Volume 18 Issue 1

Latest articles

- Researchpp 584-598Han, M., Lin, L., Guo, X., An, M., Geng, Y., Xin, C., Ma, L., Mi, Q., Ping, A., Yang, Q., Zhang, T., and An, Q. (2023). "Comparative analysis of the laccase secretion ability of five white-rot fungi in submerged fermentation with lignocellulosic biomass," BioResources 18(1), 584-598.AbstractArticlePDF

Lignocellulosic biomass is widely used in the field of laccase production because it has the advantages of low price and easy availability. Thus, a comparative analysis was performed of the laccase secretion ability of five white-rot fungi in submerged fermentation using single or mixtures of lignocellulosic biomass. Maximum laccase activity of Trametes gibbosa An 360, Vanderbylia fraxinea An 369, Perenniporia pyricola Han 202, Coriolopsis trogii Han 474, and Trametes versicolor Han 1504 was 55.83 ± 0.28 U/L on the mixture of corncob and cottonseed hull, 77.96 ± 1.60 U/L on corncob, 443.33 ± 15.49 U/L on corncob, 686.57 ± 16.49 U/L on corncob, and 162.04 ± 11.33 U/L on cottonseed hull. The mixed lignocellulosic material effectively improved the laccase activity of T. gibbosa An 360 compared with other fungal strains. However, the presence of corncob contributed to the secretion of laccase activity for V. fraxinea An 369, P. pyricola Han 202, and C. trogii Han 474. Meanwhile, cottonseed hull was conducive to the secretion of laccase of T. versicolor Han 1504. Laccase activity of P. pyricola Han 202 was very stable throughout most of the fermentation time. The results from this study provide new methods and increase fungal strains to improve laccase activity.

- Researchpp 599-612Liszkowska, W., Motyl, I., Pielech-Przybylska, K., Szulc, J., Sypka, M., Dziugan, P., and Berlowska, J. (2023). "Plant biomass as a source of low-temperature yeasts," BioResources 18(1), 599-612.AbstractArticlePDF

More than 40 yeast strains were isolated from various types of plant biomass and then evaluated for potential applications in biotechnological processes conducted at low temperature. Adaptation to low temperature was tested by passaging the isolates at decreasing temperatures, from 30 to 15 °C. Only the strains that were able to adapt to the final temperature and reached the stationary growth phase relatively quickly were submitted to further experimentation. These included eight environmental yeast isolates from four types of materials of plant origin: wheat, rye, and cucumber, containing glucose, fructose, sucrose, and starch; yeast-fermentable sugars; red beetroot, containing large amounts of glucose and fructose; and fruits (grapes and apples) containing glucose, fructose, and sucrose. The strains were identified and then subjected to a series of experiments to assess their suitability for use in low-temperature biotechnological industrial processes incorporating microbial biomass. The growth dynamics and assimilation profiles of the yeast strains were investigated, as well as their ability to produce volatile compounds.

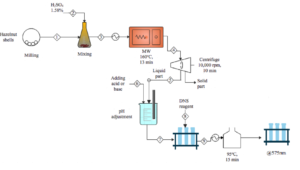

- Researchpp 613-628Uzuner, S. (2023). "Improvement of fermentable sugar extraction from hazelnut shells through microwave assisted dilute acid pretreatment," BioResources 18(1), 613-628.AbstractArticlePDF

The most effective method for producing fermentable sugars (FSs) from biomass is thermochemical pretreatment assisted by enzymatic hydrolysis. However, the enzymatic hydrolysis-assisted thermochemical pretreatment method is limited by the formation of fermentation inhibitors, and it is time-consuming. There is growing interest in using a microwave (MW) pretreatment due to its uniform and rapid heating. This study aimed to determine, perform data-driven modeling, and optimize the effect of MW combined with dilute acid pretreatment (MW-DA) on the production of FSs from hazelnut shells. An artificial neural networks (ANNs) model based on Box-Behnken Design (BBD) was the best model described for fermentable sugar extraction (FSE). Optimization via BBD-based ANNs model was carried out for an acid concentration of 0.5 to 2% (w/w), a pretreatment time of 5 to 25 min, a pressure of 5 to 15 bar, and a temperature of 120 to 160 °C. The optimized FSE was estimated at 374 mg/g (81.4% conversion efficiency), with a severity factor of 3.61 under 1.58% H2SO4 for 13 min at 160 °C and 8.5 bar. Using the MW-DA pretreatment process lowered the costs significantly due to the decreases in acid concentration and pretreatment time.

- Researchpp 629-640Liu, X., Yang, S., Zhang, C., Huang, H., and Varodi, A. M. (2023). "Comparative study on slow pyrolysis products of abandoned furniture materials," BioResources 18(1), 629-640.AbstractArticlePDF

Pyrolysis is an effective way to use abandoned furniture materials. This work dealt with solid wood, particle board, and medium density board obtained from dismantling discarded furniture as experimental materials. Slow pyrolysis was performed at a heating rate of 150 °C/h and pyrolysis temperatures of 400, 500, and 600 °C, and the products were analyzed. With the increase of pyrolysis temperature, the yield of solid products gradually decreased, while the yield of liquid products and non-condensing gases gradually increased. The carbon content in solid products reached 63.6 to 94.4%. The pyrolysis solution was acidic to weakly alkaline due to the different types and contents of adhesives in the three pyrolysis materials. Understanding the yield and characteristics of the pyrolysis products of waste furniture can provide more research directions for the recycling and utilization of these materials.

- Researchpp 641-652de Lima, N. N., de Castro, V. R., Lopes, N. F., Nunes, Í. L., Andrade, F. A., Zanuncio, A. J. V., Carneiro, A. O. C., and Araujo, S. O. (2023). "Tannin extracts as a preservative for pine thermo-mechanically densified wood," BioResources 18(1), 641-652.AbstractArticlePDF

Thermo-mechanical densification modifies wood to produce a more dense and resistant lignocellulosic material and may degrade extractives that contribute to the increased susceptibility of wood to attack by xylophagous organisms. This study evaluated the efficiency of tannin extracts of Acacia mearnsii in the treatment of thermo-mechanical densified pine wood in relation to physical, mechanical, and biological resistance (Cryptotermes brevis) properties. Pinus elliottii samples were pretreated with oxalic acid in a Parr reactor, then treated by diffusion in tannin solutions at concentrations 5, 10, and 15%, and finally hot pressed. The apparent density of the modified wood was 87.8% greater than that of the in natura wood (control) with tannins at 15%. The mechanical strength increased, especially the parallel compressive strength, which had an average increase of 169% for the wood with tannins at 10 and 15%, compared with the in natura wood. There was an increase in termite mortality and a reduction in damage for the modified wood treated with 15% tannins, obtaining the best results in mechanical and biological resistance and for the physical parameters. Thermal densification pine wood and preserved with tannin extractives proved to be a potential alternative as a high performance material.

- Researchpp 653-677Trost, D., Polcar, A., Boldor, D., and Kumbar, V. (2023). "Pour point and predictive models for the viscosity-temperature non-linear behaviour of ternary fuel blends for a compression ignition engine," BioResources 18(1), 653-677.AbstractArticlePDF

Due to the ever-increasing consumption of fossil fuels, their impact on the environment, and the volatility of the market, it is advisable to use biofuels that can be produced locally from renewable sources, which supports the local economy, agriculture, and related processing industries. This article deals with how to improve the flow properties and pour point of biofuels for diesel engines. For the experiment, biodiesels in the form of rapeseed methyl ester (RME) and methyl ester made from waste animal fats and tallow (WAFME) were used. The pour point, viscosity, and density of WAFME were improved by mixing with RME and/or by adding bio-alcohols (alcohols produced from biomass, e.g., lignocellulosic). All used biofuels were classified as 2nd generation biofuels. The flow properties of the mixtures were monitored and subsequently modelled at temperatures from -10 to 60 °C. The addition of bio-alcohol had a statistically significant effect on the decrease in the viscosity and pour point of ternary blends (p < 0.05). Mathematical models of the dependence of kinematic viscosity on the temperature of mixtures (power law, exponential, Arrhenius, and Vogel) were created.

- Researchpp 678-700Lou, J., Yue, X., and Yang, Y. (2023). "Nano Co3O4/NiO catalysts pyrolysis of Cotinus nana bark for bio-oil and biochemicals raw material," BioResources 18(1), 678-700.AbstractArticlePDF

Cotinus nana W. W. Smith is a valued landscape shrub and a good afforestation species that is also widely used in the pharmaceutical industry. In this study, the use of Cotinus nana’s bark (CNB) as biofuel and a biochemical under the catalysis of nano-Co3O4/NiO was explored by various thermogravimetric methods and Fourier transform infrared (FTIR) analysis. The bark powder was extracted using a methanol/benzene solution, and then analyzed by FTIR and gas chromatography-mass spectrometry (GC-MS). The results showed that the pyrolysis products of CNB are rich in phenols, alcohols, and biofuels. The Co3O4 and NiO act as nanometal catalysts in the release of pyrolysis gases, accelerating the precipitation of gaseous products. Among them, NiO has the most obvious catalytic effect in the pyrolysis process of the material components. At the same time, in the temperature range of 40 to 850 °C, as the pyrolysis rate of the sample increases, the pyrolysis process becomes more intense. In contrast, the contents of the extracts N,N-diethyl-formamide, butyric acid, and oleic acid are not only widely used in industry, but also play a pivotal role in medicine. Therefore, the bark of Cotinus nana is an excellent plant material for biofuels and biochemicals.

- Researchpp 701-719Zhan, Y., Huang, W., Si, R., Xiang, T., and Hao, L. (2023). "Shear behavior of notched connection for glubam-geopolymer concrete composite structures: Experimental investigation," BioResources 18(1), 701-719.AbstractArticlePDF

The glubam (glue-laminated bamboo)-geopolymer concrete composite (BGCC) structure is a possible way to achieve sustainable construction due to its combination of renewable resources and industrial waste. This study combined glubam and geopolymer concrete in composite structures and investigated the shear behavior of BGCC structures with notched connections. Four groups of push-out tests were designed to evaluate the influence of the number of notches and screws on the slip modulus and shear capacity. The results showed that the composite structures with notched connections failed first due to shear cracking at the interface notch. The double-notch specimens increased the shear capacity by 54% compared to single-notch specimens. The shearing bearing capacity rose by 35% on average as a screw increased in a single notch. The ductility and slip modulus were influenced primarily by the screws, with each extra screw in a single notch increasing the slip modulus by 21% in each stage. Based on the test results, a modified formula was proposed to predict the shear-bearing capacity of notched connections in BGCC structures. This study provides comparison data for further studies in the long-term behavior of BGCC structures.

- Researchpp 720-732Khafhafera, A., and DeMartini, N. (2023). "Solubility of sodium oxalate in kraft black liquors above 100 °C," BioResources 18(1), 720-732.AbstractArticlePDF

The solubility of sodium oxalate was measured in kraft black liquors at temperatures of 115 °C to 140 °C with dry solid contents of 45% to 70%. The composition of black liquors studied were varied with respect to sodium concentration by addition of sodium salts. The solubility of sodium oxalate increased with increasing temperature and decreased with increasing liquor dry solid contents. The solubility data showed no dependence on the liquor composition at a constant concentration of sodium. A mathematical expression was derived and validated from the experimental data at the conditions investigated to predict the solubility of sodium oxalate as a function of temperature and sodium concentration. An application to assess the solubility and precipitation risk of sodium oxalate is demonstrated in seven evaporator bodies using the newly derived models.

- Researchpp 733-747Zhang, Y., Xu, Y., Pei, Y., and Yin, X. (2023). "Green liquor desilication via black liquor combustion process for bamboo pulping," BioResources 18(1), 733-747.AbstractArticlePDF

The presence of silicon in non-wood raw materials is known to interfere with the causticization of green liquor and the calcination of white mud, which has provided motivation for advances in alkali recovery technology. Therefore, reducing the silicon content of green liquor is the fundamental way to solve the problem. However, there are certain defects in conventional green liquor desilication, so this study provides a basis for desilication from green liquor via black liquor combustion and studies the desilication effect of a compound desilication agent on bamboo pulping black liquor. The results show that the desilication effect was better and the desilication rate could reach 84% when the Mg/Al proportion in compound desilication agent was 1:0.6. Meanwhile, the content of residual aluminum in green liquor decreased, which can avoid the influence of residual desilication agent on subsequent stages. Scanning electron microscopic images show that green-liquor-silicon-insoluble (GLSI) substance is a granular precipitate, and the X-ray diffraction analysis shows that GLSI substance has a complex structure similar to 3Al2O3•2SiO2•MgO. This implies that the desilication mechanism consists of chemical precipitation and physical adsorption.