatum 13-2-1 and UV-visible spectral characteristics of active degraded products," BioResources 18(1), 1260-1278.AbstractArticlePDF

Weathered coal is widely distributed in many provinces in China. It has great potential utilization values as soil ameliorant in sustainable agriculture. To find the optimal condition for the biodegradation of weathered coal and obtain the spectral characteristics of active degraded products of coal, the bioactivation of humic acid in weathered coal is essential. In this study, a fungal strain (Penicillium aculeatum 13-2-1) capable of degrading weathered coal was isolated from the rhizosphere of Zelkova serrata. The experimental results using classical one factor at a time method showed that weathered coal of 1.0 g, inoculum of 150 µL, and sodium nitrate of 0.10 g in 100 mL broth were the optimal conditions for the biodegradation of coal, respectively. The variance analysis of orthogonal tests illustrated that the three factors had little effects on biodegradation of weathered coal, but the weathered coal significantly negatively affected the contents of soluble humic acids in liquid coal products. Different diluted solutions of liquid coal products for all orthogonal combinations promoted the growth of the seeds of Brassica napus L., especially on radicles. The UV-visible spectra of the liquid coal products for all combinations presented the differential absorbance closely associated with the quantity of sodium nitrate in medium.

- Researchpp 1279-1292Jang, J. W., Lee, J.-H., Youn, H. J., and Lee, H. L. (2023). "The distribution of poly-DADMAC additive in the inkjet coating layer and its influence on the print quality," BioResources 18(1), 1279-1292.AbstractArticlePDF

Maximizing the functionality of cationic polydiallyldimethylammonium chloride (poly-DADMAC) additive with minimal dosage in inkjet coatings can contribute to both an improvement in quality and a cost reduction. To do this, it is essential to understand how the cationic additive is distributed in the coating layer and how it affects the print quality. This study presents a three-step investigation to enhance the understanding of the distribution of poly-DADMAC, as well as its effect on inkjet print quality. First, the adsorption behavior of poly-DADMAC on silica pigments was investigated by measuring the surface charge of silica and the adsorption of the cationic additive. Second, the influence of poly-DADMAC on the printability of binder films was investigated. Finally, the effect of poly-DADMAC on the print quality of inkjet paper was examined. The addition of poly-DADMAC improved the print quality of the inkjet paper because of the improved holdout of the negatively charged colorants in the ink.

- Researchpp 1293-1329Meekum, U. (2023). "Manufacturing of wood plastic composite from polyethylene/poly(ethylene terephthalate) waste/ultra high molecular weight polyethylene blends and rice husk fiber: Raw materials preparation and preliminary processing investigation," BioResources 18(1), 1293-1329.AbstractArticlePDF

The processing temperature of poly(ethylene terephthalate) waste (rPET) and ultra-high molecular weight polyethylene (UHMWPE) was lowered by blending to avoid decomposition of rice husk fiber (RHF) during the manufacturing of wood plastic composite (WPC). Maleic anhydride (MA) grafted blends of HDPE/LDPE/UHMWPE-g-MA and rPET/LDPE-MA were prepared. Those blends were flowable at 240 °C. They were employed as blended matrices to make HDPE/LDPE/UHMWPE-g-MA/rPET/LDPE-MA/RHF wood composite at processing temperatures not exceeding 240 °C. The study of RHF loading on the WPC performance revealed that melt flow index (MFI) and mechanical performances measured by impact, flexural, and tensile properties were weakened, but heat distortion temperature (HDT) was enhanced at high RHF loading. When the stabilizer content did not exceed 2 phf, the toughness and ductility were improved. Surface treatment of RHF by MA and dicumyl peroxide (DCP) enhanced the interfacial surface adhesion, but the toughness and ductility of the WPC were reduced at high MA/DCP dosing. The formation of crosslink structure via peroxide free radical initiated reaction at the MA grafted branch chains was the prime suspect for the inferiority of the mechanical performances.

- Researchpp 1330-1346Vititnev, A., Marchenko, R., Matygulina, V., Rubinskaya, A., and Shishmareva, A. (2023). "Wood fibre recapture from process water during wet-forming of fiberboard: Process modelling with environmental and economic assessment," BioResources 18(1), 1330-1346.AbstractArticlePDF

This article presents the rationale for modelling the process of internal recapture of wood fibre from wastewater in fibreboard production using conventional refining methods and a new refiner disc design. New experimental studies to obtain mathematical dependencies for confirming the possibility of reusing cellulosic fines in comparing conventional and new refiner discs for fibreboard production are presented. Models reflecting the internal reuse of cellulosic fines from wastewater were developed. In this article, for comparative assessment of the efficiency of the proposed technologies, an environmental and economic assessment of cellulosic fines in modelling the process of its obtainment in fibreboard production was performed.

- Researchpp 1347-1367Hashemzehi, M., and Sjöstrand, B. (2023). "Cationized dialdehyde cellulose synthesized with deep eutectic-like solvents: Effects on sheet dewatering and mechanical properties when used as wet-end additive," BioResources, 18(1), 1347-1367.AbstractArticlePDF

The ability of cationized dialdehyde cellulose to improve the mechanical properties of paper was evaluated. The majority of cationized additives are synthesized by introducing cationic groups through chemical reactions. Here, cationized additives were produced in a more environmentally friendly manner by use of non-toxic and readily biodegradable deep eutectic-like solvent mixtures (DESs). The modified cellulose’s properties were characterized by FTIR, polarized-light optical microscopy, charge titrations, and SEM/EDX. The cationized additives were investigated as strength additives for papermaking. Three different amounts of cationic additive (2%, 5%, and 10%) were added to the pulp, and the properties of handsheets were studied. Because increasing the additive content can affect dewatering of the process, the dewatering capabilities of the pulps with additives were evaluated by Schopper-Riegler (°SR) value, water retention value (WRV), and vacuum dewatering. Finally, the recyclability of the DES was assessed in terms of cationization reaction efficiency and their effect on paper mechanical properties.

- Researchpp 1368-1383Bakir, D. (2023). "Anatomical structure and copper microdistribution in mechanical, biological, and laser incised spruce and larch refractory woods," BioResources 18(1), 1368-1383.AbstractArticlePDF

The anatomical structure of wood and the application of three different incision pretreatments affect the distribution of preservatives in refractory woods. This study focused on Picea orientalis (L.) Peterm.) and Larix decidua Mill. and investigated the distribution of copper-based preservatives in the wood microstructure. Different incision pretreatments were applied before impregnation to increase the permeability of spruce and larch sapwood samples. After the incision pretreatments, transverse cross-sectional surfaces of the samples were sealed with polyurethane-based paint to prevent excessive preservative uptake into open ends of longitudinal tracheid lumens. The samples were then impregnated with Celcure C4, by applying a vacuum method. The structure of wood samples with preservatives before and after the incision pretreatments were observed. Copper microdistribution was observed to increase significantly in refractory wood species after different incision pretreatments, especially in larch wood. The degradation of pits caused by biological incision effectively increased the microdistribution of copper. The difference in the microdistribution of increased copper with the laser and mechanical incision pretreatments – following the same incision model – was attributed to the different anatomical structure and density of spruce and larch wood species and the fact that the hole depth and geometry were different in the laser and mechanical incision processes.