Volume 17 Issue 1

Latest articles

- Researchpp 132-143Narlıoğlu, N. (2022). "Effect of butyric anhydride modification on properties of wood-polylactic acid 3D-printed composites," BioResources 17(1), 132-143.AbstractArticlePDF

Scotch pine wood flour was modified with butyric anhydride to determine the effect of wood modification on the properties of 3D-printed composites. The 3D printer filaments were obtained by mixing wood flour and polylactic acid (PLA) with a twin-screw extruder. The composites were printed via a 3D printer from the obtained filaments. The mechanical, thermal, and morphological properties of the composites were investigated. According to the mechanical test results, the tensile strength values of the modified wood flour (MWF)-added composites were higher than the unmodified wood flour (UMWF)-added composites. It was also observed that the flexural strength and flexural modulus of MWF-added composites decreased compared to the UMWF-added composites. According to the investigation of the thermal properties of the composites, the thermal degradation temperature value of the 20% MWF-added PLA composite was higher than other composites. Therefore, through the investigation of breaking surfaces of the composites using scanning electron microscopy, it was observed that the interface bonding between PLA polymer matrix and wood flour was improved by modification.

- Researchpp 144-158Bi, D., Huang, F., Zhang, K., Sun, H., Li, Y., Liu, S., and Yin, X. (2022). "Influence of disturbances in the operating conditions on the refrigeration performance of a regenerative solar absorption refrigeration system with a biomass assisted combustion device," BioResources 17(1), 144-158.AbstractArticlePDF

To reduce the fluctuation of the heat source water temperature and ambient temperature caused by variations in solar radiation, a solar absorption refrigeration system with a supplementary biomass combustion device for the office area of a factory was designed. A numerical model of the solar energy absorption refrigeration system based on the Aspen Plus software was developed. In particular, the effects of the heat source water temperature, condenser temperature, evaporation temperature, and dilute solution flow rate on the cooling capacity, coefficient of performance, unit equipment duty, and generator temperature during actual operation were investigated. The heat load of each piece of equipment in the unit were found to increase correspondingly with the increase of the heat source temperature when the evaporating temperature and condensing temperature are constant. The coefficient of performance of the unit decreased as the condensing temperature increased keeping the temperature of the heat source constant. The results demonstrated that the flow rate of the dilute solution has effects on the occurrence temperature, cooling capacity, and the unit performance coefficient.

- Researchpp 159-176Çamlıbel, O., and Aydın, M. (2022). "The effects of continuous press speed and conditioning time on the particleboard properties at industrial scale," BioResources 17(1), 159-176.AbstractArticlePDF

Effects of continuous press speed (580 and 600 mm/s) and conditioning time (0 and 72 h) on some physical and mechanical properties and formaldehyde content of particleboards were investigated. The 18 mm thick boards were manufactured using urea-formaldehyde, with a 50% pine, 40% oak wood, and 10% poplar biomass mixture of the wood materials. According to the results of the unconditioned samples, the density, modulus of rupture (MOR), moisture content (MC), thickness swelling (TS), and water absorption (WA) were increased 0.8%, 4.4%, 0.4%, 4.4%, and 5.5% when press speed increased from 580 to 600 mm/s, while thickness, modulus of elasticity (MOE), internal bond (IB), surface soundness (SS), and free formaldehyde (FF) were decreased 0.3%, 4.9%, 2.4%, 10.6%, and 21.1%, respectively. On the contrary to the results of unconditioned samples, MOE and SS were increased 1% and 1.4%, respectively, and WA was decreased 3.5% with the increase in press speed when samples were conditioned for 72 h. Free formaldehyde content was the most prominent parameter influenced by the increase in press speed both for the unconditioned and 72 h conditioned samples.

- Researchpp 177-189Mao, B., Huang, W., Zhang, C., Lan, H., Zhu, L., and Zhang, B. (2022). "The mechanism of high butanol acetone ratio in ABE fermentation with fern root as substrate," BioResources 17(1), 177-189.AbstractArticlePDF

The butanol acetone ratio (B/A ratio) is a critical index to evaluate the process of ABE fermentation. In this article, fern root starch with yeast extract added (FY) was used as substrate for ABE fermentation. The final B/A ratio in a 5 L anaerobic fermentor reached the highest levels of 3.42, which signified an increment of 41% compared with corn. The mechanisms for the high B/A ratio of FY substrate were as follows: 1) the weakened organic acid circuit resulted in decreased acetone synthesis; 2) the NADH level of butanol synthesis was high; 3) coA transferase activity was low and butanol dehydrogenase activity was high. The final butanol concentration and substrate utilization were examined in a 5 L anaerobic fermentor, and the results validated the feasibility of ABE fermentation with FY as substrate.

- Researchpp 190-206Dewi, G. K., Widyorini, R., and Lukmandaru, G. (2021). "Application of maltodextrin-based adhesive on particleboard made from Salacca frond," BioResources 17(1), 190-206.AbstractArticlePDF

Maltodextrin is a potential natural adhesive for particleboard because it is reactive and freely soluble in water. However, maltodextrin has a low water resistance and a high melting point that hinder its development as a particleboard adhesive. An addition of ammonium dihydrogen phosphate (ADP) as a catalyst of maltodextrin was expected to overcome its weaknesses. The optimal pressing temperature was expected to be affected due to the addition of catalysts. This research aimed to investigate the effect of maltodextrin/ADP ratios and pressing temperatures on particleboard properties made from Salacca frond. The maltodextrin/ADP ratios used in this research were 100/0, 90/10, and 80/20 wt%, and the pressing temperatures were set at 200 and 220 °C. The combination of an increased ADP ratio in maltodextrin and an increased pressing temperature improved the particleboard properties. The water resistance was also significantly improved by addition of ADP and increased pressing temperature. Thermal analyses showed that the onset temperature of weight reduction of maltodextrin added particles was lowered by addition of ADP. The results suggested that a maltodextrin/ADP mixture could be a promising particleboard binder.

- Researchpp 207-222Wong, L. J., H’ng, P. S., Abdullah, L. C., Paridah, M. T., and Chin, K. L. (2022). "Effect of chemical steeping on yields of glucose and xylose from dilute acid hydrolysis of extract from oil palm trunk," BioResources 17(1), 207-222.AbstractArticlePDF

The effectiveness of chemical steeping was examined as a novel pretreatment prior to hydrolysis to influence the extractable yield of glucose and xylose from oil palm trunk (OPT). The chemical steeping parameters were 0.2% sodium metabisulphite (w/v), 0.5% lactic acid (v/v), 26 ± 2 °C, and 1 h, followed by dilute acid hydrolysis (2%, 4%, and 6% of sulphuric acid (v/v); 115 °C, 120 °C, and 130 °C; 15 min, 30 min, and 60 min). For comparison, the glucose and xylose yield extracted from untreated OPT was also examined. Thermal analysis showed that the lactic acid and sodium metabisulphite successfully degraded the lignocellulose of OPT. The total extracted glucose and xylose yield was improved, and was approximately 2.5% to 28.8% higher than the yield extracted from non-pretreated OPT fines. RSM analysis showed that the 130 °C x 50 min x 2% was predicted as the optimum parameters for the extraction of glucose and xylose through chemically treated OPT, and followed the dilute acid hydrolysis process. Analysis of variance showed that the hydrolysis parameters were significant model terms for the glucose and xylose yield. In conclusion, chemical steeping was successful as a pretreatment to increase the extractable glucose and xylose yield from OPT.

- Researchpp 223-242Merabtene, M., Tanninen, P., Varis, J., and Leminen, V. (2022). "Heat sealing evaluation and runnability issues of flexible paper materials in a vertical form fill seal packaging machine," BioResources 17(1), 223-242.AbstractArticlePDF

Vertical form fill seal machines are commonly used to form pouches. This paper aimed to optimize the sealing parameters and evaluate the runnability of flexible paper-based packaging materials with a polyethylene coating, differentiated by their grammages and thicknesses. This was done in comparison with a commercial plastic film, an oriented polypropylene and polyethylene laminate, using two different sealing jaw patterns in an industrial-scale vertical form fill seal machine. Based on the results obtained, the first observable seal was found at a sealing temperature of 90 °C for the paper-based material and a sealing temperature of 100 °C for thermoplastic film, both at a dwell time of 2 s. It was shown that the paper-based material had a larger sealing window, up to a sealing temperature of 220 °C, before the material started to turn brown, while the thermoplastic film shrank at a sealing temperature of 140 °C. Several peel and compression strength tests were performed to evaluate the flexible paper-based material. Furthermore, several hindering issues were observed in the paper-based material during the production runs. These included wrinkling, web buckling, friction in the forming tubes, pouches airtightness, etc. As such, recommendations for further investigations and future studies are given.

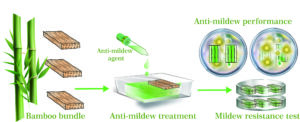

- Researchpp 243-254Wu, Z., Aladejana, J. T., Huang, D., Gong, X., Liu, S., Wang, X., and Xie, Y. (2021). "Comparative effect of selected anti-mildew agents on bamboo bundles," BioResources 17(1), 243-254.AbstractArticlePDF

Nutrient-rich raw bamboo materials can be infected by mildew when exposed to water or high humid environments. This not only affects the appearance of bamboo products, but it also contributes to respiratory diseases. Herein, four anti-mildew agents, i.e., boric acid, copper sulphate, alumina phosphate sol, and alumina silicate sol, were used to evaluate their anti-mildew performances. The results showed that the adequate anti-mold concentrations of boron and copper were 2% and 0.7%, respectively. The optimum mass ratio of aluminum phosphate sol and silicone aluminum sol were 1 to 1 (2% phosphoric acid addition) and 10 to 1 (aluminum salt addition was 1.5%). There were significant differences in the prevention and treatment effects of different mold inhibitors on mold and discoloration bacteria. The efficacies order of the anti-mildew property was as follows: copper sulphate > alumina silicate sol > boric acid > alumina phosphate sol. In addition, the order for stain fungi resistance was: boric acid > alumina phosphate sol > alumina silicate sol > copper sulphate. The selected anti-mildew agents showed promising application requirements as an active ingredient in bamboo preservative systems.

- Researchpp 255-268Shen, Z., He, Y., Sayed, U., Wang, J., Zhou, Y., and Wang, Z. (2022). "Measurement of the elastic constants of carbon fiber board based on modal analysis," BioResources 17(1), 255-268.AbstractArticlePDF

As a strategic new material with excellent performance, carbon fiber has attracted much attention in the wood structure industry. In this paper, the test modal and computational modal analysis methods are used to study the mode shape and modal parameters of carbon fiber board, calculate the elastic constants, i.e., the elastic modulus, shear modulus, and Poisson’s ratio, and analyze the coupling of the results. The conclusions show that the numerical results of the mode shape and elastic constants of the carbon fiber board obtained via the computational modal and test modal analysis are highly coupled. The first-order bending and first-order torsional modes of the carbon fiber board obtained via the two analysis methods are consistent, and the frequency error rate is less than 5%. The error rates of the elastic modulus and shear modulus are 0.7% and 7.8%, respectively. In addition, the research is conducive to strengthening the work of finite element computational modal analysis, and better promoting the application of non-destructive testing and quality grading of carbon fiber board. The above-mentioned optimization design work for improving the dynamic characteristics of carbon fiber board, and further research on the detection and optimization of the performance when the carbon fiber material is combined with wood, also has engineering application value for promoting the faster development of the wood structure market.

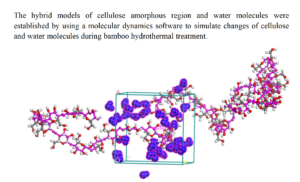

- Researchpp 269-280Wang, W., Ma, W., Wu, M., and Sun, L. (2022). "Effect of water molecules at different temperatures on properties of cellulose based on molecular dynamics simulation," BioResources, 17(1), 269-280.AbstractArticlePDF

Six hybrid models of cellulose amorphous region and water molecules were established by using a molecular dynamics software to simulate changes of cellulose and water molecules during bamboo hydrothermal treatment. The results indicated that in the range of hydrothermal treatment temperature of bamboo from 150 to 240 °C, the diffusion coefficient of water molecules increased with the increase of temperature, conducive to the processing efficiency of hydrothermal treatment. The mean square displacement (MSD) of the bamboo cellulose chain increased with the increase of temperature, not conducive to the thermal stability of cellulose. The energy change of the system predicts that a higher hydrothermal treatment temperature will result in faster material aging degradation. The comprehensive analysis of mechanical parameters showed that when the hydrothermal treatment temperature did not exceed 180 °C, bamboo cellulose had better plasticity and toughness.