Volume 18 Issue 1

Latest articles

- Researchpp 2011-2023Liu, W., Zhang, X., Ren, H., Hu, X., Yang, X., and Liu, H. (2023). "Fluorine-free and durable hydrophobic coating made with corn straw-derived silane modified epoxy resin," BioResources 18(1), 2011-2023.AbstractArticlePDF

Hydrophobic materials have promising applications. However, fluorine present in hydrophobic materials can lead to health risks and environmental pollution. This study investigated an environmentally friendly route to produce fluorine-free hydrophobic coatings with good wear resistance. Wear-resistant hydrophobic coatings were prepared by introducing different ratios of spirocyclic alkoxysilane into the epoxy resin. Characterization by Fourier transform infrared spectroscopy, water contact angle measurement, scanning electron microscope, tape adhesion test, and abrasion testing showed that the multi-methyl group and double-ring rigid skeleton structure of spirocyclic alkoxysilane can remarkably improve the hydrophobic performance and wear resistance of the epoxy resin. The modified hydrophobic coatings can withstand more than 1600 instances of controlled rubbing. Furthermore, the maximum water contact angle can reach 110° after substantial abrasion. The novelty of the work is that the authors successfully synthesized spirocyclic alkoxysilane for the first-time using corn straw ash. The prepared spirocyclic alkoxysilane was then used as a modifier to prepare hydrophobic epoxy resin coating. This approach can broaden the utilization of corn straw ash. Therefore, this method can achieve a green and low-cost preparation of wear-resistant hydrophobic coatings without the introduction of fluorine.

- Researchpp 2024-2044Torkghashghaei, M., Shaffer, W., Ugulino, B., Georges, R., Hernandez, R., and Blais, C. (2023). "Improved life of circular saws used in primary wood processing," BioResources 18(1), 2024-2044.AbstractArticlePDF

The effects of the Engineered Micro-Geometry (EMG) of the carbide teeth of circular saws on their wear rate and resulting sawing variation for 2-time intervals were studied. The objective was to improve the wear resistance of circular saws used during the primary transformation of wood. The tests were carried out under industrial production conditions with two series of circular saws; 1- with up-sharp tips, and 2- with cutting edges honed to adopt a waterfall geometry. The duration of the tests was 255 min and 645 min. Wood studs were sampled to measure sawing variation. Recession on the rake and clearance faces of the tips as well as the width of the wear land were measured. The wear mechanisms of the cutting edges of both types of saws were studied. Chipping and cracking were the two dominant wear mechanisms observed on the up-sharp tips. Saws with waterfall hone tips showed remarkably reduced chipping and cracking. Wear rate of the latter was notably lower than that of saws with up-sharp tips at both periods of sawing. Between-stud, within-stud, and total sawing variations decreased when saws with modified cutting edges were used.

- Researchpp 2045-2063Keskin, İ., Şentürk, İ., Yumrutaş, H. I., Totiç, E., and Ateş, A. (2023). "An environmentally friendly approach to soil improvement with by-product of the manufacture of iron," BioResources 18(1), 2045-2063.AbstractArticlePDF

Blast furnace slag has been used for many years in various applications related to civil engineering. Many studies have created a wide variety of cost-effective and environmentally friendly solutions for this industrial by-product. This study aims to contribute to the performance evaluations of the usability of the blast furnace slag for soil improvement and the effects of the additive ratio and curing time. Bentonite samples were prepared with the addition of blast furnace slag at 5%, 10%, 15%, and 20% ratios by weight at optimum water content (wopt). Results were evaluated using the liquid limit, plastic limit, unconfined compressive strength, and swelling tests performed after 1, 7, 14, and 28 days of curing time. Results revealed that the liquid limit value decreased, and the unconfined compressive strength increased with increasing curing time and blast furnace slag ratio in the mixture. Additionally, swelling pressure generally decreased with increasing slag contribution and curing time. The lowest values of the unconfined compressive strength were observed on the 7th day of curing time, and the minimum value was obtained at 10% mixing ratio. The highest unconfined compressive strength values were observed on the 28th days of curing time. The optimum mixing ratio was 5%.

- Researchpp 2064-2082Hwang, S., Chung, H., Lee, T., Kwak, H., Choi, I., and Yeo, H. (2023). "Investigation of NIR spectroscopy and electrical resistance-based approaches for moisture determination of logging residues and sweet sorghum," BioResources 18(1), 2064-2082.AbstractArticlePDF

Techniques based on electrical resistance and near-infrared (NIR) spectroscopy were used to determine the moisture content (MC) of logging residues and sweet sorghum. The MC of biomass is a factor to be controlled that can affect the quality of final products. To accurately measure the moisture in fragmented materials, it is essential to increase the bulk density of the materials by compression. The low bulk density increased the error from the oven-drying MC and the variation between repeated measurements. The calculated correction factor made it possible to use a commercial wood moisture meter for biomass materials. Ordinary least squares regression models built with the electrical resistance data achieved coefficients of determination (R2) of 0.933 and 0.833 with root mean square errors (RMSE) of 0.505 and 0.891, respectively, for the MC predictions of logging residue and sweet sorghum. Partial least squares regression models combined with NIR spectroscopy achieved R2 of 0.942 and 0.958 with RMSE of 1.318 and 3.681 for logging residue and sweet sorghum, respectively. In contrast to the electrical resistance-based models, the NIR-based models could predict the MC regardless of the bulk density of the materials. Data transformation by the second derivative and removal of outliers contributed to the improvement of the prediction of the NIR-based models.

- Researchpp 2083-2099Zeng, P., Xu, Y.-H., and Li, M.-F. (2023). "Catalytic reductive depolymerization of corncob lignin to produce bio-oil via formic acid/ethanol system," BioResources 18(1), 2083-2099.AbstractArticlePDF

Formic acid (FA) was used for reductive depolymerization of industrial corncob lignin via ethanol and Pt/C system. The highest yield of bio-oil obtained was 71.4% when the reaction was conducted at 260 °C with an FA/lignin ratio of 8 for 0.5 h. The bio-oil was composed of oligomers (Mw within 600 Da) and lignin depolymerized fragments (Mw beyond 600 Da). Reaction temperature was the most important factor affecting the properties of bio-oil. Although excessive temperature could increase the C/H ratio and higher heating value (HHV) of bio-oil, it would lead to repolymerization of lignin degraded fragments, thus resulting in a higher molecular weight of bio-oil. Additionally, alkylphenols were major products in bio-oil, and the amount of alkyl phenols could be increased by increasing the temperature and extending the retention time appropriately. This study reveals the effects of various reaction conditions on the yield and properties of bio-oil, providing a theoretical basis for subsequent upgrading of bio-oil to biofuels and aromatic chemicals.

- Researchpp 2100-2111Župčić, I., Šafran, B., and Hasan, M. (2023). "Influence of biological pretreatment of wooden dowels on strength of rotary welded joints," BioResources 18(1), 2100-2111.AbstractArticlePDF

Welding wood achieves joints whose strength is comparable with the strength of glued joints. When welding, the top of the dowel is not welded because of the lack of melted lignin. To achieve satisfactory strength of a welded joint, it is necessary to optimize the main welding factors such as interference fit, frequency of dowel rotation, welding depth, welding duration, etc. There are also other ideas to increase the strength of welded joints. One of these ideas involves pre-treatment of dowels with wood decaying fungi to increase the proportion of lignin on the surface of the dowels and thus in the melt. This paper presents the results of the impact of pretreatment of beech wood dowels with the brown-rot fungus Gloeophyllum trabeum. Results showed that biological pretreatment of the dowels had a significant impact on the pull-out force of the joint. Pretreatment for 4 weeks caused a substantial increase in pull-out force, while pretreatment for 2 weeks did not have a positive effect on the strength of the welded joint. Grooved dowels exhibited an increase in pull-out force of 26.9%, while smooth dowels had an increase of 21.1% of pull-out force. Research also determined additional vibrations during welding.

- Researchpp 2112-2136Li, L., Niu, W., Cong, H., Meng, H., Niu, Z., Shen, X., Cao, L., and Kong, X. (2023). "Effects of pyrolysis temperature on the release characteristics of polycyclic aromatic hydrocarbons during pyrolysis of corn stover pellet," BioResources 18(1), 2112-2136.AbstractArticlePDF

The release characteristics of polycyclic aromatic hydrocarbons during the pyrolysis of biomass remain poorly understood. This study investigated the effects of pyrolysis temperature on the polycyclic aromatic hydrocarbon release characteristics by analyzing both the transient vapor products and the physicochemical properties of corresponding biochar from the pyrolysis of corn stover pellets. The results revealed that the transient volatile compounds mainly included phenols, ketones, acids, furans, aldehydes, substances containing benzene ring, polycyclic aromatic compounds, and gaseous products. A range of 2 to 4 ring polycyclic aromatic hydrocarbons were generated at 400 to 700 °C with the peak at 560 °C, and the sum of relative content of polycyclic aromatic hydrocarbons ranged from 0.23% to 40.36%. For the biochar, the carbonization stage (400 to 700 °C) of corn stover pellets was further divided into three evolutionary stages, including the preliminary carbonization stage (380 to 480 °C), amorphous carbon structure stage (480 to 600 °C), and the stage of dehydrogenation and growth of aromatic rings (600 to 700 °C).The relationship between polycyclic aromatic hydrocarbon release in volatile compounds and H/C ratio of the biochar could be described by a power function.

- Researchpp 2137-2145Trnka, J., Kantová, N., Holubčík, M., Čaja, A., Najser, T., and Najser, J. (2023). "Comparison of energy properties of pellets from shells of different nut species," BioResources 18(1), 2137-2145.AbstractArticlePDF

Bio-waste is a source of energy-rich material. Therefore, it can be used in further processes and efficiently utilized. Further processes of waste utilization include compressing them to pellets. However, this type of pellet often has a low bulk density, high ash content, low ash melting temperature, and low calorific value. This research dealt with the energy properties of peanut and pistachio nut shells that were pure or mixed with spruce sawdust in half proportion and compressed into pellets. As a continuation of previous research, the properties of these pellets prepared were measured and compared with pure spruce pellets and with pellets from walnut shells. The tested shell pellets had calorific values similar to wood pellets from spruce. However, mixing nut shells with spruce solved the problems of high ash content and low ash melting temperatures. The amount of wood present in the pellets resulted in increased ash melting temperatures and decreased the ash content.

- Researchpp 2146-2154Duan, G., Wang, M., Yang, X., and Jiang, L. (2023). "Comparison of properties of wood-plastic composites based on alternate degradation in seawater and acid rain," BioResources 18(1), 2146-2154.AbstractArticlePDF

To investigate the change of the service performance of wood-plastic composites degraded by sea water and acid rain, three types of wood-plastic composite materials were prepared with sorghum straw reinforced with high-density polyethylene (SS/HDPE), polypropylene (SS/PP), and polyvinyl chloride (SS/PVC). Under the extreme alternate degradation conditions simulated by seawater (salinity 3.5%, temperature 55 °C) and acid rain (pH 2.5, temperature 55 °C), the effects on the mechanical and wear properties and the chemical structures of the composites were determined. The exposure to the alternate sea water and acid rain deteriorated the fiber/matrix bonding quality of the composites; the mechanical and wear properties decreased accordingly. Before and after degradation, the three composites were sorted in descending order of the mechanical and wear properties as follows: SS/PVC composites > SS/PP composites > SS/HDPE composites. Sorghum straw /PVC had the best resistance to degradation and sorghum straw /HDPE composite had the least resistance. The matrix molecular chains of the SS/HDPE under the conditions of exposure were broken after 12 days.

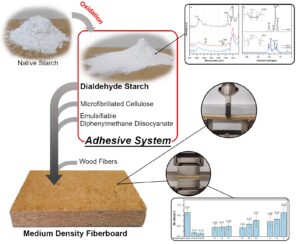

- Researchpp 2155-2171Neitzel, N., Hosseinpourpia, R., and Adamopoulos, S. (2023). "A dialdehyde starch-based adhesive for medium-density fiberboards," BioResources 18(1), 2155-2171.AbstractArticlePDF

Bio-based adhesives have gained considerable attention in the last years as more sustainable and healthier alternatives to the formaldehyde-based adhesives used today in wood-based panel manufacturing. In this study, dialdehyde starch (DAS) with various aldehyde contents was prepared by using sodium metaperiodate as an oxidizing agent. Characterizations were performed by employing Fourier-transform infrared spectroscopy, nuclear magnetic resonance, and thermal stability analysis. Different adhesive compositions were used for making medium-density fiberboard (MDF) panels. They were based on DAS (12 wt% based on fiber), emulsifiable diphenylmethane diisocyanate (eMDI, 2-4 wt% based on DAS), and microfibrillated cellulose (MFC, 0.5-1.0 wt% based on DAS). Fibers and the adhesive components were mixed with a combination of dry mixing and wet spraying. The physical and mechanical properties of MDF panels bonded with different DAS-based adhesives were compared with those of melamine urea-formaldehyde (MUF) adhesive and sole eMDI. The results showed that the MDF panels made with DAS-MFC-eMDI of 99.52% bio-based content showed comparable properties to standard panels with a commercial MUF adhesive. It was implied that DAS in the presence of small amount of eMDI can create strong bonds with wood fibers, while an additional positive effect on bonding was due to the contact surface enlargement of MFC.